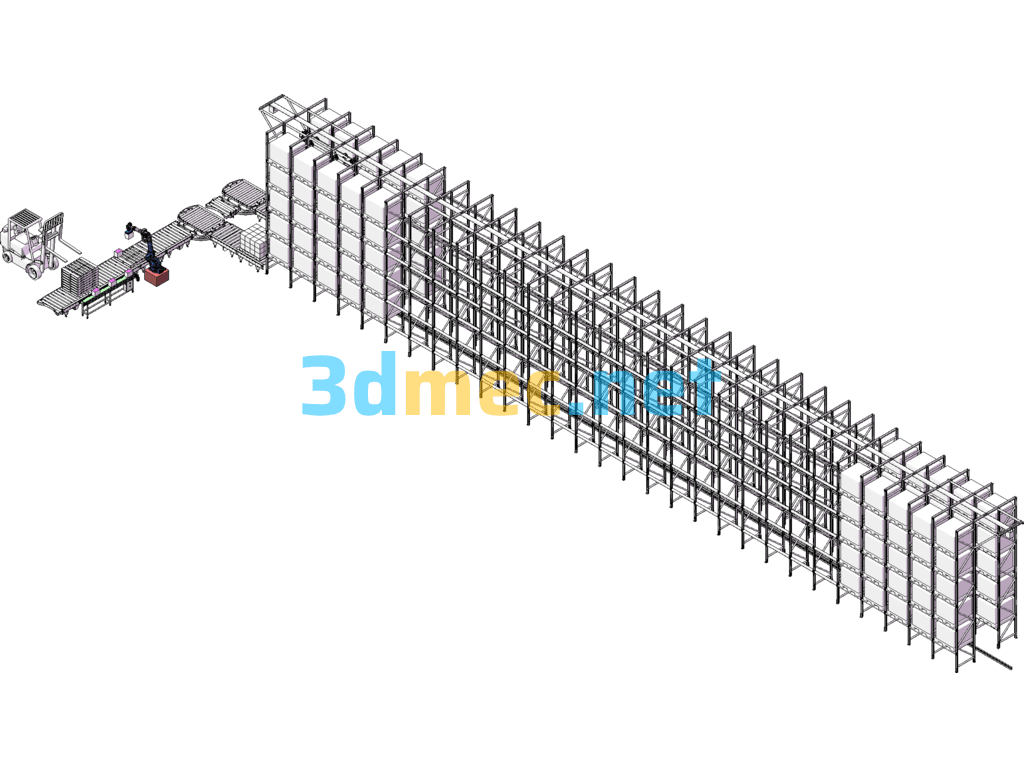

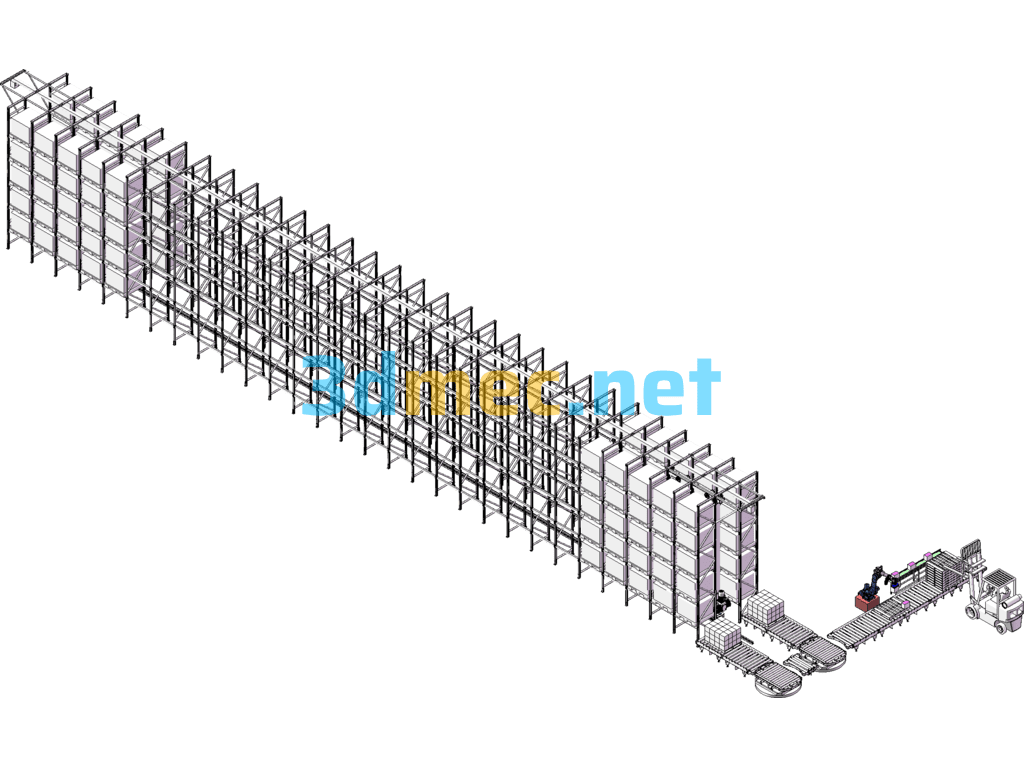

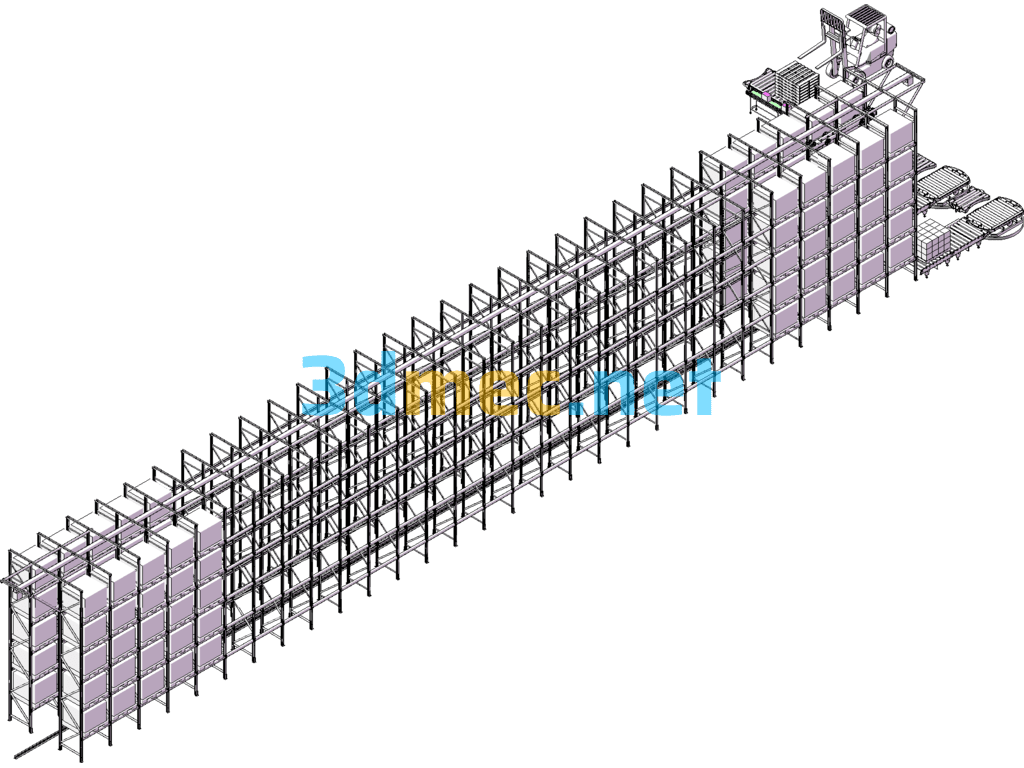

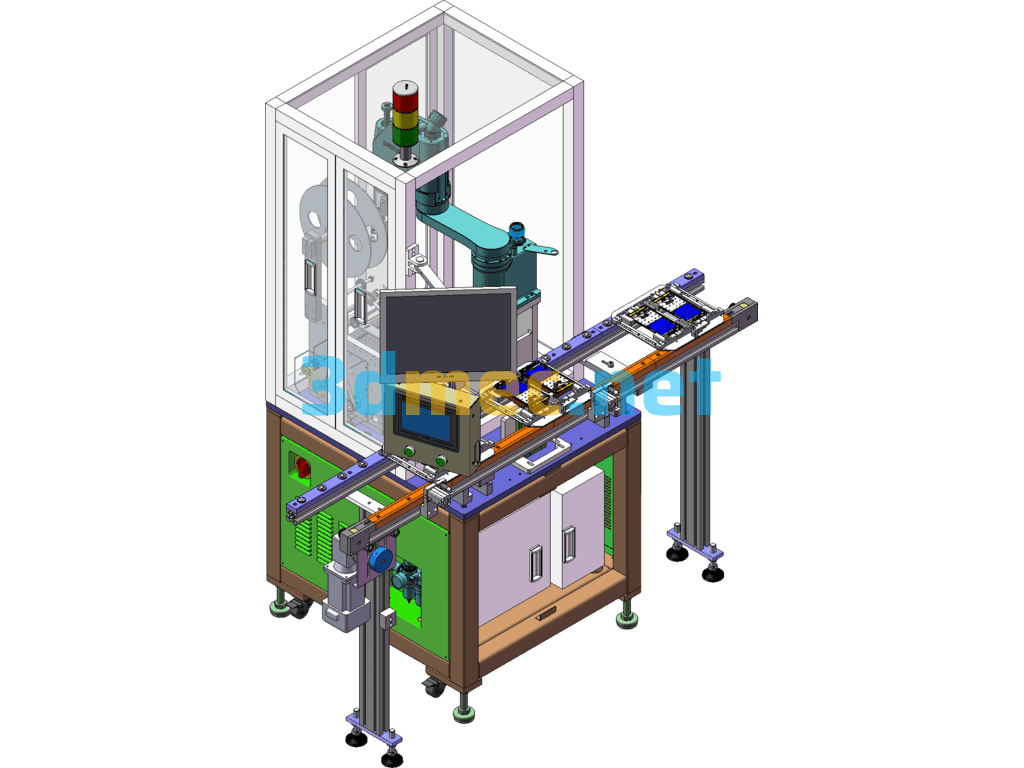

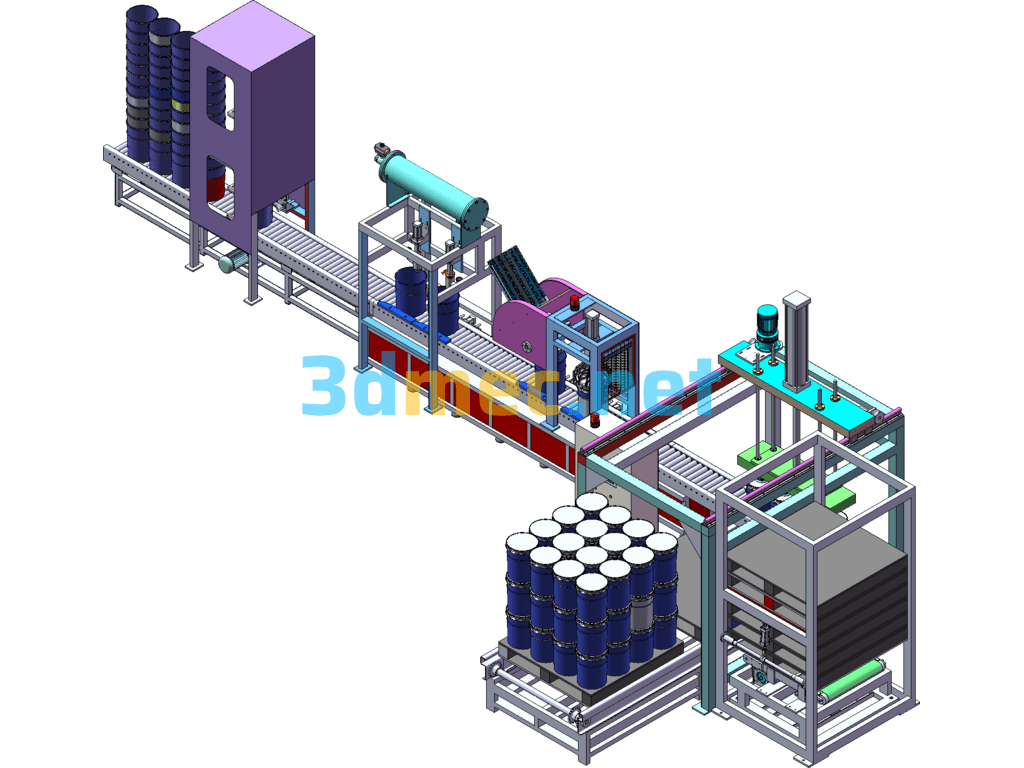

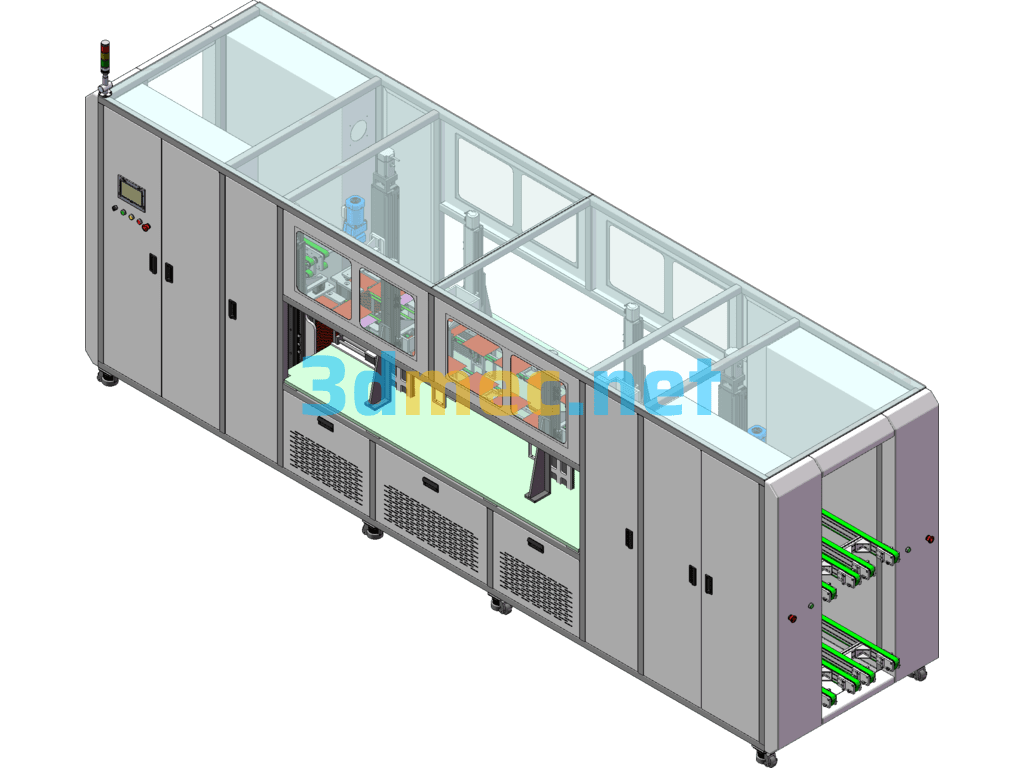

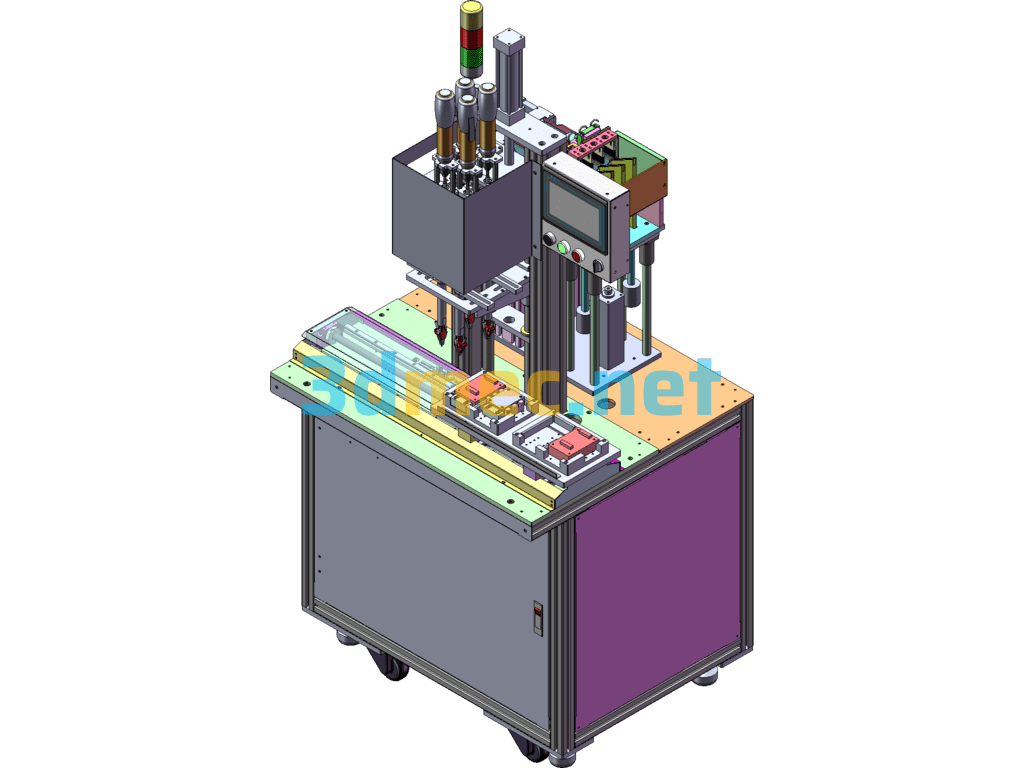

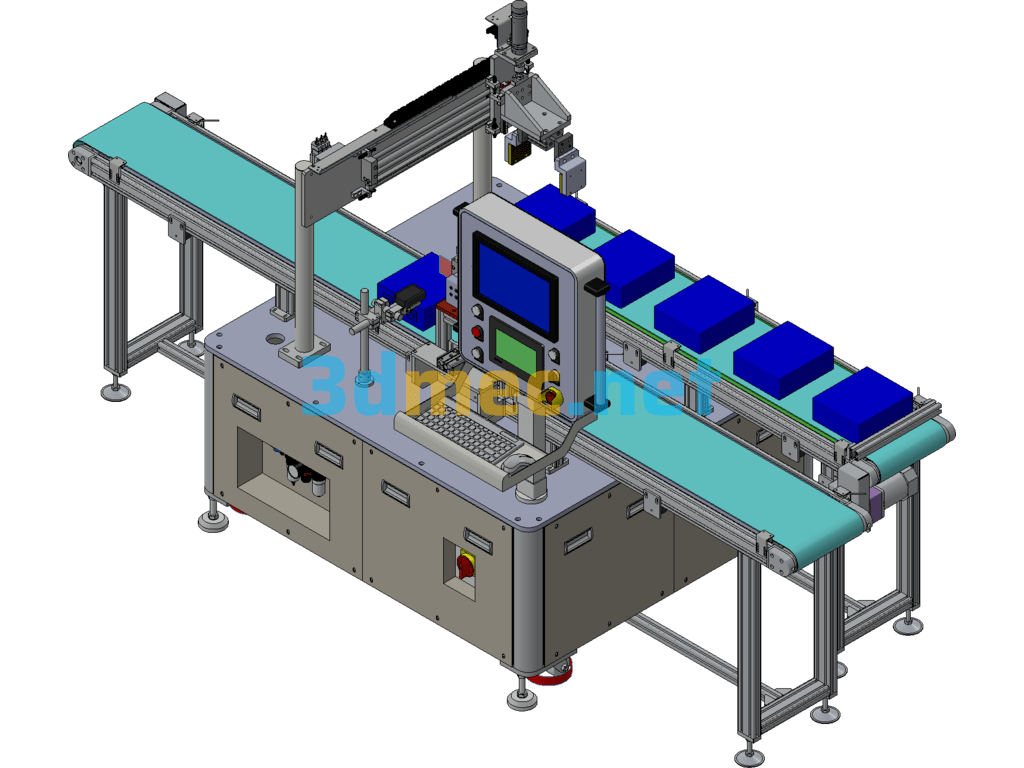

Special Reminder: The document is an application of joint automation of three-dimensional warehouse and robot. Mainly, the robot palletizes the boxes into standard shape on standard pallets, then conveys them through the conveyor line to the entrance of the target warehouse, and then the shuttle of the three-dimensional warehouse delivers the fully loaded standard pallets at the entrance of the warehouse to the target warehouse. At the same time the shuttle can also take out the items in the warehouse and put them at the exit of the warehouse position, and then convey them to the outside through the conveyor line, and then the manual forklift will pick up the fully loaded pallet. n This document can be used as a reference design for program, detailed design or workshop planning. Because the file is too large, the document only shows two rows of three-dimensional warehouse shelves and a shuttle, if there is a need for a larger warehouse can be copied. Also lengthen the matching roller conveyor line can be. n The main equipment is Yaskawa MH110 six-axis articulated robot, three-dimensional warehouse shelves, three-dimensional warehouse shuttle, power roller conveyor line, belt conveyor line, etc.. n Into the warehouse: small boxes through the belt conveyor line from the upper process to the robot near the robot, the robot in accordance with the standard shape of the small boxes yards to the pallet, the pallet is full with the conveyor line forward conveyor, through the turntable conveyor line turn and then transported to the corresponding warehouse, and then put into the warehouse by the shuttle machine. The robot takes out an empty pallet from the roller conveyor line and continues the next process. If the number of empty pallets is insufficient, the system sends out an alarm message, and manually replenish the empty pallets by forklift. n Out of warehouse: the shuttle machine takes out the target pallet to the out of warehouse position according to the instruction, the target pallet is transported to the specified position by the turntable conveyor and the power conveyor line in cooperation with the standard pallet, and then picked up by the manual forklift. n The files are made with solidworks2016, only .asm and .Prt files are provided. n The robot model involved in the baby is a 3D model of an industrial tandem multi-joint robot with solidworks version 2016. The position and range of motion of each axis is done according to the parameters provided by the manufacturer. The theoretical reach of the robot is the position accessible from the center of the robot’s end flange. In solidworks version 2016 and above, open the attached assembly file and drag any part of the robot (except the base) with the mouse to move the robot within the range of motion of each axis, which can be used to visualize the working range of the robot. n I. How to assemble and customize the 3D model n If the top level assembly file is A.asm, then the robot attachment is the sub-assembly B.asm under A.asm. If the robot is equipped with a fixture at the end, and there are no moving parts inside the fixture, then the fixture can be directly mounted on the end flange. If the fixture has movable parts and you want to show the movable parts, then define the fixture as several parts according to the range and size of the movable parts and install them into B.asm in sequence. n Second, how to drag this robot model freely in the assembly n Assemble the top assembly A.asm according to the above rules, open the assembly, right click on the properties in the feature tree, open the properties tab and select “Solve for Flex” in the lower right corner, then you can move the joints and fixtures of the robot in A.asm freely, so that you can easily show the robot’s reachable area and the details of the different viewpoints. Since the “Solve for Flexibility” function takes up a lot of memory and computing resources, turn off the “Solve for Flexibility” function when it is not in use. n Introduction of the main parameters of the model n The model consists of three main parts: the length of the robot axes, the mounting method of the axes, and the movement angle of the axes. The length and appearance of the axes are designed and determined by the robot company. The mounting method of the axis and the size of the motion angle are defined and constrained according to the parameters provided by the robotics company (the current latest). nPs1: Note for model use, when the robot axes are moving to the limit position, force dragging with the mouse in the direction of the limit position, the model may skip directly over the limiting motion region and reach the non-limiting region directly. Especially the J1 axis, the limit area is relatively small, or can be ±180 degrees or more rotation, J1 axis can be circular non-stop rotation, when using, please pay attention to a small drag the axes, to reach the limit position will feel a pause, if you continue to drag, it will be moving to the limit of the activity area. Other axes may also appear similar situation, this is a software bug or not defined, similar to the robot’s singularity. nPS2: There is a standard format STP-AP214 file provided in the attachment, which is convenient for friends with solidworks version lower than 2016 or other 3D software to open the stp and set the model by themselves according to the parameters in the attachment. nPS3: The parts prt files and parameters of the model are from the public information of the robotics company, this model is only used for learning and as a demonstration, if it is used for industrial design or on-site production, please contact the robot supplier to double-check the dimensions and parameters of the model.

Specification: YASKAWA MH110 Robot Automated Palletizing Intelligent Three-Dimensional Warehouse Access Applications SolidWorks 3D Model

|

User Reviews

Be the first to review “YASKAWA MH110 Robot Automated Palletizing Intelligent Three-Dimensional Warehouse Access Applications SolidWorks 3D Model”

You must be logged in to post a review.

There are no reviews yet.