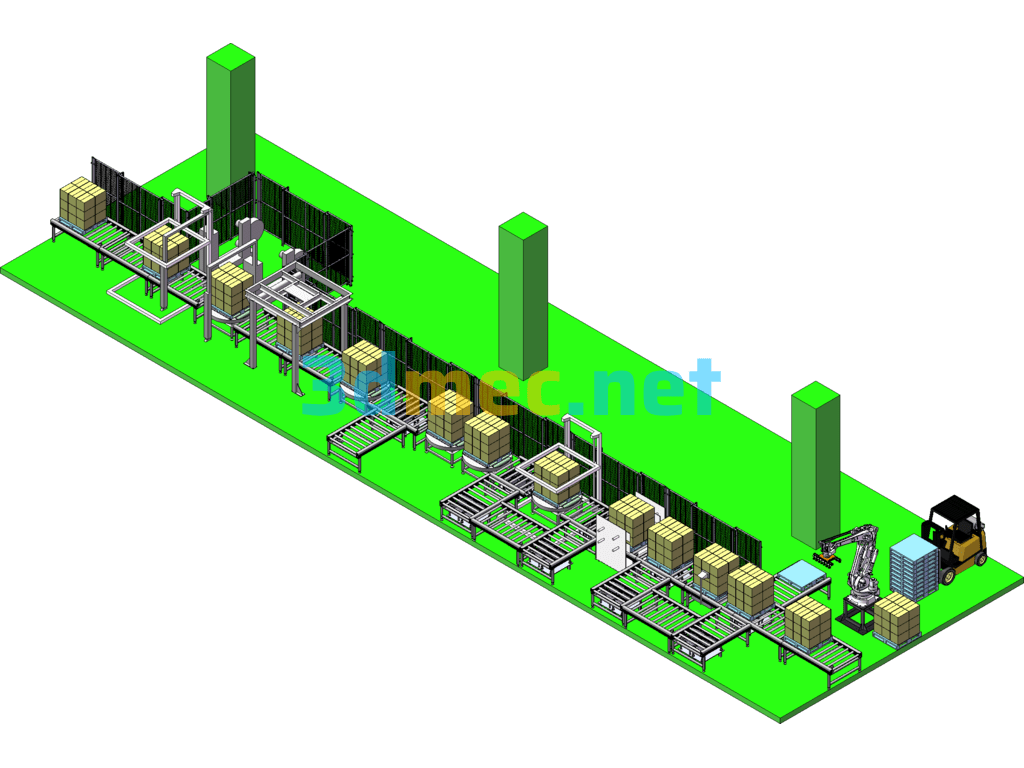

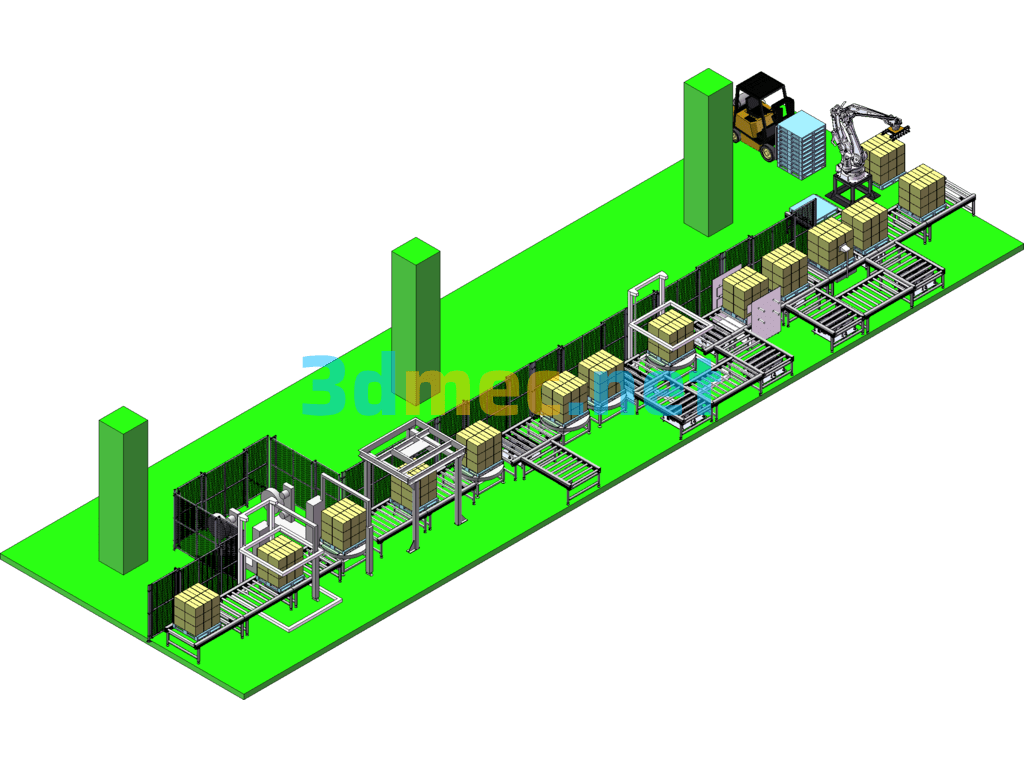

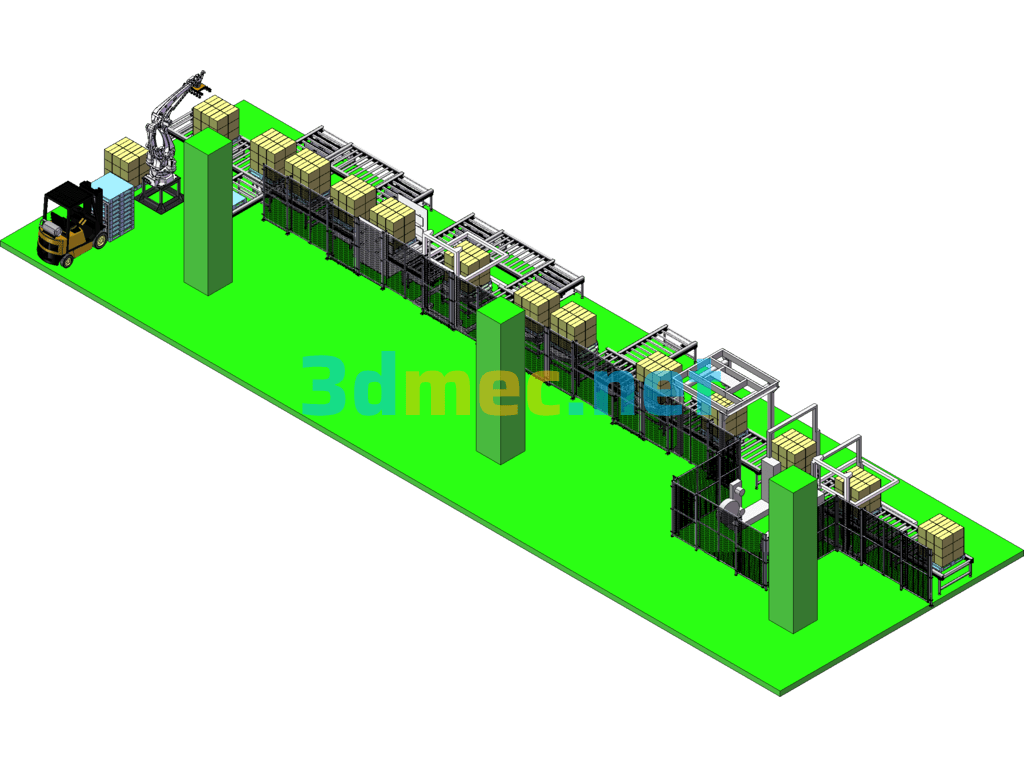

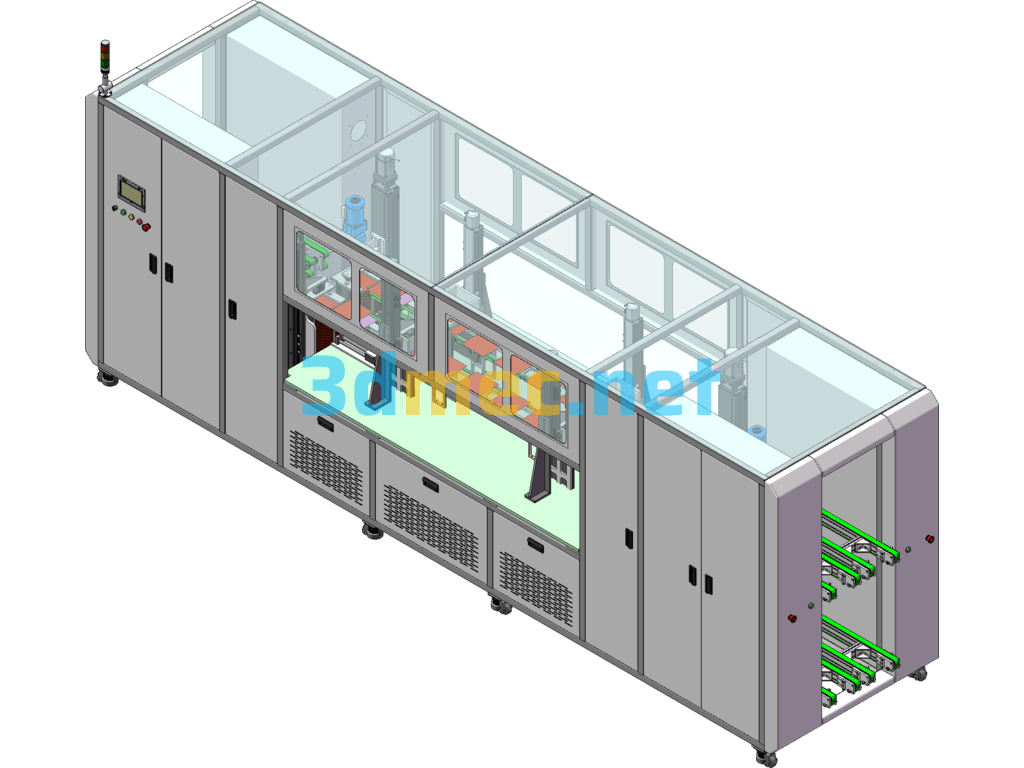

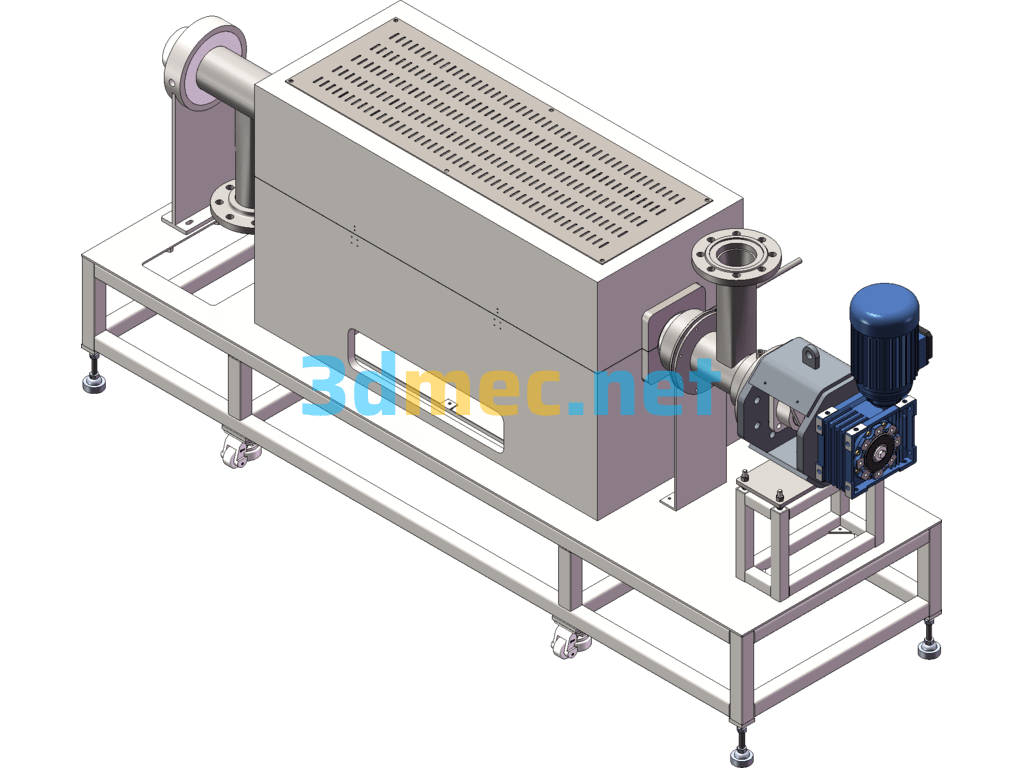

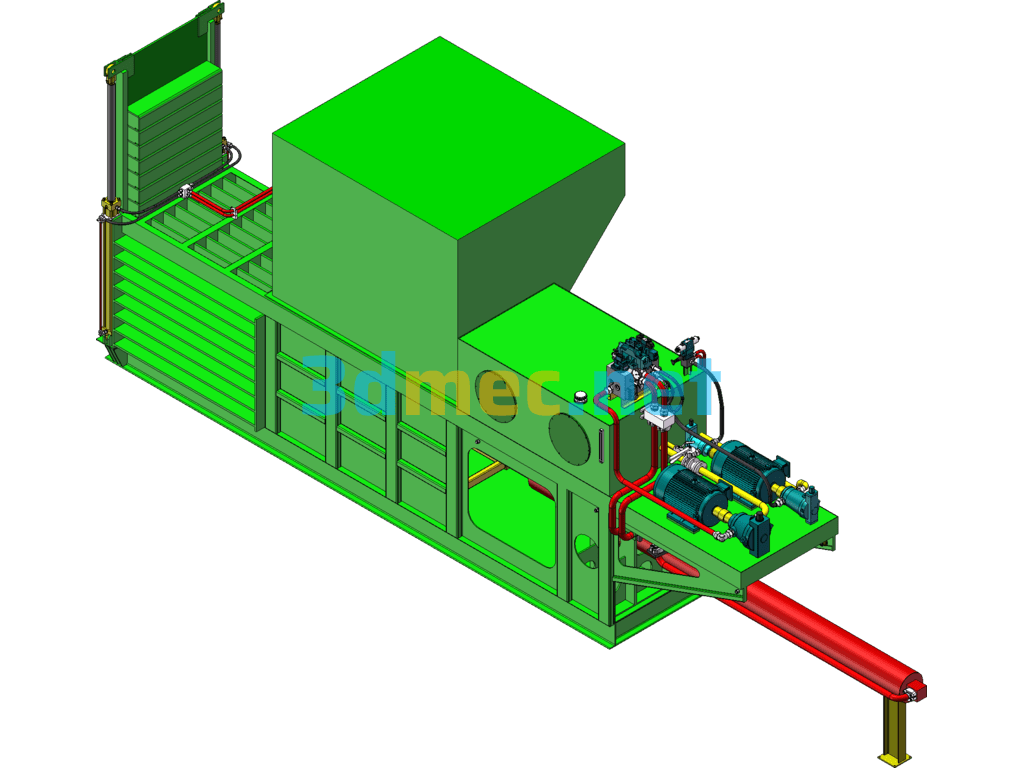

Xiamen Tianma Packing Line – 3D Model SolidWorks

The project uses automatic code scanning for in and out of the warehouse; forklift AGV is used to realize the turnover storage of goods in the warehouse; and the automated packaging line is used to pack the outgoing goods to complete the entire warehousing, packaging and delivery automation process. The warehouse adopts a back-to-back layout, which can realize the placement and retrieval of products, as shown in the figure below. According to the maximum external dimensions of the pallet of 1200mmX1100mm, I chose a forklift AGV with a non-reflective plate laser navigation and an external dimension of L2700*W920*H2200. There is a logistics channel between every two rows of goods, with a horizontal width of 3000mm and a vertical width of 1500mm. There are code scanning areas and exception handling areas designed at the entrance, and code scanning areas and exception handling areas designed at the exit. There are scrapped product processing areas and sampling areas near the pedestrian passage in the warehouse. The entire warehouse area and the artificial activity area are isolated by fences. According to the layout, at least 1,812 storage locations can be realized. The storage locations are managed by WMS, and WMS is connected to the AGVS system to realize unmanned transportation of the entire factory logistics. Using 6 forklift AGVs can realize the demand rhythm.

Specification: Xiamen Tianma Packing Line – 3D Model SolidWorks

|

User Reviews

Be the first to review “Xiamen Tianma Packing Line – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.