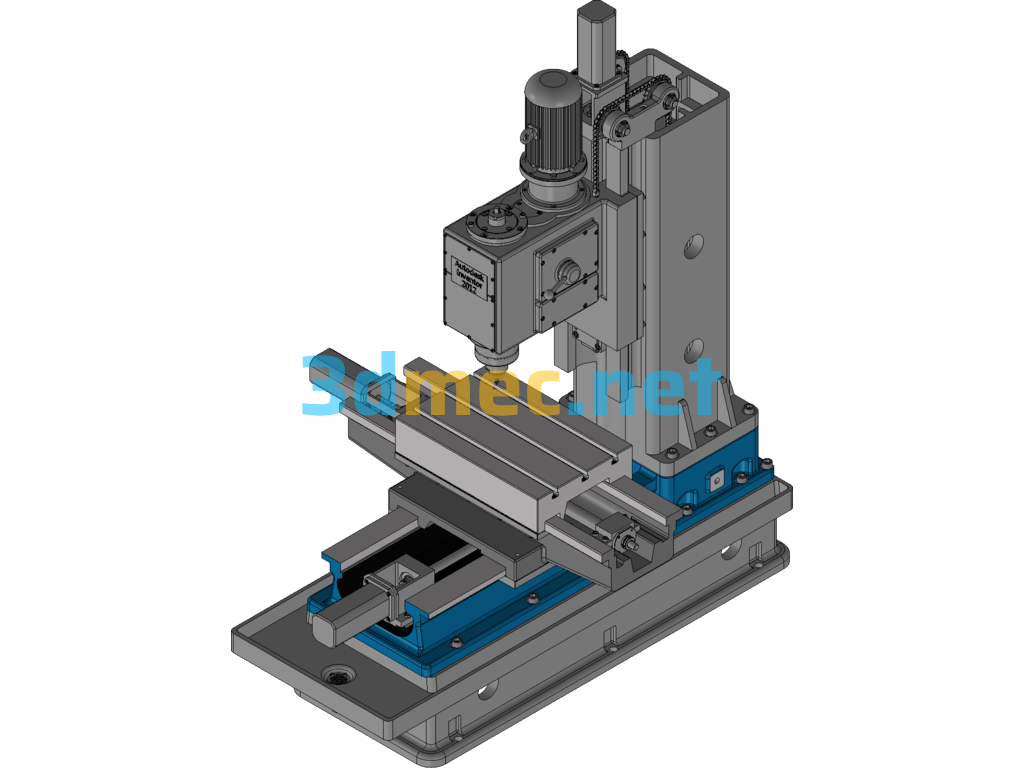

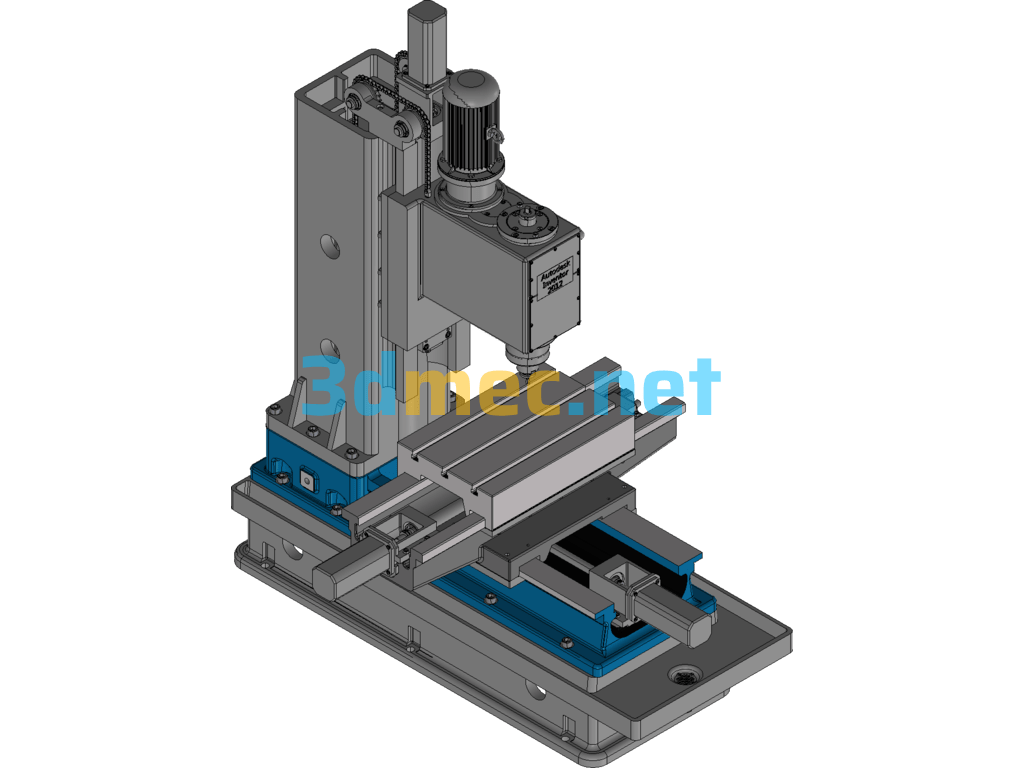

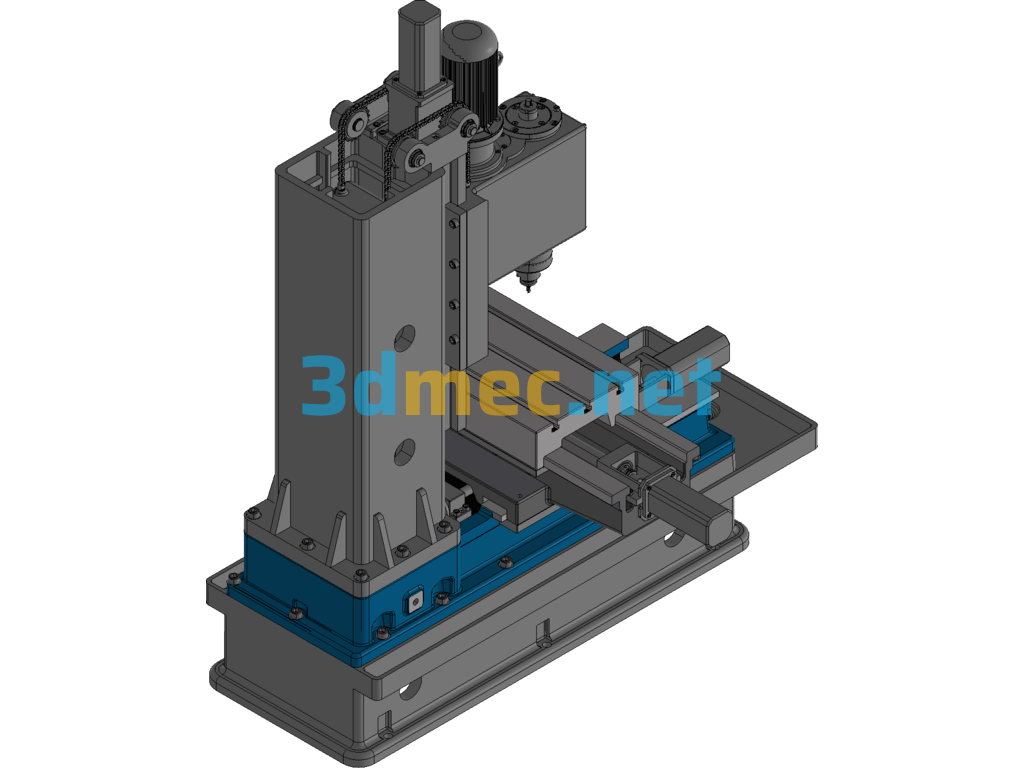

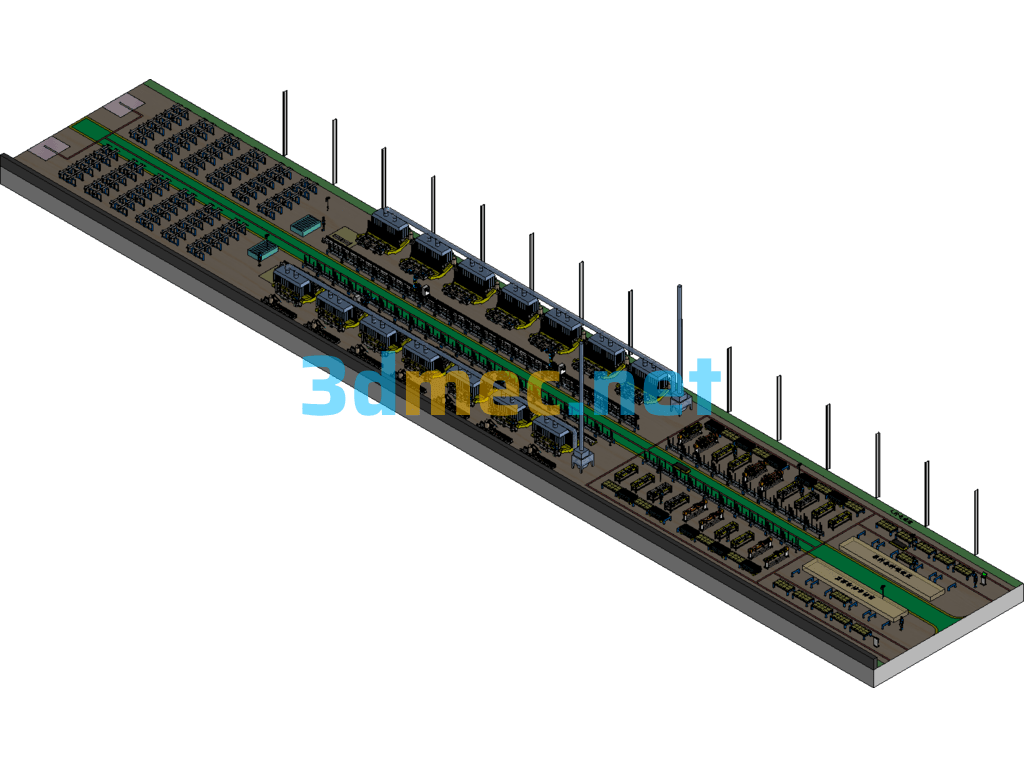

X7132 Milling And Drilling Machine – 3D Model Inventor

1. The application of standard parts such as screws, nuts, washers, etc. in the standard parts library;

2. For the use of design accelerators in Inventor, during the learning period, we learned how to draw worm gears, spur gears, helical gears, synchronous belts, sprockets, etc., which made us find the convenience and flexibility of using design accelerators in some designs. At the same time, we learned the part parameters of spur gears, helical gears and worm gears, understood and recognized the module, number of teeth, and pitch circle, and mastered the calculation and drawing of the module and transmission ratio of gears;

3. We have a preliminary understanding and knowledge of the types, models, and functions of bearings;

4. We have a certain understanding of structural transmission. In gear transmission, we understand the structure of the gearbox and the principle of speed change, the structure of the reduction box and the principle of deceleration, as well as matters that need to be paid attention to during transmission, etc.;

5. We have learned and understood the project management of files in the process of using the software;

6. We are more proficient in the use of Inventor software;

Specification: X7132 Milling And Drilling Machine – 3D Model Inventor

|

User Reviews

Be the first to review “X7132 Milling And Drilling Machine – 3D Model Inventor”

You must be logged in to post a review.

There are no reviews yet.