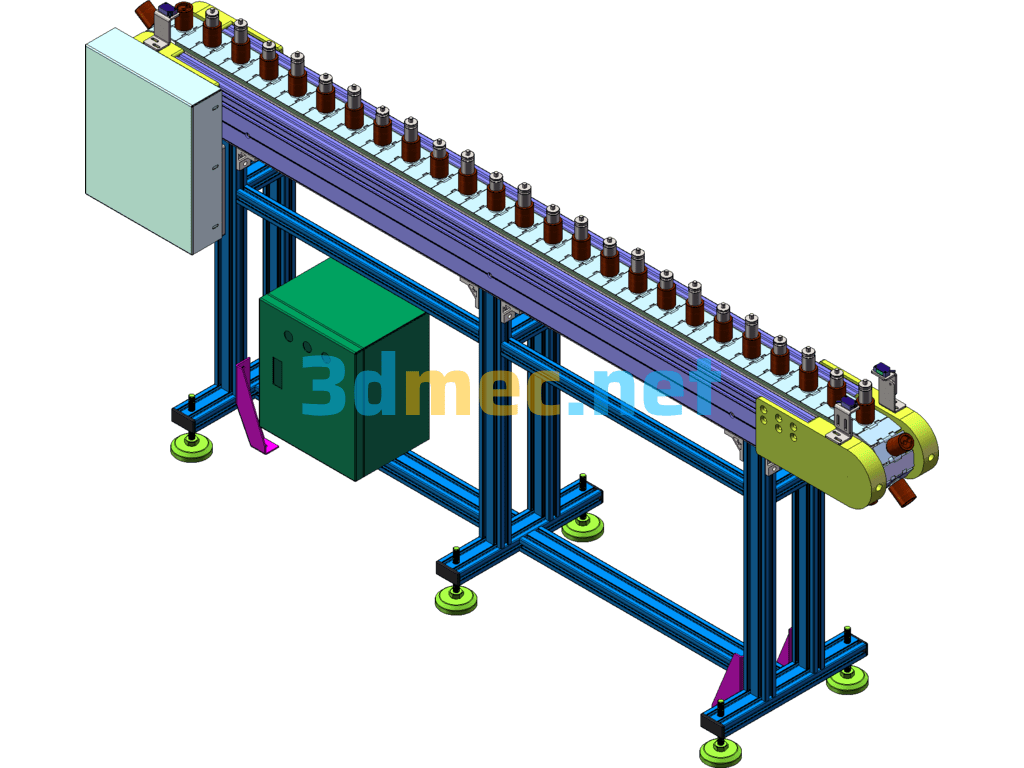

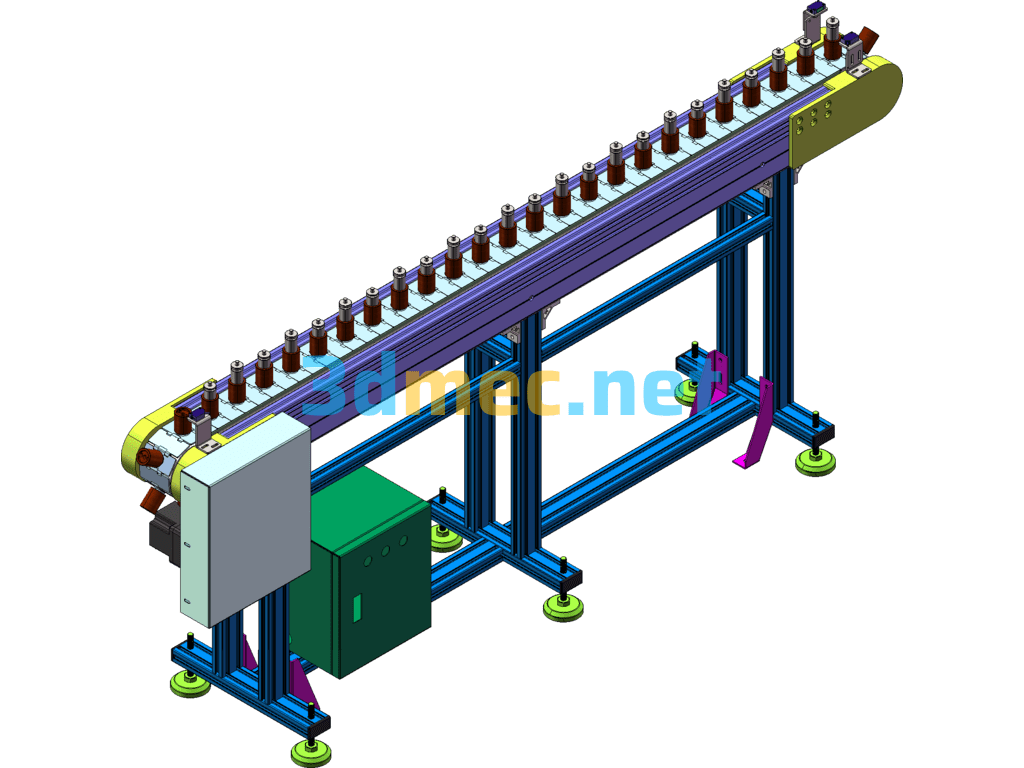

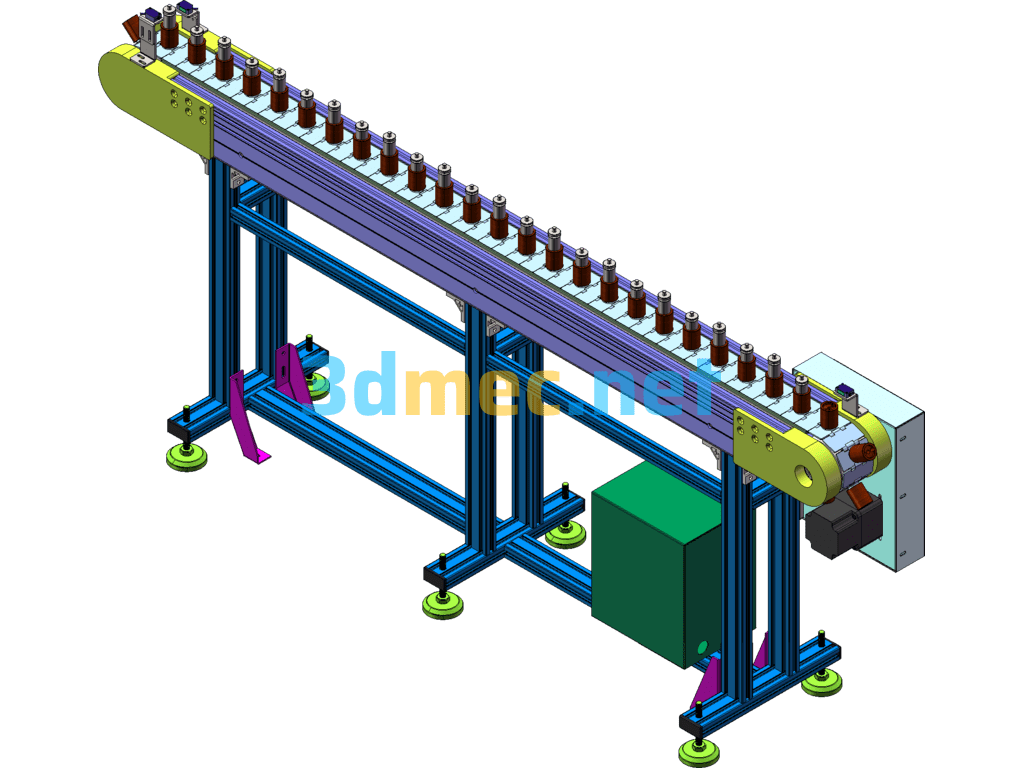

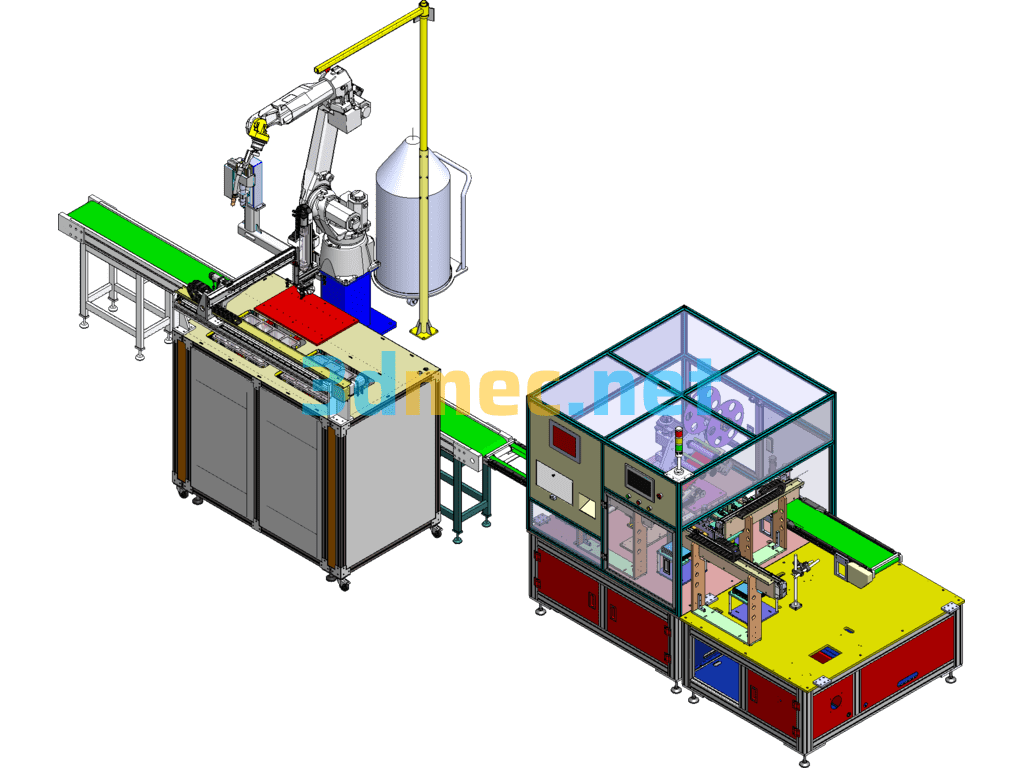

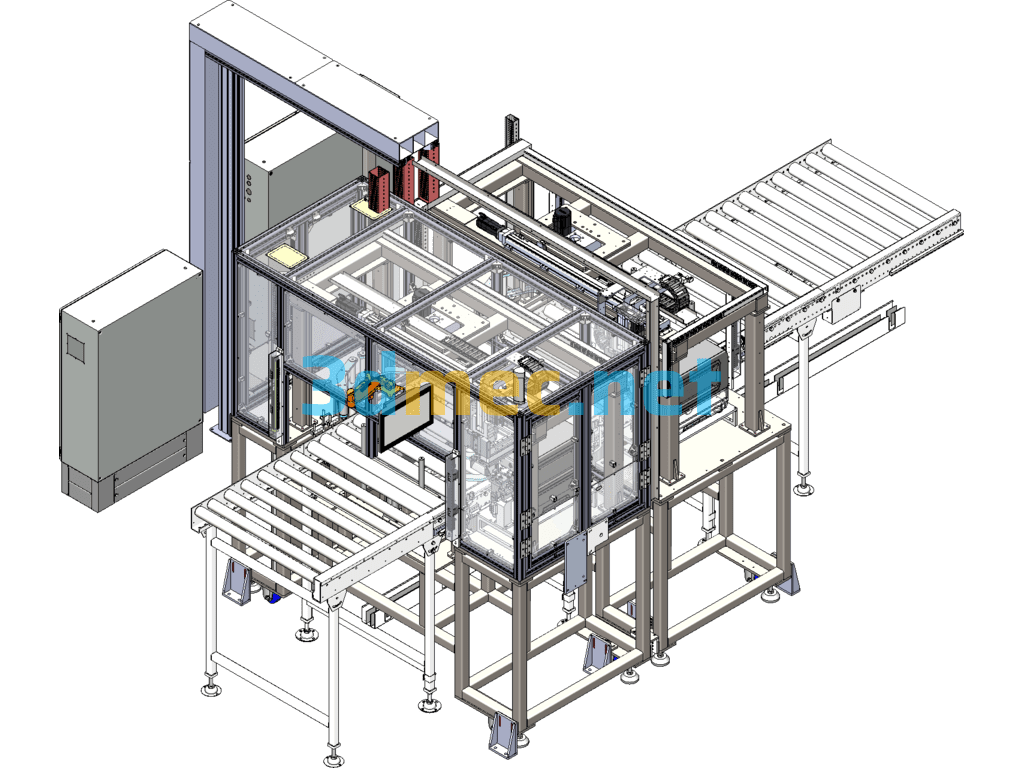

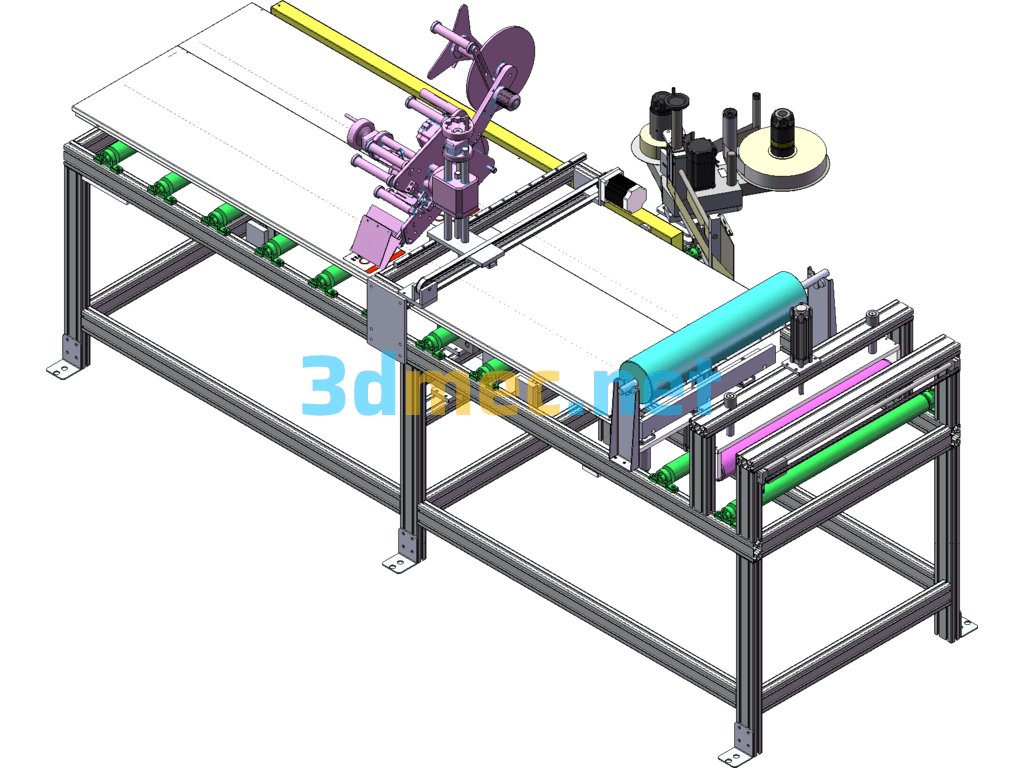

Workstation Positioning Conveyor – 3D Model SolidWorks

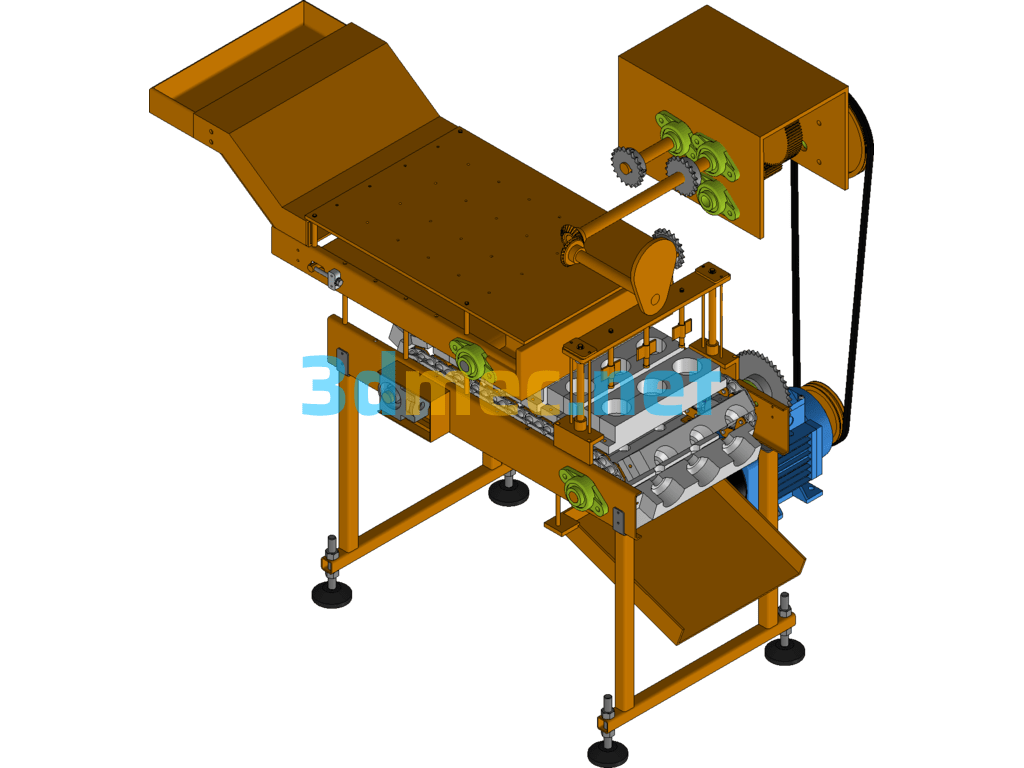

The chain conveyor can meet the single-row conveying requirements of beverage labeling, filling, cleaning and other equipment. It can also make a single row into multiple rows and walk slowly, thereby generating storage capacity to meet the large-scale feeding requirements of sterilizers, bottle storage tables, and bottle coolers. We can make the head and tail of the two chain conveyors into overlapping mixed chains, so that the bottle (can) body is in a dynamic transition state, so that there is no bottle retention on the conveyor line, and it can meet the pressure and pressure-free conveying of empty and full bottles. Chain material: carbon steel, stainless steel, thermoplastic chain. According to the needs of your products, you can choose chain plates of different widths and shapes to complete plane conveying, plane turning, lifting, and lowering. Chain specifications: The width of the straight conveying chain plate is 63.5, 82.5, 101.6, 114.3, 152.4, 190.5, 254, 304.8; the width of the turning chain plate is 82.5, 114.3, 152.4, 190.5, 304.8. Application range: Widely used in automatic conveying, distribution, and in-line conveying of downstream packaging of food, canned food, medicine, beverages, cosmetics and detergents, paper products, condiments, dairy products, tobacco, etc. Features: 1. The conveying surface of the chain conveyor is flat and smooth, with low friction, and the material transition between conveyor lines is smooth. It can convey various types of glass bottles, PET bottles, cans, etc., and can also convey various types of bags. 2. The chain plate is made of materials such as stainless steel and engineering plastics, with a wide variety of specifications. It can be selected according to the conveying materials and process requirements to meet the different needs of various industries. 3. It has a large conveying capacity and can carry large loads, such as electric vehicles, motorcycles, generators, etc.; 4. The conveying speed is accurate and stable, which can ensure precise synchronous conveying. 5. The chain conveyor [1] can generally be directly rinsed with water or immersed in water. The equipment is easy to clean and can meet the hygiene requirements of the food and beverage industry. 6. The equipment layout is flexible. Horizontal, inclined and turning conveying can be completed on one conveyor line. 7. The equipment has a simple structure and is easy to maintain.

Specification: Workstation Positioning Conveyor – 3D Model SolidWorks

|

User Reviews

Be the first to review “Workstation Positioning Conveyor – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.