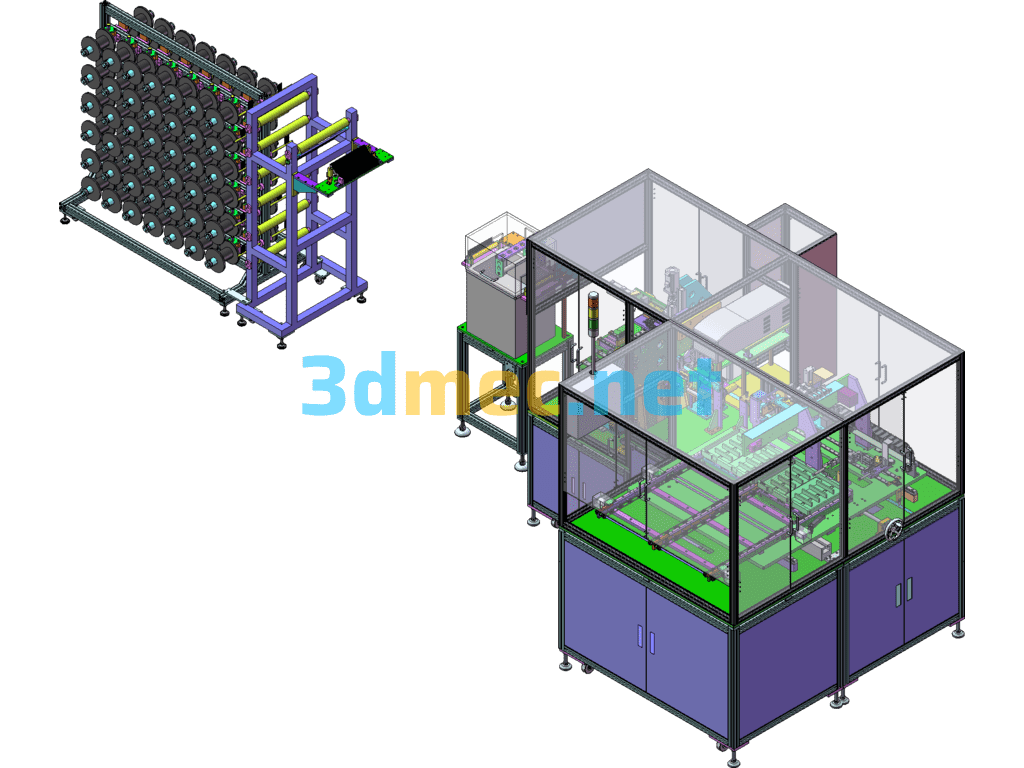

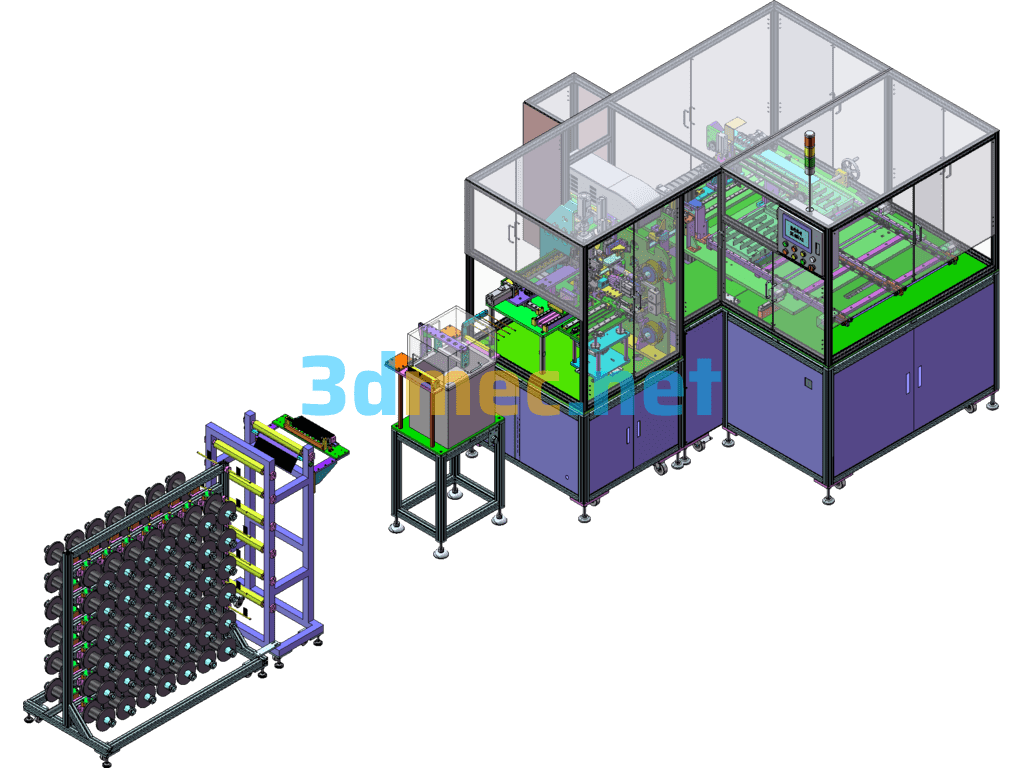

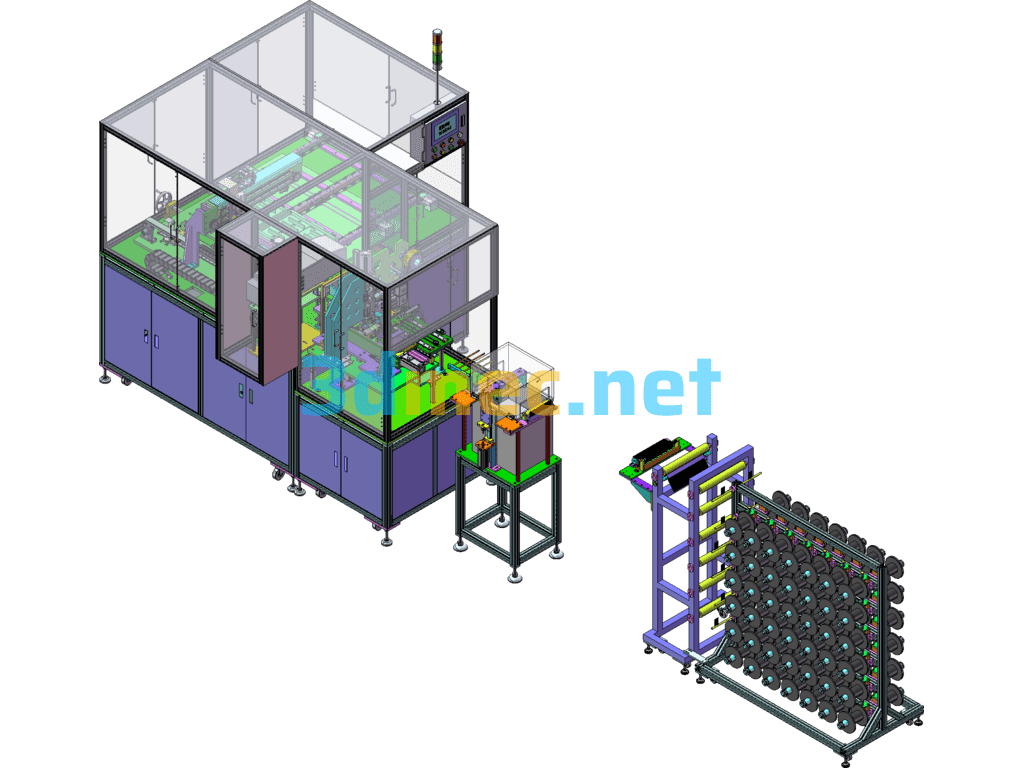

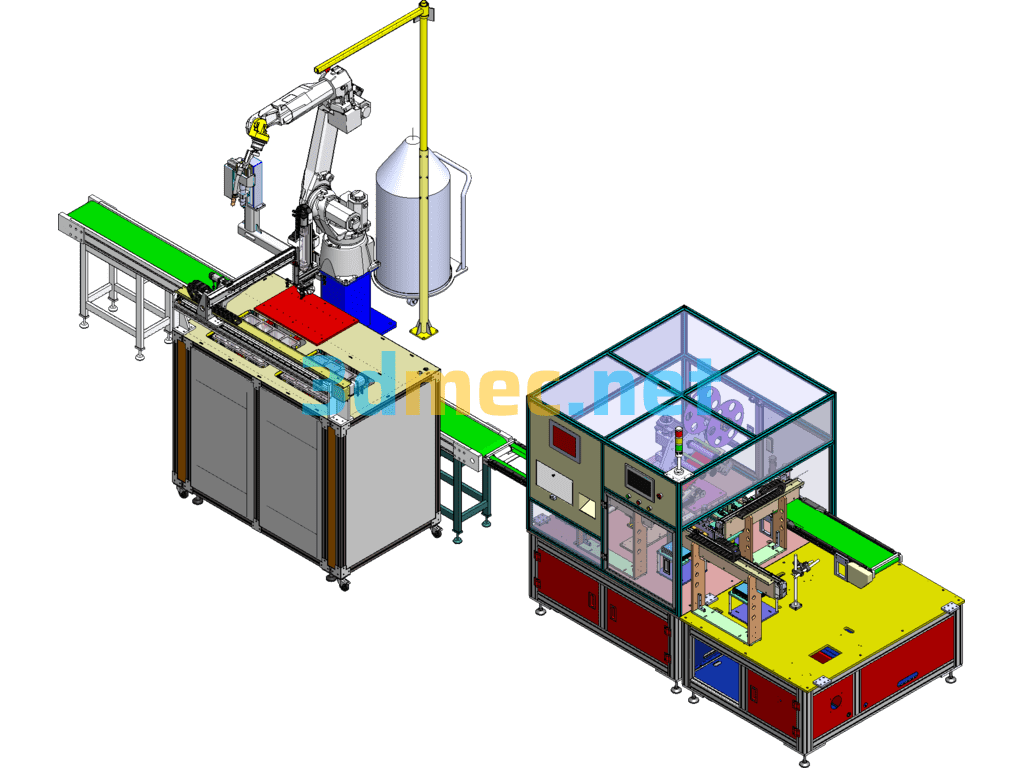

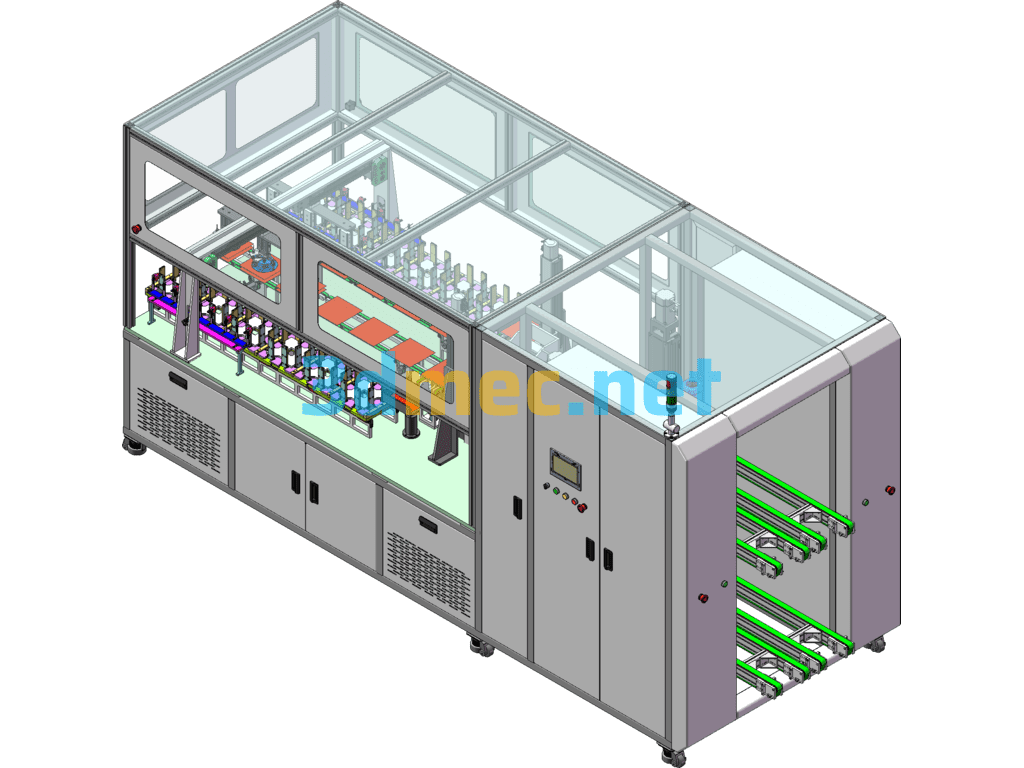

Wire Gluing Laser Cutting Material Collection Automatic Line/Copper Axis Ultrasonic Cleaning FPC Glue Tape Laser Cutting Peeling Machine Automation Equipment – 3D Model SolidWorks

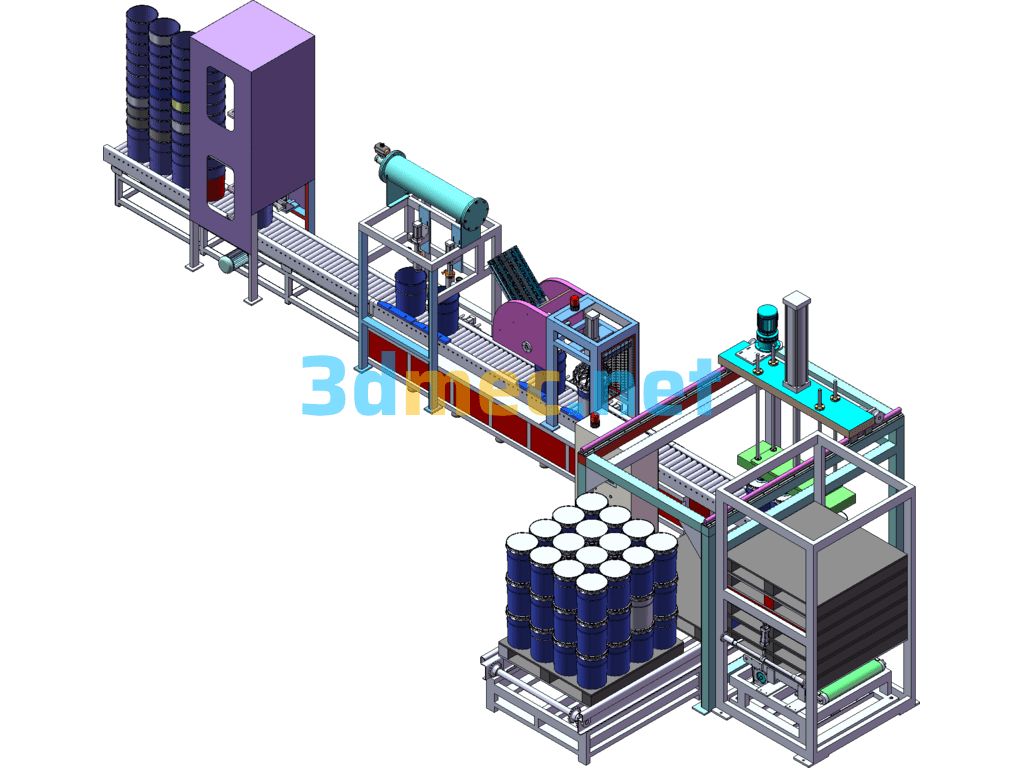

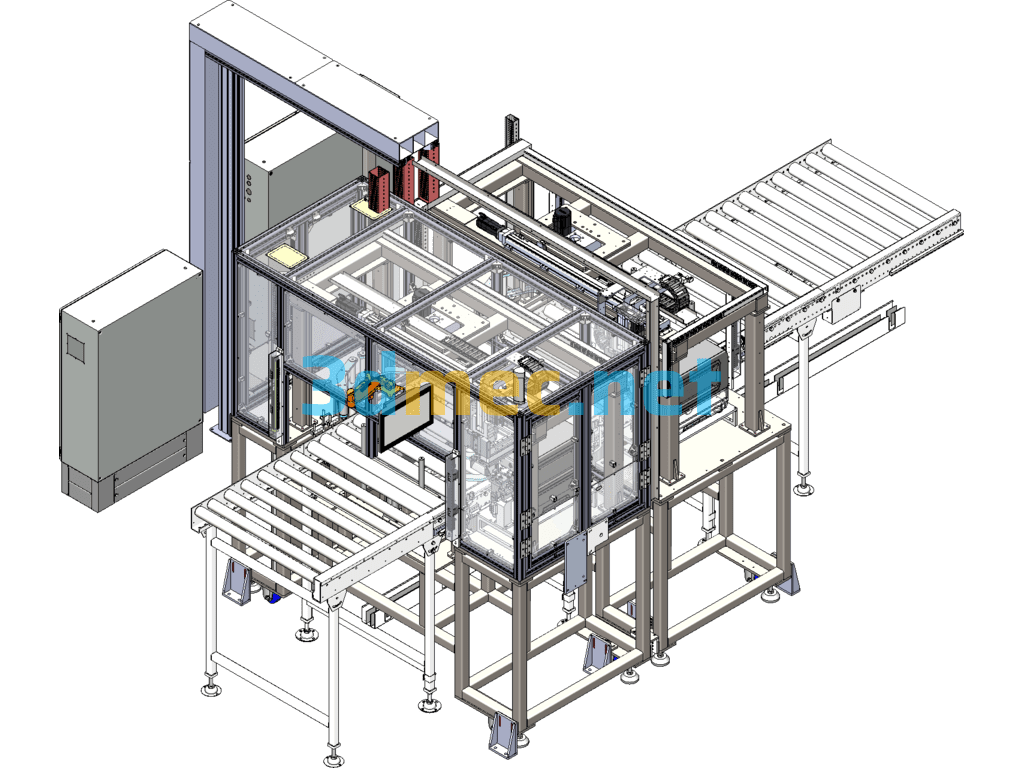

The wire gluing laser cutting and receiving automatic line equipment is suitable for the following products: industrial wires, FPC, FFX soft flat cables, 0.3-1MM wire diameter, various products glue laser cutting, etc. This equipment is mainly a copper wire cutting and processing equipment: the full set of drawings has more than 300 MB after decompression, and the switchboard has more than 900 parts. The equipment is mainly used for cutting and gluing copper wire FPC soft flat cables. The main highlights of the equipment are the wire loading rack part and the complex gluing structure. This loading rack can load dozens of wire rolls at a time. The main functions of the equipment are: 1. Wire feeding, 2. Wire ultrasonic cleaning, 3. Wire body adhesive tape mechanism, 4. Soft flat cable laser cutting and stripping, 5. Cable cutting, 6. Soft flat cable automatic receiving robot, 7. Automatic feed tray circulating conveyor belt, the equipment bus is an integrated fully automatic operation, with manual assisted loading and unloading, and the loading rack structure is suitable for various sizes of roll barrels. The copper wire FPC soft cable has simple loading and unloading operations. You only need to put the wire into the rotating shaft of the loading rack. The copper wire in the material rack is ultrasonically cleaned after passing through the roller and the wire harness sorting structure. The cleaned wire enters the glue sticking machine. The incoming wire body can arrange up to 30 wires. The number of wires can be automatically selected and arranged, and the size of the glue tape can also be selected. When the wire enters the glue sticking station, the glue pulling mechanism pulls out the adhesive tape and cuts it off and then sticks it on the wire. The upper and lower sides are stuck together to tie the wires together. The battery cell glue sticking material pulling structure is a stepper motor moving structure with a complex structure. The switchboard uses 2 servo motors, a stepper motor and more than a dozen cylinders. This is a complex glue sticking paper mechanism with a labeling head and suction. The label is vacuum adsorption type, the length of the glue position can be adjusted according to the requirements, and the adjustable range is relatively large. The wire feeding structure is also cleverly designed. The glue position of the cable arrangement is segmented, and then the laser cutting on the surface is also cut at the rear end of the glue. After laser cutting, the wire body is cut by the cutting machine, and the cutting length is set manually. After cutting, the material is directly grabbed into the receiving box by the material taking robot. The receiving box is recycled and the material tray is transported by the discharging conveyor belt. The conveyor belt has a total of 6 small motors, including 2 conveyor belts for one section, 2 jacking and transferring machines for the second section, and 2 each. The conveyor belt is divided into one in and one out. The feeding conveyor is on the left and the discharging conveyor is on the right. The carrier in the left feeding conveyor belt is in the state when there is product, and when the product is used up , the empty carrier plate or blister plate is lifted and loaded into the empty conveyor belt on the right by the lifting and transferring conveyor, and then the empty material plate is recycled. The motor power of this conveyor belt is relatively small and the conveyed product is also relatively light, so a round belt design is adopted, which is very convenient in installation and debugging, and the round belt is more wear-resistant and it is also very convenient to replace. Because the movement in the equipment is more complicated and there are more cylinder structures, most of the structures can be seen from the pictures. Friends who need and are interested can download and study the drawings. The content is very good for reference. After downloading, you can analyze and study it carefully, and you can definitely learn a lot. I will not give other detailed introductions here. The above is the entire structure and working principle of this equipment.

Specification: Wire Gluing Laser Cutting Material Collection Automatic Line/Copper Axis Ultrasonic Cleaning FPC Glue Tape Laser Cutting Peeling Machine Automation Equipment – 3D Model SolidWorks

|

User Reviews

Be the first to review “Wire Gluing Laser Cutting Material Collection Automatic Line/Copper Axis Ultrasonic Cleaning FPC Glue Tape Laser Cutting Peeling Machine Automation Equipment – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.