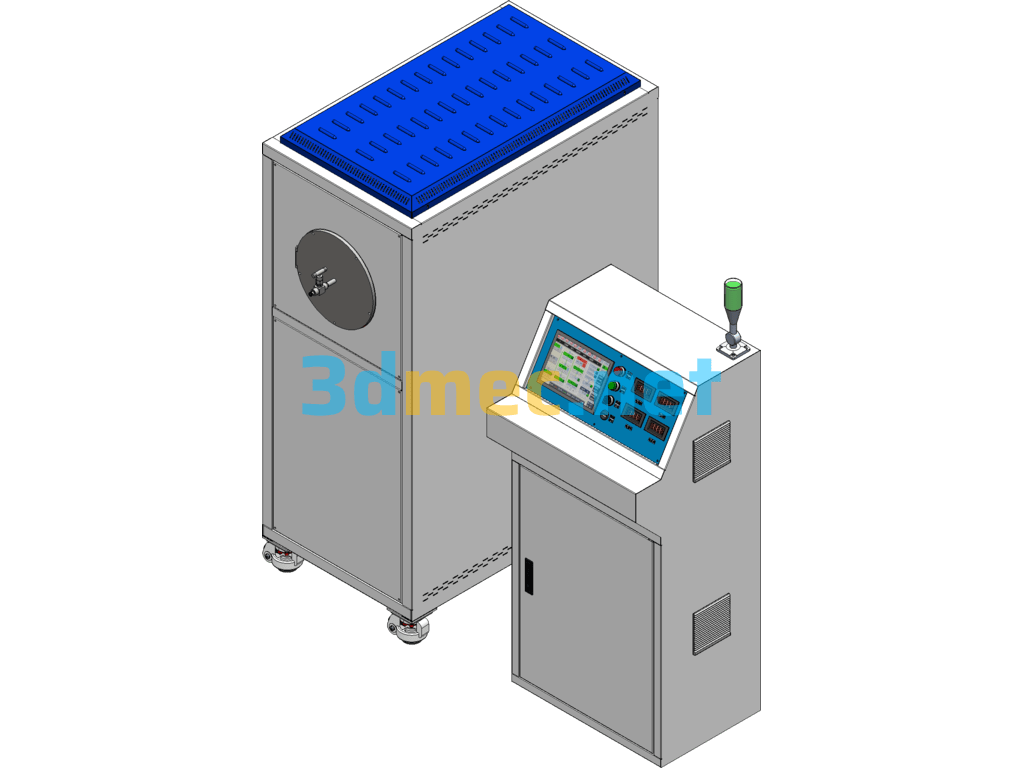

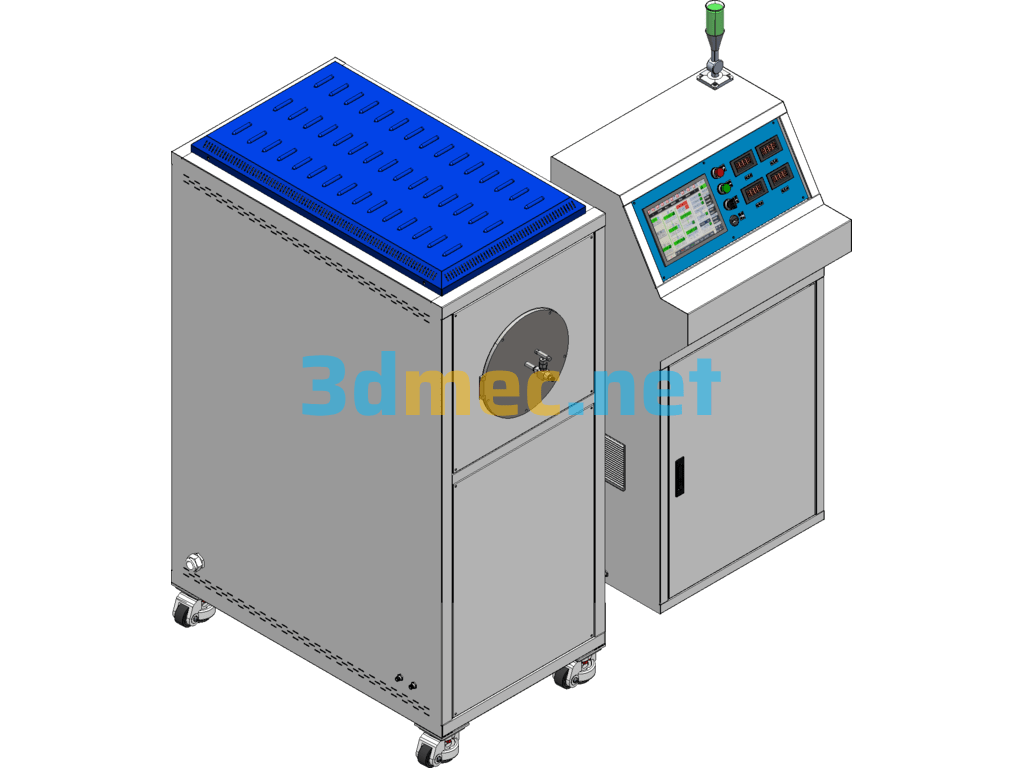

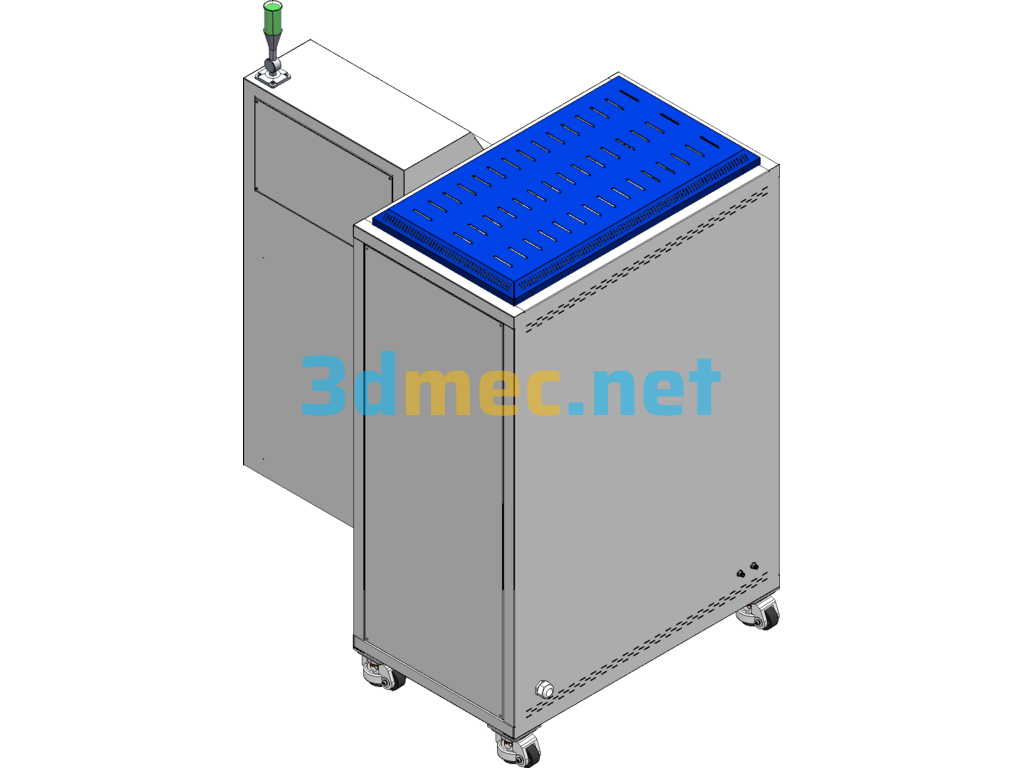

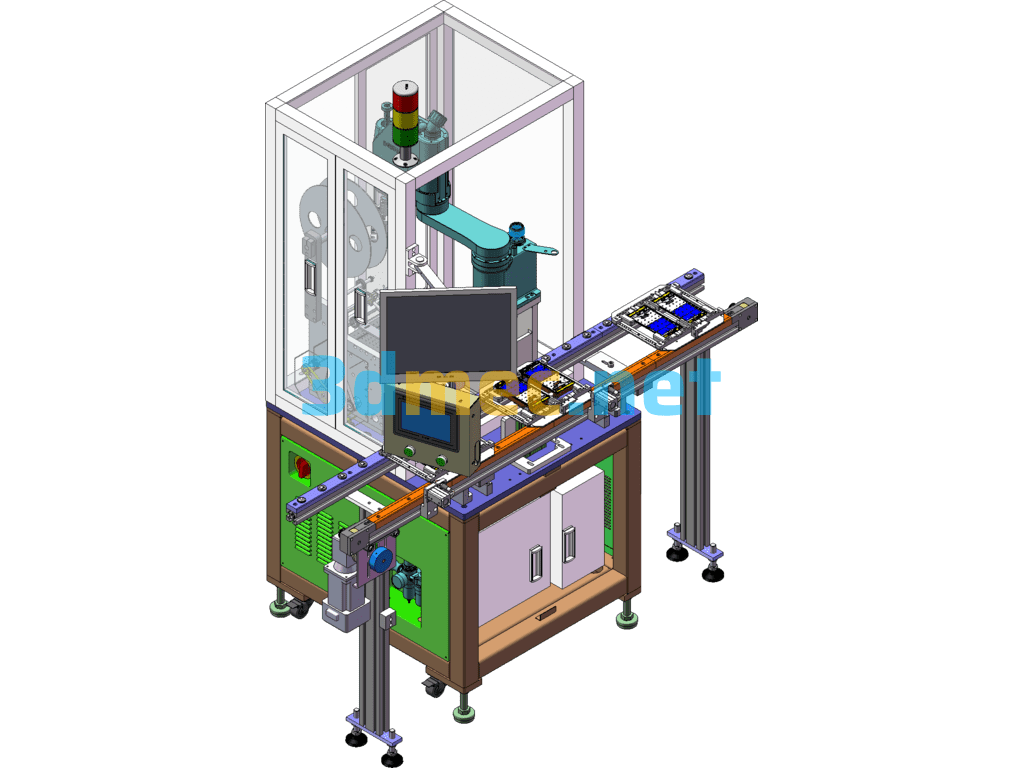

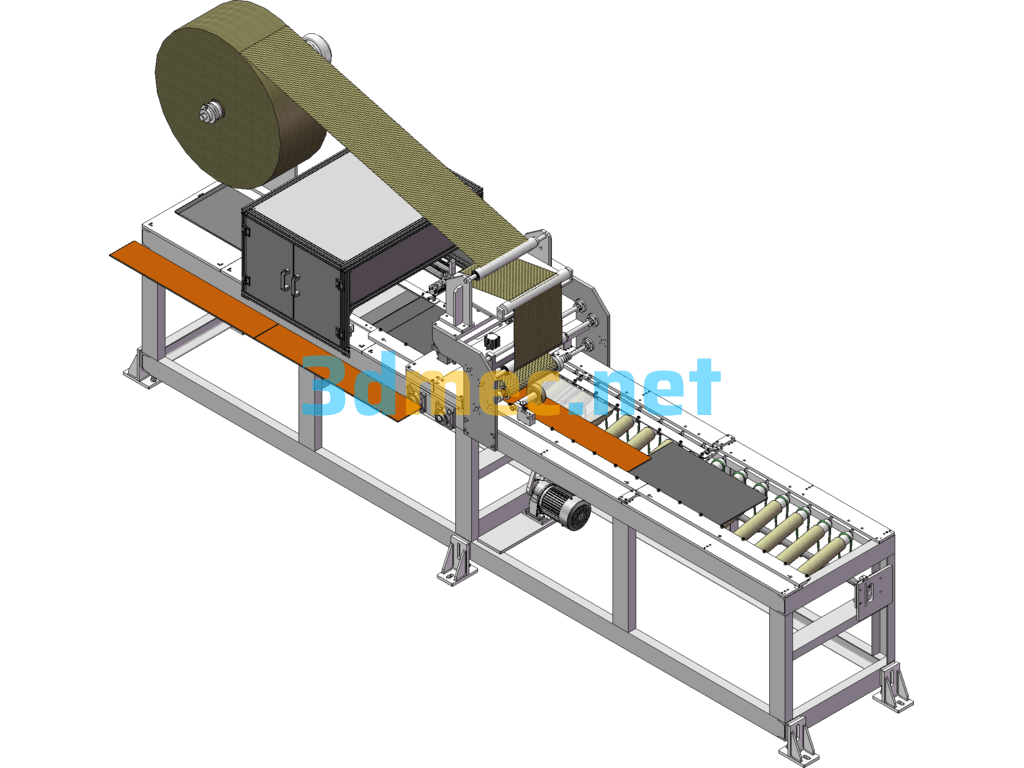

Tube Furnace – 3D Model SolidWorks

1. The furnace chamber is made of imported alumina polycrystalline fiber material with good thermal insulation performance. 2. The heating element is made of imported alloy wire 0Cr27Al7Mo2, and the temperature can reach 1000℃. 3. The double-layer shell structure is adopted, combined with thermal induction technology, and equipped with an air cooling system to quickly cool the surface temperature of the furnace body. 4. The KF fast flange connection is adopted to reduce the possibility of damage to the heating tube, and it is more convenient and quick to take and put materials. 5. The upper opening furnace cover design can observe the heated materials in real time and can quickly cool down to meet the experimental needs of sudden cooling and heating of materials; 6. Intelligent PID control, self-tuning function, 30-stage programmable control, 30-stage heating and cooling programs can be set, and power loss is achieved. 7. Reserve vacuum and gas path quick interfaces, used with our vacuum and gas mixing systems; meet the needs of users to conduct experiments under different vacuum states and different atmosphere conditions.

Specification: Tube Furnace – 3D Model SolidWorks

|

User Reviews

Be the first to review “Tube Furnace – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.