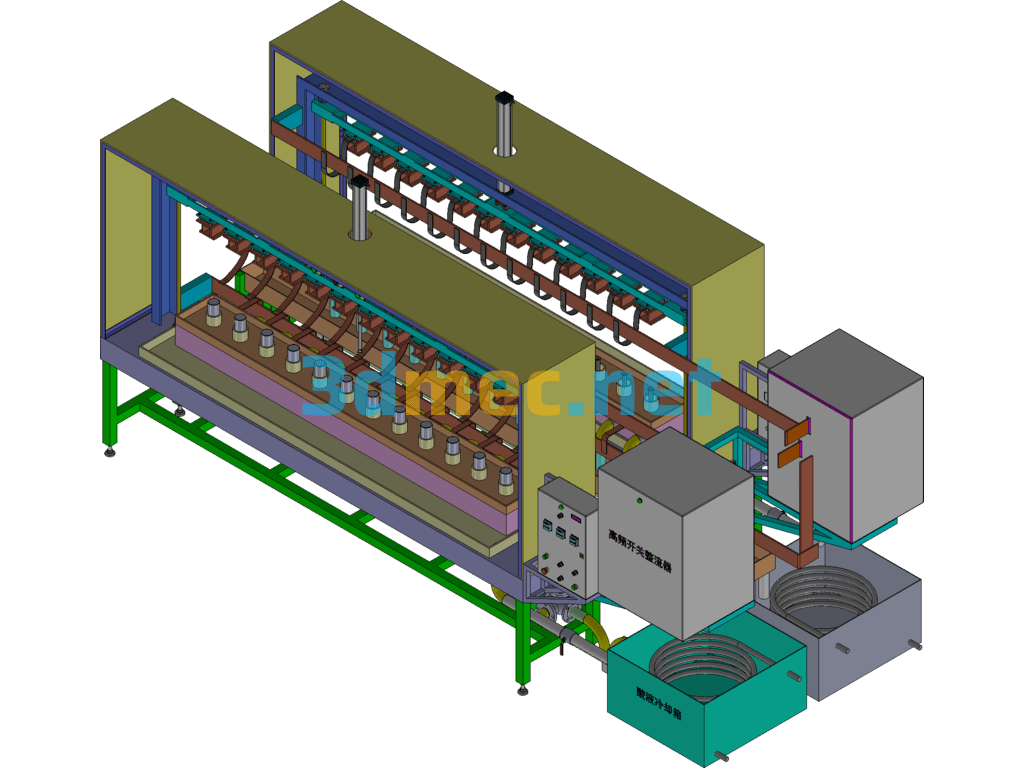

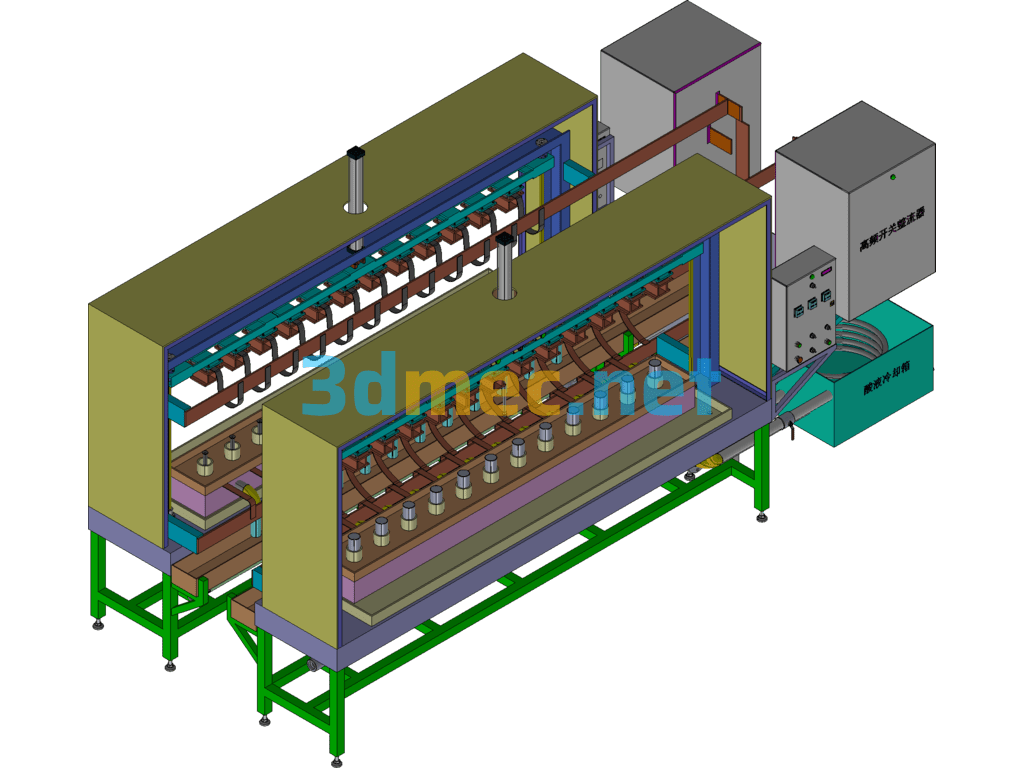

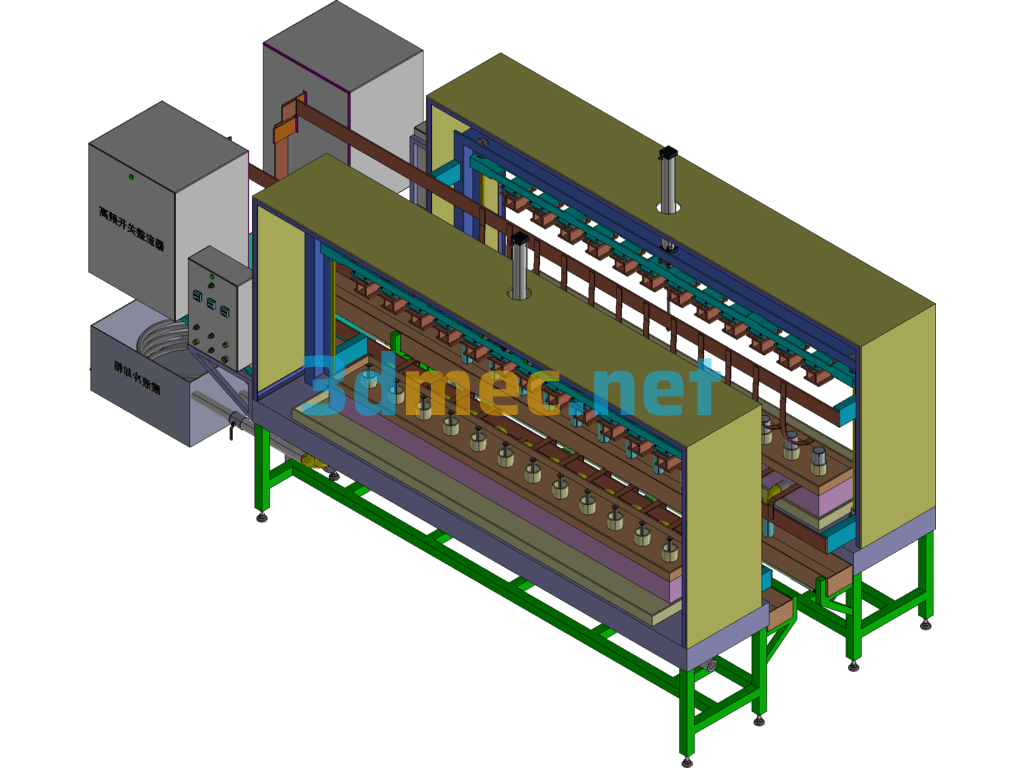

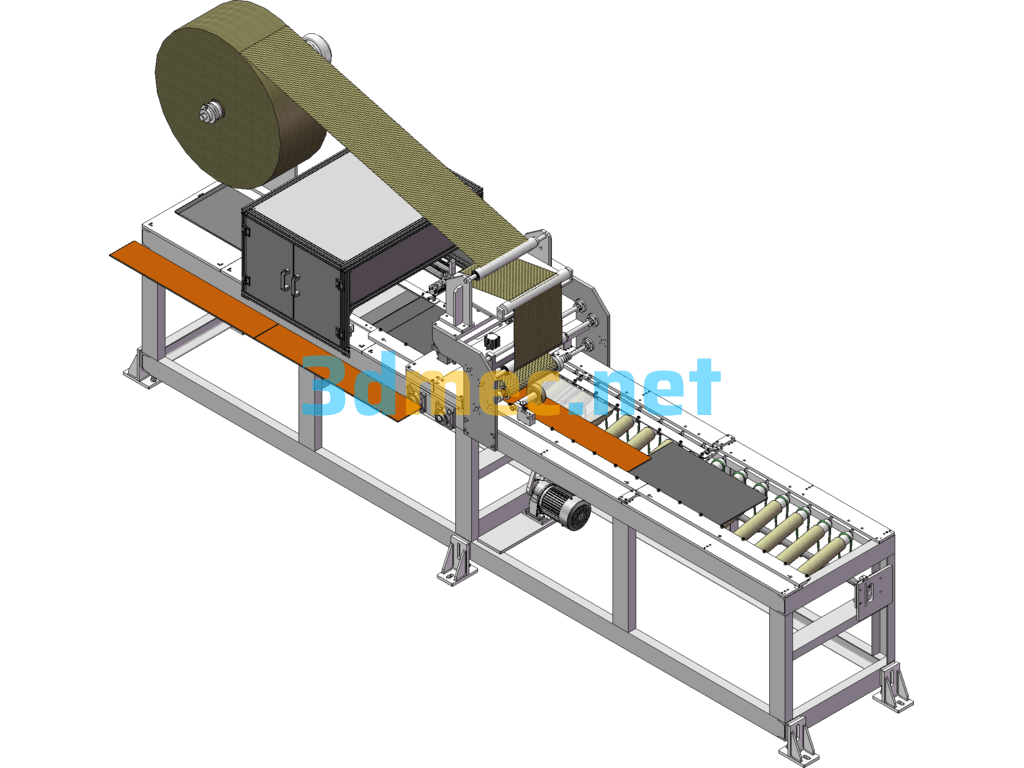

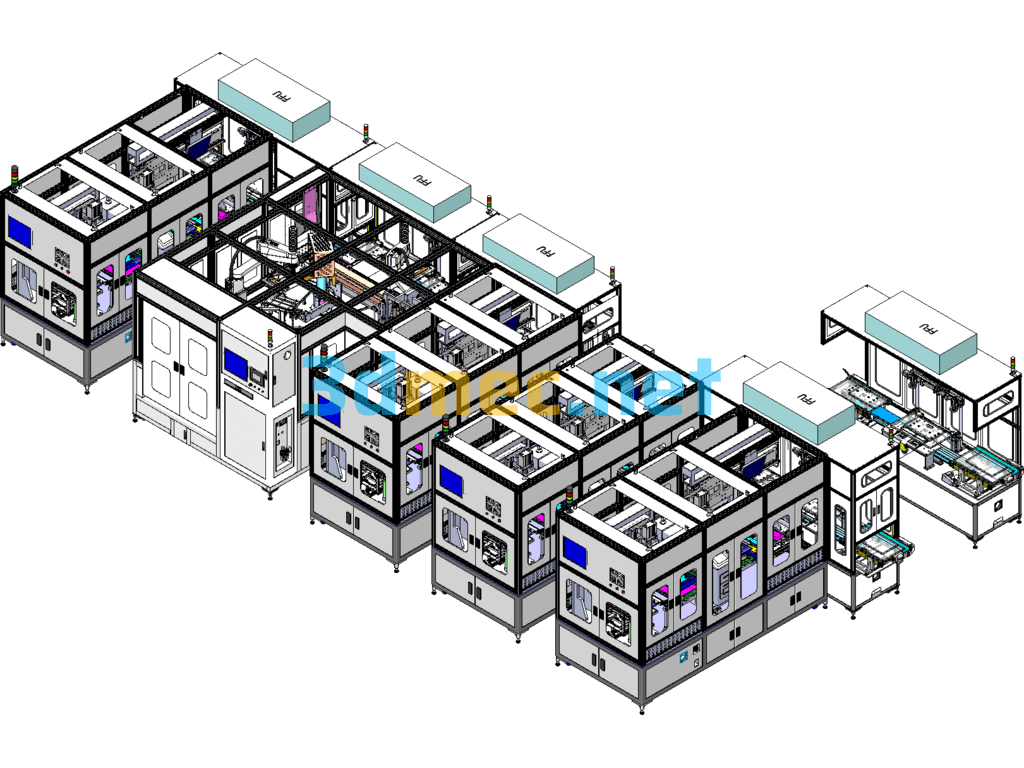

Thermos Cup Electrolysis Machine Solution- – 3D Model Exported

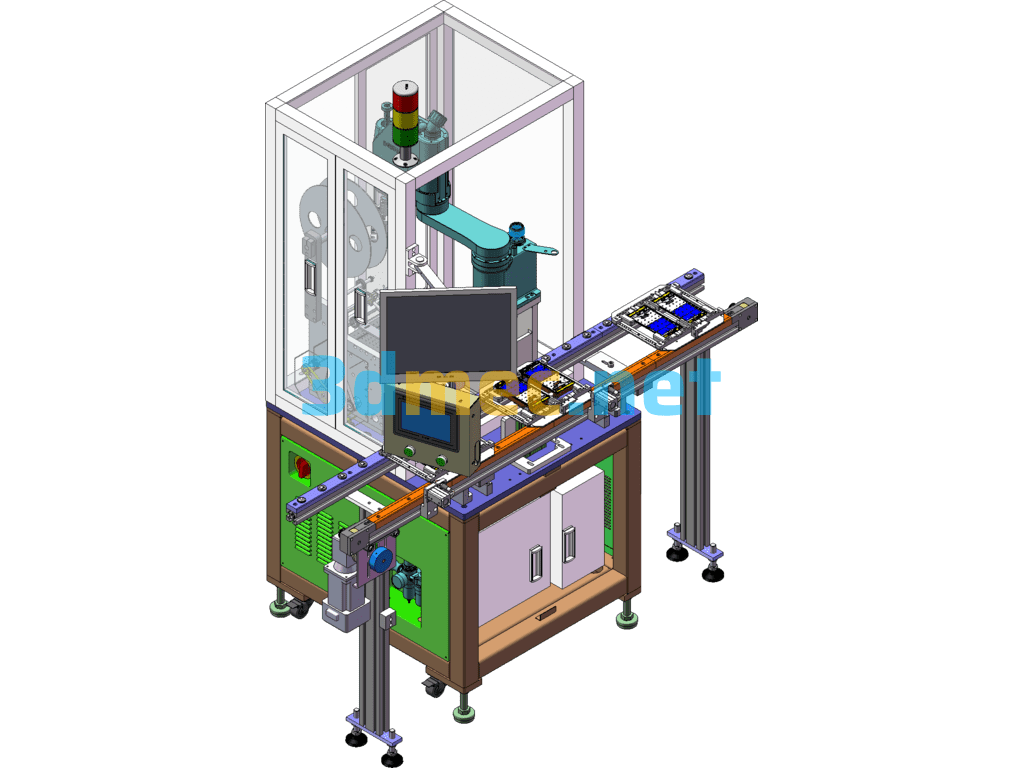

Thermos cup electrolysis machine solution -, automatically cleans the inner wall of the thermos cup to ensure that the inside and outside of the thermos cup are smooth

1. The equipment has 24 stations (12 stations on one side);

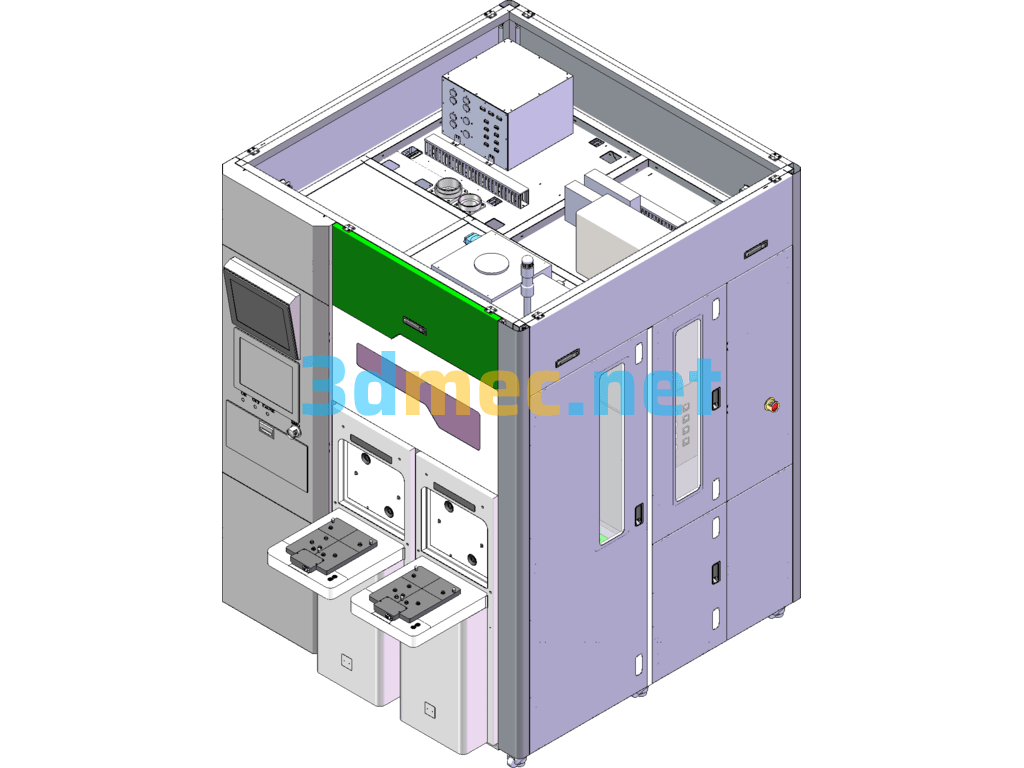

2. Flushing method (recoil);

3. Acid pool temperature control (the default recommended circulating cooling water flow is 70L/min), (customers can choose to use a chiller to control ±5℃);

4. Add a blowing device for the acid left in the thermos cup;

5. High-frequency switching rectifier (3000A);

6. Some equipment materials are stainless steel SUS316L and other corrosion-resistant materials with a thickness of 5mm, 3mm;

7. Limit accuracy, ±5mm;

8. Acid pool exhaust pipe (excluding purification equipment);

9. The equipment is equipped with 5 types of thermos cup fixtures (customers are required to provide thermos cup size drawings);

10. Acid pump and acid valve (imported and national quality customers can choose to import);

Specification: Thermos Cup Electrolysis Machine Solution- – 3D Model Exported

|

User Reviews

Be the first to review “Thermos Cup Electrolysis Machine Solution- – 3D Model Exported”

You must be logged in to post a review.

There are no reviews yet.