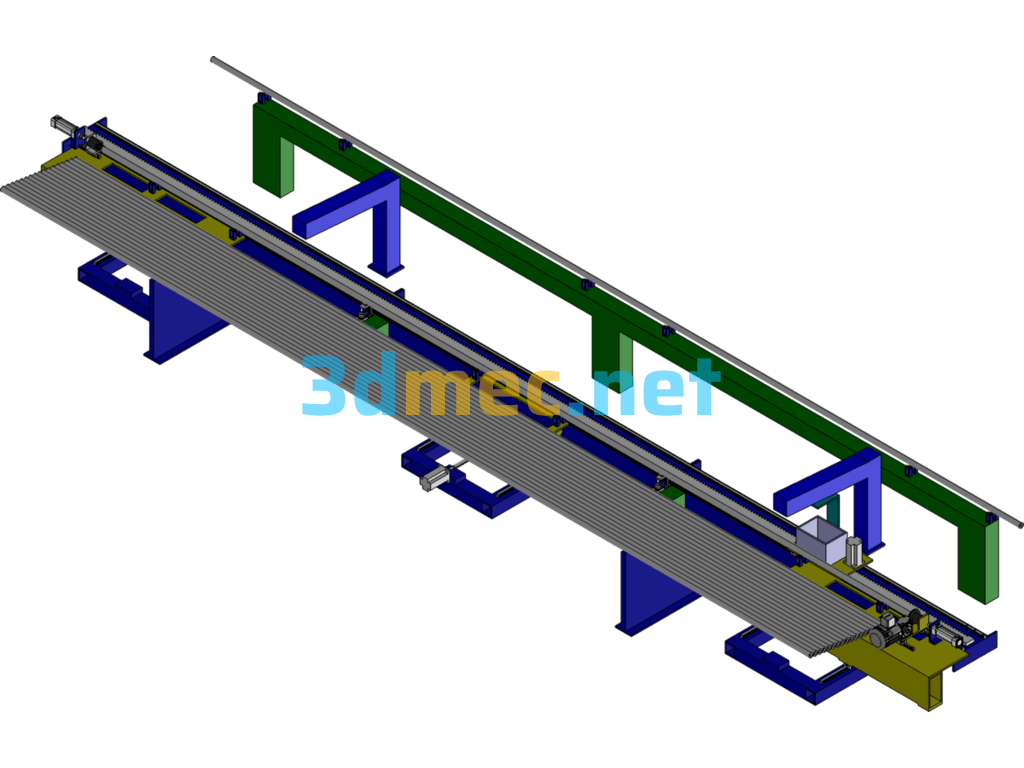

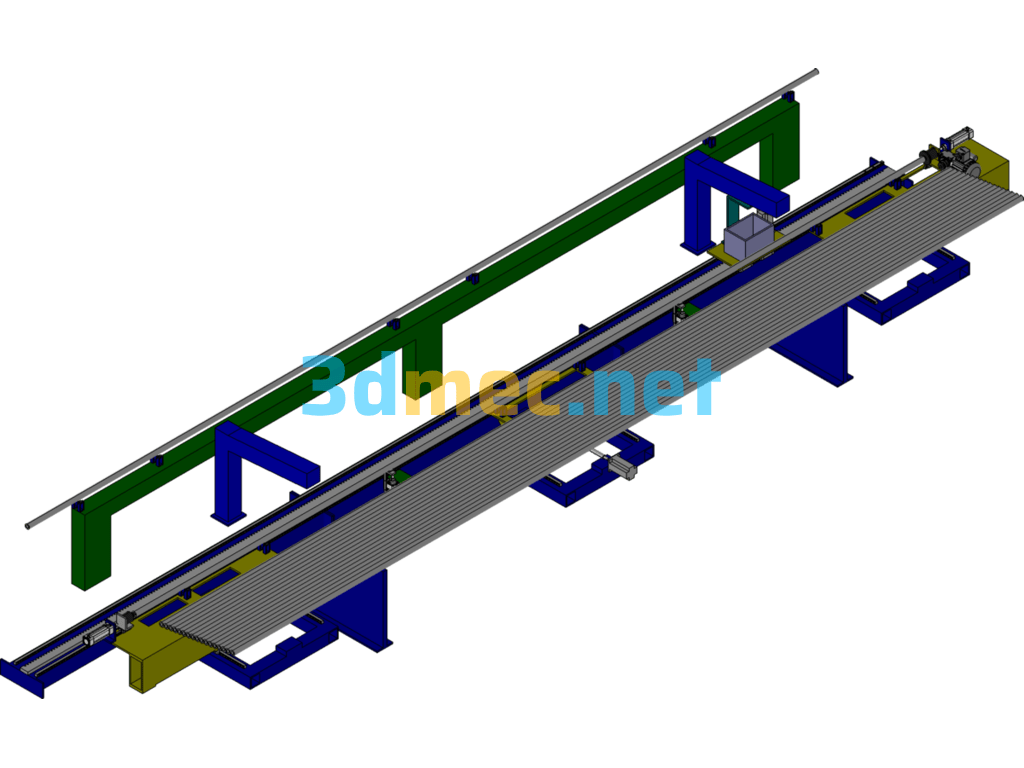

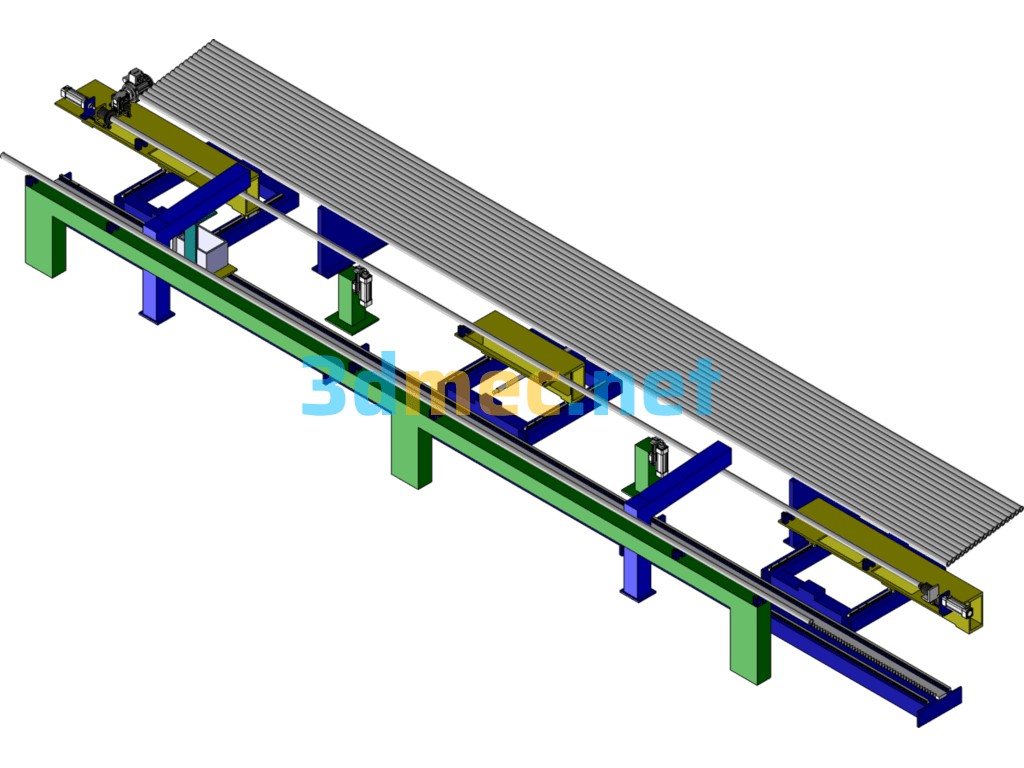

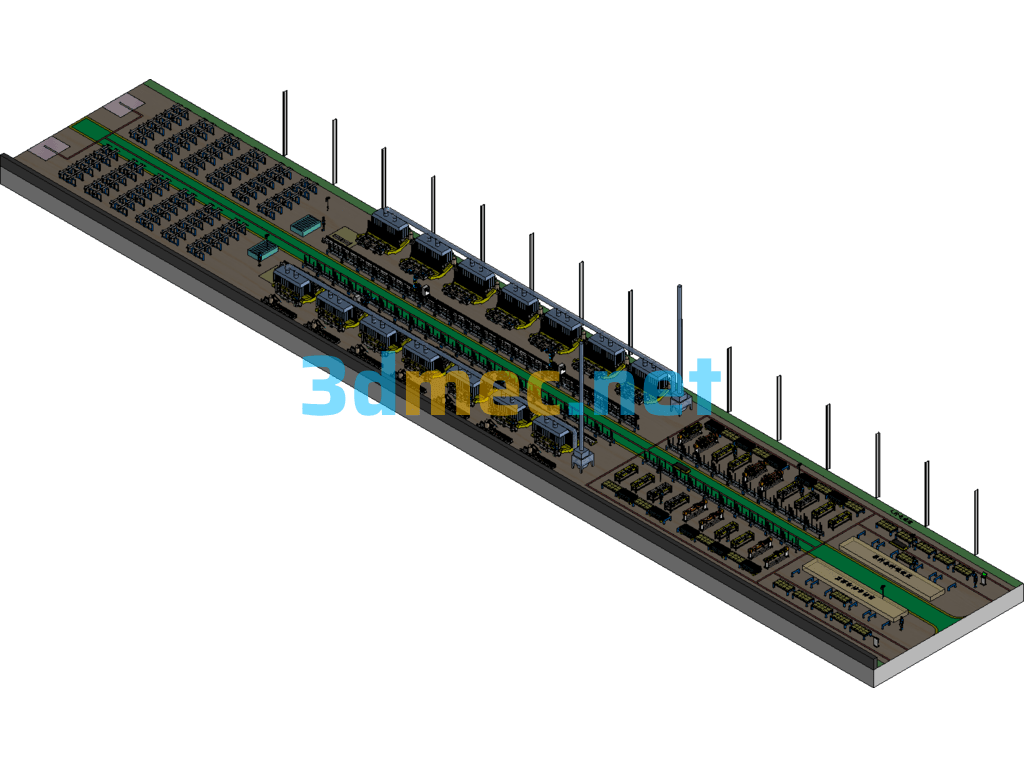

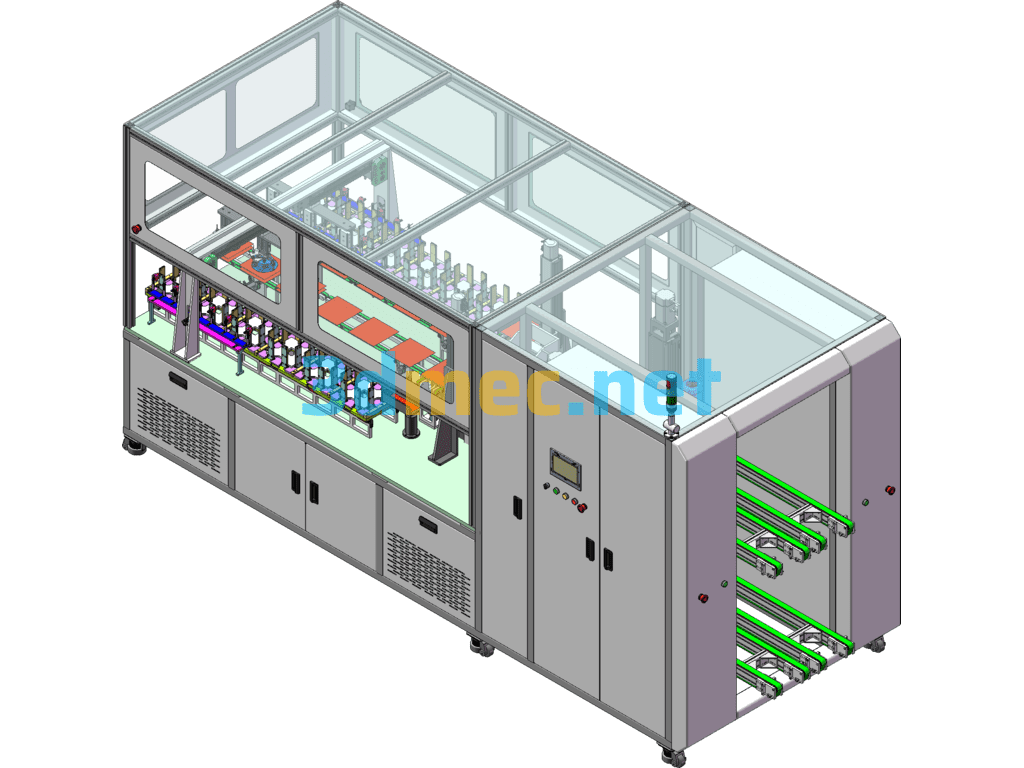

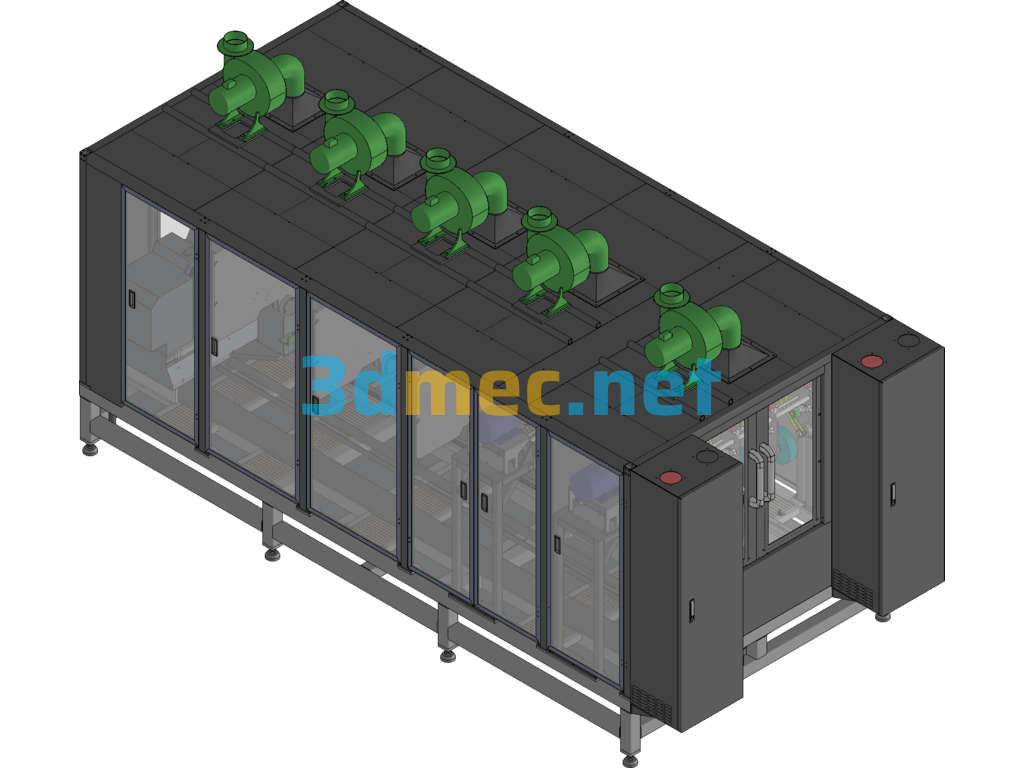

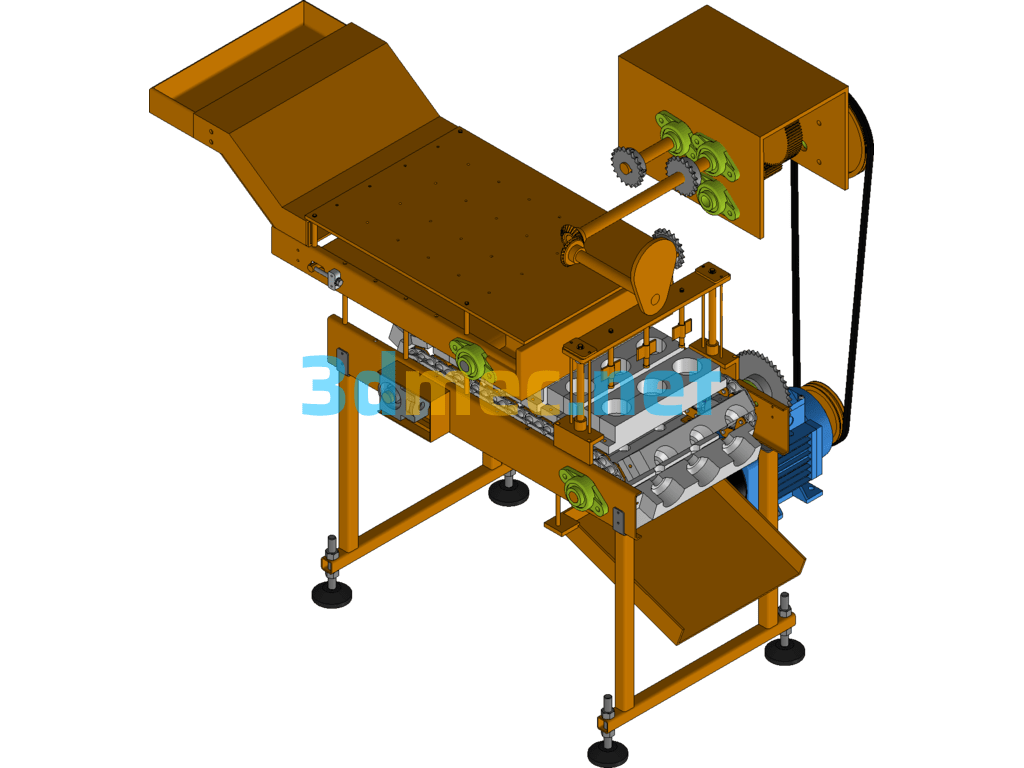

Equipment for automatic flaw detection of steel pipes for engineering machinery, flaw detection and cutting machine flaw detection scheme, steel pipe flaw detection and testing equipment

The steel pipe flaw detector displays the surface and internal defects of parts and welds processed from materials to evaluate the quality of finished products. It displays the location, shape and size of discontinuities. It can detect extremely fine cracks, hairlines, white spots, folds, inclusions and other defects on the surface of the material. It has a high detection sensitivity and can intuitively display the location, shape, size and severity of the defects. The repeatability of the defect inspection is good. It has been widely used in the flaw detection of pipes, bars, profiles, welded parts, machined parts, and forgings, especially in the regular inspection of pressure vessels and bearings. It plays a unique role.

Specification: Steel Pipe Flaw Detection Testing Equipment (Steel Pipe Flaw Detector) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Steel Pipe Flaw Detection Testing Equipment (Steel Pipe Flaw Detector) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.