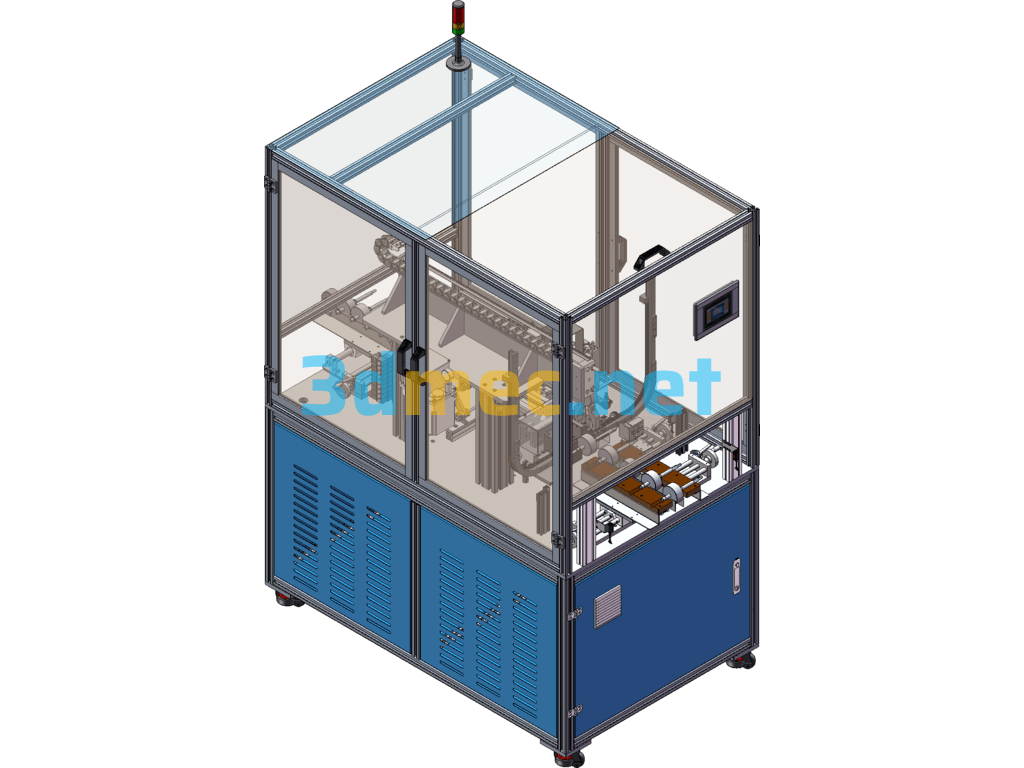

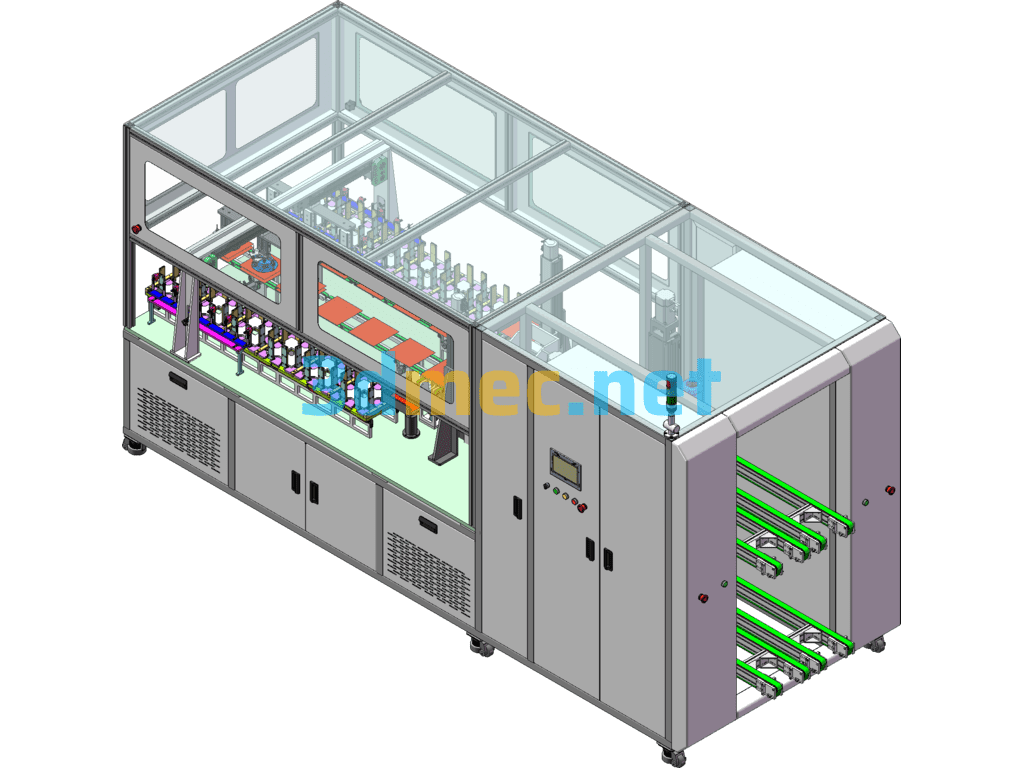

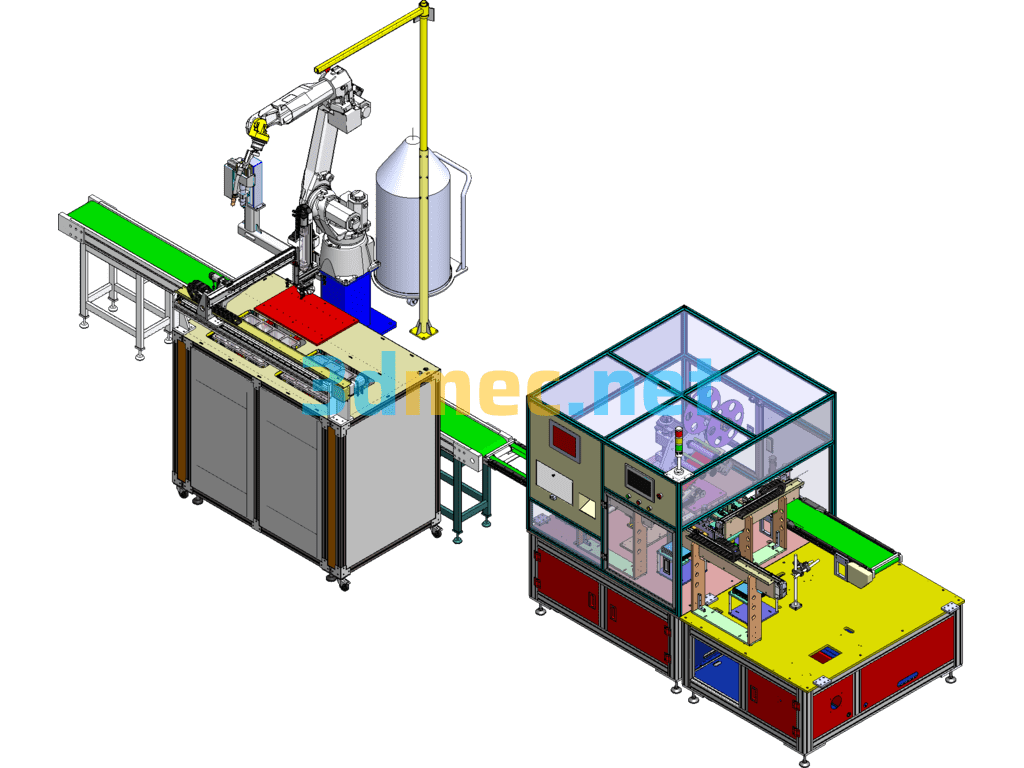

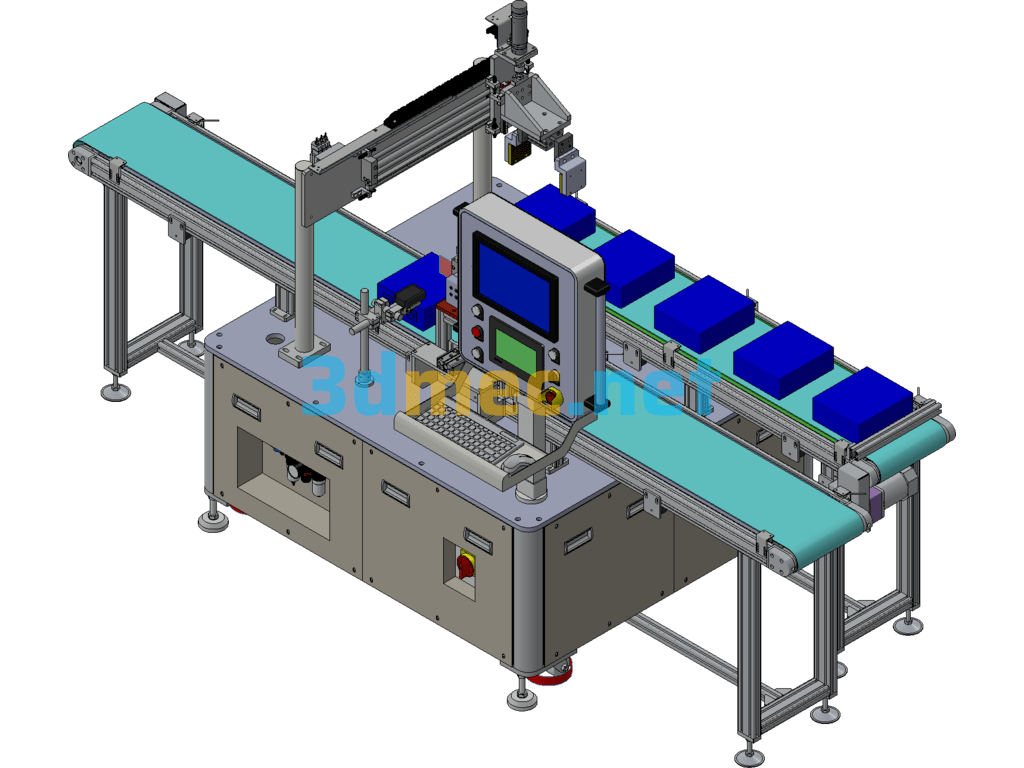

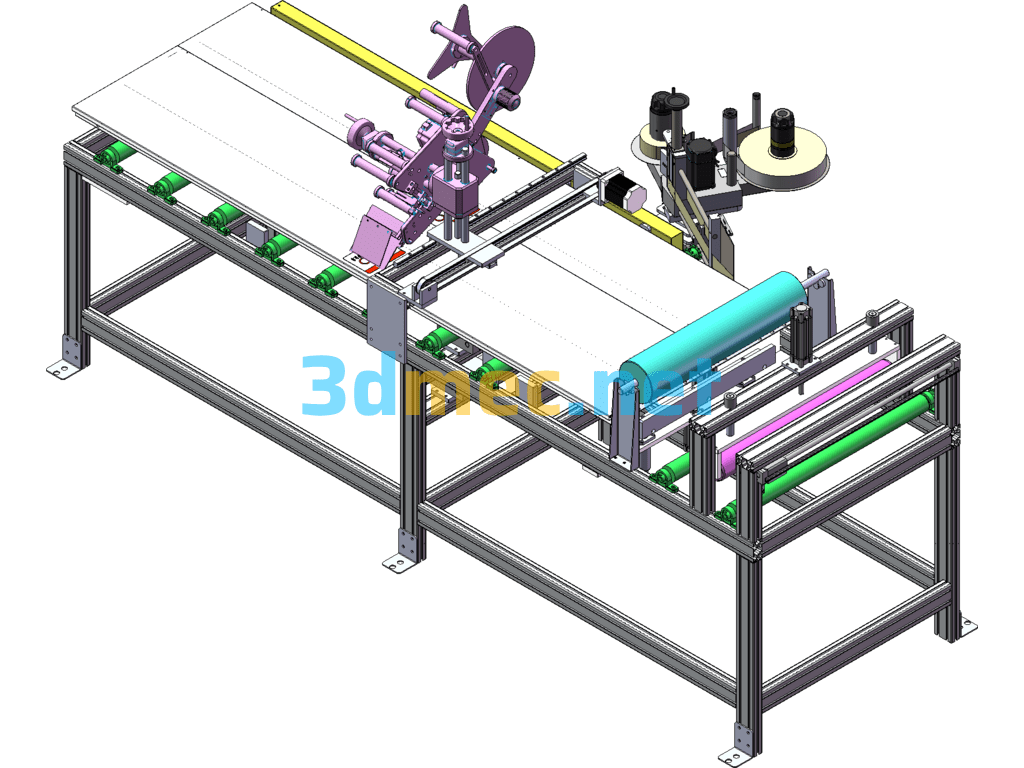

Rotor Circling Oiler Machine This equipment is used for rotor processing of squirrel cage rotor manufacturers, the main function of the rotor bearing position circling assembly and squirrel cage rotor coated with antirust oil (light gold water). The rotor is fed into the circlip assembly through the loading mechanism, after the rotor bearing position circlip is assembled in place, the rotor is sent to the anti-rust oiling station through the pneumatic transplanting mechanism, at this time, the oiling roller is moved to the rotor shaft through the transplanting mechanism to drive the rotor to rotate and apply the oiling, and the linkage transplanting mechanism sends the rotor to the discharging chute after the completion of the process.

Specification: Rust Preventive Oiling Machine For Spring Assembly SolidWorks 3D Model

|

User Reviews

Be the first to review “Rust Preventive Oiling Machine For Spring Assembly SolidWorks 3D Model”

You must be logged in to post a review.

There are no reviews yet.