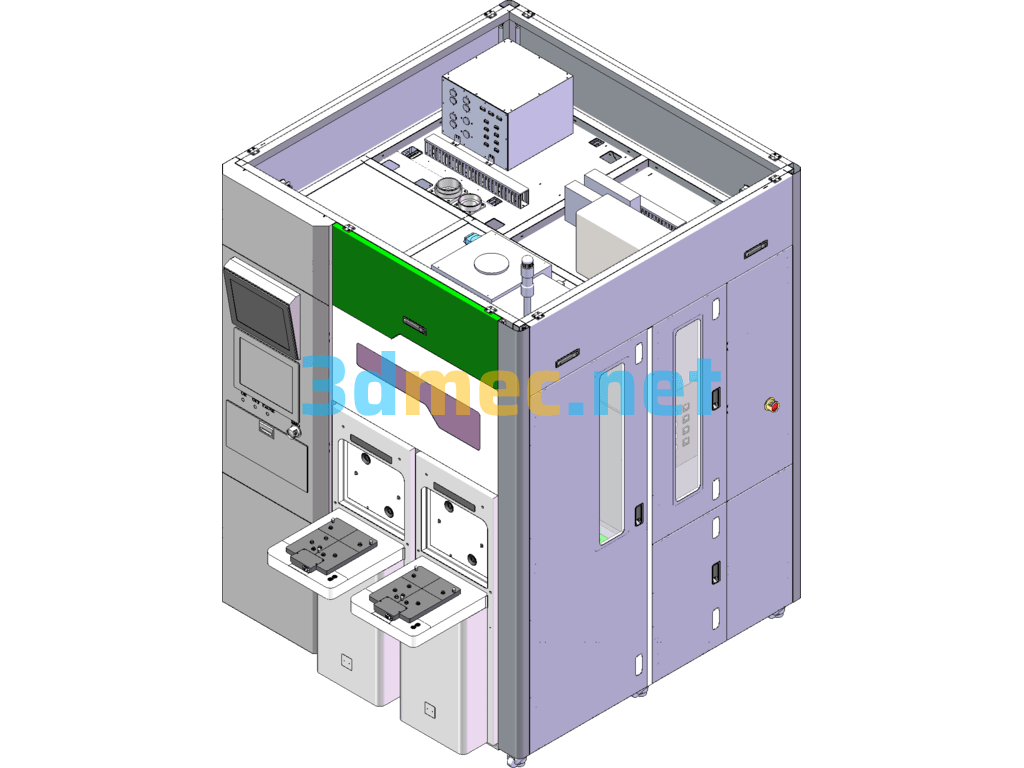

Robot Punch Loading And Unloading – 3D Model SolidWorks

Your custom info text here.

Loading 3D Preview...

Due to web version limitations, it may not display completely. You can download this Project to use the full data

Description

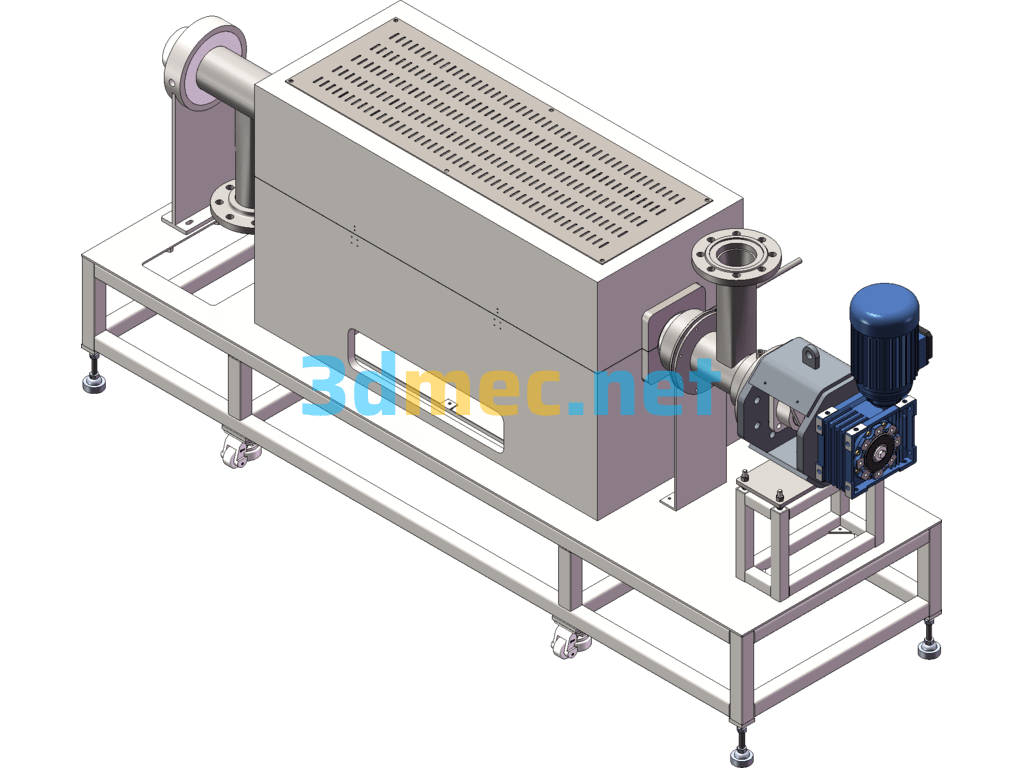

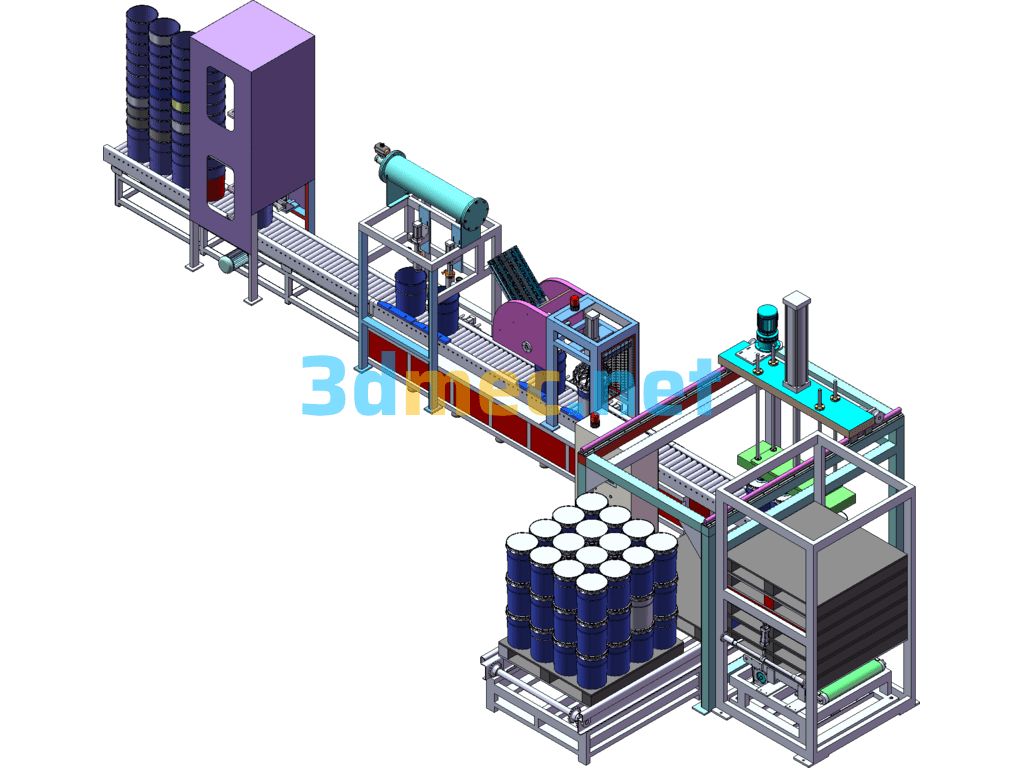

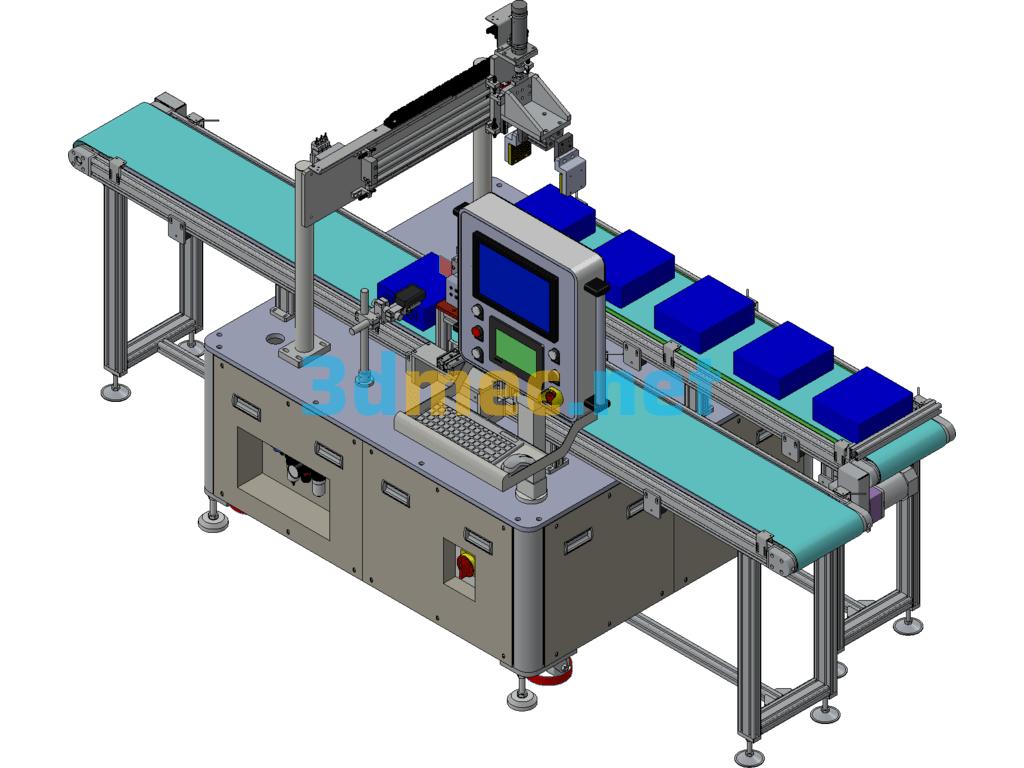

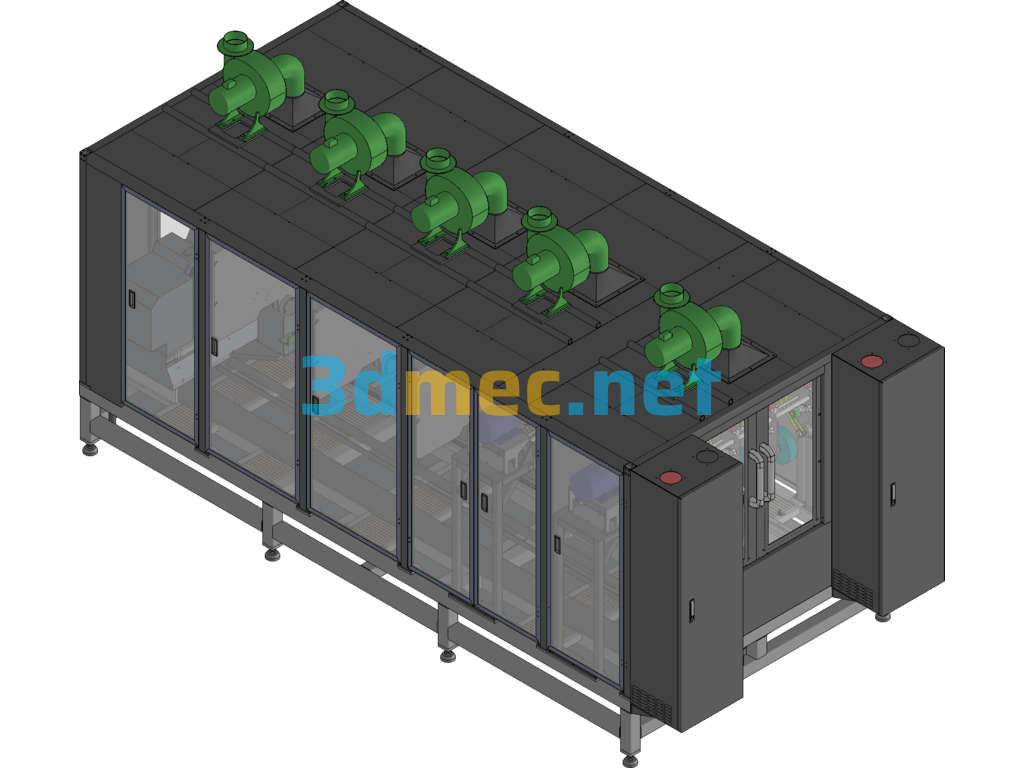

The robot punch press loads and unloads materials, and the operation process is: incoming material tray> robot grab> position correction equipment> robot grab> punch press> robot grab> outgoing material tray 1. Use the incoming material tray to load materials (the materials are stacked in sequence in the tray and do not require precise positioning), and slide the incoming material tray on the guide rail until the magnetic lock is locked to complete the loading process; 2. After the robot grabs the incoming material, it places it on the position correction equipment, and then releases the material; 3. The cylinder of the position correction equipment pushes the material to complete the position correction; 4. The robot grabs the material and sends it to the punch press; 5. After the robot places the material, it exits and the material is processed; 6. After the processing is completed, the robot grabs the material and places it on the outgoing material tray.

Specification: Robot Punch Loading And Unloading – 3D Model SolidWorks

|

Published by: Caleb Powell

Date: August 26, 2024

Related products

About 3DMec.net

3DMec.net is a sharing community of Mechanical Engineers, Where you can share and download mechanical drawing library, cad drawings, 3d model.

Including automation equipment, non-standard equipment, mold, robot, machine tool, conveyor, jig, manipulator, assembly machine, welding machine, packing machine, flow line, testing machine, dispensing machine, production line, labeling machine, conveyor, locking screw machine, feeder, former, lifting machine, cam Equipment, automotive and other large machinery and equipment drawings.

User Reviews

There are no reviews yet.