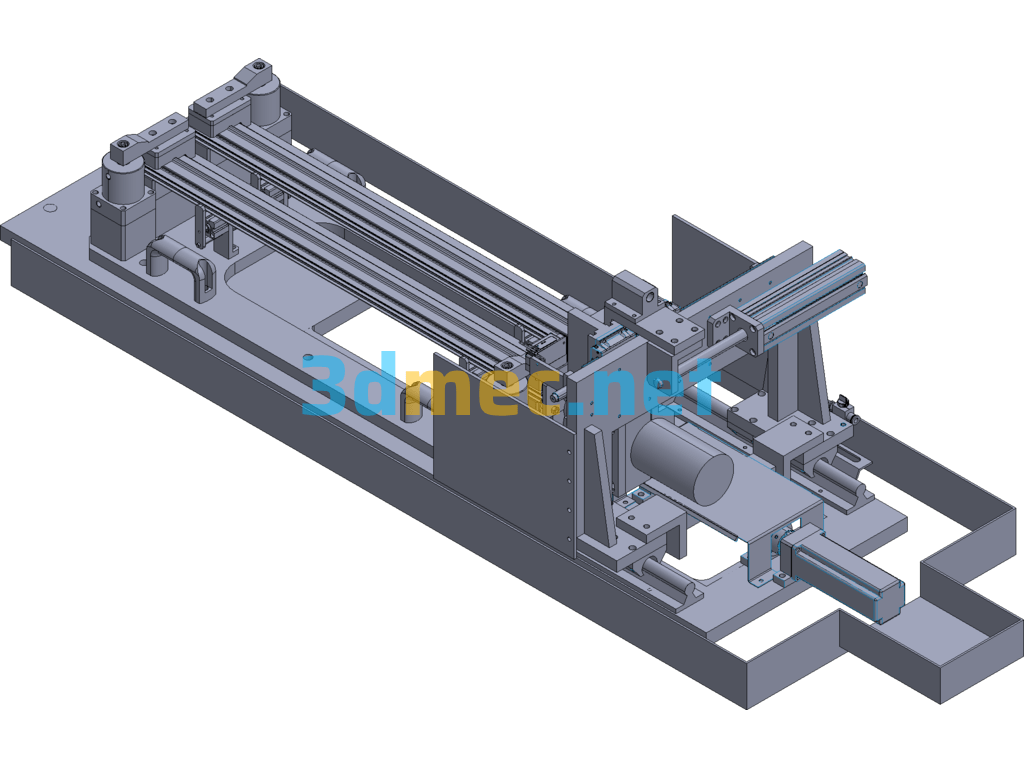

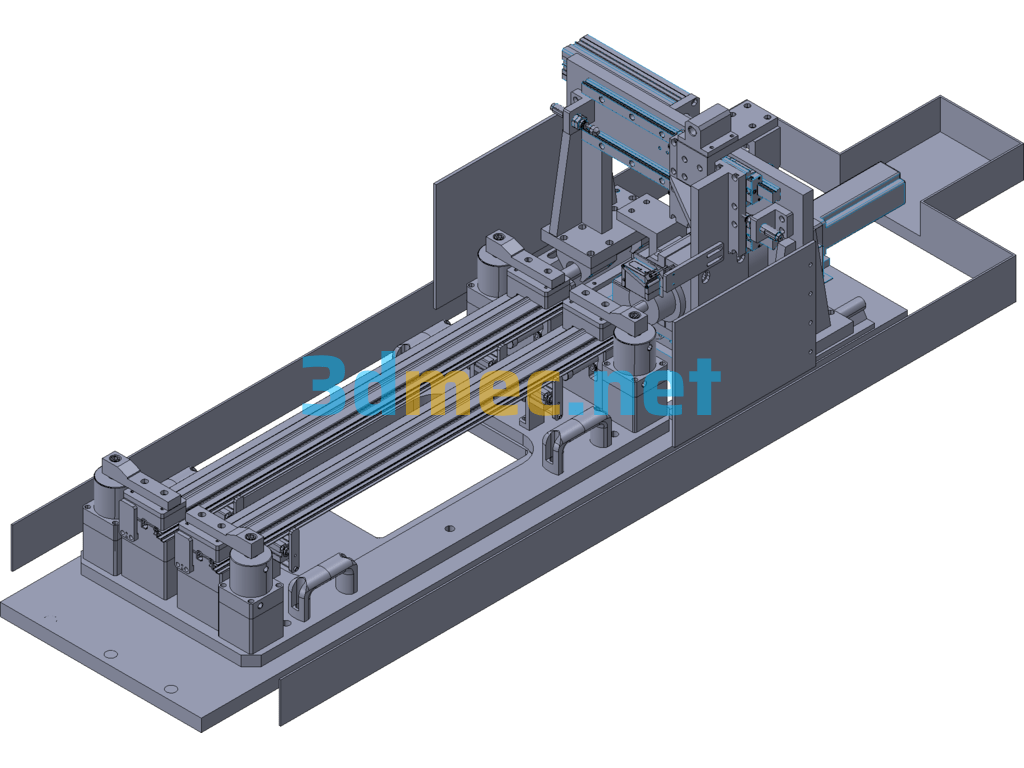

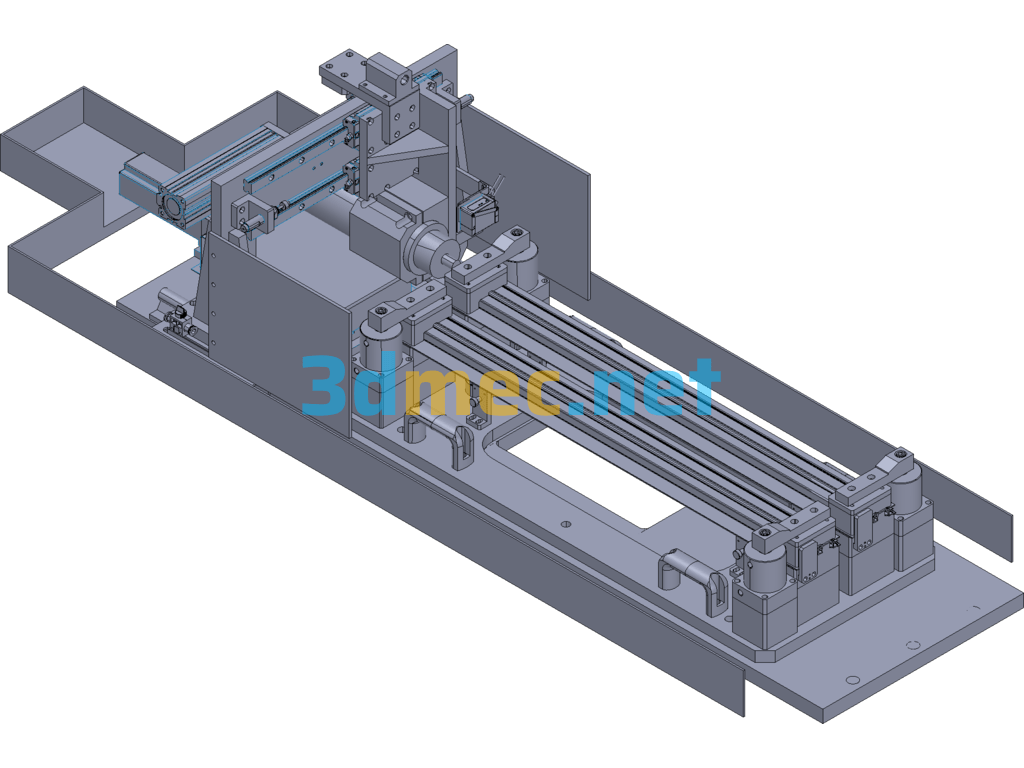

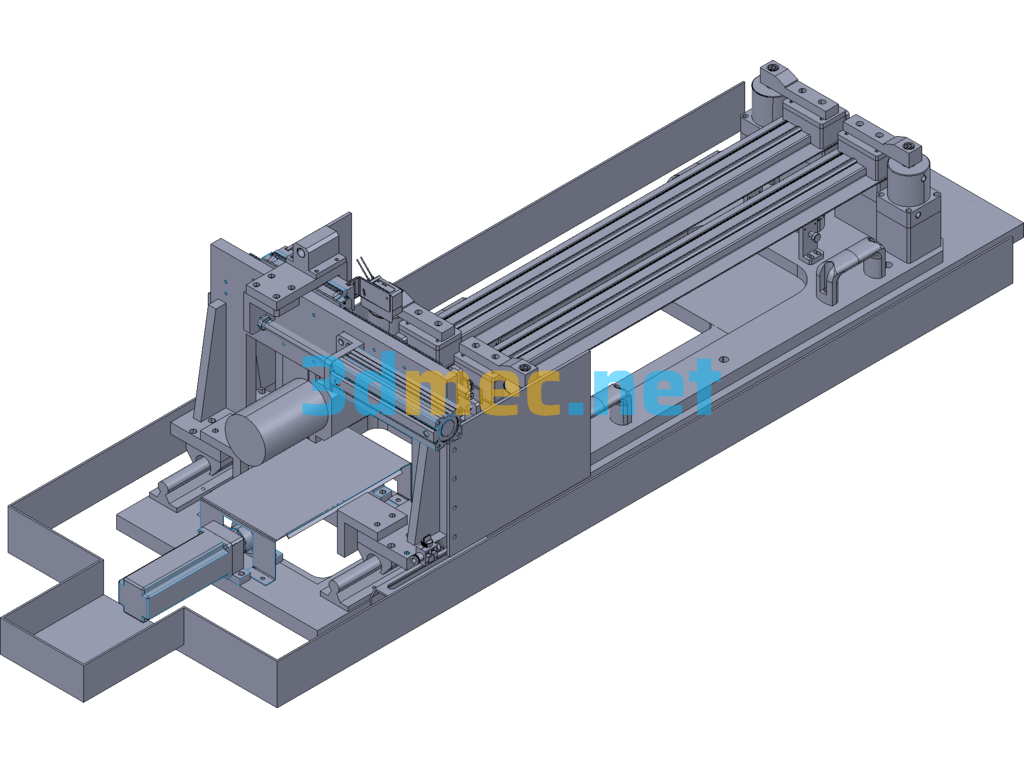

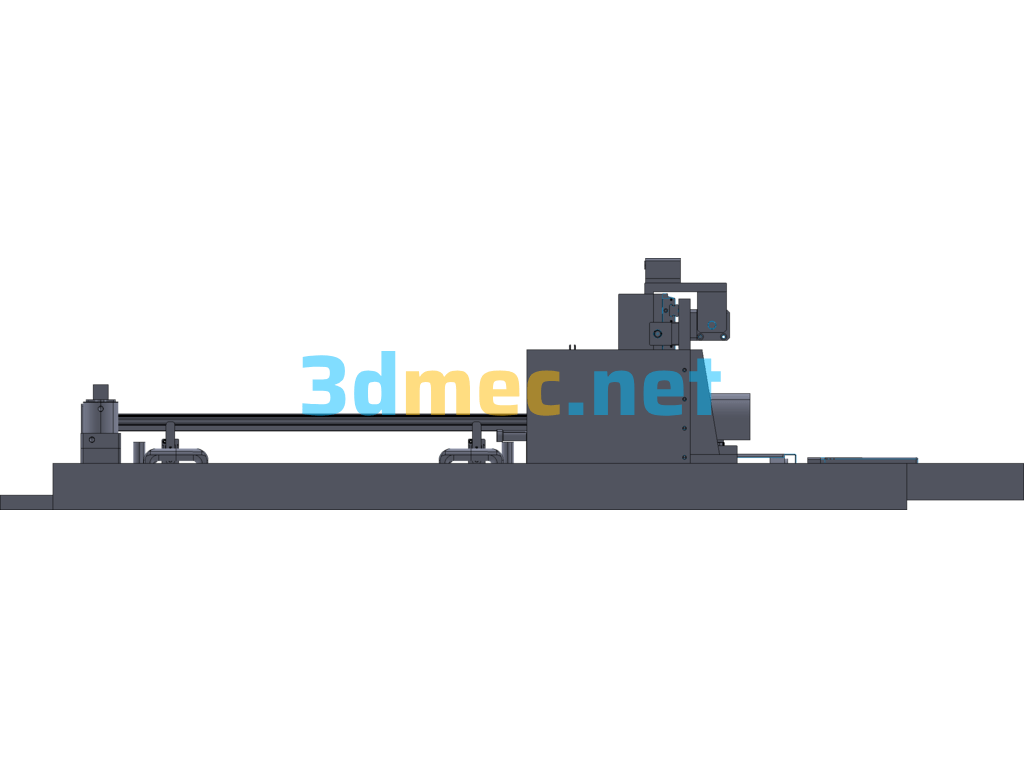

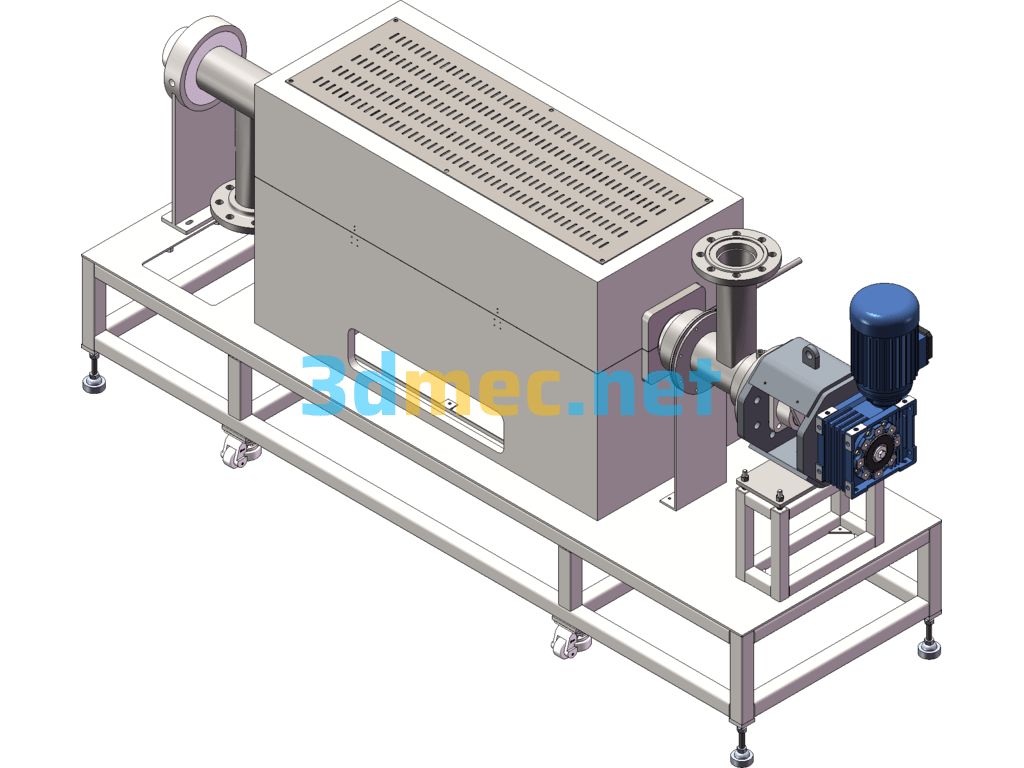

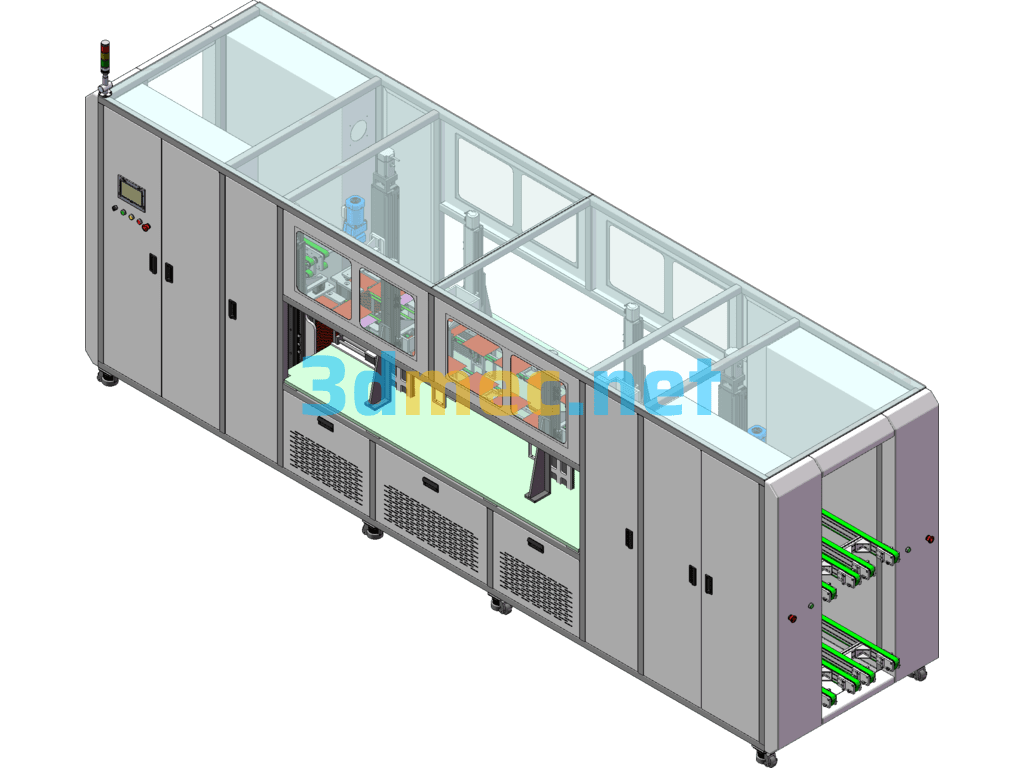

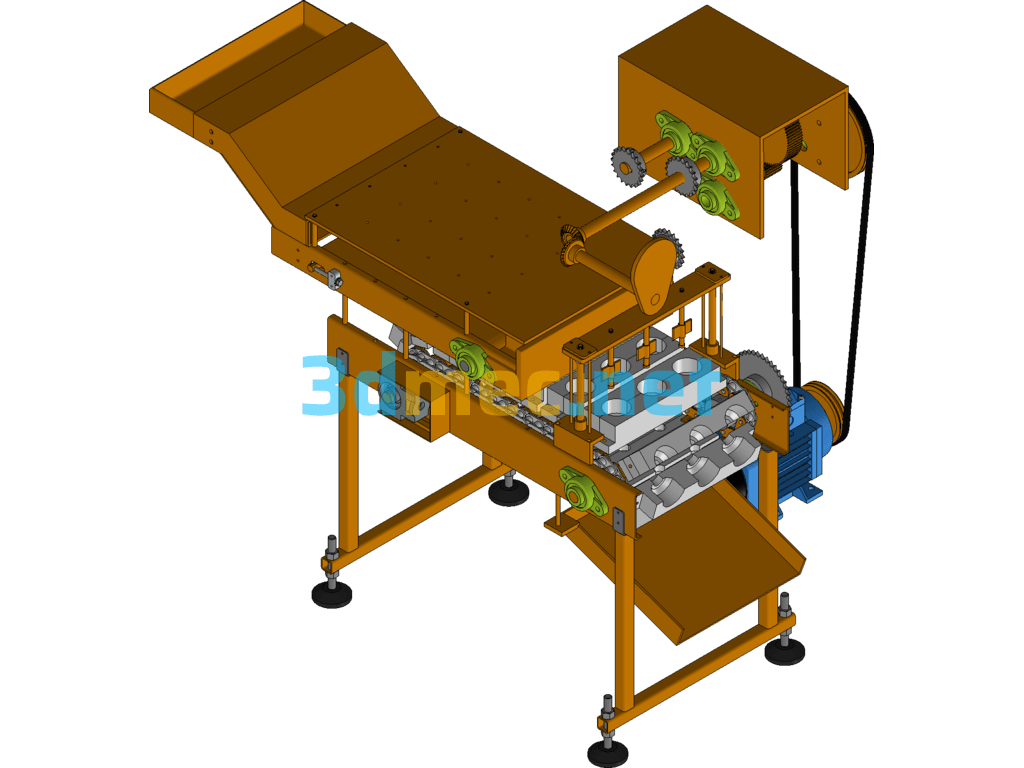

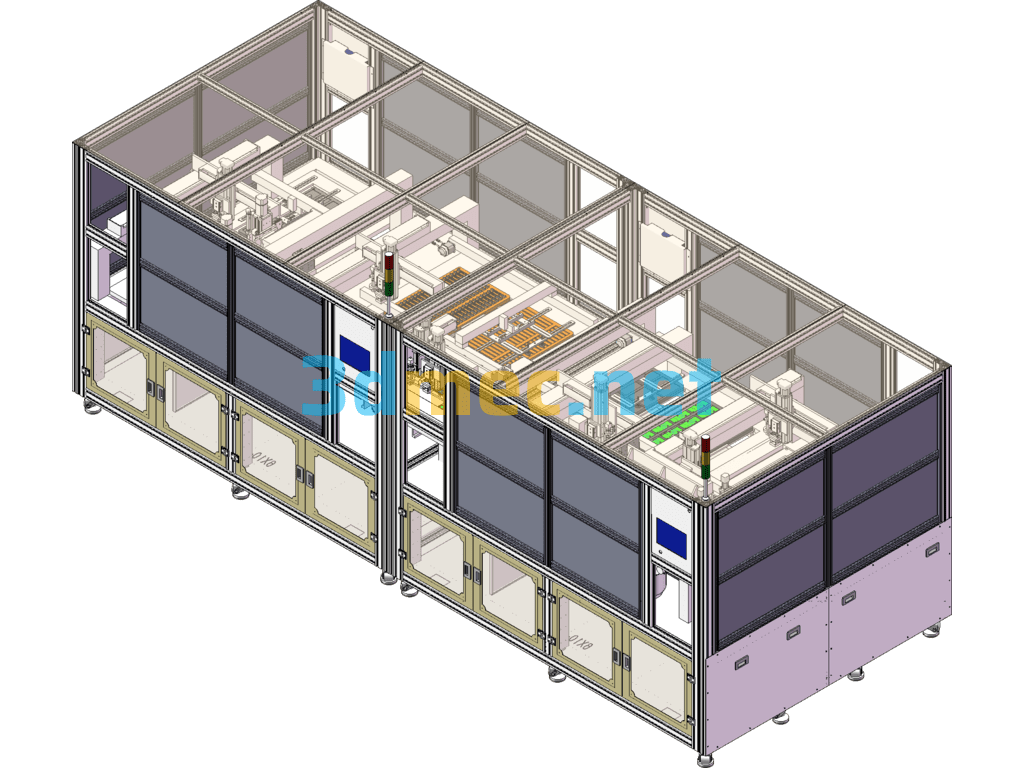

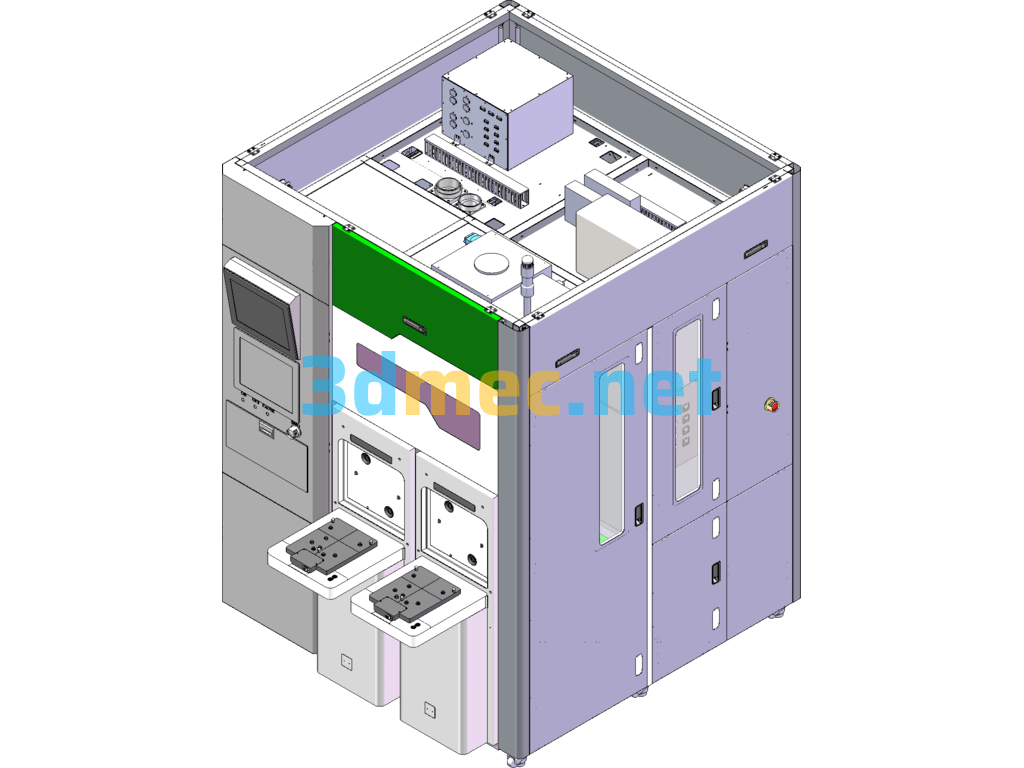

This is a carving machine technological transformation to add a machine head in order to simultaneously achieve the chamfering of the skylight rail and pouring the lasso hole, the original two processes shortened a process, in order to meet the original machine mobile slide rail load-bearing and strength, the whole machine structural components load-bearing plate using 704A super stone hard aluminum material processing, and do the deformation of the force analysis, and the results show the effect of meeting the requirements n The whole structure is designed and analyzed by CREO, which is now turned into STP format and can be opened directly. The drilling host uses a 2.2KW electric spindle, and the collet adopts ER16 CNC collet, which can clamp the shank of the tool with a diameter of 6-10mm, and cooperate with fiber-optic sensors to realize the effective compensation of deviation of the guide rail length. The workpiece part adopts Adecco rotatable cylinder with delicate and compact structure. n Now we share it with you for learning and communication.

Specification: Retrofitting Of Engraving Machine With Head Exported 3D Model

|

User Reviews

Be the first to review “Retrofitting Of Engraving Machine With Head Exported 3D Model”

You must be logged in to post a review.

There are no reviews yet.