Punch Blanking Machine Mechanical Drawing + Equipment Overall Process Description – 3D Model SolidWorks

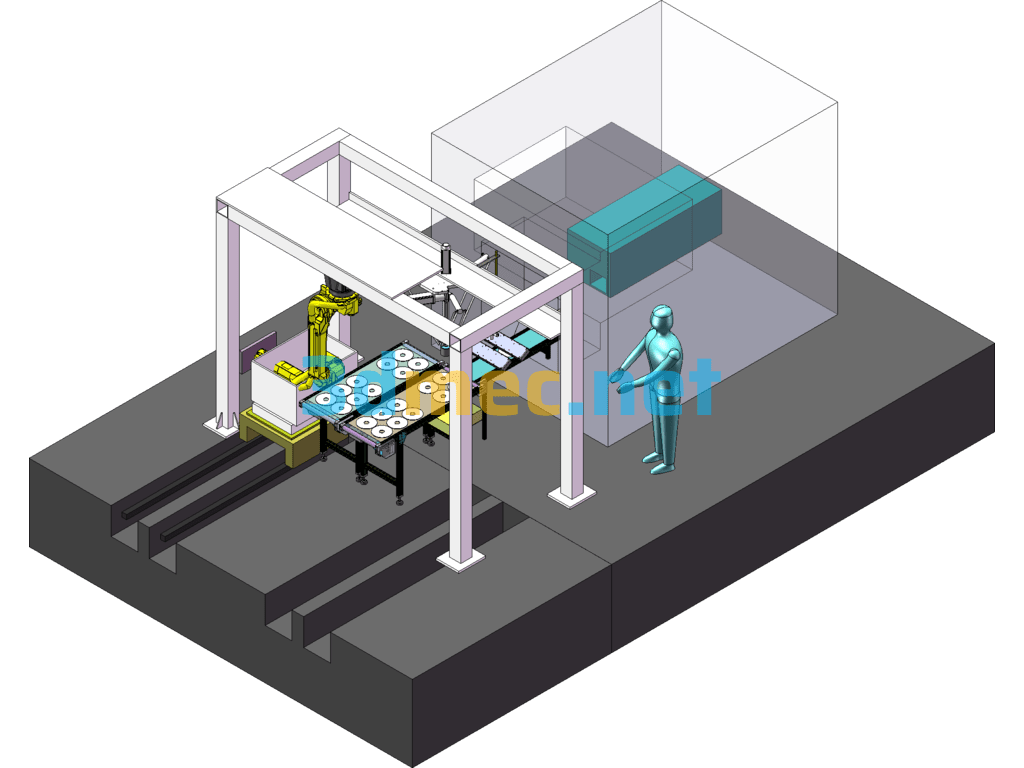

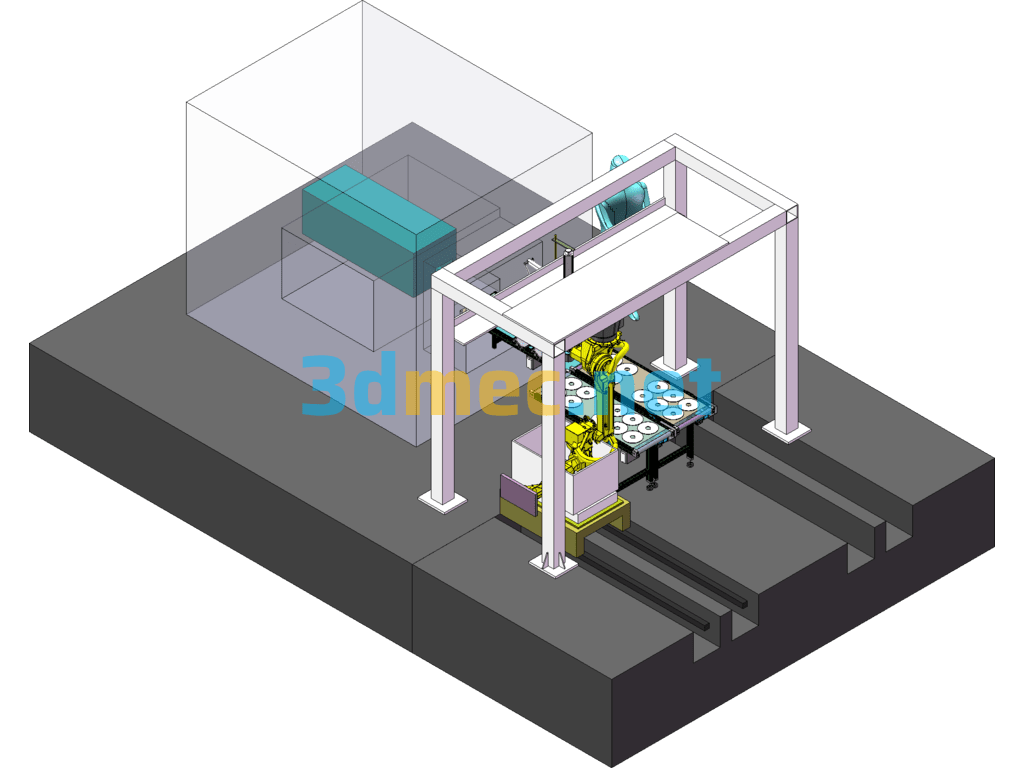

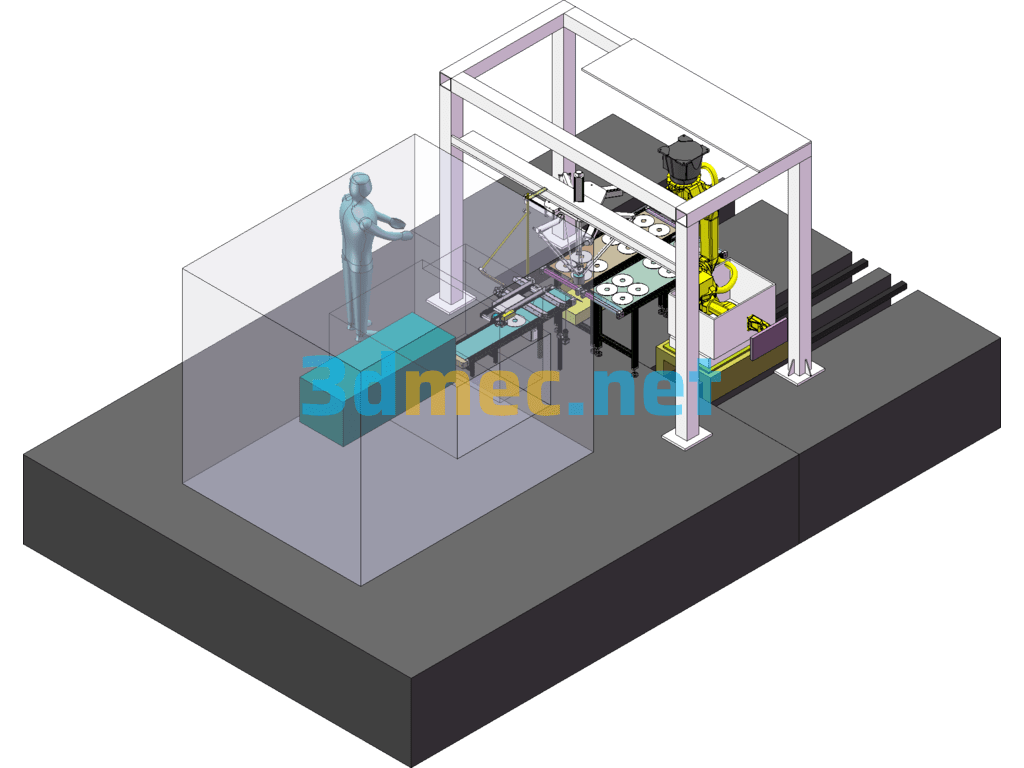

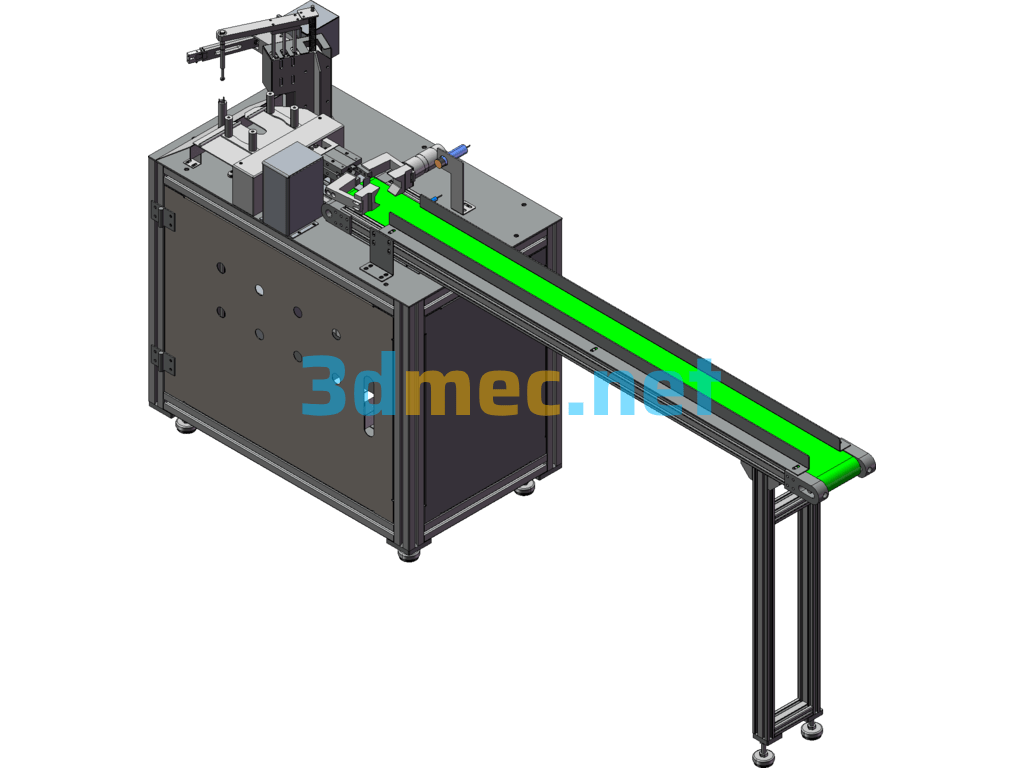

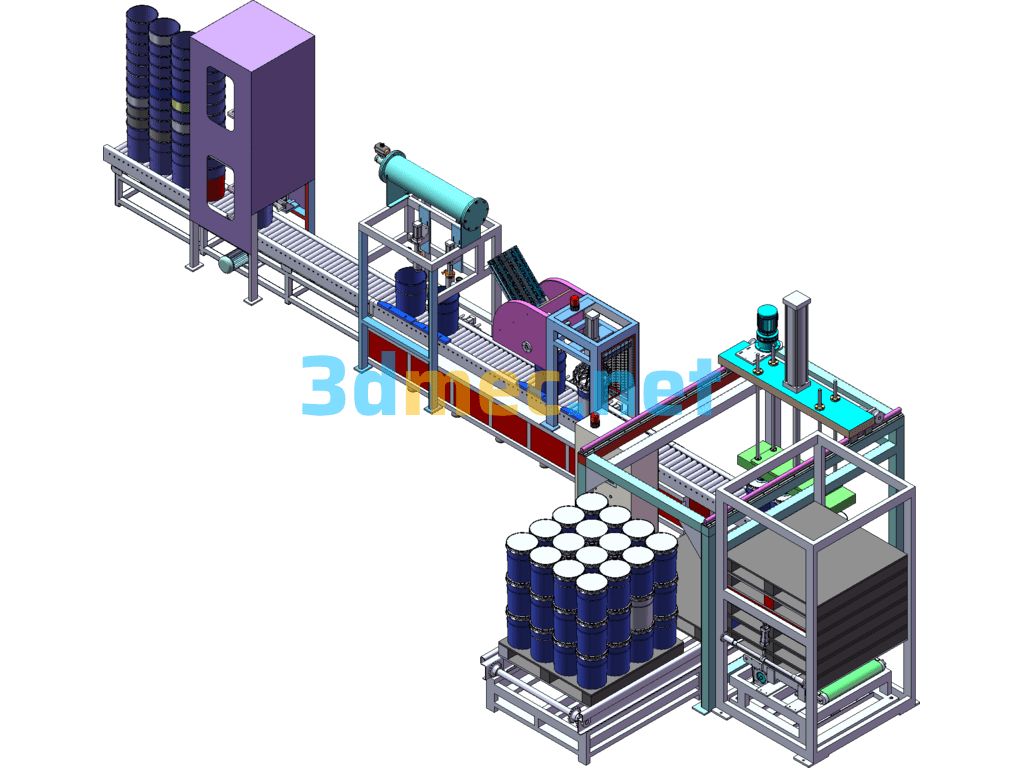

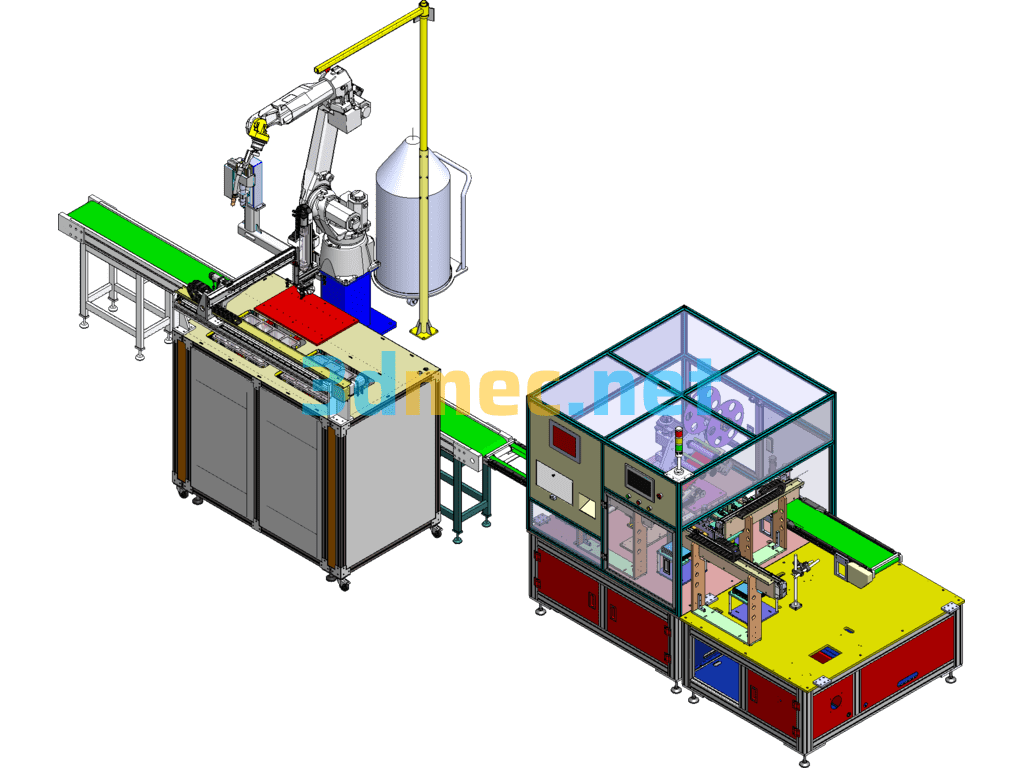

The overall process of Taidong punch unloading machine equipment: 1. The stamped products automatically flow to the discharge belt line (the discharge belt line can be adjusted according to different products). 2. The defect camera automatically takes pictures, the positioning camera locates the product direction, the encoder calculates the product movement distance, and the data is transmitted to the controller. 3. The parallel robot accurately locates the moving products based on the above data, uses electromagnets to suck the products, puts NG products on the NG belt, and puts OK products on the wide belt. At the same time, align the products, put 4 to 5 large products, and 5 to 6 small products. 4. The wide belt moves the product to the 6-axis robot station. The non-slip wide belt prevents the product from sliding during movement. The 6-axis robot uses an electromagnet to suck 4 large products and puts them in the collection basket at the same time. After sucking the A belt, suck the B belt. The 6-axis robot does not stop, fills the collection basket A, and continues to put the collection basket B.

5. Use the counting function to detect whether the receiving basket is full of products. If it is full, use the floor rail to automatically move it to the aisle, and the forklift will take it away and put the empty basket on.

6. The 6-axis robot does not stop, and the cycle continues.

Specification: Punch Blanking Machine Mechanical Drawing + Equipment Overall Process Description – 3D Model SolidWorks

|

User Reviews

Be the first to review “Punch Blanking Machine Mechanical Drawing + Equipment Overall Process Description – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.