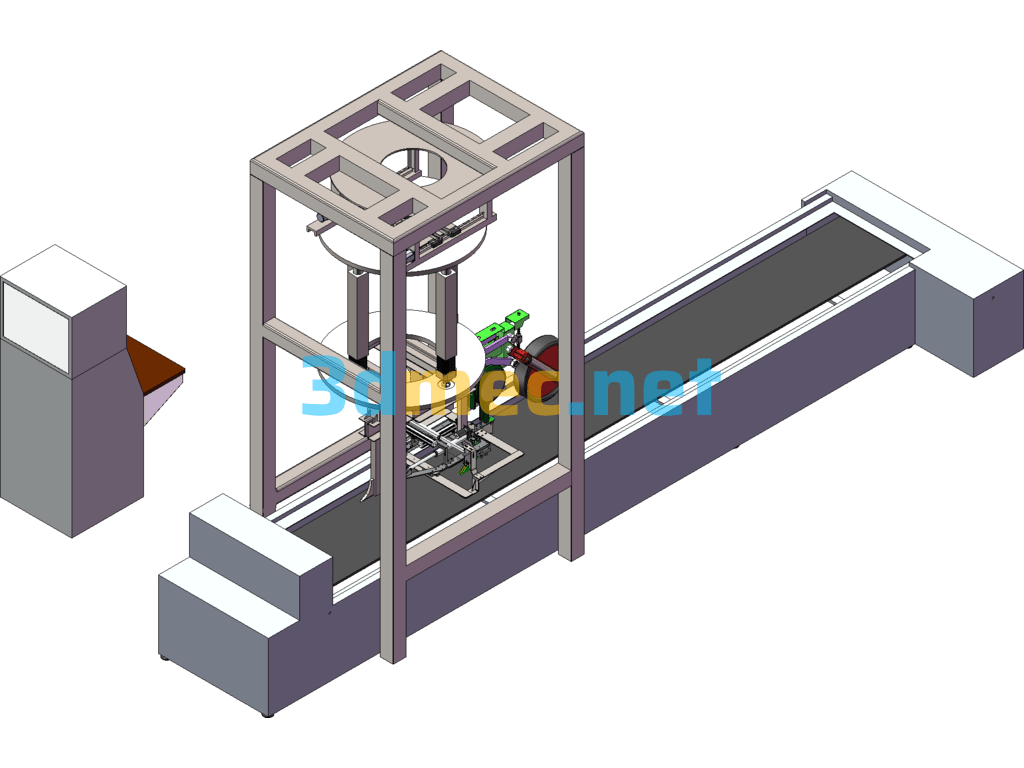

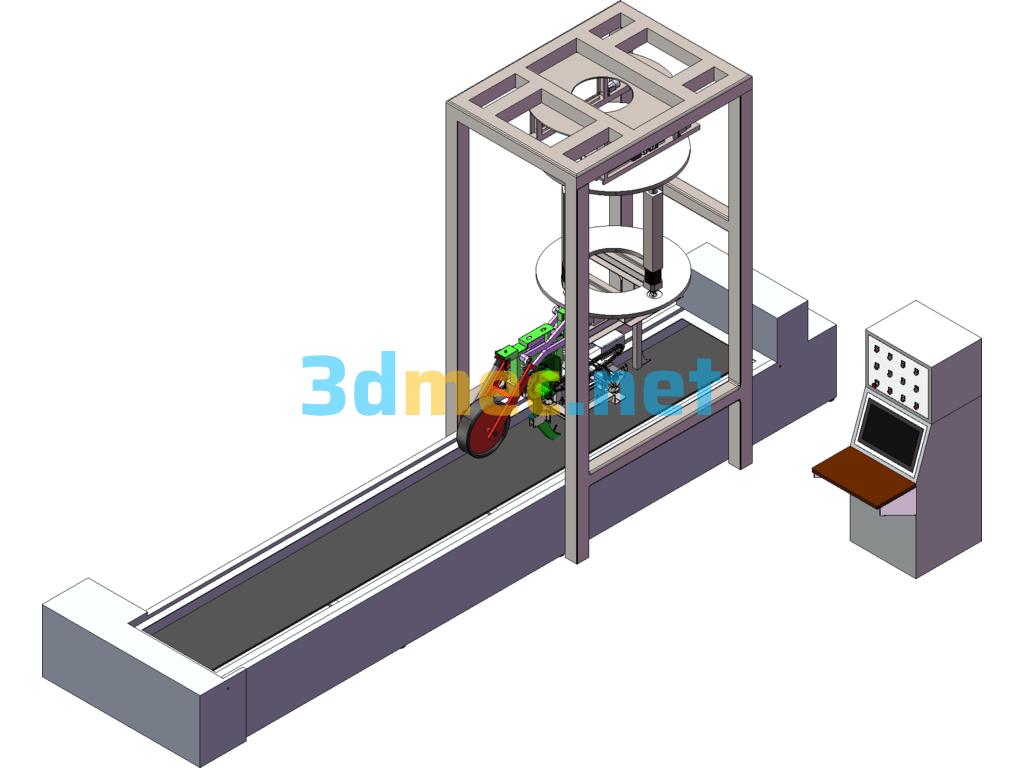

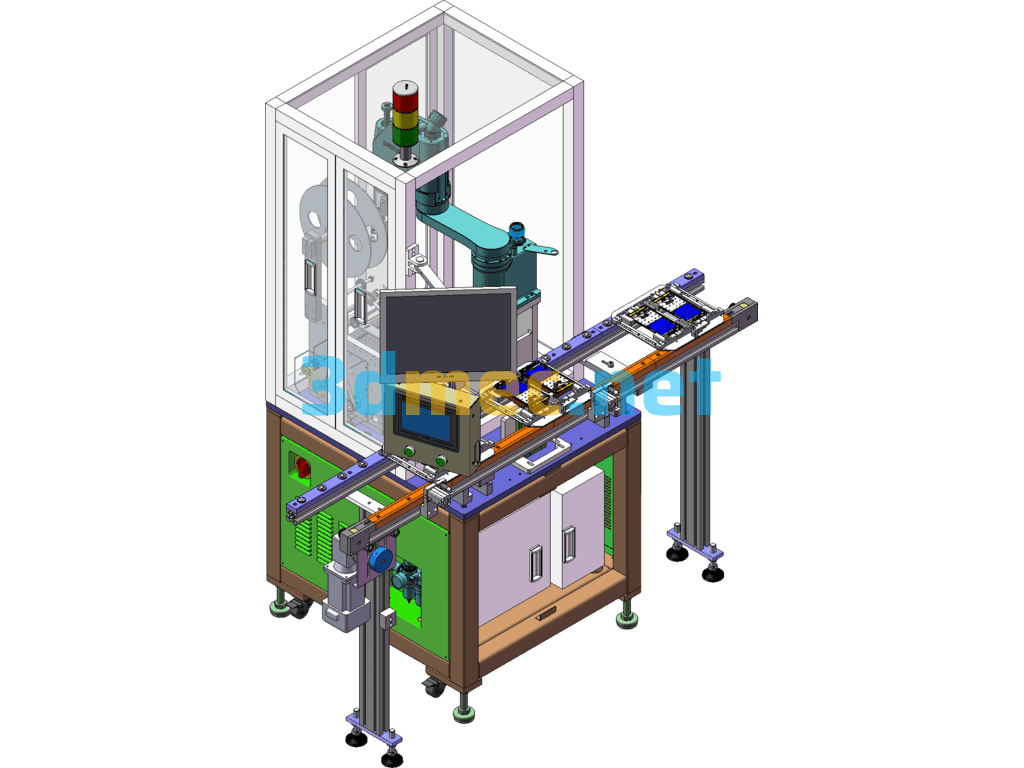

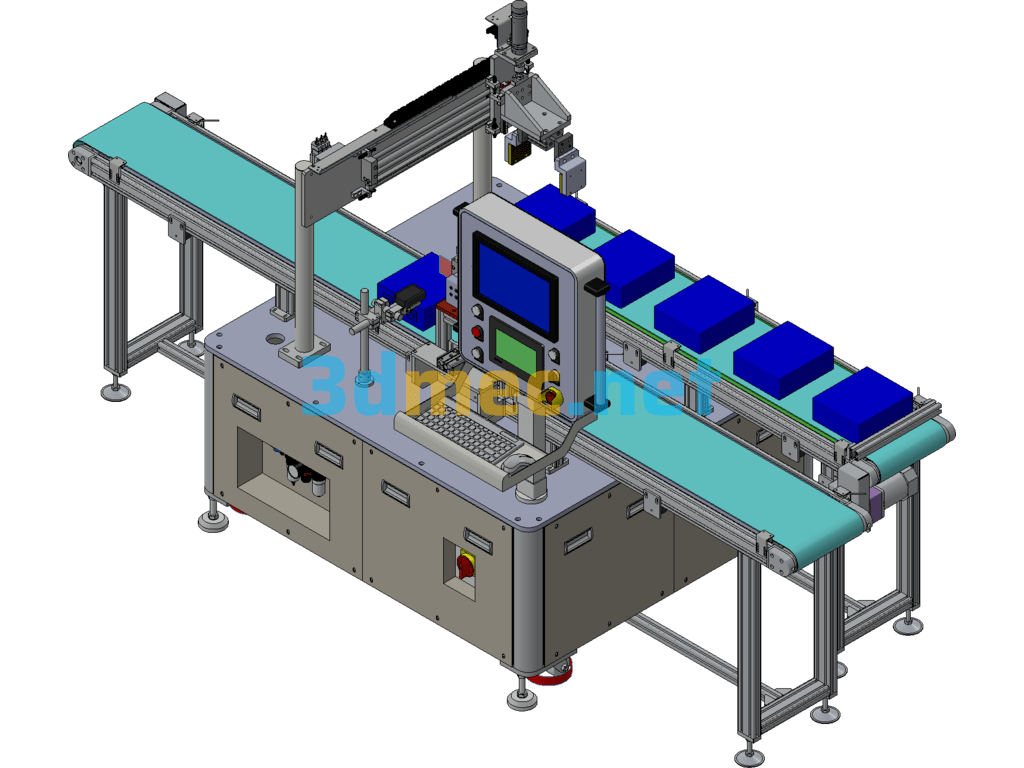

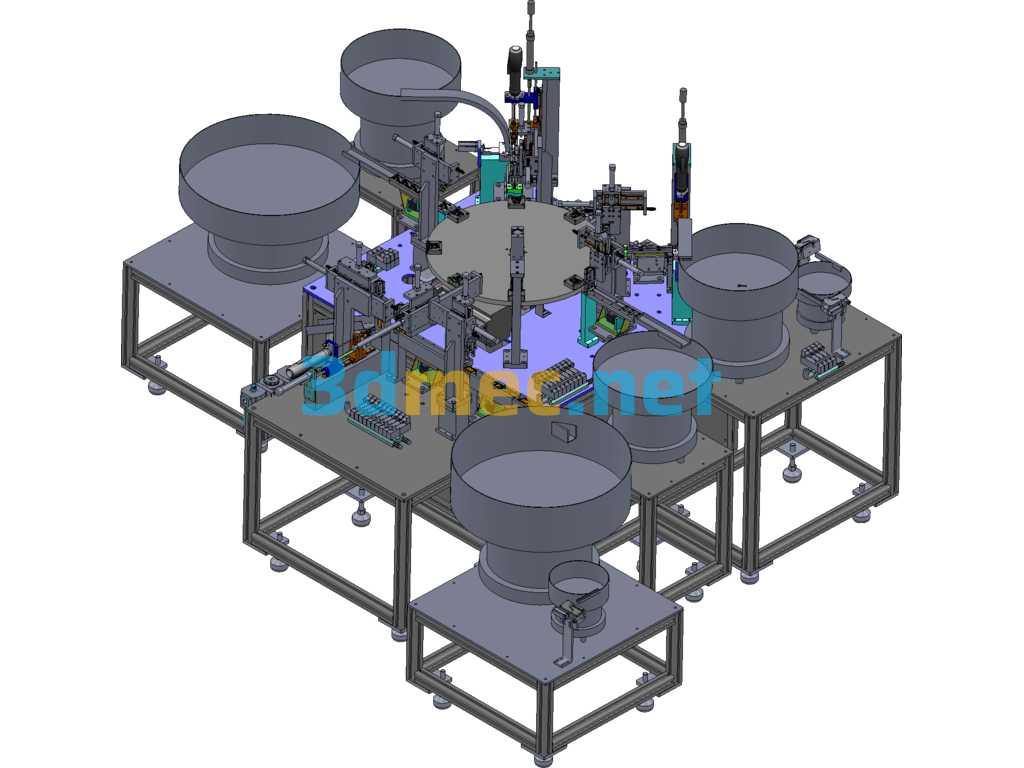

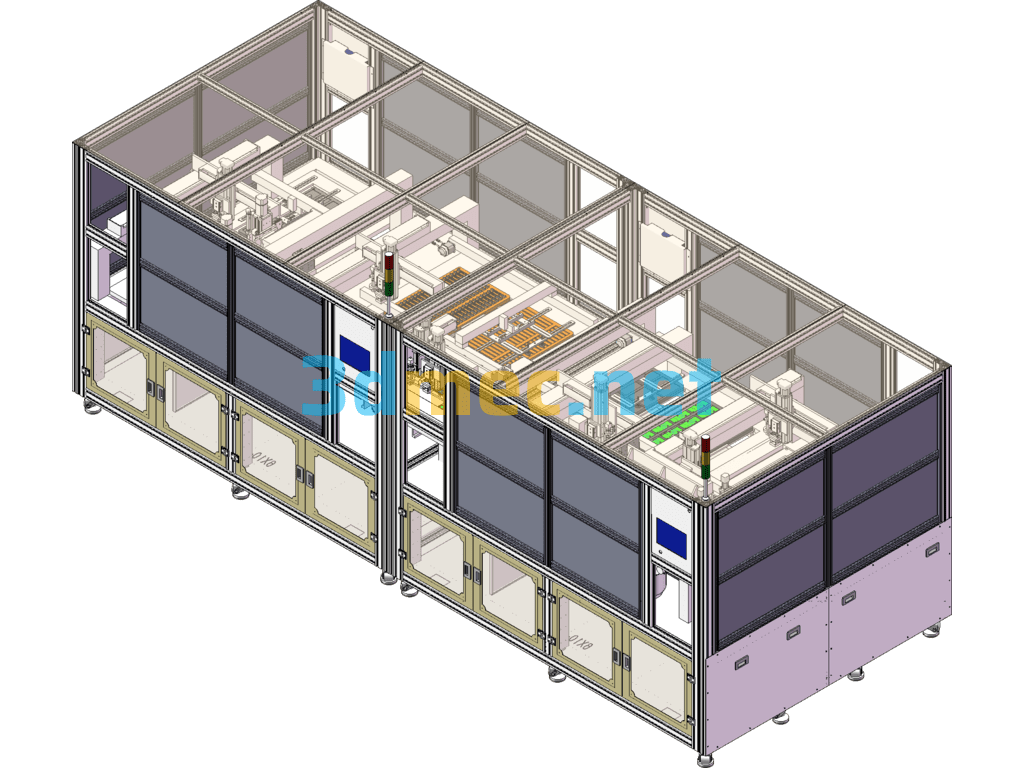

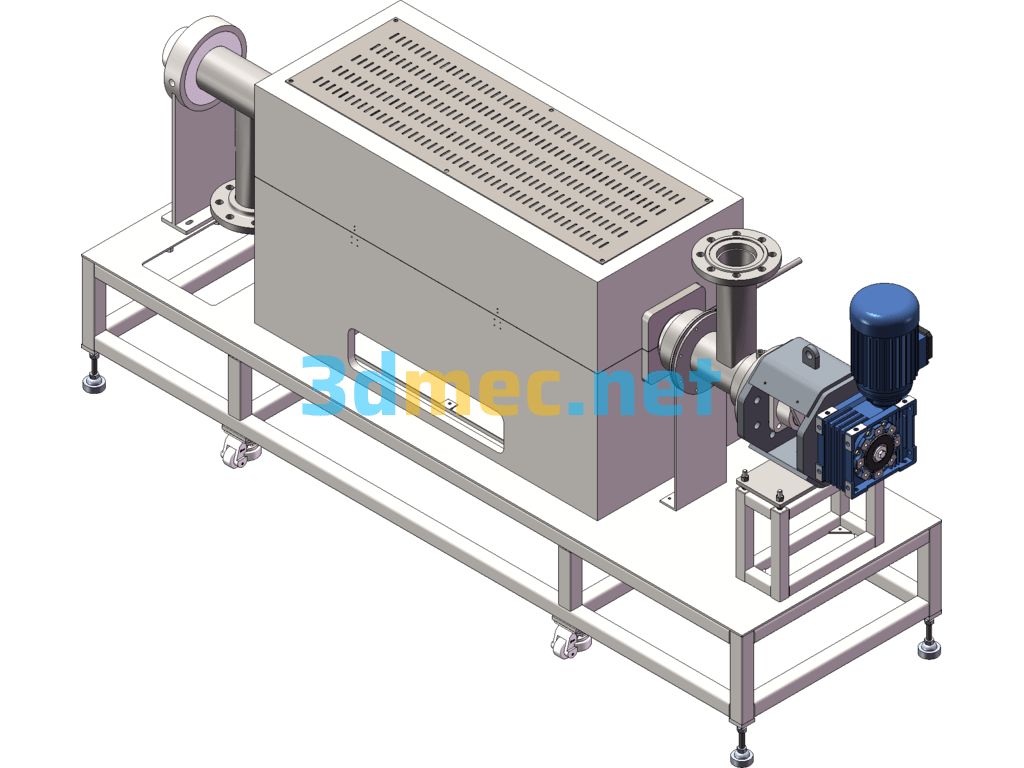

The technical solution of the present invention will be described in detail with the following accompanying drawings and examples will be given to illustrate its workflow. n Fig. 1 shows that this is a front view of a corn precision sowing variable fertilizer applicator; it contains 1, a sowing quality controller 2 a fertilizer box, 3 a fertilizer applicator device, 5 a sowing mulching wheel, 6 a sowing drive wheel 7 a sowing and fertilizer applicator frame and 8 a rower. The fertilizer boxes 2 are located above and below the sowing and fertilizing machine frame 7 connected to the fertilizer application device 3 wherein the rower 8 is connected to the sowing and fertilizing machine frame 7; each of the fertilizer boxes 2 is equipped with a material level detecting sensor 12 for implementing the detection of the state of the material in the box; the sowing quality controller 1 is mounted at the front end of the fertilizer boxes. n Further reference is made to FIGS. 2 and 3 to illustrate the relative positional relationship of each; FIGS. 2 and 3 contain 9 weed splitter assemblies 10 fertilizer openers 11 servo drive motors 12 material level monitoring sensors and 13 seeding boxes 14 fertilizer replenishment boxes 15 fertilizer replenishment mulching wheels 16 sowing mechanism assemblies; wherein the sowing drive ground wheels 6 are located in the middle of the 7 of the frame of the sowing fertilizer applicator and the four fertilizer openers 10 are symmetrically Distribution; four grass splitter assembly 9 is located in the back of each fertilizer opener 10 and fertilizer sowing machine frame 7 connection; the rear end of the frame is connected in turn to the seeding mechanism assembly 16 and fertilizer replenishment mechanism. The mounting positions of its Omron proximity speed switch 18 and capacitive fertilizer clogging sensor 23 are referred to Figures 4 and 5; the fertilizer application vehicle terminal 21 and the seeding vehicle terminal 22 are located at the front end of the tractor’s cockpit as shown in Figure 6, and are connected to the controller on the planter via a CAN bus protocol. n Method of implementing precision seeding control; n A photoelectric sensor is provided at the side wall position of the seed discharge tube in the seeding mechanism assembly for detecting the implementation of the seeding state; at the same time, the Omron proximity tacho switch 18 implements the detection of the implementation of the speed of the transmission shaft tacho gear 20; the measurement signals of the two are transmitted to the seeding quality controller 1 for analysis, and the theoretical seeding state is analyzed by the Omron proximity tacho switch 18, and the photoelectric sensor signals are analyzed to analyze the actual seeding state,. Comparison of the two after the analysis of the results of the seeding whether there is a leakage of seeding and the amount of leakage combined with the vehicle GPS system can be a real-time record of the location of the leakage of seeding and the work of the information transmitted to the seeding vehicle terminal 21 through the CAN bus protocol to generate the relevant technical documents to store and display the sowing status; to facilitate the subsequent operation of the intelligent leakage seeding to make up for the operation to achieve the control of the precise amount of sowing; at the same time, seeding box 14 is equipped with a level sensor to monitor the state of the seed material in real time. Meanwhile, the seeding box 14 is equipped with a material level sensor that can monitor the state of the seed material in real time and transmit it to the vehicle-mounted seeding terminal 22 for display, providing the driver with an early warning of the lack of seed. n Variable fertilizer application control method; n The present invention uses a corn no-till fertilization planter, which needs to go through two fertilizer application processes when planting; one for deep fertilization and one for surface replenishment. Fertilizer application, each fertilizer tube 22 side wall is installed with capacitive fertilizer clogging sensor 23 used to detect the clogging condition of the fertilizer and the actual fertilizer application rate of the fertilizer if there is a clogging or fertilizer application rate does not match the set rate of the situation will be in the fertilizer on-board terminal 21 for alarm reminders; in addition to the fertilizer through the fertilizer quality controller 4 to drive and control the rotational speed of servo motors 11 to control the fertilizer application rate to meet the requirements of the fertilizer application rate. Each fertilization box 3 and replenishment box 15 are equipped with material level monitoring sensor 12 for the implementation of the detection of the amount of fertilizer and fertilizer warning. Using the existing land required fertilizer amount of information through the combination of fertilizer vehicle terminal 22 within the GPS module to obtain latitude and longitude information and machine operating speed, to determine the current machine location of the amount of fertilizer; the use of the terminal data acquisition module to collect and process sensors to provide the amount of material drive shaft rotation speed, DC servomotor rotation speed, clogging and lack of fertilizer information, as well as GPS and other sensors; the terminal within the fertilizer quality control system according to the data acquisition module to collect and process the information. Control system according to the data acquisition module collected by each sensor information, born fertilization decision, its real-time to the fertilization quality controller 4, to achieve the machine in the current position of the accurate fertilization. Operation parameters such as operation speed, latitude and longitude information, current fertilizer application amount, current discharging amount and blockage are displayed in real time through the fertilizer vehicle-mounted terminal; thus realizing the control of variable fertilizer application. n (At that time, I wrote the invention patent for my own design, and I was a student at school, so I hope to help my friends in need.)

Specification: Precision Variable Seeder No-Till Fertilizer Seeder For Corn SolidWorks 3D Model

|

User Reviews

Be the first to review “Precision Variable Seeder No-Till Fertilizer Seeder For Corn SolidWorks 3D Model”

You must be logged in to post a review.

There are no reviews yet.