Precision Variable Seeder Corn No-Till Fertilization Seeder – 3D Model SolidWorks

The technical solution of the present invention will be described in detail in conjunction with the following drawings and its working process will be explained by examples.

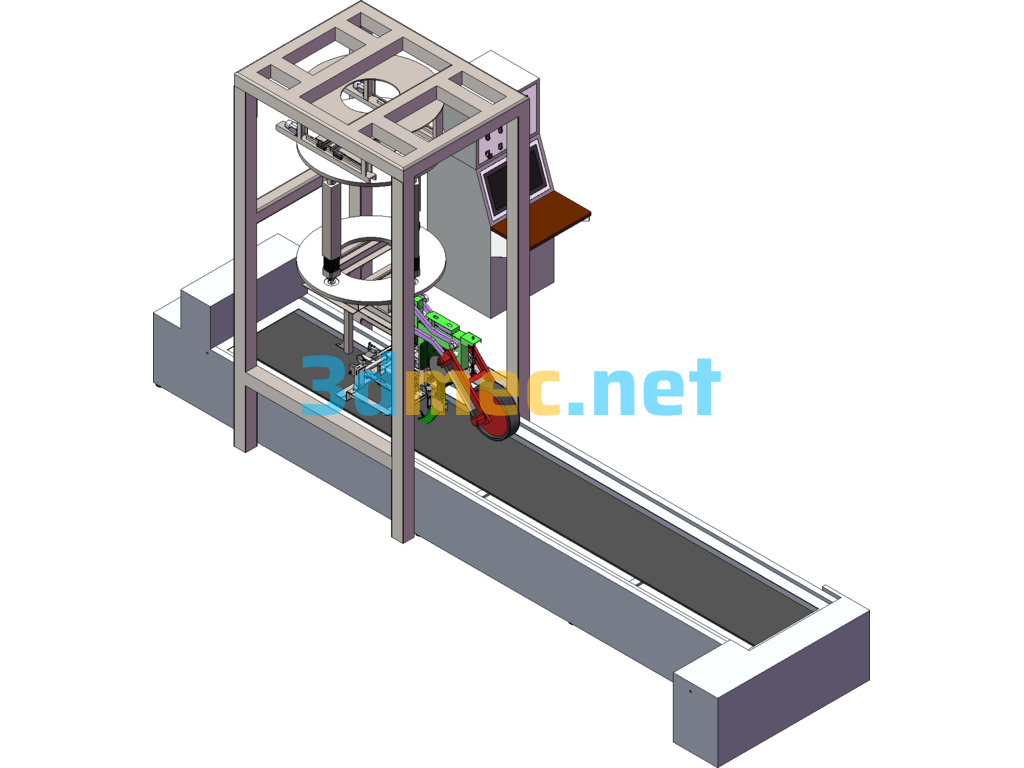

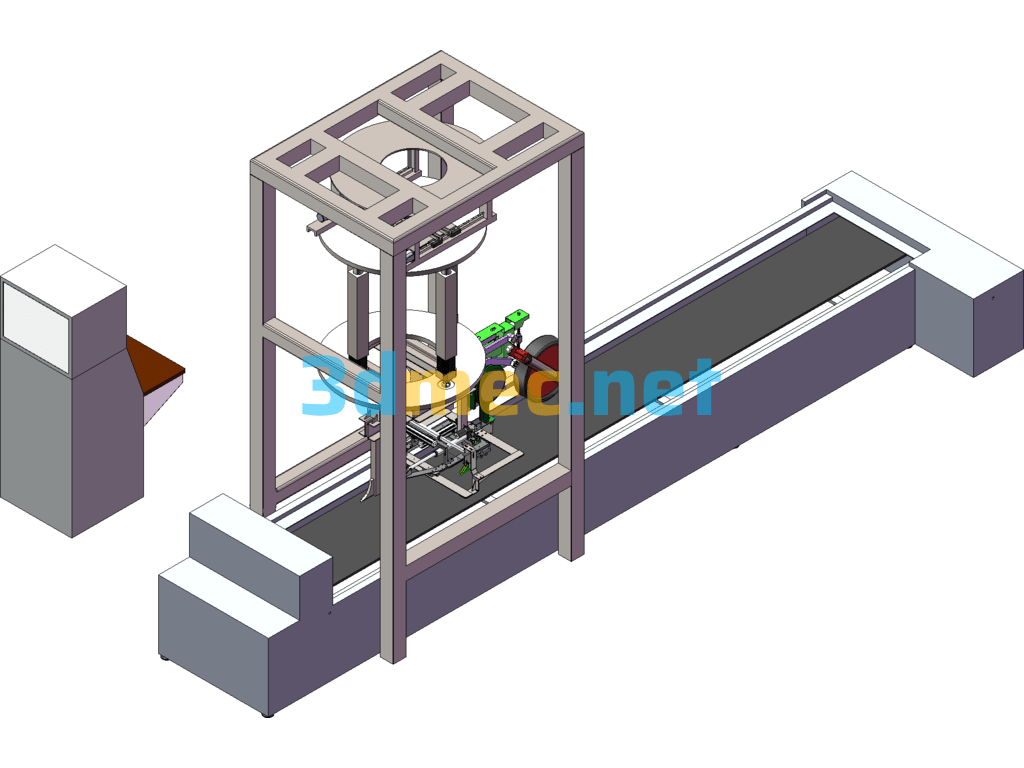

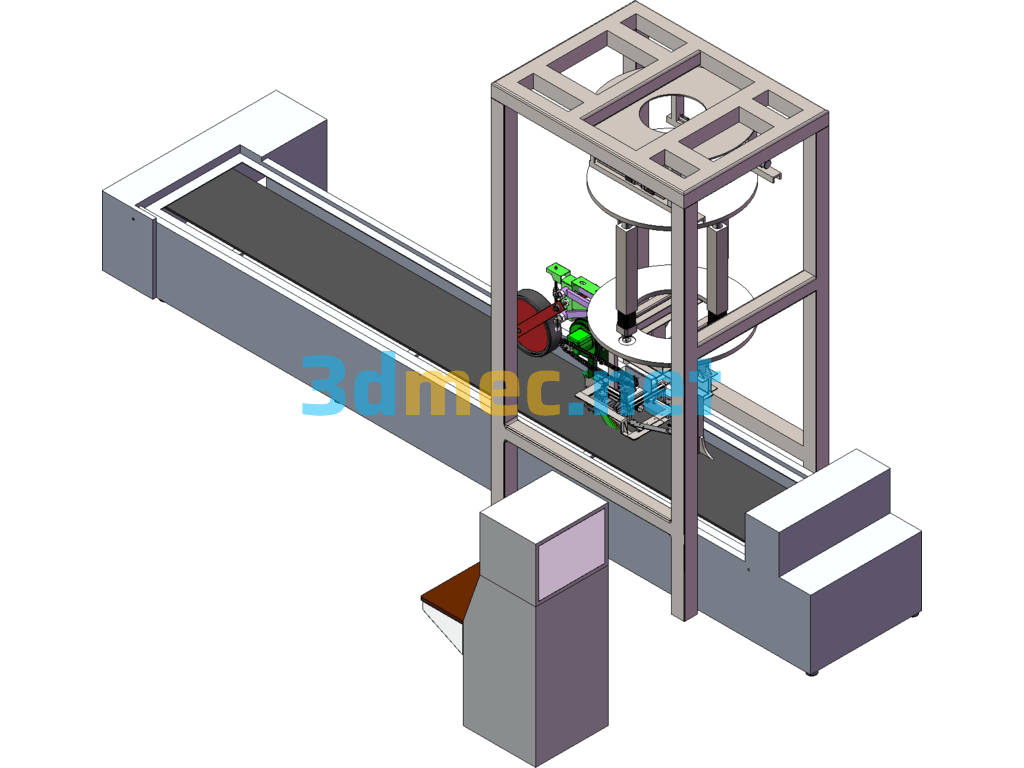

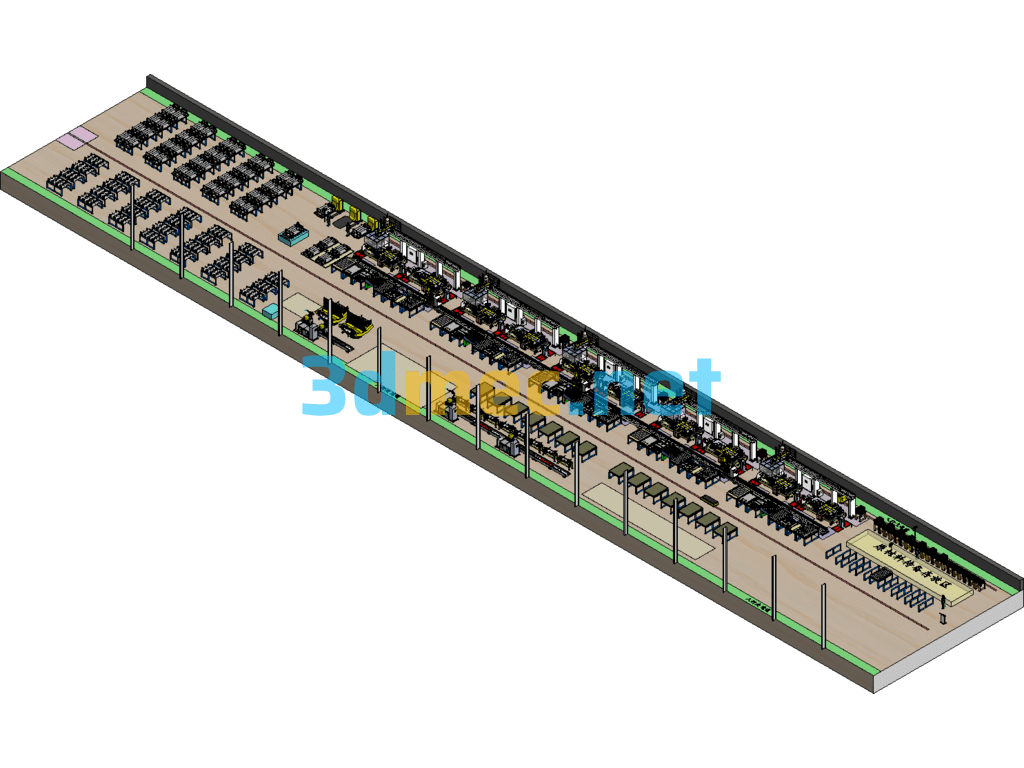

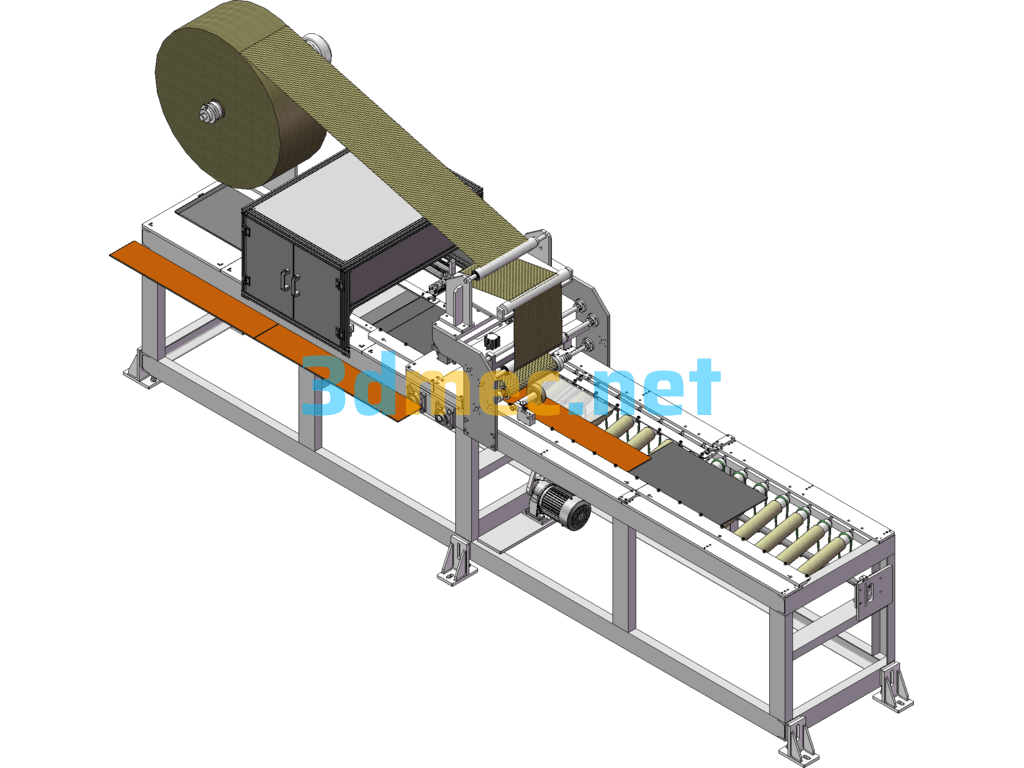

As shown in Figure 1, this is a front view of a variable fertilizer applicator for precision corn seeding; it includes 1, a seeding quality controller 2, a fertilizer box, 3 a fertilizer device, 5 a seeding covering wheel, 6 a seeding transmission ground wheel, 7 a seeding and fertilizing machine frame, and 8 a row marker. The fertilizer box 2 is located above and below the seeding and fertilizing machine frame 7, and is connected to the fertilizer device 3, wherein the row marker 8 is connected to the seeding and fertilizing machine frame 7; each fertilizer box 2 is equipped with a material level detection sensor 12 for detecting the state of the material in the box; the seeding quality controller 1 is installed at the front end of the fertilizer box.

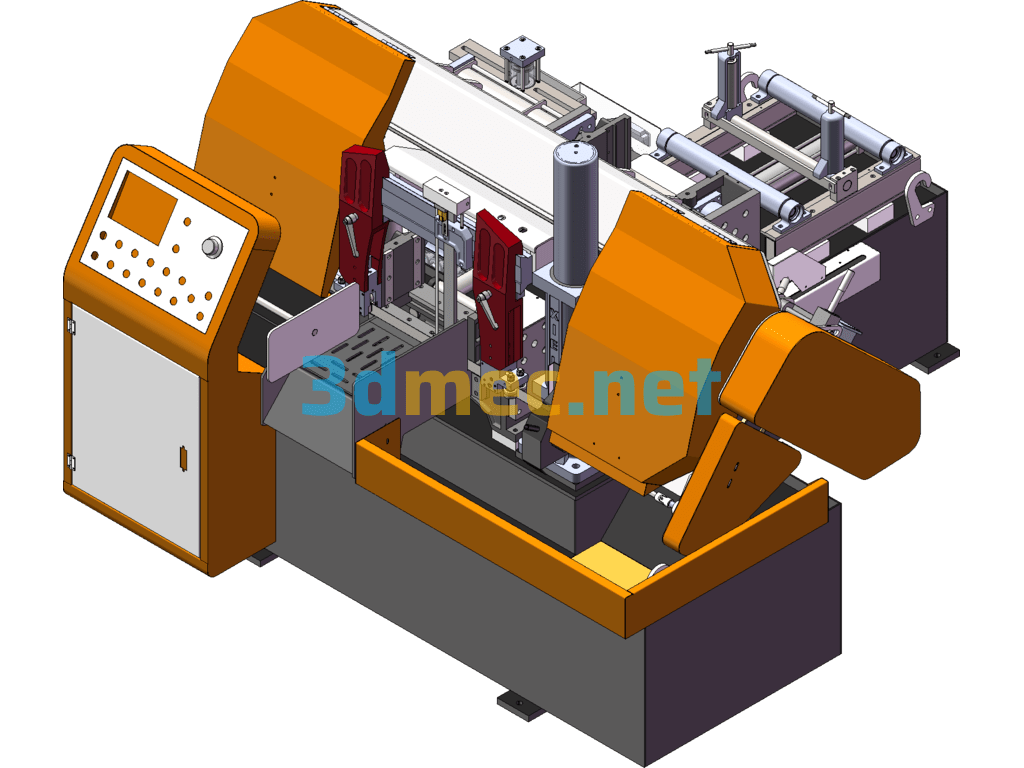

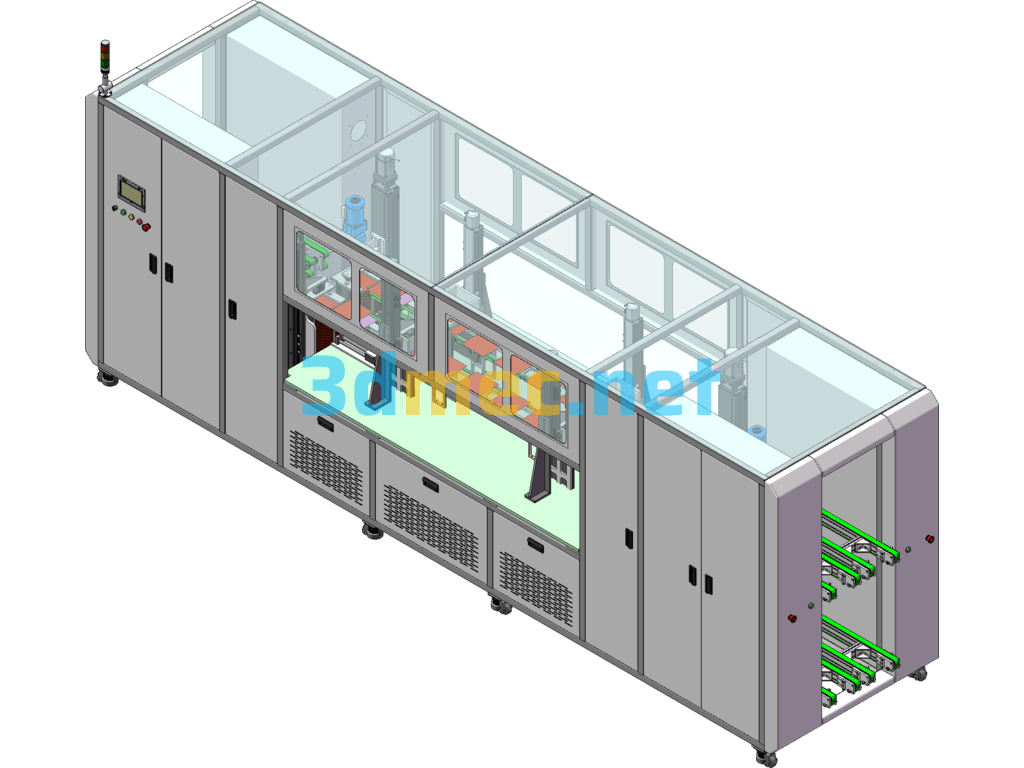

Further refer to Figures 2 and 3 to illustrate the relative position relationship; Figures 2 and 3 include 9 grass divider assembly 10 fertilizer furrow opener 11 servo drive motor 12 material level monitoring sensor and 13 seeding box 14 fertilizer box 15 fertilizer covering wheel 16 seeding mechanism assembly; the seeding transmission ground wheel 6 is located in the middle of the seeding and fertilizing machine frame 7, and there are four fertilizer furrow openers 10 symmetrically distributed under the frame; the four grass divider assemblies 9 are located behind each fertilizer furrow opener 10 and connected to the fertilizer seeding machine frame 7; the rear end of the frame is connected in turn to the seeding mechanism assembly 16 and the fertilizer mechanism. The installation position of the Omron proximity speed switch 18 and the capacitive fertilizer blockage sensor 23 is shown in Figures 4 and 5; the fertilizer vehicle terminal 21 and the seeding vehicle terminal 22 are located at the front end of the tractor cockpit as shown in Figure 6, and are connected to the controller on the seeding machine through the CAN bus protocol.

Implementation method of precision seeding control;

A photoelectric sensor is installed on the side wall of the seed tube in the seeding mechanism assembly to detect the implementation status of seeding; at the same time, the Omron proximity speed switch 18 implements the detection of the implementation speed of the transmission shaft speed measuring gear 20; the measurement signals of the two are transmitted to the seeding quality controller 1 for analysis, and the theoretical seeding status is analyzed by the Omron proximity speed switch 18, and the actual seeding status is analyzed by the photoelectric sensor signal. After comparison and analysis of the two, the results are obtained to determine whether there is any missed seeding and the amount of missed seeding. Combined with the on-board GPS system, the position of the missed seeding can be recorded in real time, and the working information can be transmitted to the on-board terminal 21 of the seeding through the CAN bus protocol to generate relevant technical documents to store and display the seeding status; it is convenient for subsequent intelligent missed seeding and reseeding operations, and the control of precision seeding is realized; at the same time, the seeding box 14 is equipped with a material level sensor to monitor the seed material status in real time, which is transmitted to the on-board sowing terminal 22 for display, providing the driver with a seed shortage warning.

Variable fertilization control method;

The present invention adopts a corn no-tillage fertilizer seeder, which needs to go through two fertilization processes during sowing; one is deep fertilization and the other is surface fertilization. When fertilizing, a capacitive fertilizer blockage sensor 23 is installed on the side wall of each fertilizer pipe 22 to detect the blockage condition of the fertilizer and the actual fertilization rate of the fertilizer. If there is a blockage or the fertilization rate does not match the set rate, an alarm will be issued on the fertilization vehicle terminal 21; in addition, the fertilization quality controller 4 is used to drive and control the speed of the servo motor 11 to control the fertilization rate to meet the fertilization rate requirements. Each fertilizer box 3 and the fertilizer supplement box 15 are equipped with a material level monitoring sensor 12 for detecting the amount of fertilizer and conducting fertilizer early warning. By using the existing information on the amount of fertilizer required for the land, the GPS module in the fertilization vehicle terminal 22 is combined to obtain the latitude and longitude information and the machine operation speed to determine the amount of fertilizer at the current machine position; the data acquisition module in the terminal is used to collect and process the sensor to provide the feed amount transmission shaft rotation speed, DC servo motor speed, blockage and fertilizer shortage information, and GPS and other sensor information; the fertilization quality control system in the terminal generates fertilization decisions based on the various sensor information collected by the data acquisition module, and sends it to the fertilization quality controller 4 in real time to achieve accurate fertilization of the machine at the current position. The operation speed, longitude and latitude information, current fertilizer amount, current feed amount, blockage and other operation parameters are displayed in real time through the fertilization vehicle terminal; thus, variable fertilization control is achieved.

(I designed the invention patent myself when I wrote it. I am a student at school and hope to help friends in need)

Specification: Precision Variable Seeder Corn No-Till Fertilization Seeder – 3D Model SolidWorks

|

User Reviews

Be the first to review “Precision Variable Seeder Corn No-Till Fertilization Seeder – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.