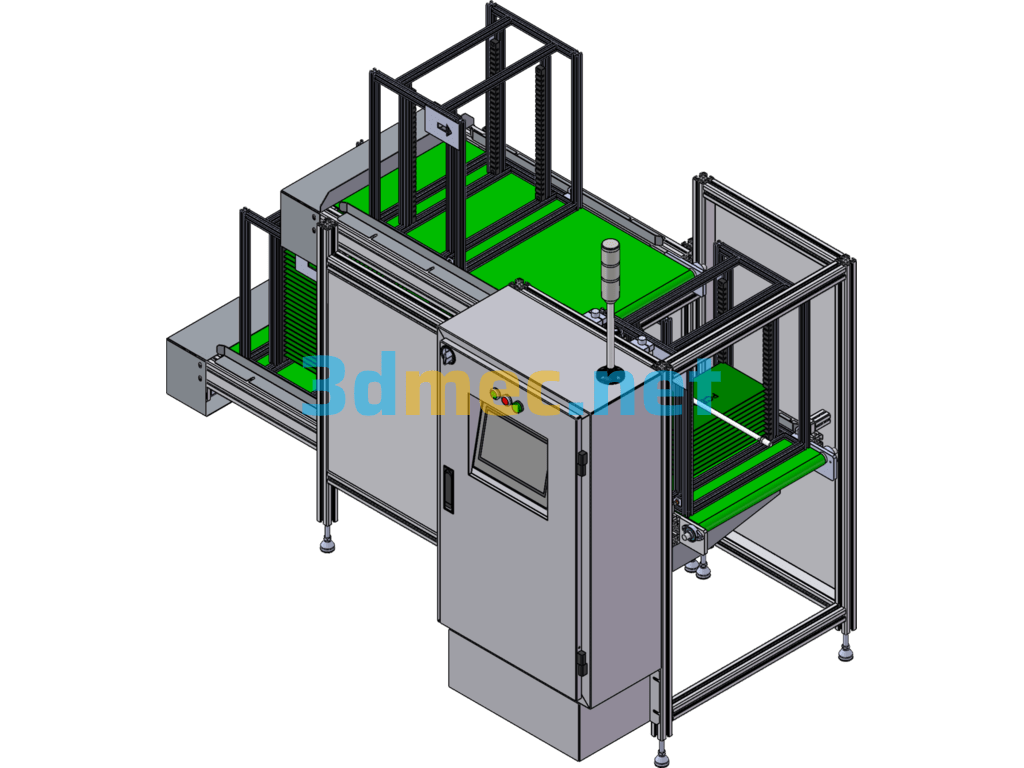

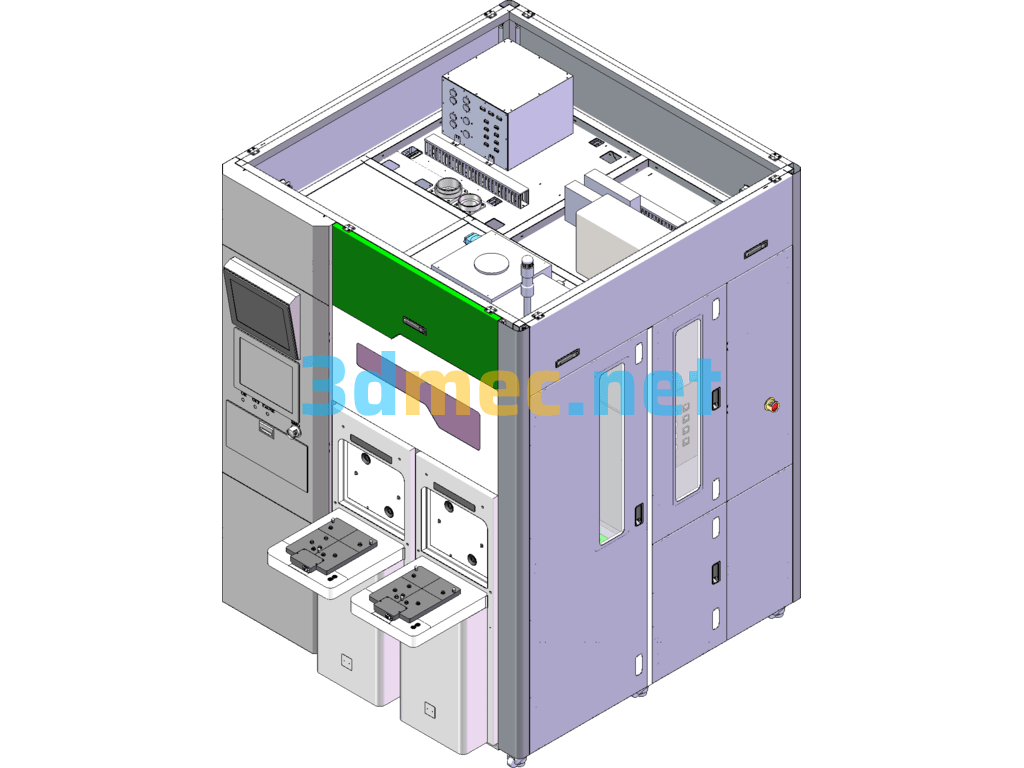

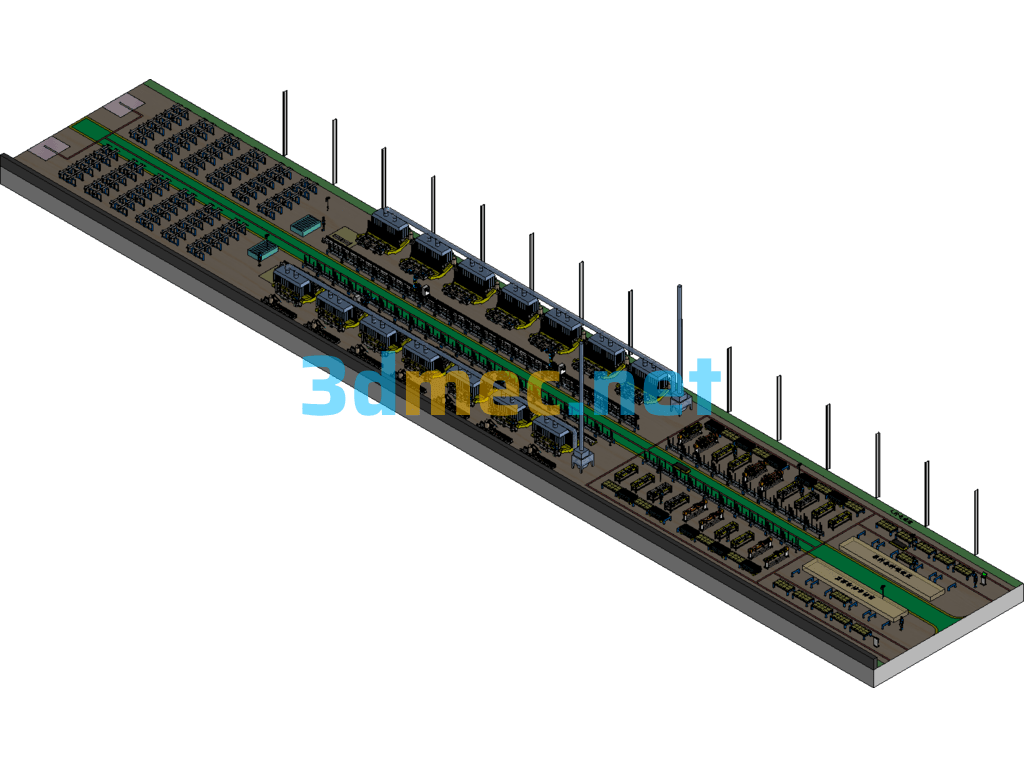

PCB Feeding Machine – 3D Model SolidWorks

PCB automatic board feeder

Process

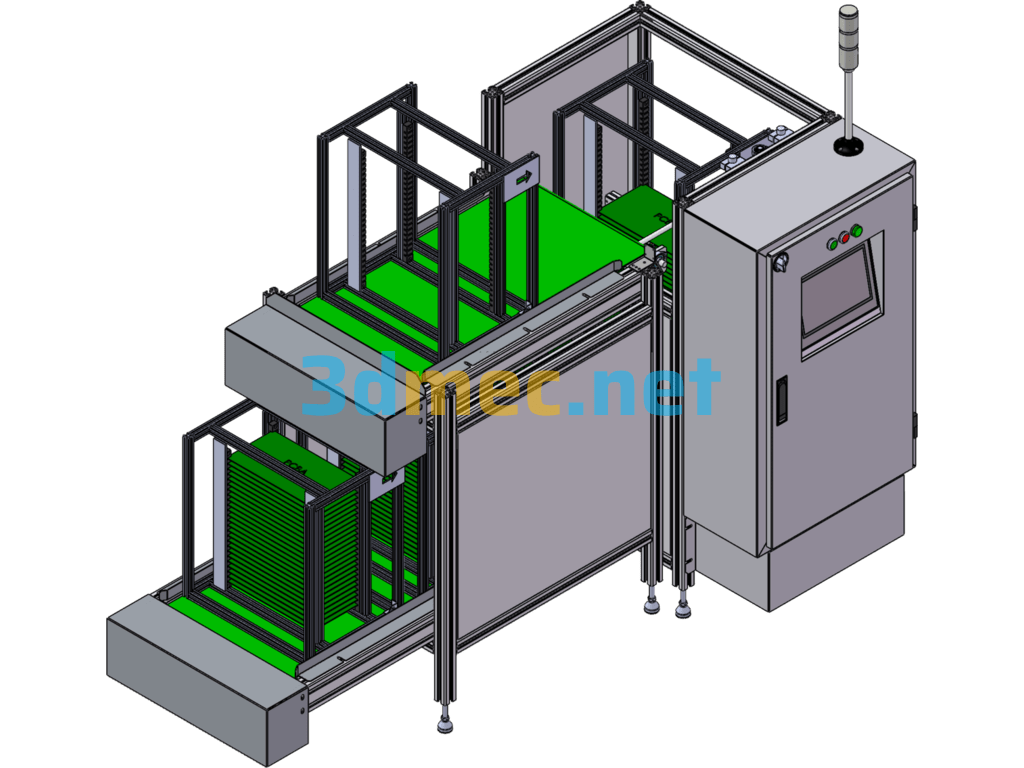

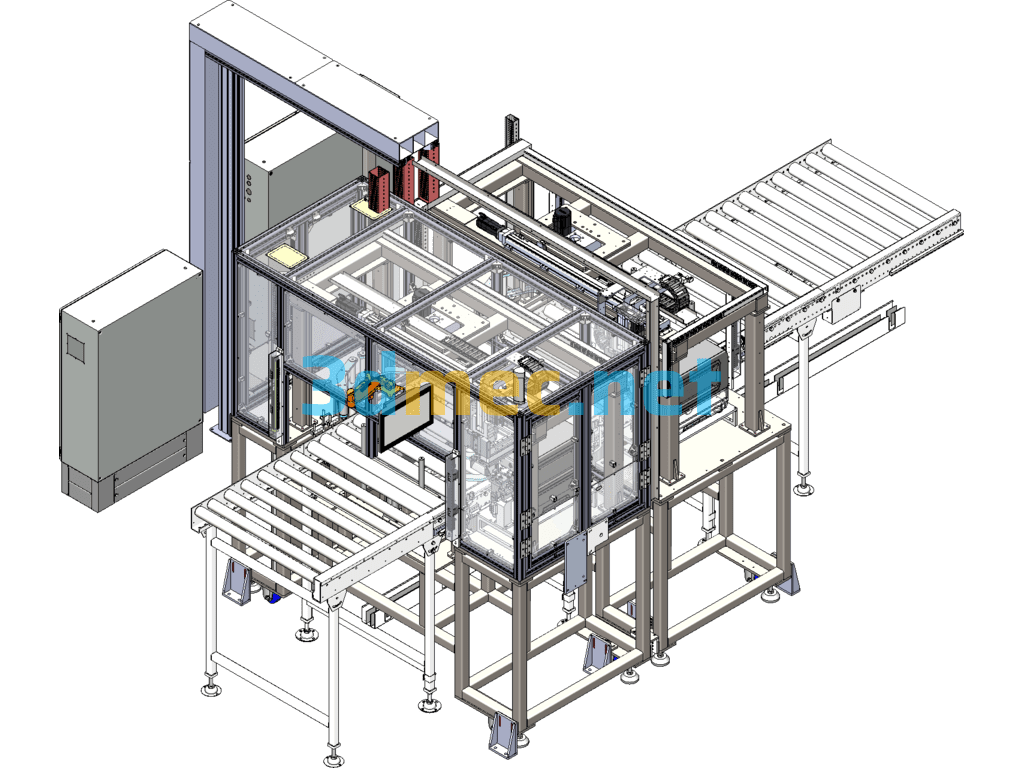

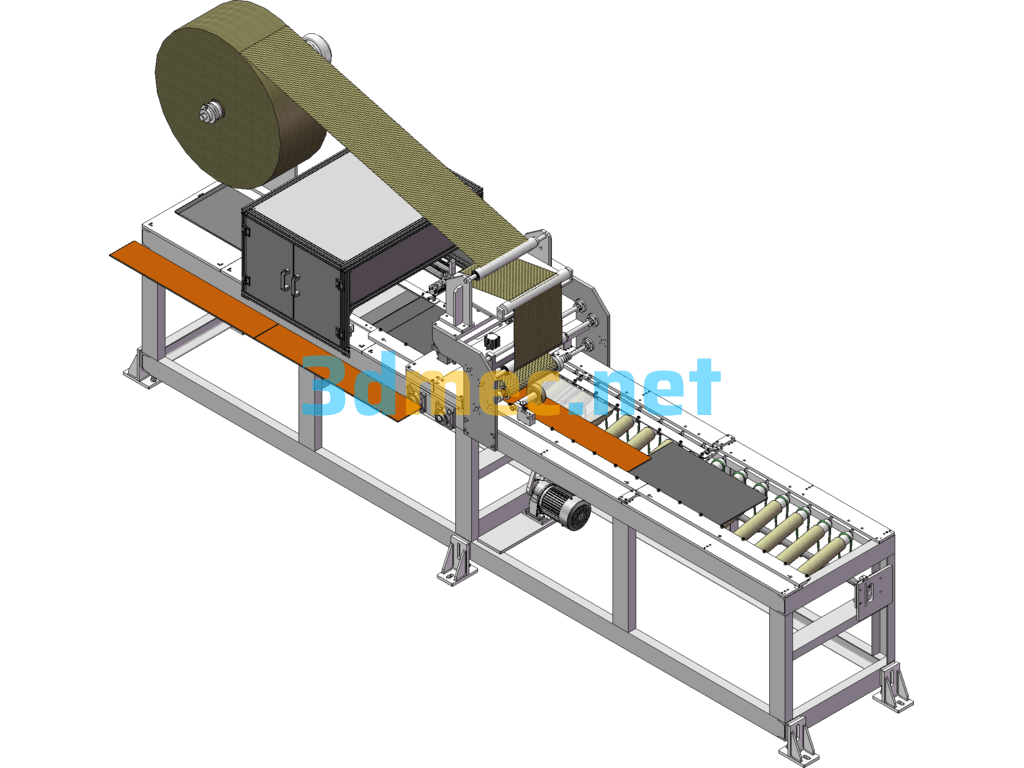

1. Manually deliver the PCB board frame (with PCB) to the lower conveyor

2. Conveyor delivers the frame to the end conveyor belt area

3. The sensor obtains the signal and establishes communication with the PLC. If the Loader device does not deliver the board, the frame will be loaded to the Loader

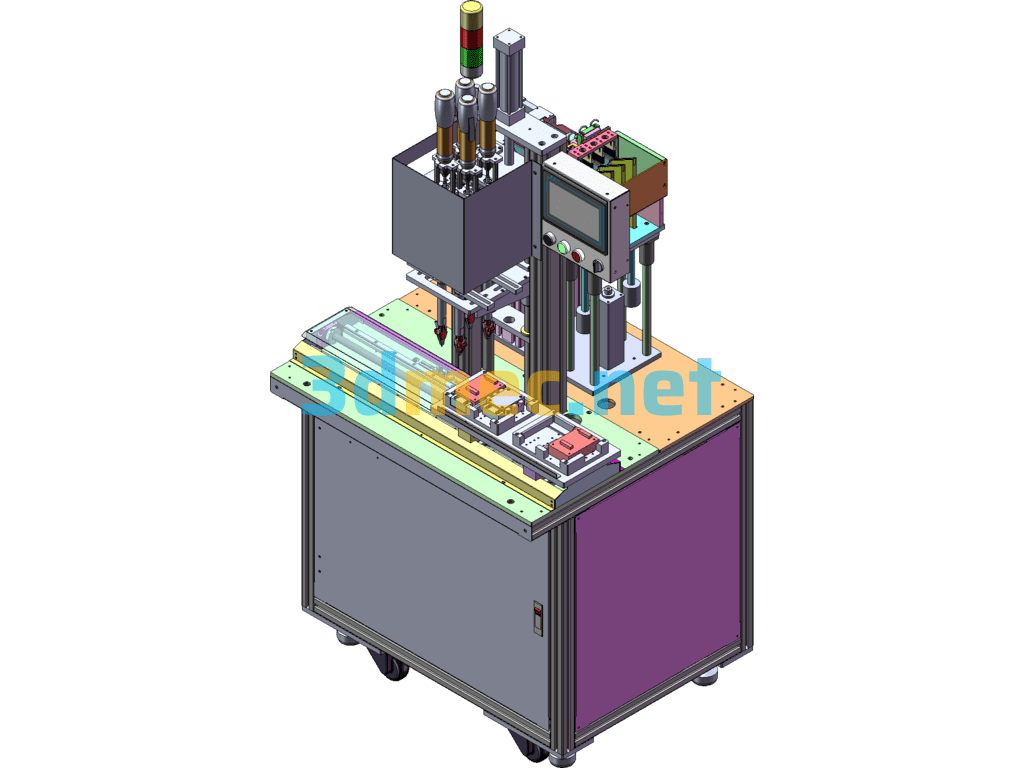

4. The Loader adopts a lead screw drive. The servo motor controls the lead screw upward and the cylinder controls the push plate to complete the push of the PCB board (PLC control)

5. When all the boards are pushed out, the board box will be recovered when the storage area is free (there is no sensor in the storage area to determine whether there is a board box. It is manually determined on the HMI control interface, and then the MES or machine sends a signal to the PLC control)

Reprinted from Vietnamese designer KUA LIN DUN

Specification: PCB Feeding Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “PCB Feeding Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.