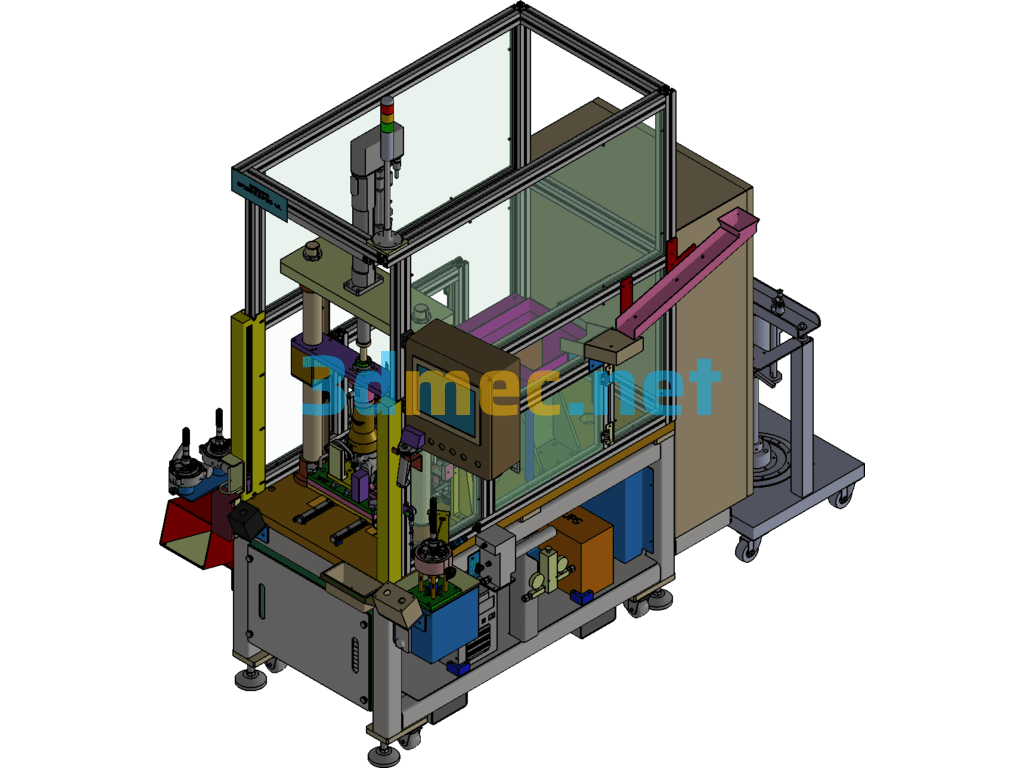

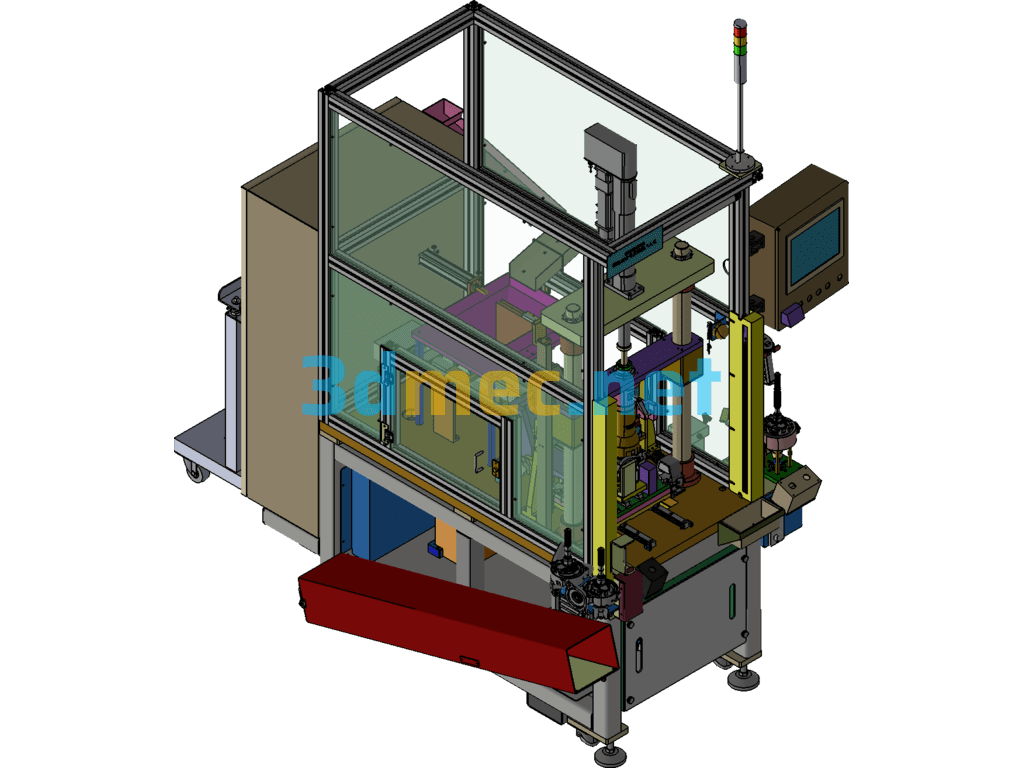

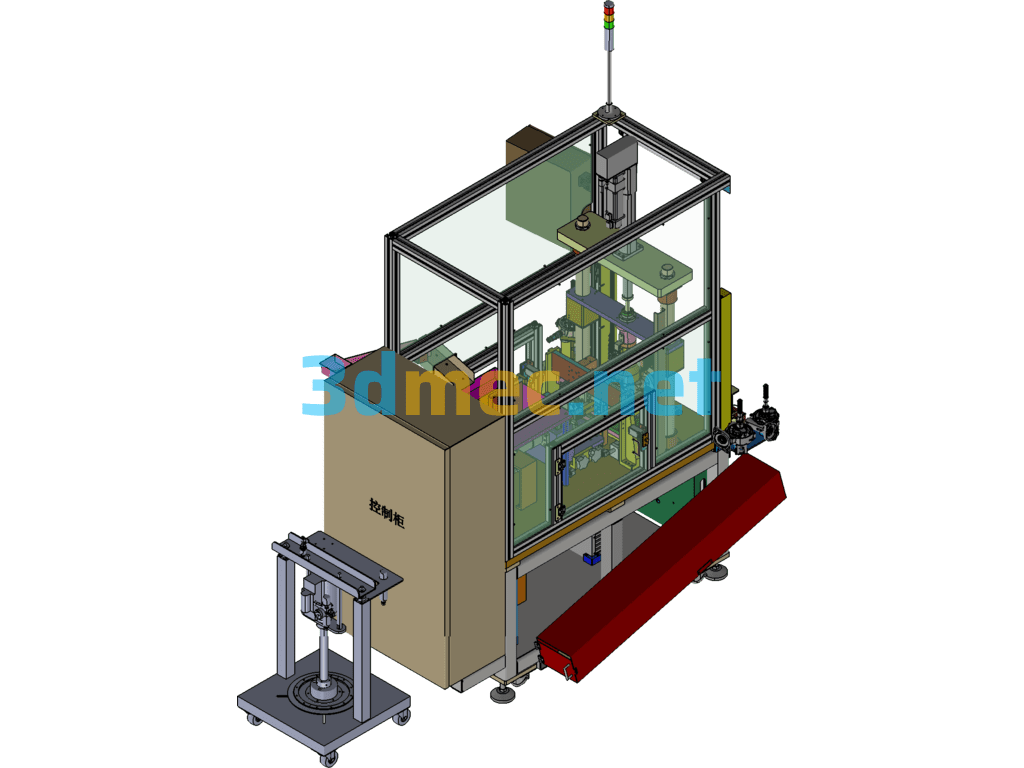

OP80&OP90 Worm Gear Box Assembly And Pin Press Machine – 3D Model Inventor

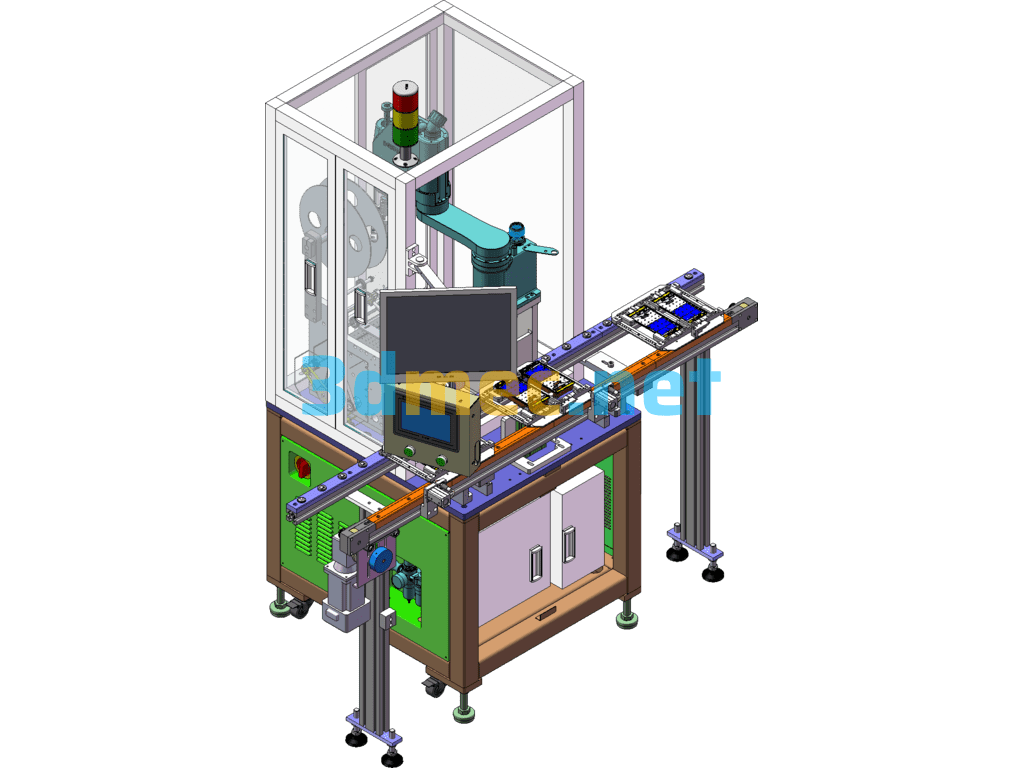

OP80 & OP90 Worm Gear Box Assembly and Pin Pressing Machine

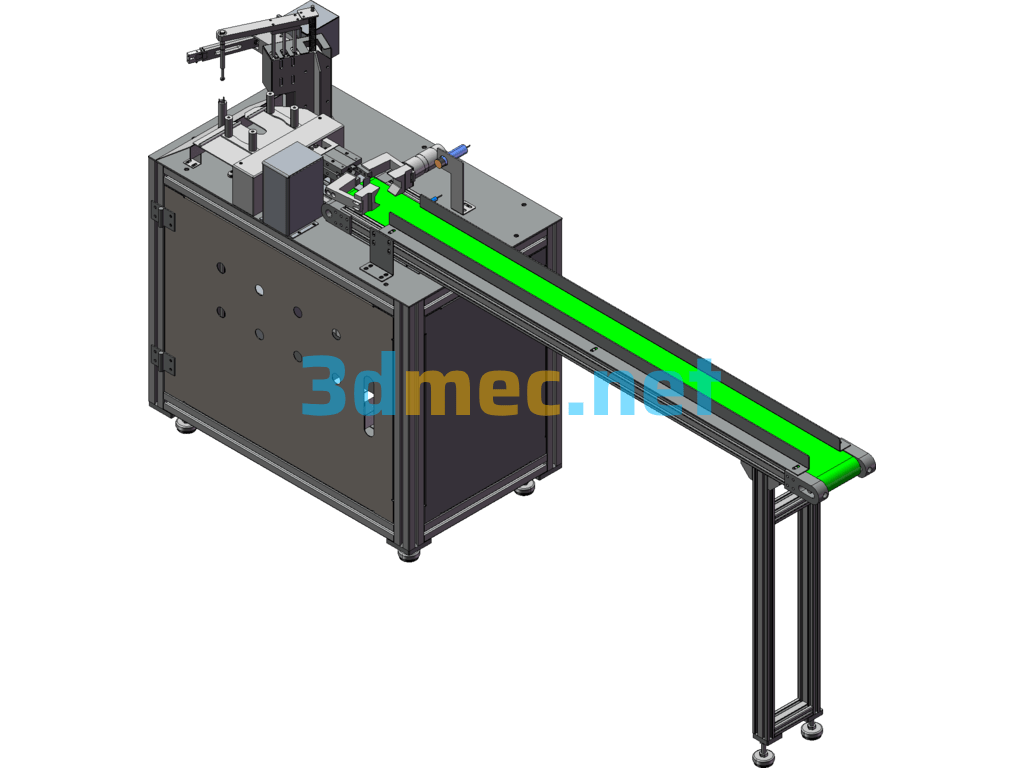

1.Purpose: To quantitatively apply oil to the worm gear tooth surface (the side surface does not need to be oiled); to press the worm gear assembly, bushing (manually) and pin into the worm gear box.

2.Compatible products: A13TE, FE-3DA, ZTM11E

3.Equipment operation process (42s)

1.Install the worm gear sensor assembly into the oiling tooling (manual, 2s)

2.Oil the worm gear (automatic 4s)

3.Manually press the bushing into the worm gear box, and then put the reduction box into the lower tooling (manual 8s)

4.Install the worm gear sensor assembly into the worm gear box and extend the directional mechanism (manual 2s)

5.Start the pull rod switch (manual 1s)

6.Clamp the worm gear box, lower the vertical servo press, and press the worm gear sensor assembly into the worm gear box

(Automatic 7s)

7. The horizontal servo press descends and automatically presses the pin into the worm gear box (automatically for 7 seconds)

8. Each actuator returns to its initial position (automatically for 5 seconds)

9. Manual unloading (manually for 2 seconds).

Specification: OP80&OP90 Worm Gear Box Assembly And Pin Press Machine – 3D Model Inventor

|

User Reviews

Be the first to review “OP80&OP90 Worm Gear Box Assembly And Pin Press Machine – 3D Model Inventor”

You must be logged in to post a review.

There are no reviews yet.