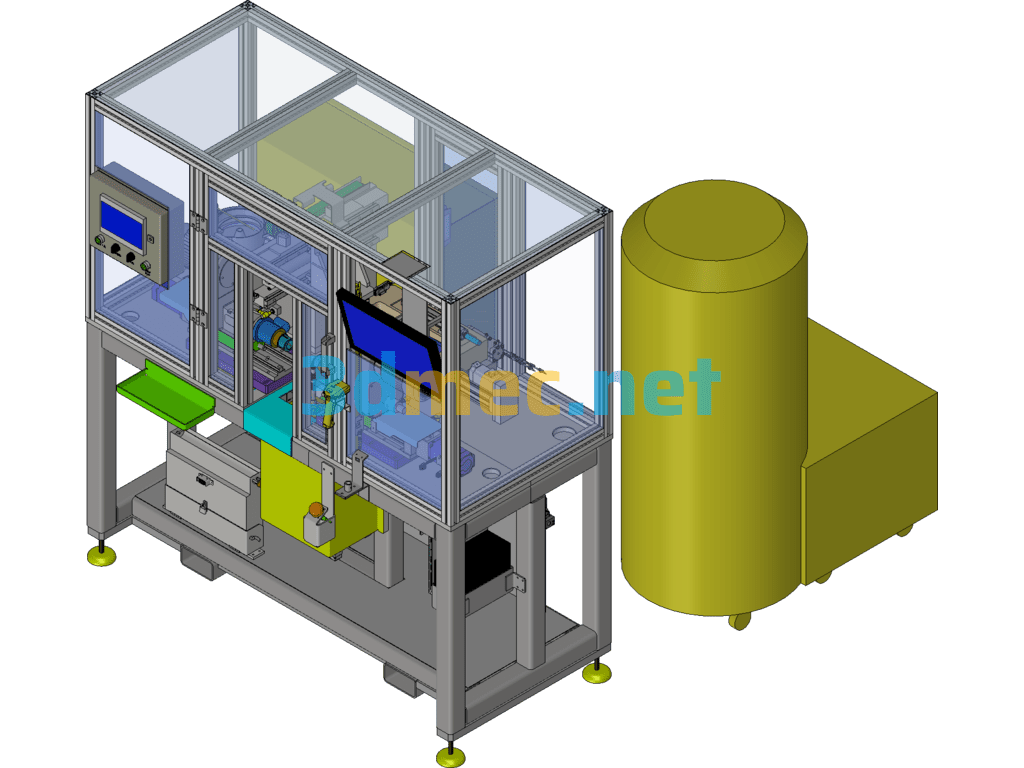

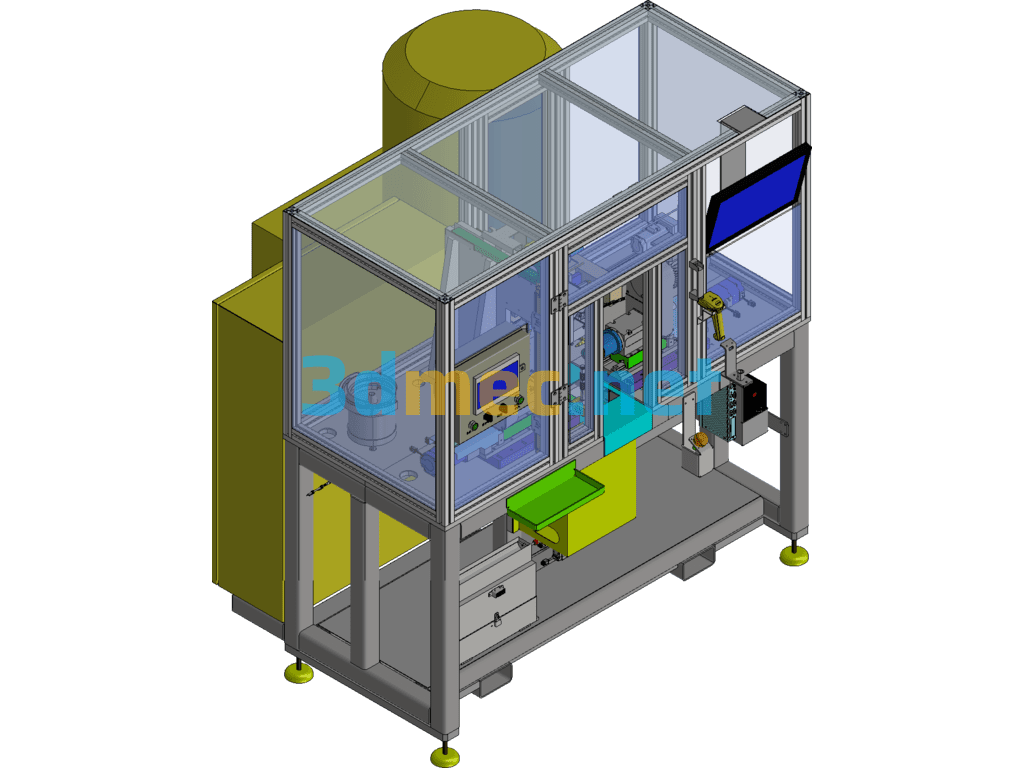

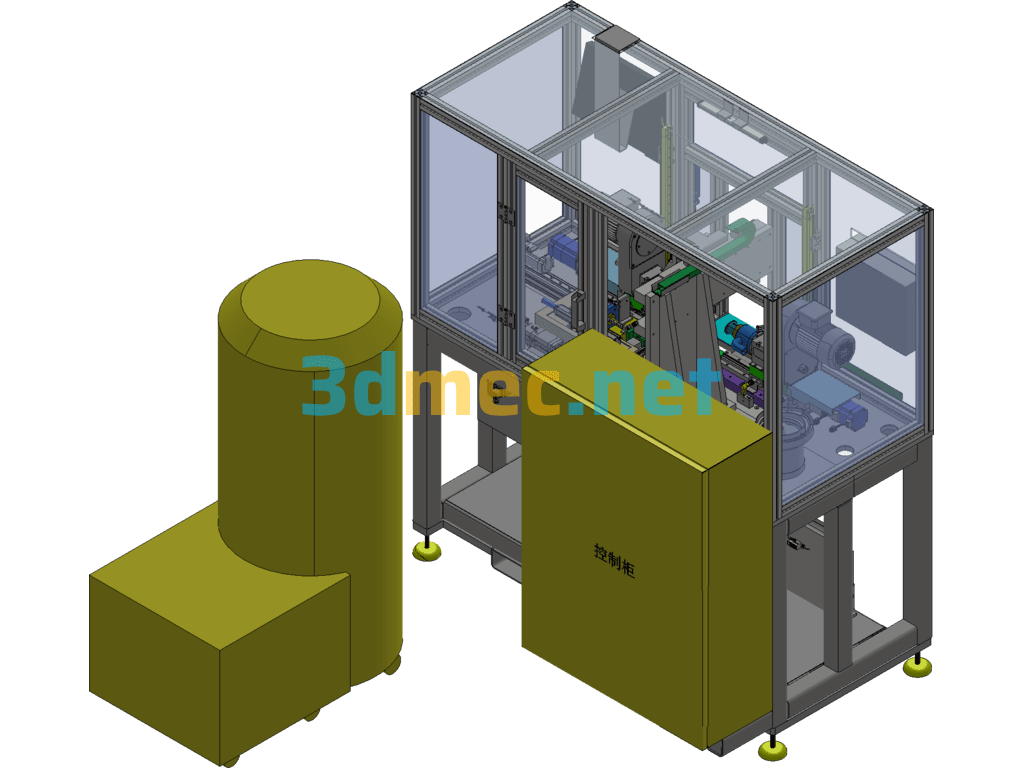

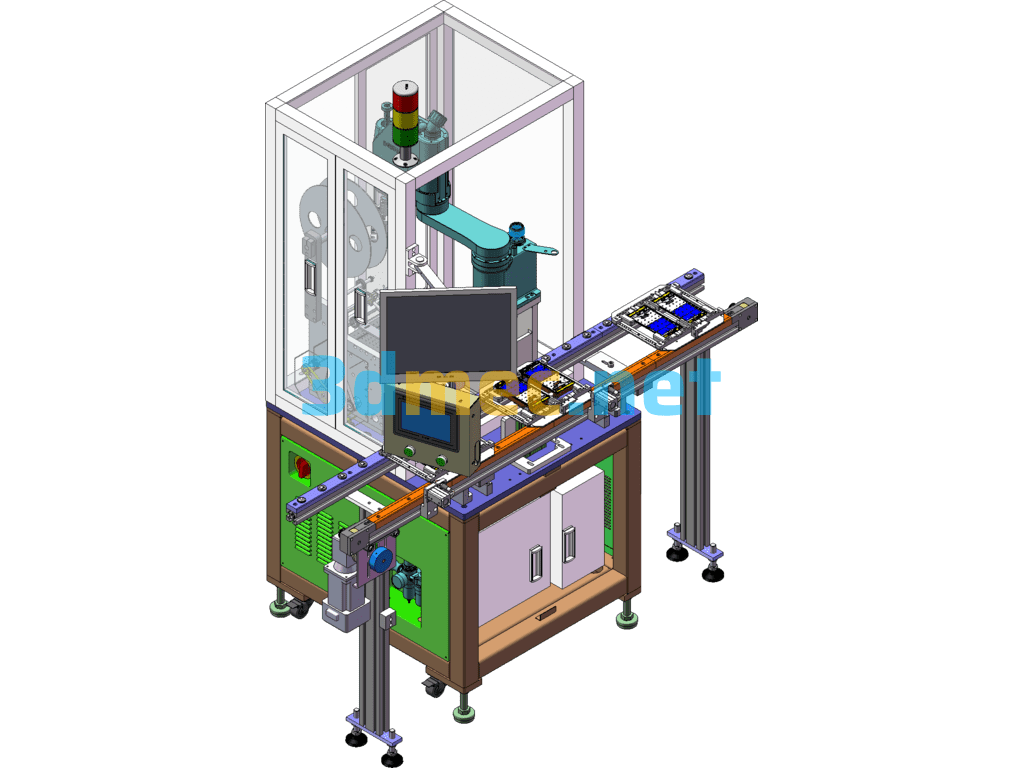

OP50 Input Shaft With Drilling And Pinning – 3D Model Inventor

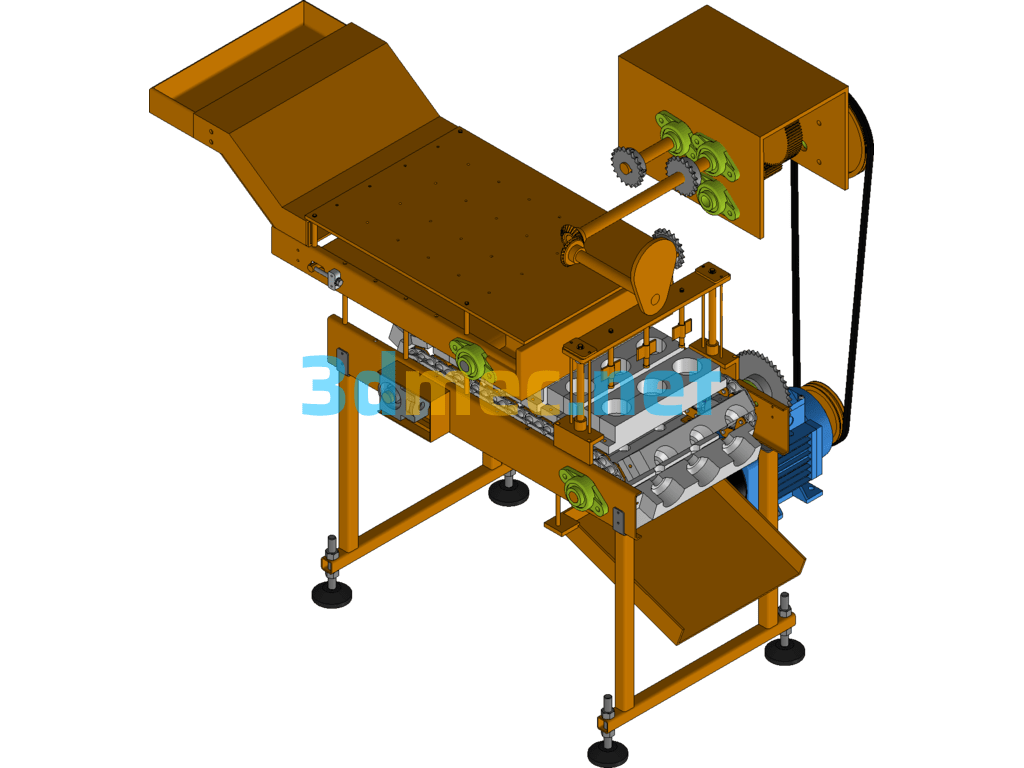

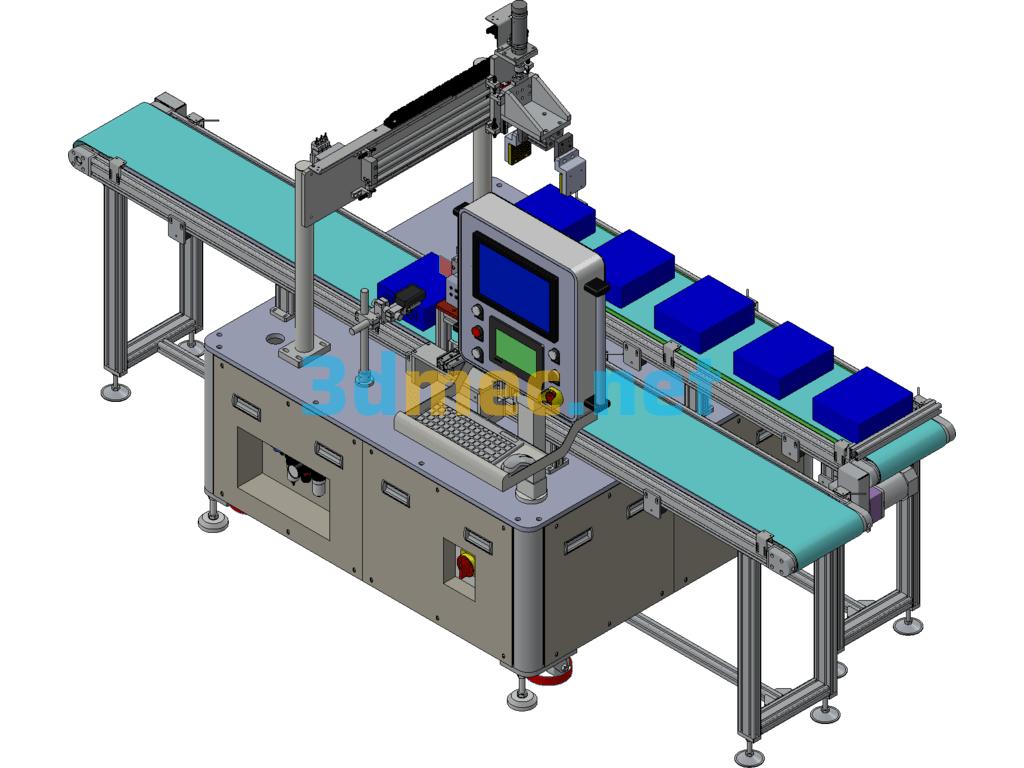

OP50 Input shaft drilling and pinning

1.Purpose: Drill and pin the input shaft and torsion bar

2.Compatible products: XK507C, JLFC3C, SP232C

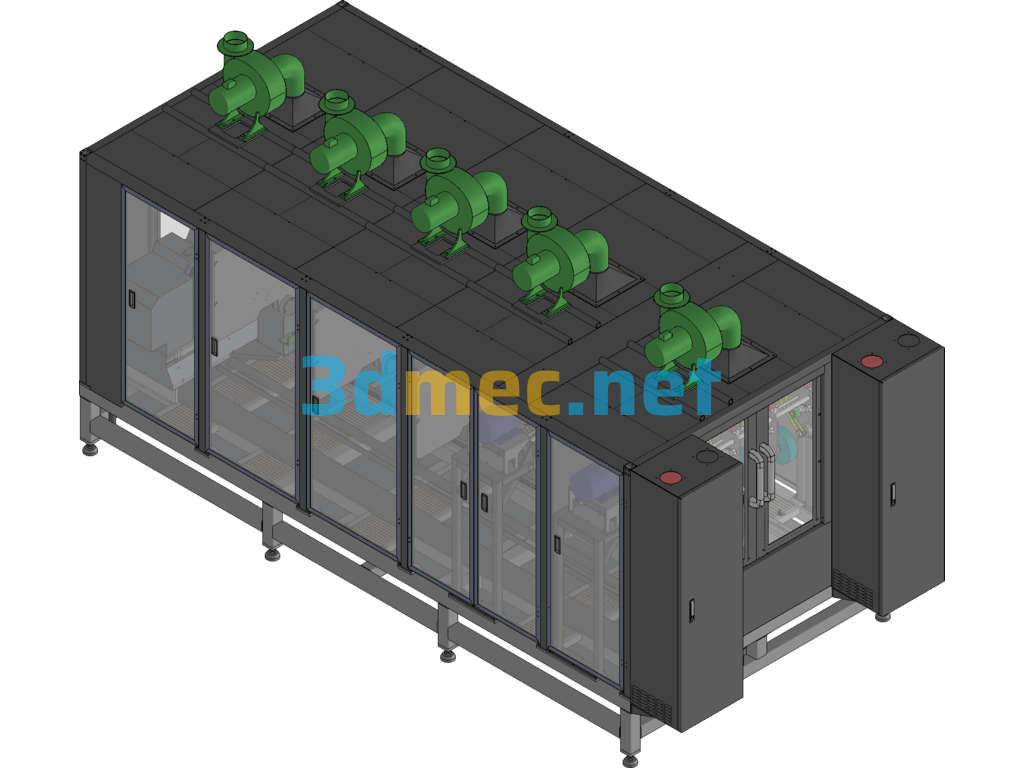

3.Equipment specifications: 1800mm(W)x1600mm(L)x 2000mm(aluminum profile H).

4.Equipment technical parameters

4.1Equipment power: 20kw

4.2Air source: ≥ 0.5Mpa oil-free, water-free clean compressed air source. Air consumption: 10L/min.

4.3 Equipment operation mode: Product loading/unloading is performed by the operator (manually), pins are automatically loaded, workpiece drilling, pin insertion, etc. are automatically completed;

4.4 Pressing force monitoring: range 30KN, accuracy 1%RO; pressure holding time is not less than 3 seconds; bearing and screw service life ≥ 10 million times.

4.5 Pressing depth control: accuracy 0.02mm; with displacement control, and can be connected to high-precision displacement sensor

4.6 Pressing judgment: whether the pressure and displacement are within the qualified range.

4.7 Machine model replacement: The fixture to be replaced is placed under the equipment, and a special placement plate is made.

Specification: OP50 Input Shaft With Drilling And Pinning – 3D Model Inventor

|

User Reviews

Be the first to review “OP50 Input Shaft With Drilling And Pinning – 3D Model Inventor”

You must be logged in to post a review.

There are no reviews yet.