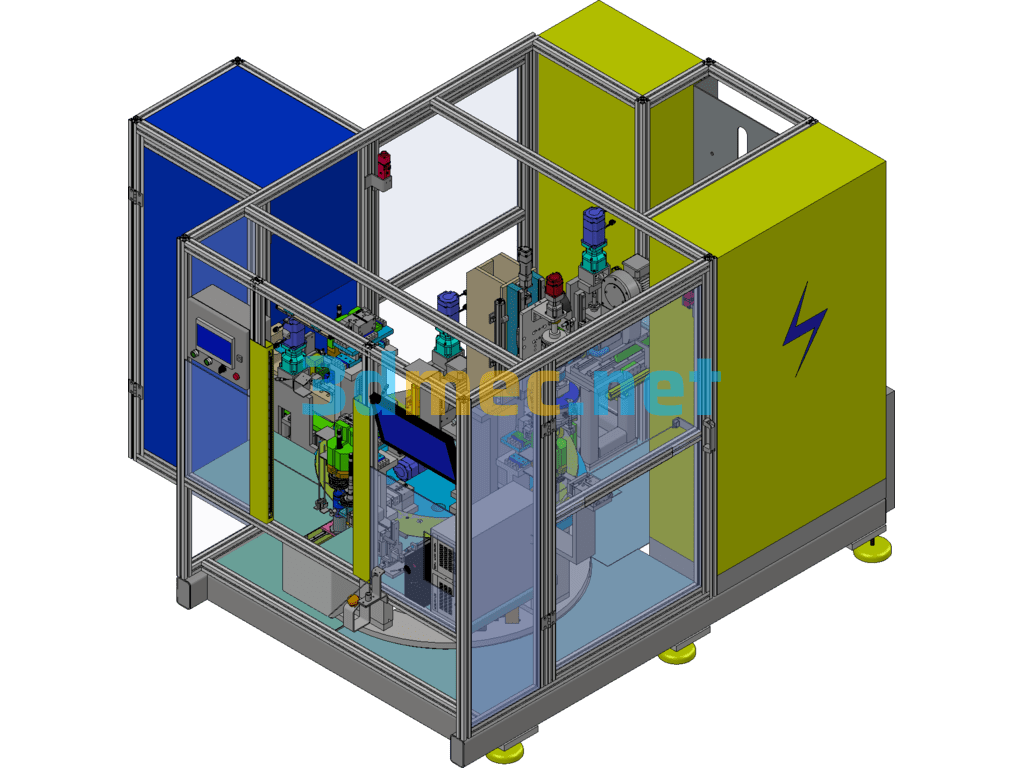

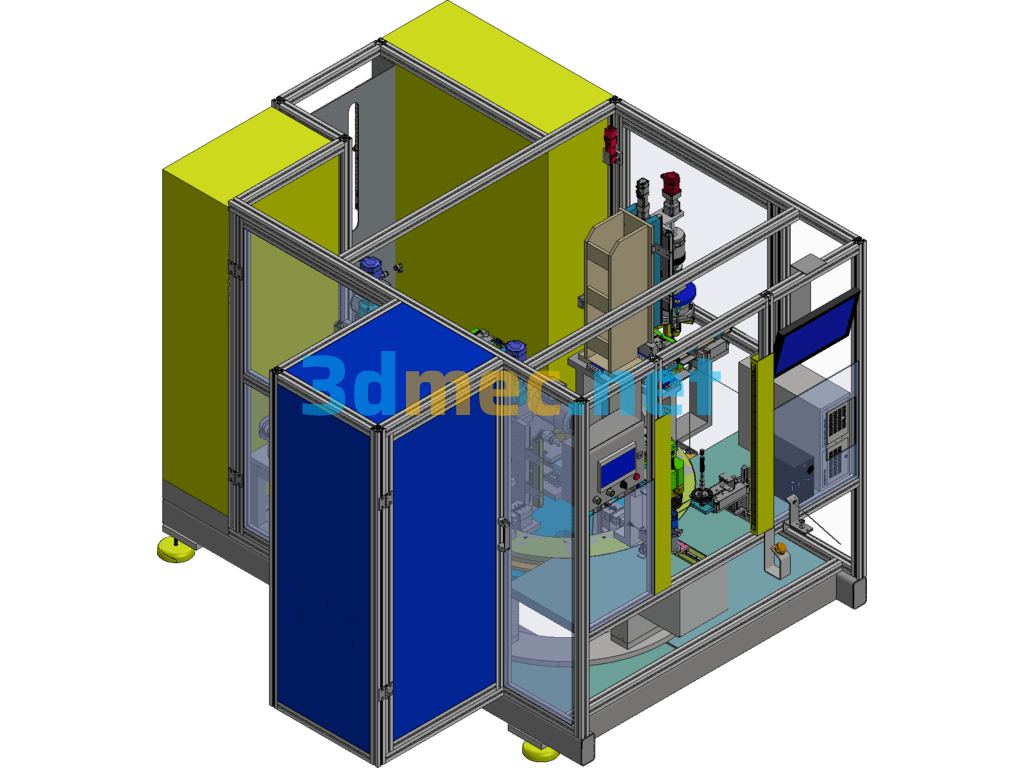

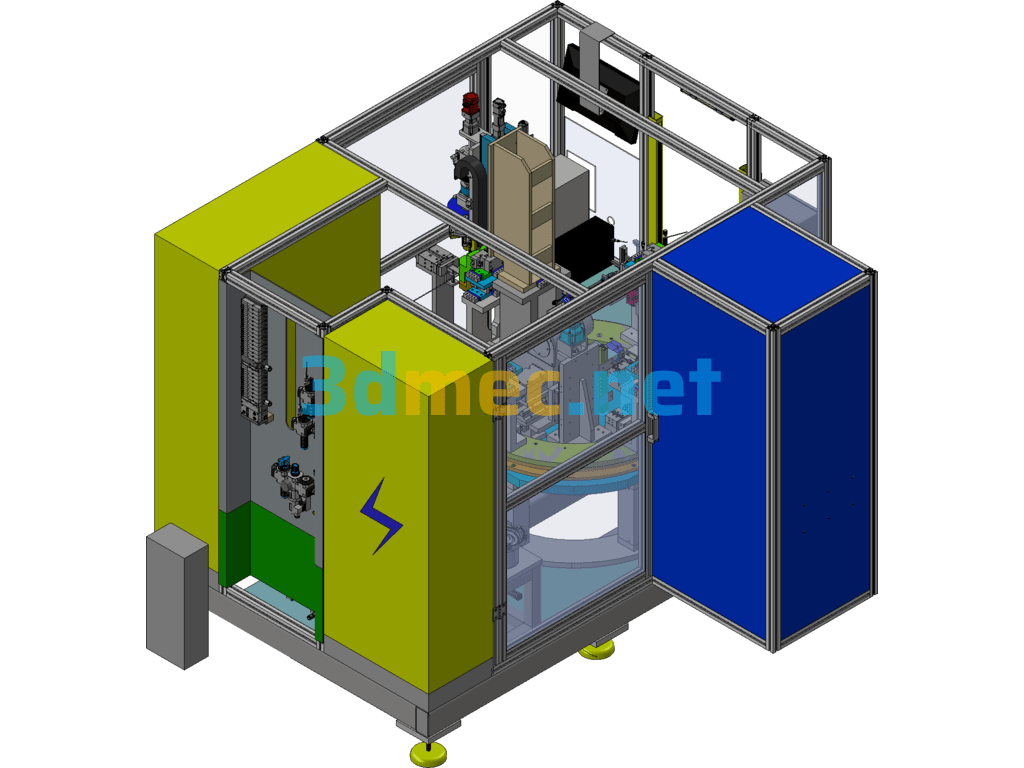

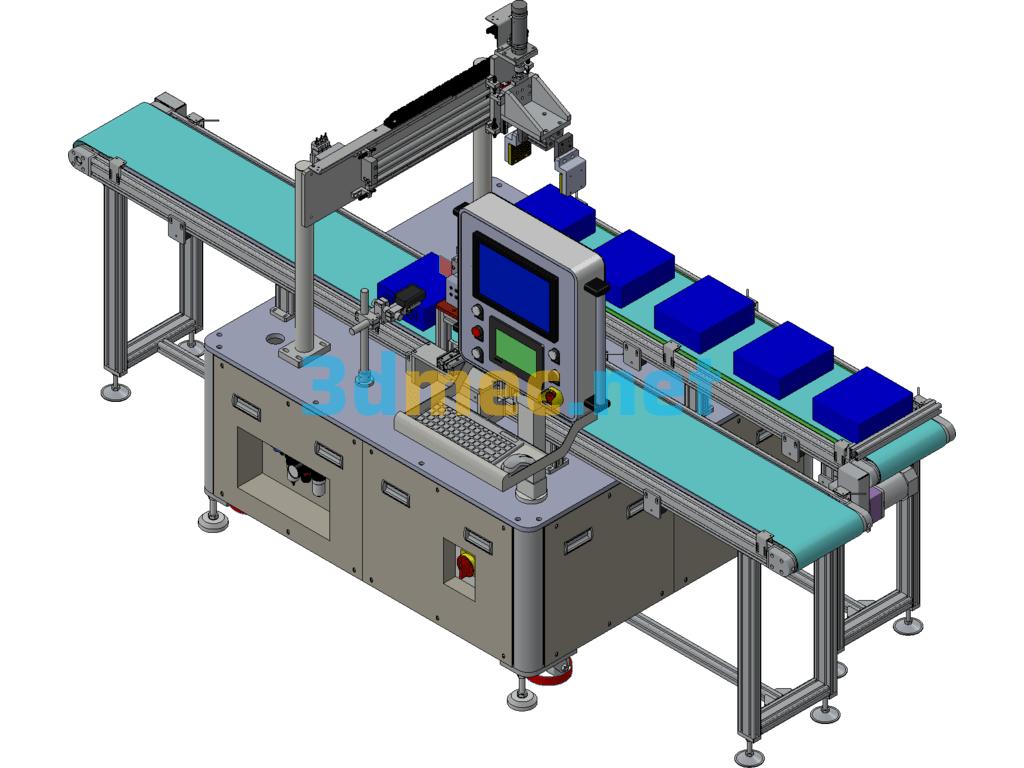

OP40 Output Shaft With Drill And Pin – 3D Model Inventor

OP40 output shaft with drilling and pinning

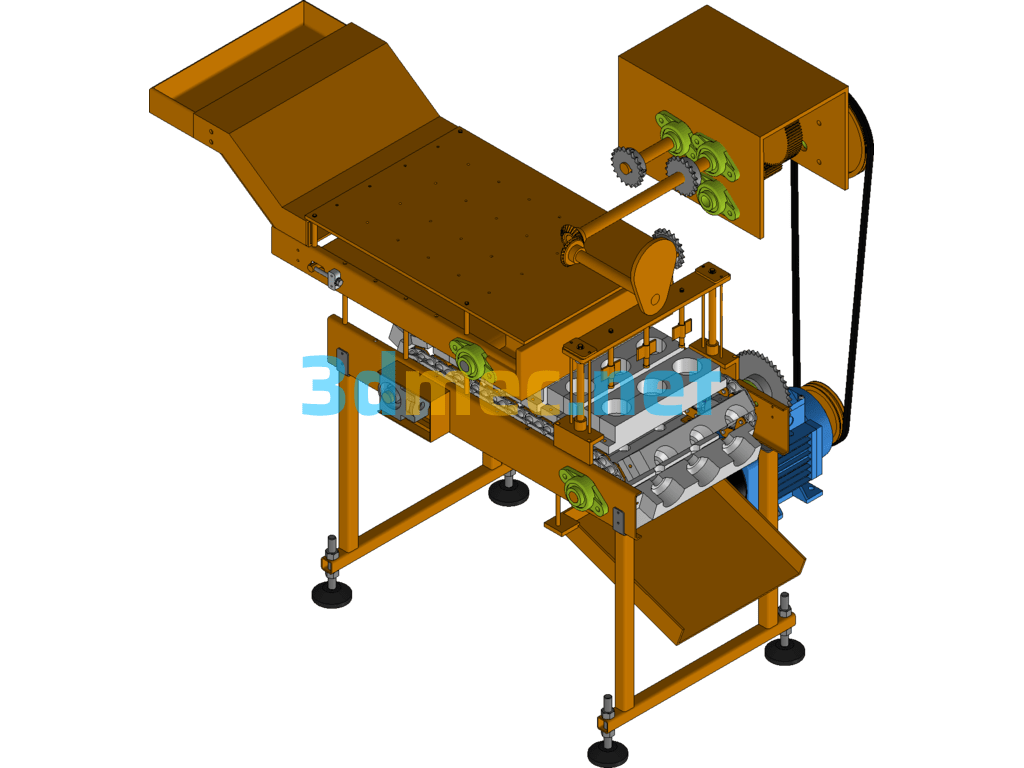

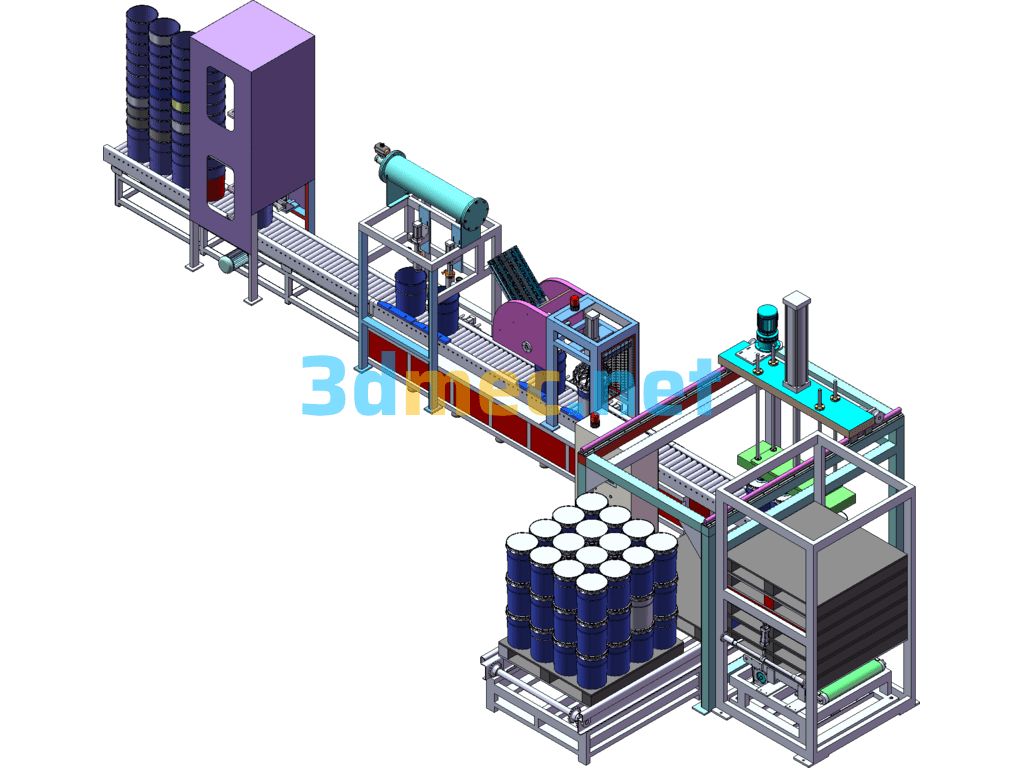

1.Purpose: to combine the output shaft assembly with the lower part of the input shaft assembly, find the center, drill holes, insert pins, and rivet;

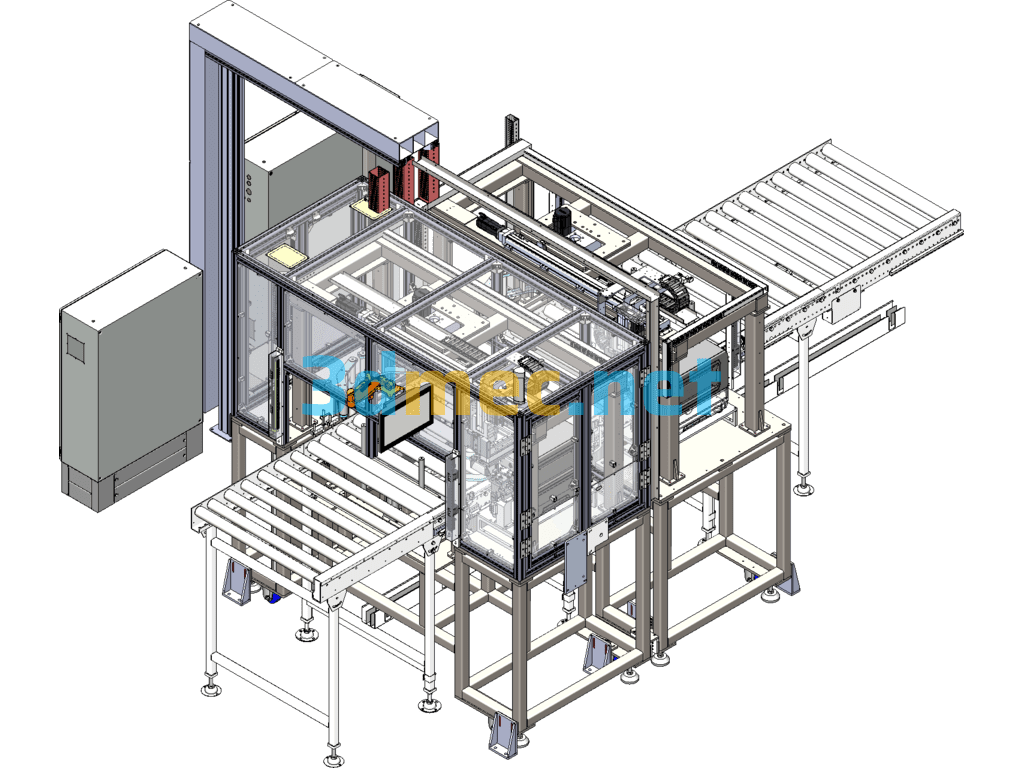

2.Compatible products:

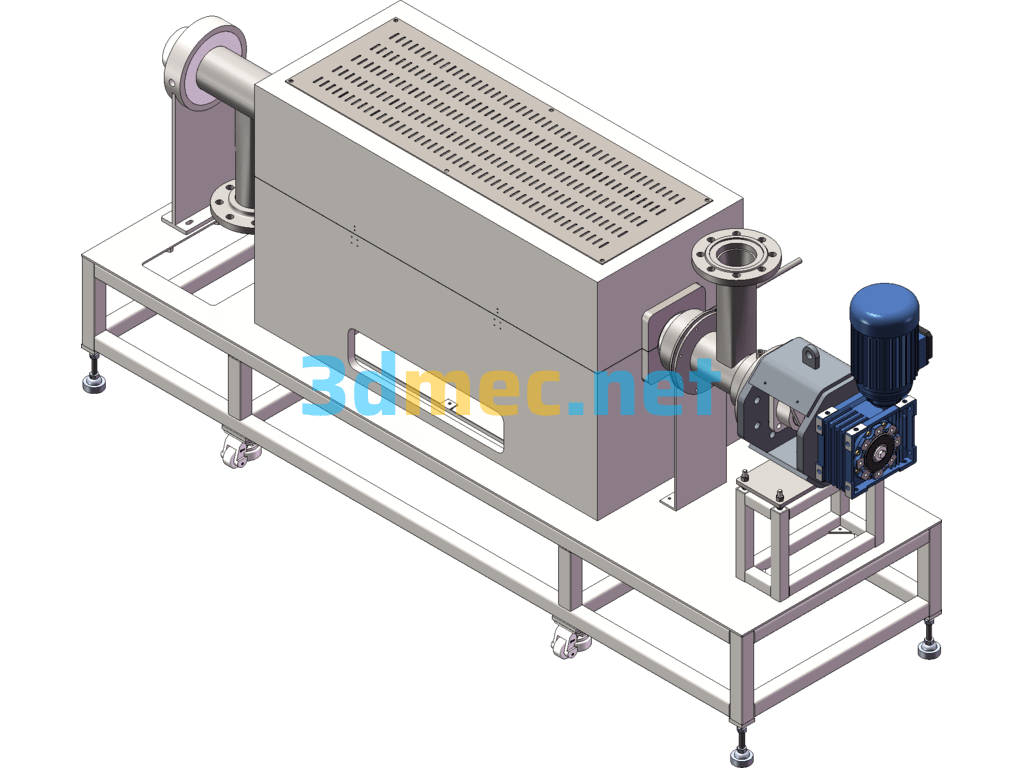

3.Equipment specifications: 2000mm(W)x2000mm(L)x 2000mm(aluminum profile H).

4.Equipment color: RAL7035

5.Production cycle: ≤ 45s

6.Equipment technical parameters

6.1Equipment power: 20kw;

6.2Air source: ≥ 0.5Mpa oil-free, water-free clean compressed air source. Air consumption: 10 liters/min.

6.3 Equipment operation mode: Product loading/unloading is performed by the operator (manually), and workpiece positioning, drilling, pinning, riveting, etc. are completed automatically;

6.4 Pressing force monitoring: range 30KN, accuracy 1%RO; holding time is not less than 3 seconds; bearing and screw service life ≥ 10 million times.

6.5 Pressing depth control:, accuracy 0.02mm; it has its own displacement control and can be connected to a high-precision displacement sensor

6.6 Pressing judgment: whether the pressure and displacement are within the qualified range.

6.7 Machine model replacement: The tooling fixture to be replaced is placed under the equipment, and a special placement plate is manufactured.

6.8 Calibration standard parts: The equipment is randomly provided with special tools for calibrating the coaxiality and displacement of the equipment. The tools are stored in special equipment, and the special equipment is fixed on the equipment.

6.9 Equipment CPK≥ 1.33

Specification: OP40 Output Shaft With Drill And Pin – 3D Model Inventor

|

User Reviews

Be the first to review “OP40 Output Shaft With Drill And Pin – 3D Model Inventor”

You must be logged in to post a review.

There are no reviews yet.