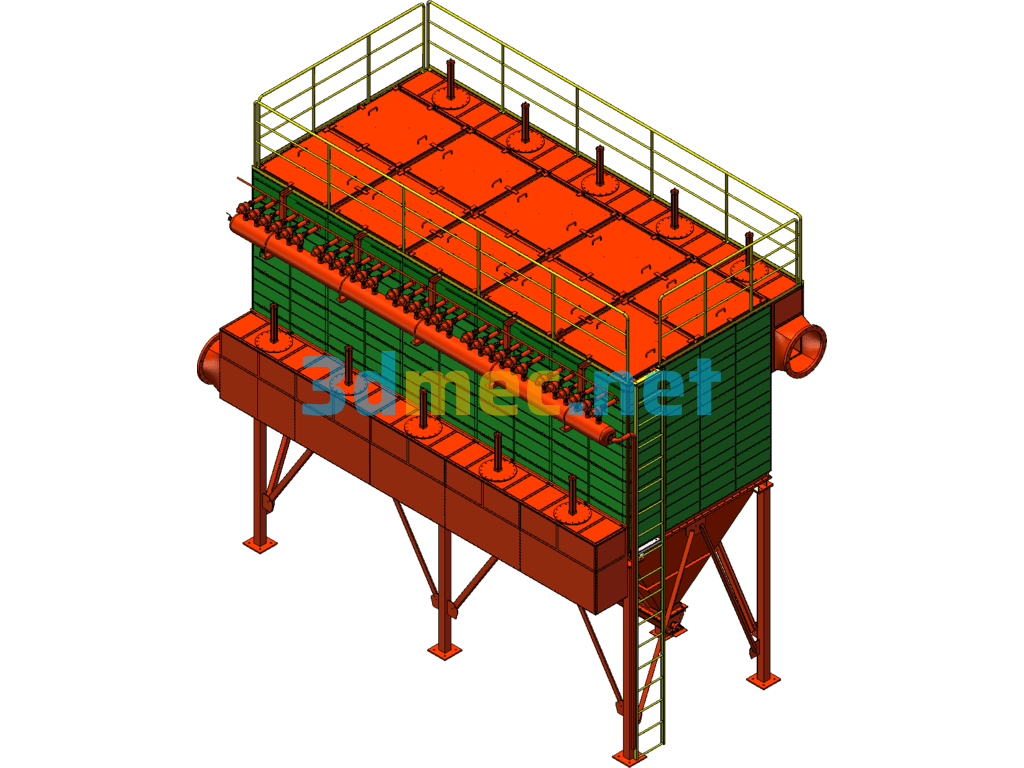

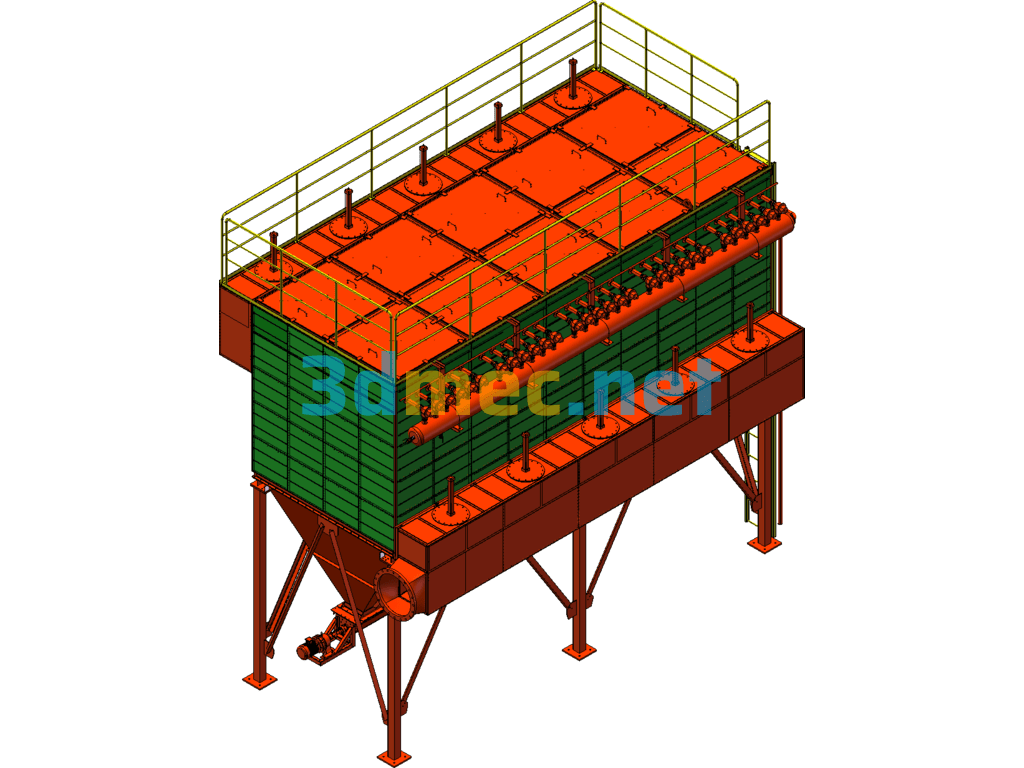

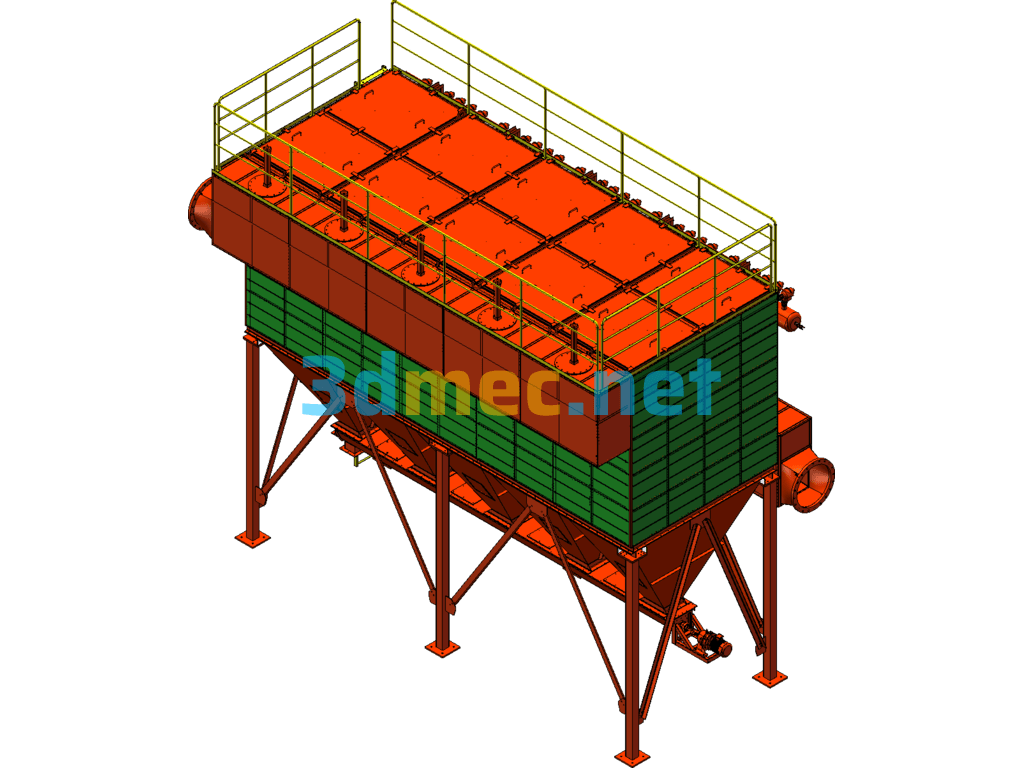

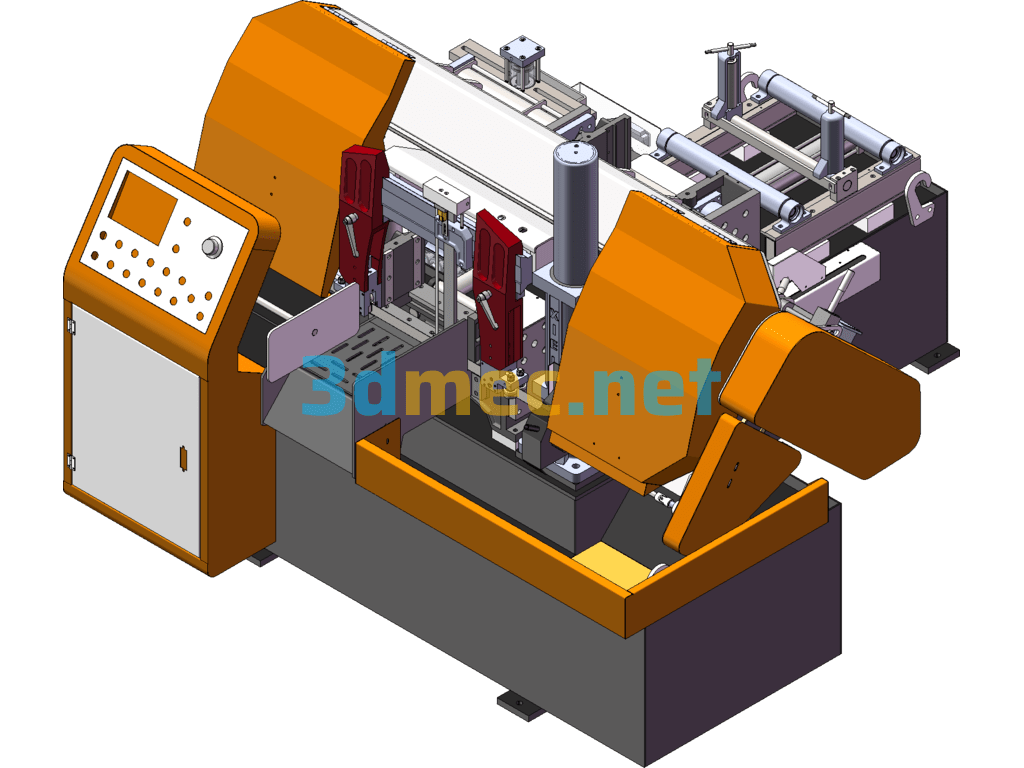

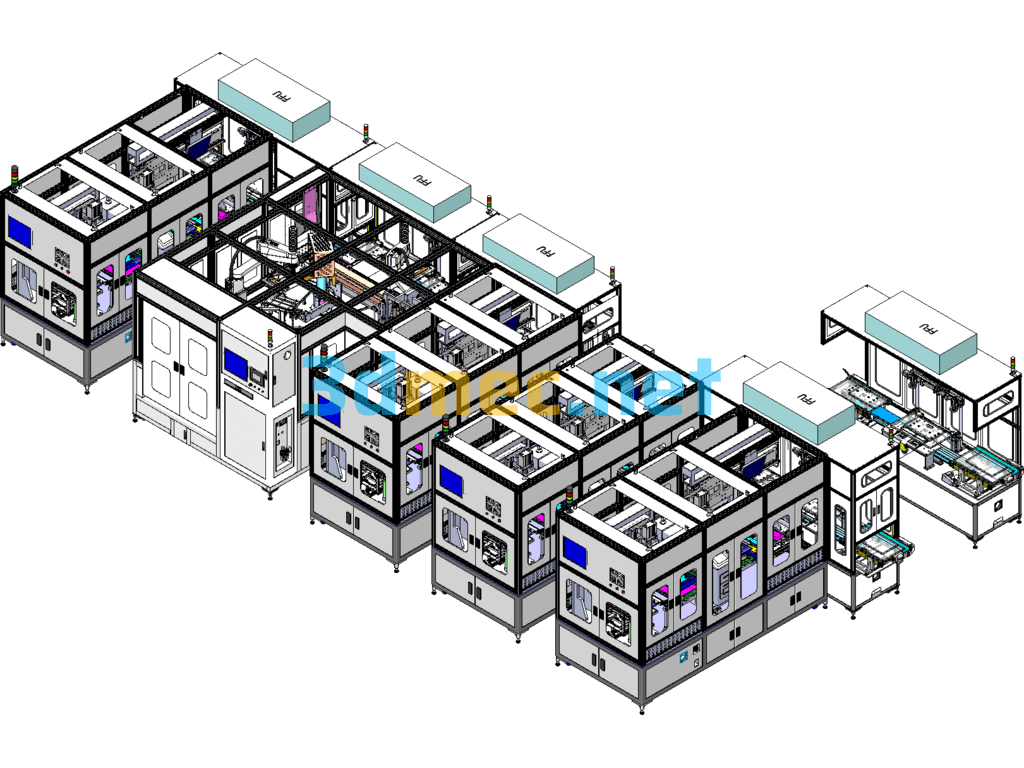

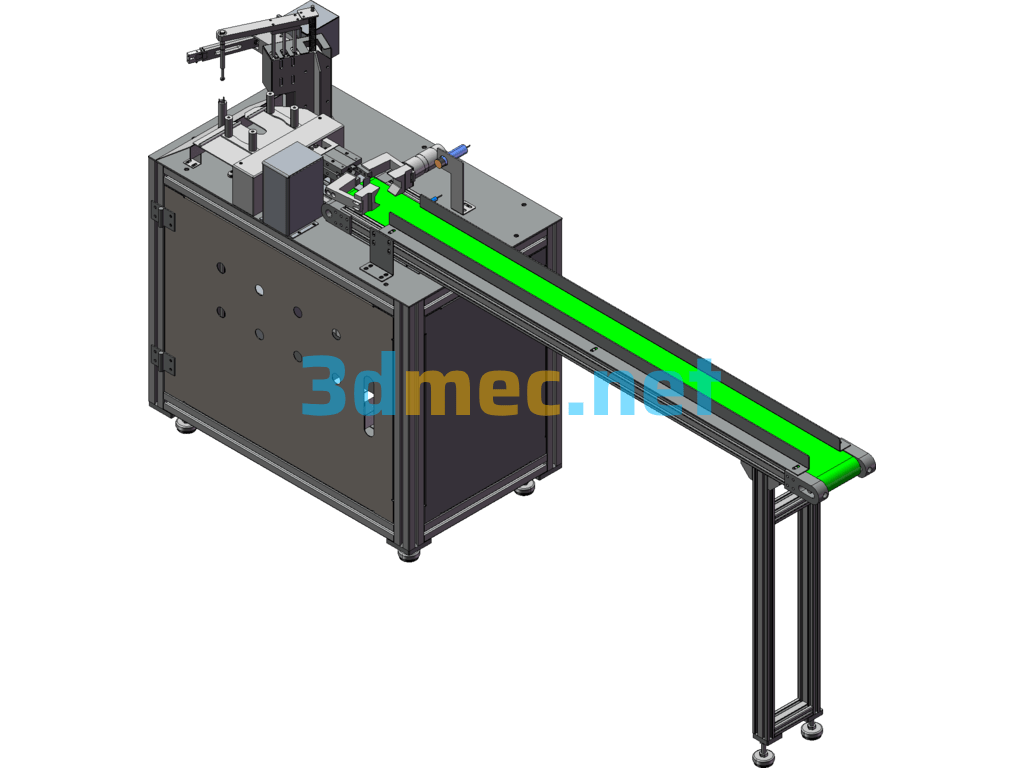

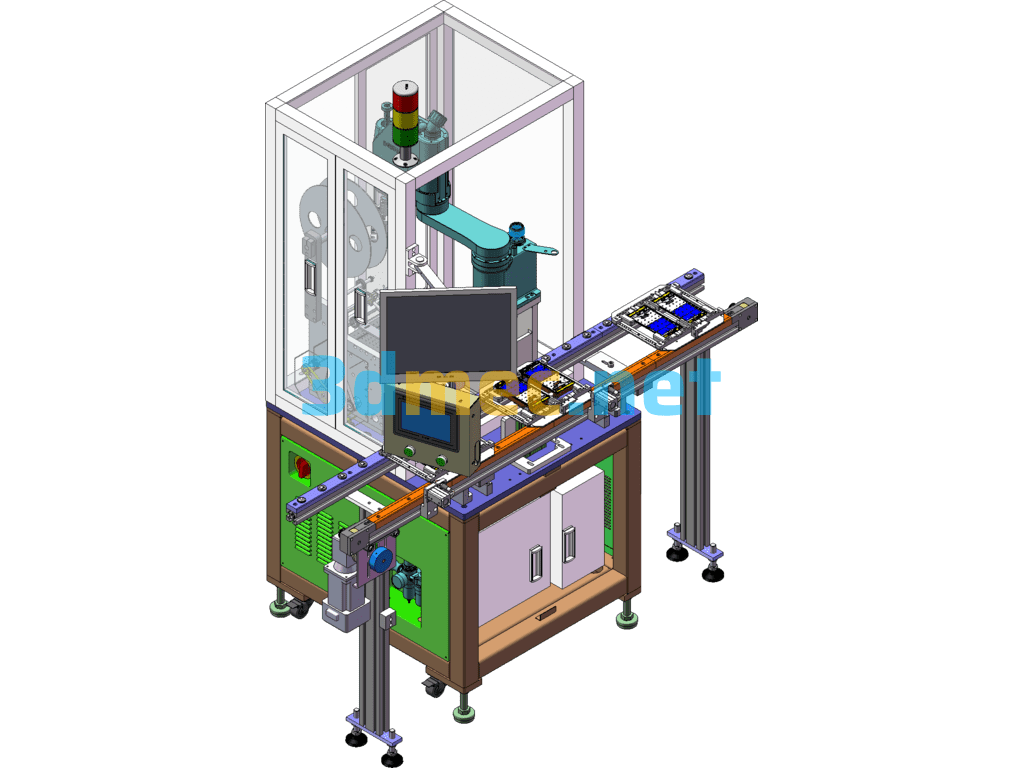

Offline Pulse Bag Dust Collector – 3D Model SolidWorks

At present, the cleaning methods of pulse bag dust collectors are divided into two methods: line-jet pulse blowing cleaning and air box pulse cleaning. The characteristics of these two cleaning methods are as follows:

Line-jet pulse blowing cleaning method: The cleaning kinetic energy is large, and each filter bag inside the dust collector can be thoroughly cleaned row by row evenly. The running resistance is small, the filter bag can be longer (can exceed 6m) and has a large aspect ratio, small size, small footprint, and light weight. Air box pulse cleaning method: The cleaning kinetic energy is large. Since one or two pulse valves are used to clean a bag chamber, to ensure that the cleaning is clean, the bag chamber cannot be too large and the filter bag cannot be too long. Large air box pulse dust collectors have a large number of filter bags and occupy a large area. Offline cleaning is adopted, but when the negative pressure in the equipment is large, it is not easy to realize online maintenance and bag replacement without stopping the machine.

Pulse jet cleaning is usually divided into high-pressure pulse jet cleaning and low-pressure pulse jet cleaning according to the air source pressure. The air source pressure range selected for this project is 0.4~0.6Mpa, that is, high-pressure pulse jet cleaning. The basis is as follows:

①High-pressure cleaning is more thorough, requires fewer cleaning times, saves high-pressure air source, brings in less external compressed air, reduces the load of the dust collector tail exhaust fan, and thus has low energy consumption and low operating costs.

②The compressed air source pressure range of the commonly used dust collector in cement plants is 0.4~0.6Mpa, which is convenient for unified management.

③High-pressure cleaning uses the least compressed air to induce more filtered clean hot air for cleaning, which is beneficial to the equipment’s anti-condensation

Specification: Offline Pulse Bag Dust Collector – 3D Model SolidWorks

|

User Reviews

Be the first to review “Offline Pulse Bag Dust Collector – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.