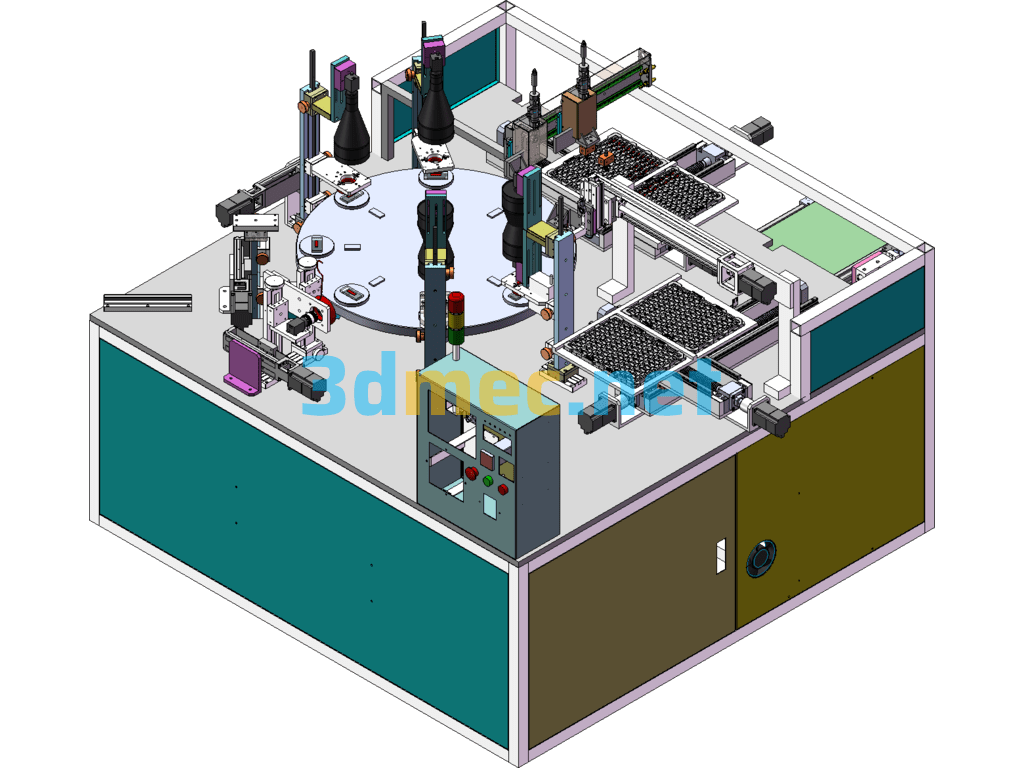

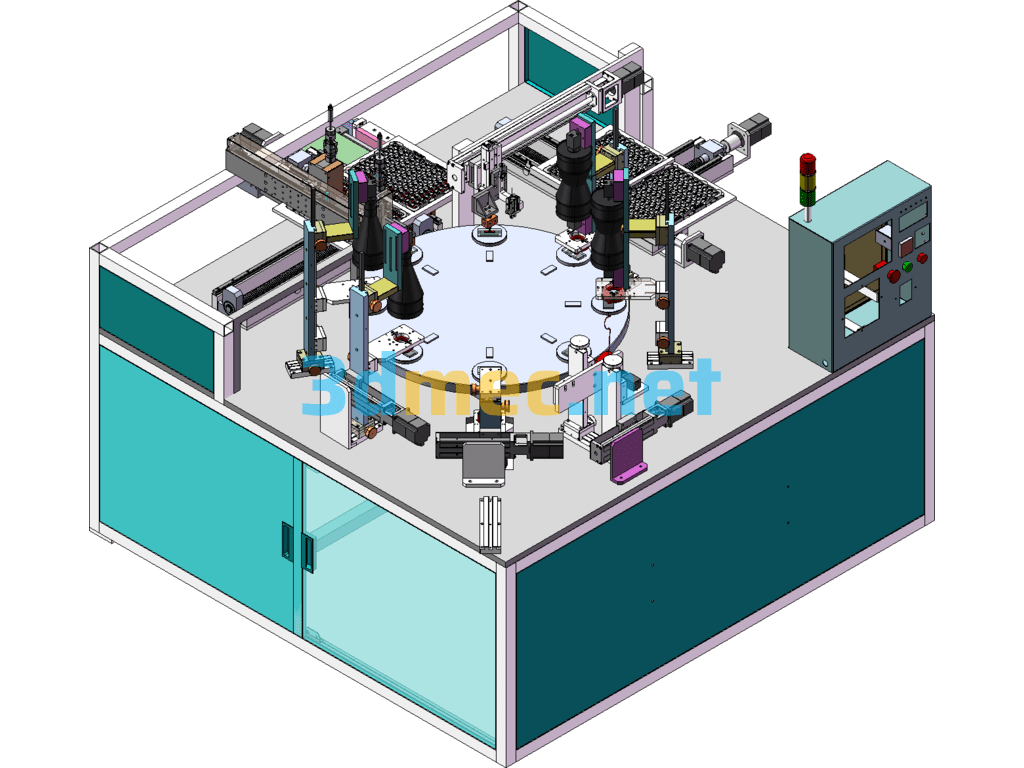

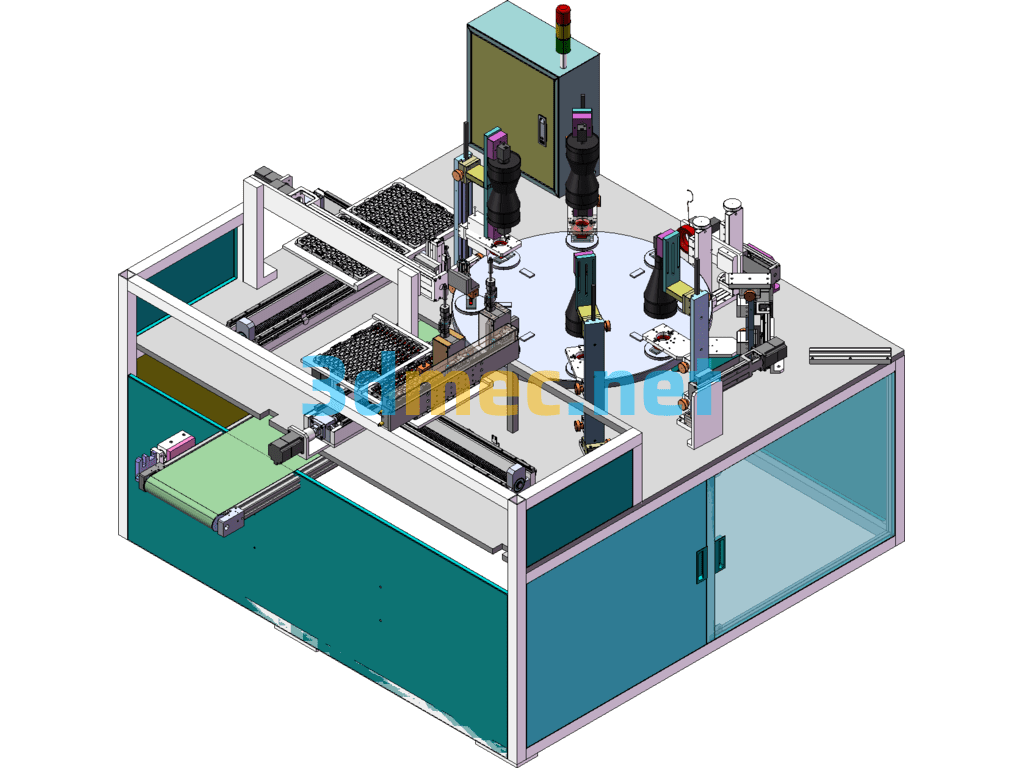

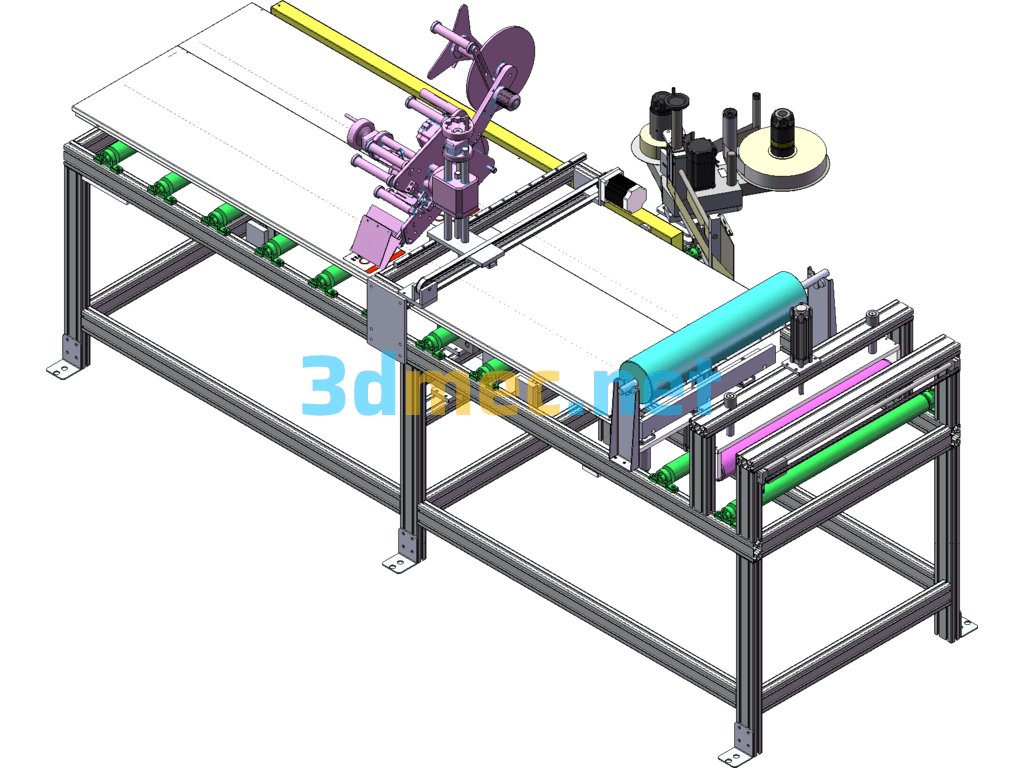

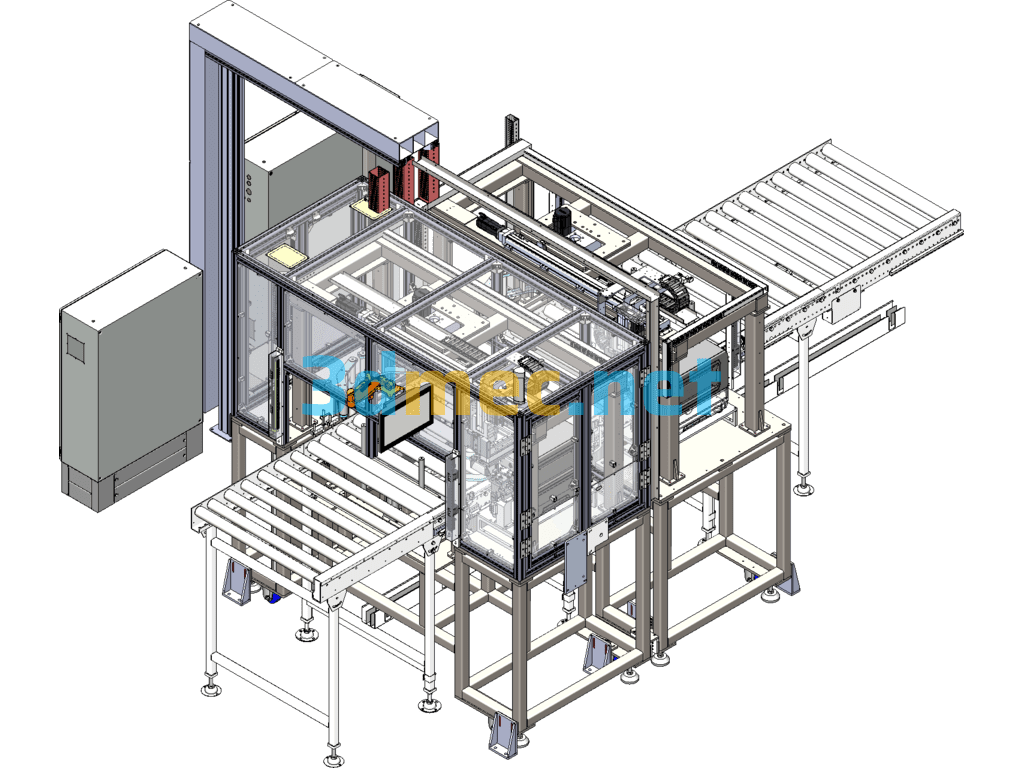

Non-Standard Composite CCD Visual Inspection Machine TCP613 – 3D Model SolidWorks

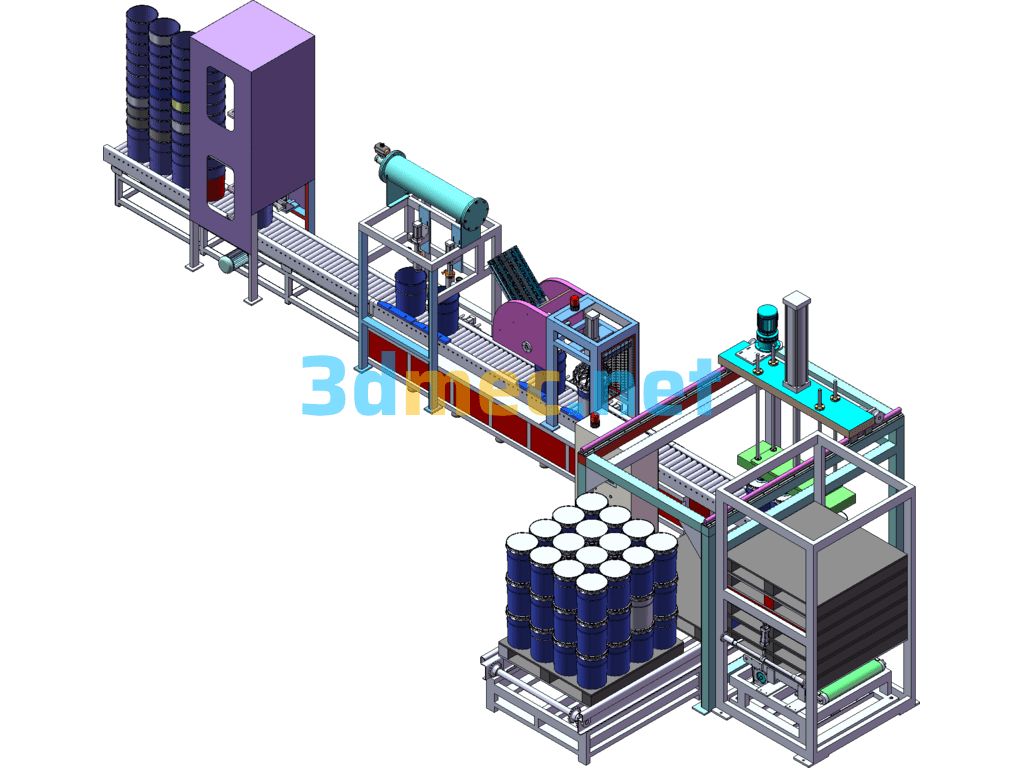

Description of the structure and principle of TCP613 composite detector 1. Equipment Description The products suitable for this detection system equipment are: TCP613 products are produced. This equipment is a multi-functional CCD vision machine: the equipment is mainly used to detect defects in appearance, flatness, etc. of precision products. For example, defects in appearance and size tolerances of precision electronic components and precision parts can be detected using this equipment. Select, the equipment has multiple functions. The whole machine is equipped with 7 CCD cameras. It can be said that basically all six sides of the product can be detected. Robot picking, CCD vision non-standard composite CCD vision inspection machine TCP613, multi-station turntable structure and This equipment is equipped with common mechanisms such as discharging conveyor belts. two. The main detection functions of the equipment are as follows: 8. 2# laser profile measuring instrument (bottom): Driven by the linear module, the measuring instrument scans the height direction dimensions of the product along the length direction of the product, and uploads the count to the host for analysis and judgment. Testing: 100.584±0.052 (FAI21), repeatability: ±0.005; 9. Discharging robot: suck the product from the indexing plate and follow the attributes indicated by the software. If it is unqualified, put it on the unqualified conveyor belt. If it is a qualified product, put it on the qualified blister tray and arrange it in order. three. Equipment performance and main configuration description: 1. Detection speed: about 15 pcs/min. 2. Repeatable detection accuracy: See the third item of Article 2 for details. 3. Description of main accessories: 1), CCD camera: German brand BASLER; 2), sensor: OMRON; 3), PLC: Japan Mitsubishi high-speed series; 4), solenoid valve: original American brand; 5), control system: Independent development. 4. Human-machine interface, the software automatically comes with a toolbox, a convenient Microsoft Windows operating system specially developed for ordinary employees; 5. Production data report statistical function: CPK, Plato, defective type items, defective ratio and other automatic generation functions can be used for It provides the basis for improving the process in the production workshop; 6. Testing data output system: This screening machine has data communication functions, data output and storage functions. The data exported by the software can be connected to the printer through the LAN for paper printing. 4. Main technical parameters: Category specification parameters Overall dimensions of the machine: 120010501700 (LWH) Input voltage: AC-220V50Hz or AC-380V 50Hz optional Maximum power of the machine: 1.2KW (at 220V) Input air source pressure: 0.4-0.6 Mpa Air consumption: 1.5 L/min Production efficiency (C/T): ≤2.0 S/one equipment utilization rate: ≥95% Processing method: automatic material taking, material changing, visual NG material distribution, conveying and unloading robot motion resolution Rate: 0.005 mm Repeatable positioning accuracy of the manipulator: ≤±0.02 mm Control communication method: Manual disk placement Programming method: Touch screen parameter modification The above are the functions and original features of this device. I won’t introduce more here. If you like it, just download it for research. Okay, if you don’t understand the detailed structure and problems of other data objects, you can have time to study and study them slowly after downloading. In short, this is a very good set of multi-functional CCD visual inspection equipment drawings. You are also welcome to study and study it. Thank you.

Specification: Non-Standard Composite CCD Visual Inspection Machine TCP613 – 3D Model SolidWorks

|

User Reviews

Be the first to review “Non-Standard Composite CCD Visual Inspection Machine TCP613 – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.