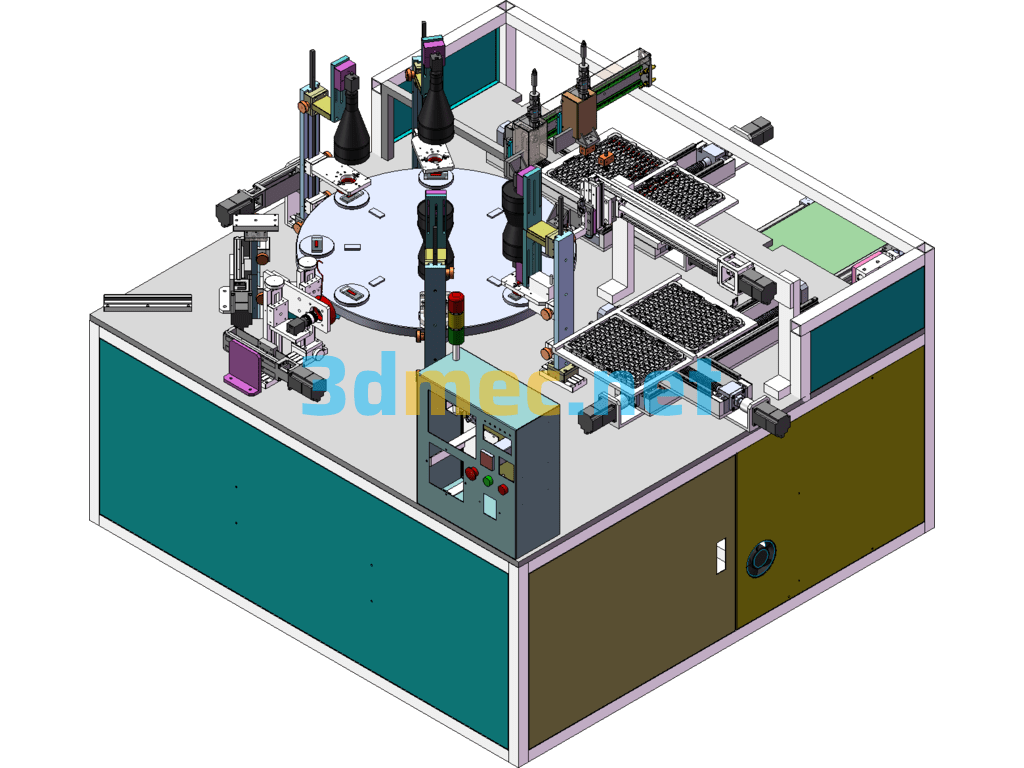

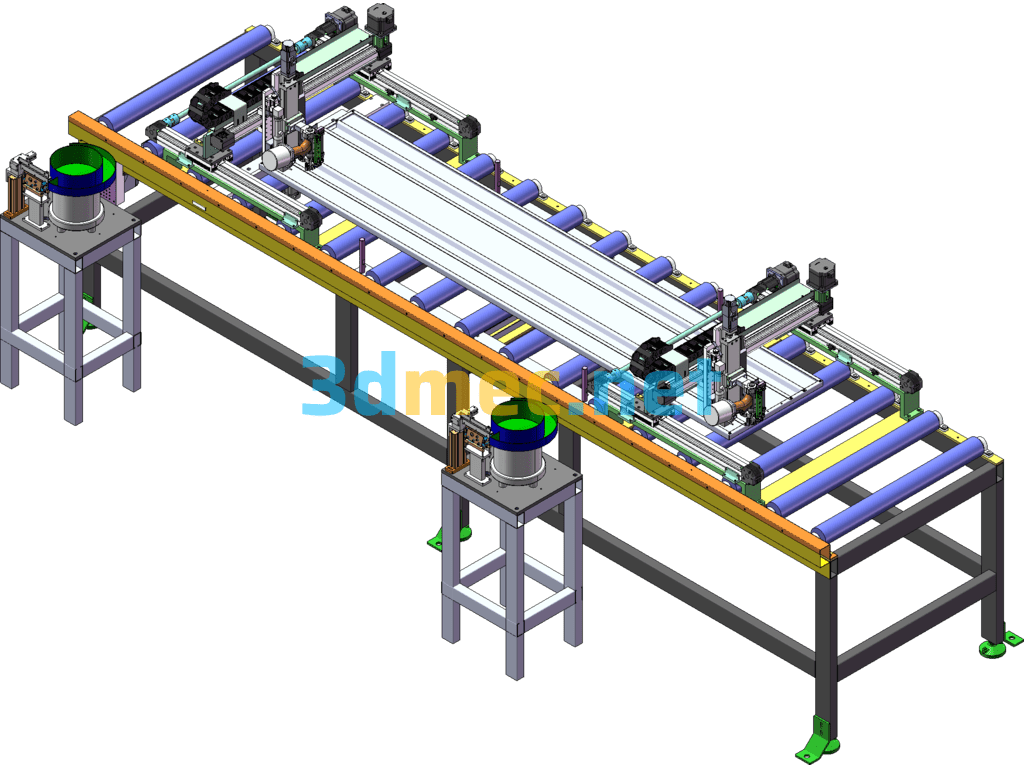

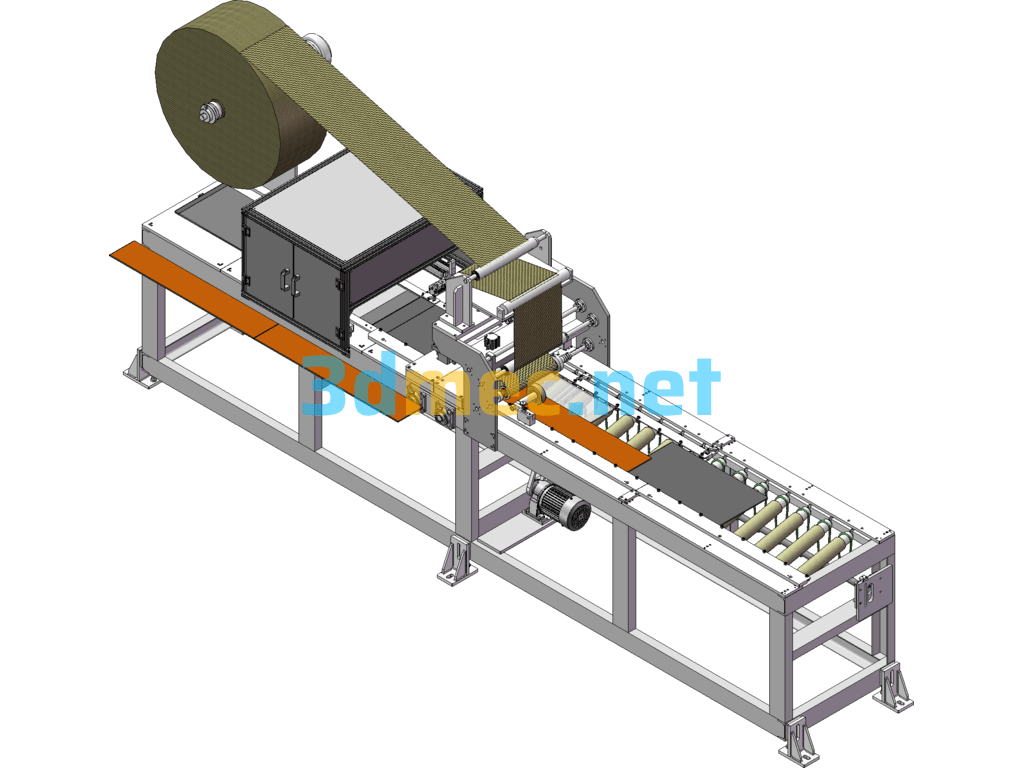

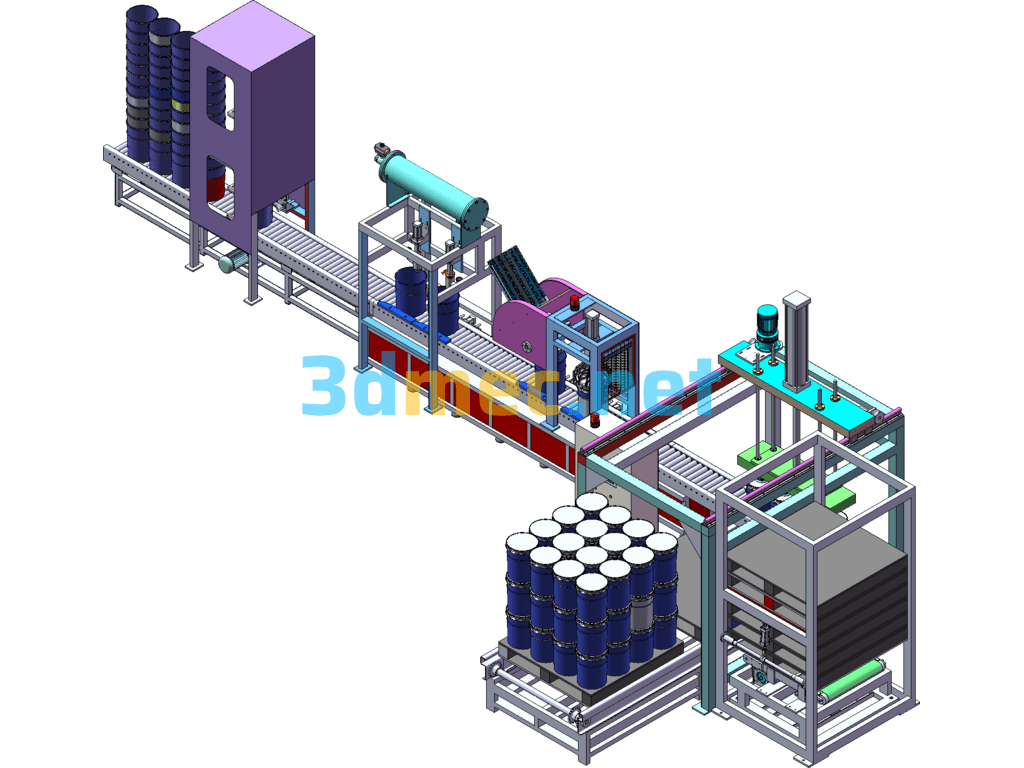

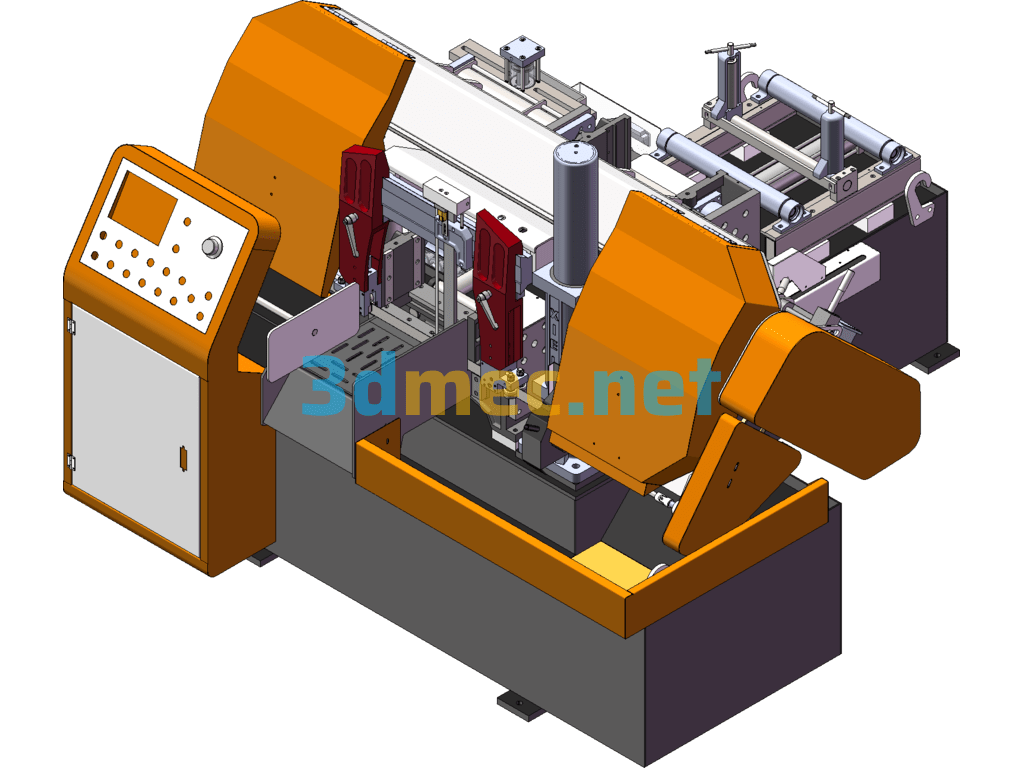

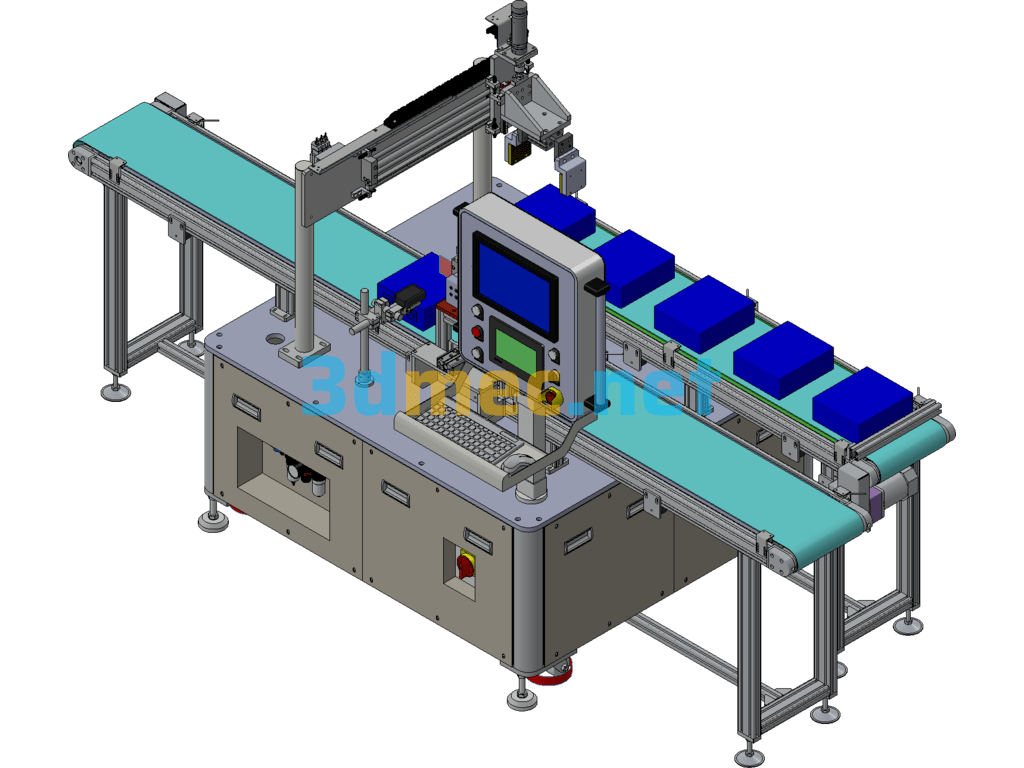

TCP613 Composite Inspection Machine Structure and Principle Help I. Equipment Description Equipment Description This inspection system is applicable to the production of TCP613 products. The equipment is a multifunctional CCD vision machine: equipment is mainly used to detect the appearance of precision products such as bad flatness bad, such as precision electronic components and precision parts of the appearance and size tolerances and other bad can be detected with this equipment to sorting, the equipment features more than the whole machine is equipped with seven CCD cameras can say that the product of the six sides basically can be detected, robot pickup, CCD vision non-standard, the CCD vision machine can be used for the inspection of the products. Composite CCD vision inspection machine TCP613,, multi-station turntable structure and discharge conveyor belt and other commonly used institutions the device have. II. The main detection function of the equipment has the following points, 8, 2 # laser contour measuring instrument (bottom): measuring instrument in the linear module driven, along the length of the product scanning product height direction dimensions, and will be uploaded to the host number of analysis and judgment, detection: 100.584 ± 0.052 (FAI21), the repeatability of accuracy: ± 0.005; 9, out of the material manipulator: from the indexing plate to absorb the product, and according to the software instructions. attributes indicated by the software, if it is unqualified, it will be put into the unqualified conveyor belt, if it is qualified product, it will be put into the qualified blister disk and arranged in order. III. The performance of the equipment and the main configuration description: 1. Detection speed: about 15 pcs/min. 2. Repeat detection accuracy: see the third item of Article 2 for details. 3. 3, the main accessories description: 1), CCD camera: German brand BASLER; 2), sensor: OMRON; 3), PLC: Japan’s Mitsubishi high-speed series; 4), solenoid valve: the original U.S. brand; 5), control system: self-developed. 4, man-machine interface, software automatically with a toolbox, developed specifically for the general staff of the convenient Microsoft Windows operating system; 5, production data report statistical functions: CPK, Plato, defective types of items, the proportion of defective and other automatic generation of the function of the production workshop can provide the basis for the improvement of the process; 6, test data output system: the screening machine has a data communication function, with data output and storage function, the data exported by the software can be through the local area network (LAN). The data exported by the software can be printed on paper by connecting the printer through LAN. IV. Main Technical Parameters: Category Specifications Dimensions: 120010501700 (LWH) Input Voltage: AC-220V50Hz or AC-380V 50Hz optional Maximum Power: 1.2K W (220V) Input Air Pressure: 0.4-0.6 Mpa Air Consumption: 1.5 L/min Production Efficiency: 1.5L/min 1.5 L/min Production efficiency (C/T): ≤ 2.0 S / a equipment load factor: ≥ 95% Processing mode: automatic pickup, material change, visual NG material, conveyor under the material manipulator movement resolution: 0.005 mm manipulator repetitive positioning accuracy: ≤ ± 0.02 mm control and communication mode: manual release of the disk programming mode: touch screen parameter modification The above is the function of the equipment and the original more There, here is not much to introduce a favorite directly download the study can be, other according to the body of the details of the structure and the problem if you do not understand if you download can have time to slowly learn to study, in short, this is a very good set of multifunctional CCD visual inspection equipment drawings, you are welcome to learn to study Thank you.

Specification: Non-Standard Composite CCD Vision Inspection Machine TCP613 SolidWorks 3D Model

|

User Reviews

Be the first to review “Non-Standard Composite CCD Vision Inspection Machine TCP613 SolidWorks 3D Model”

You must be logged in to post a review.

There are no reviews yet.