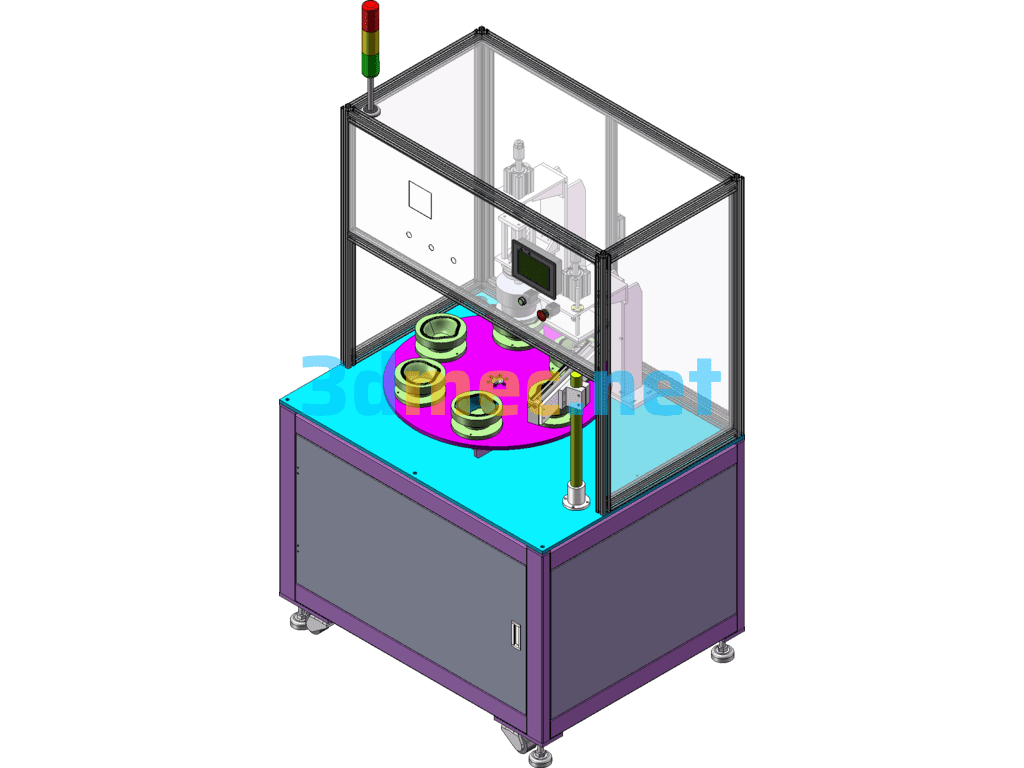

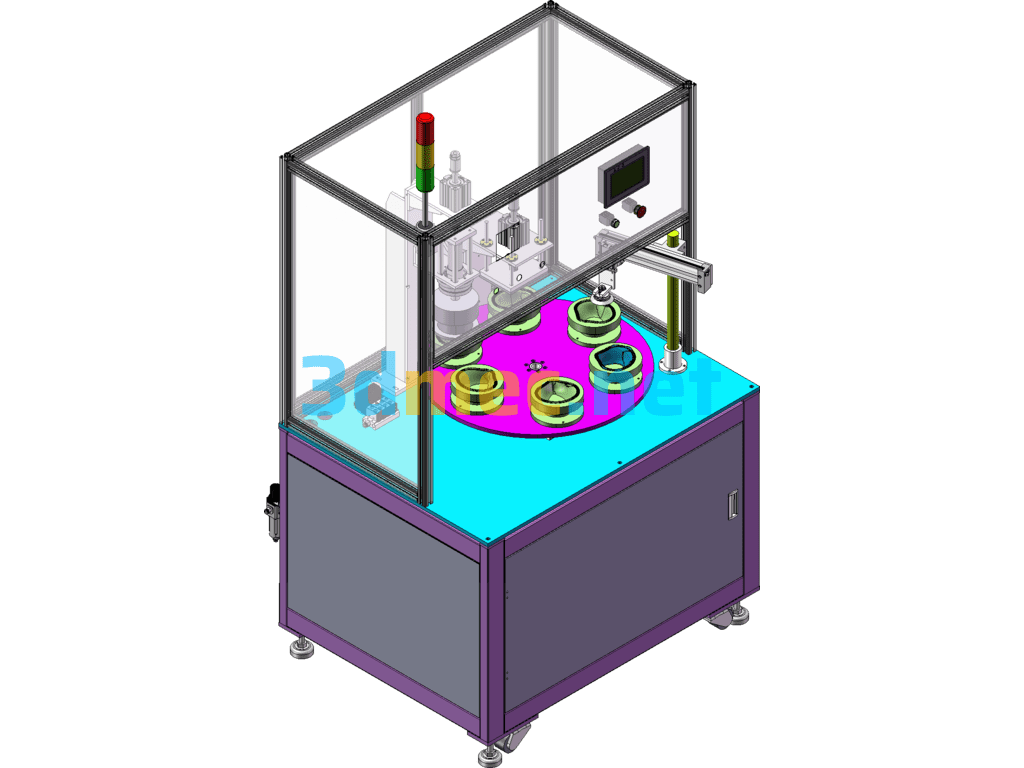

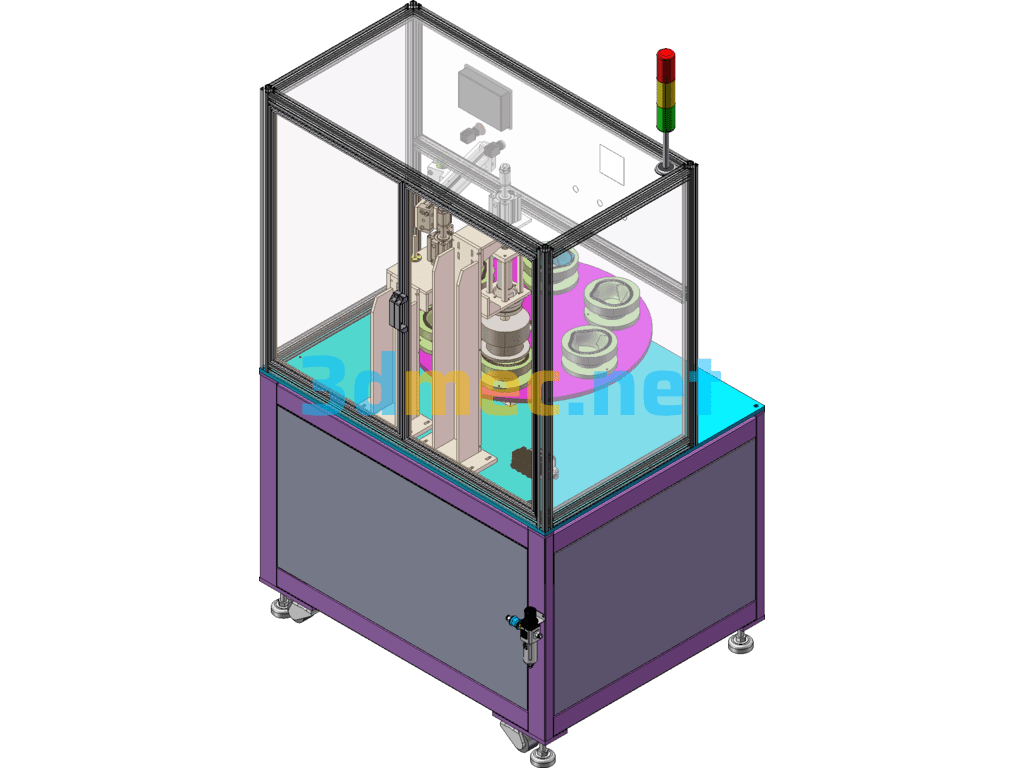

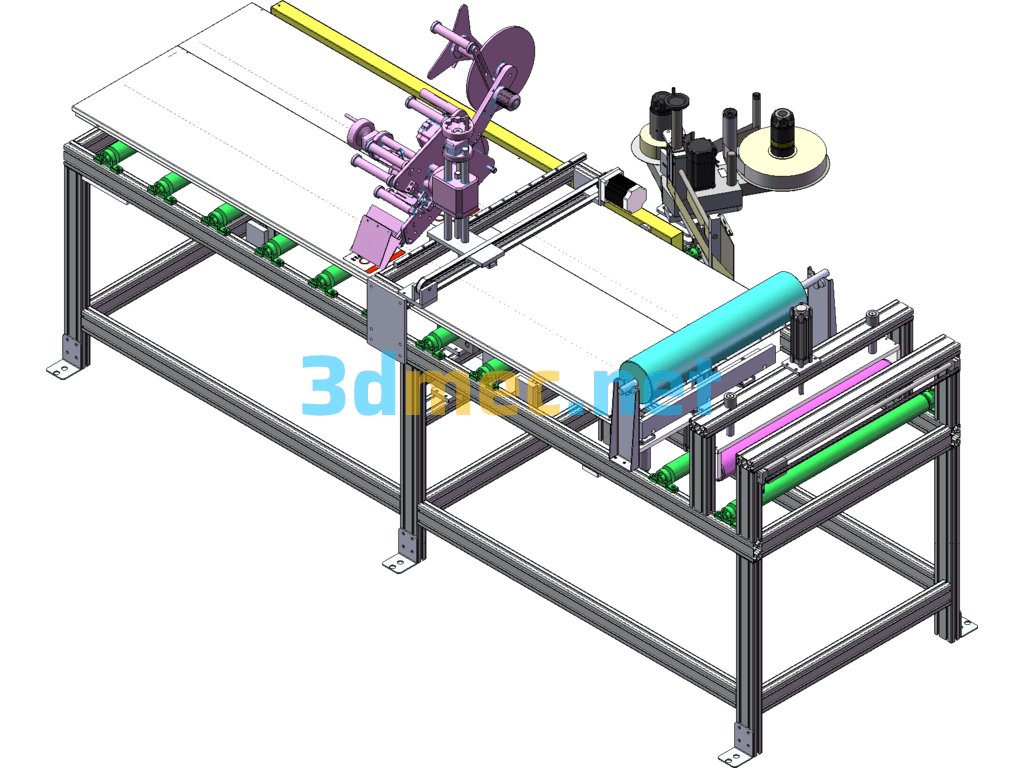

N95 Cup Mask Edge Sealing And Trimming Machine – 3D Model SolidWorks

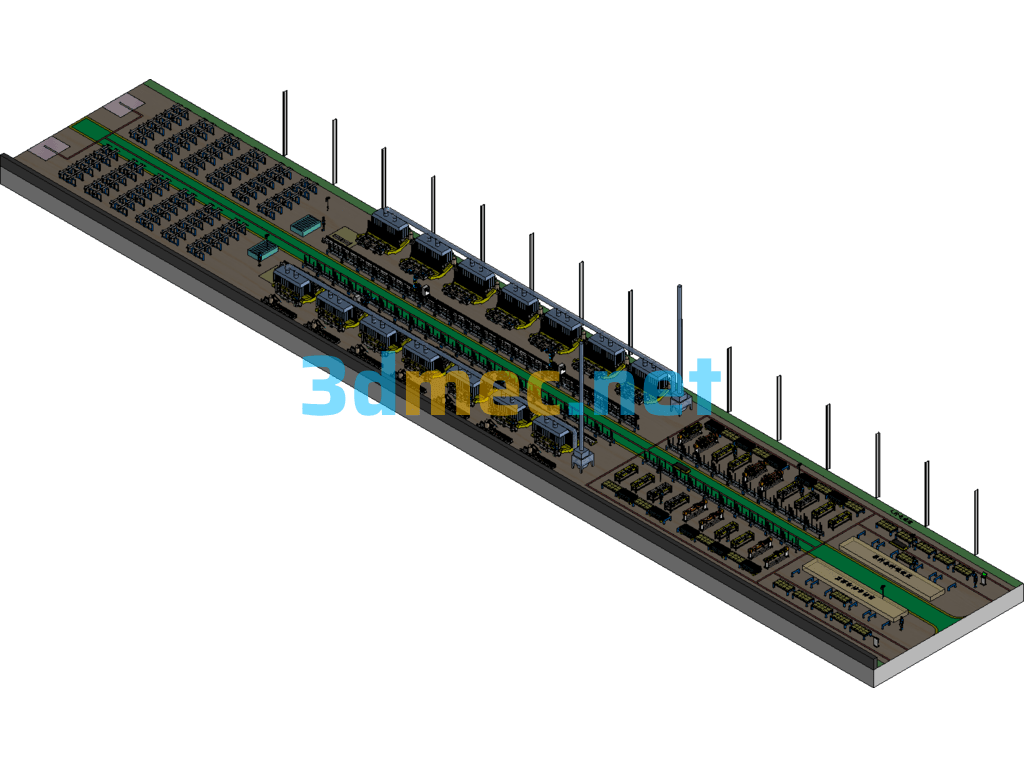

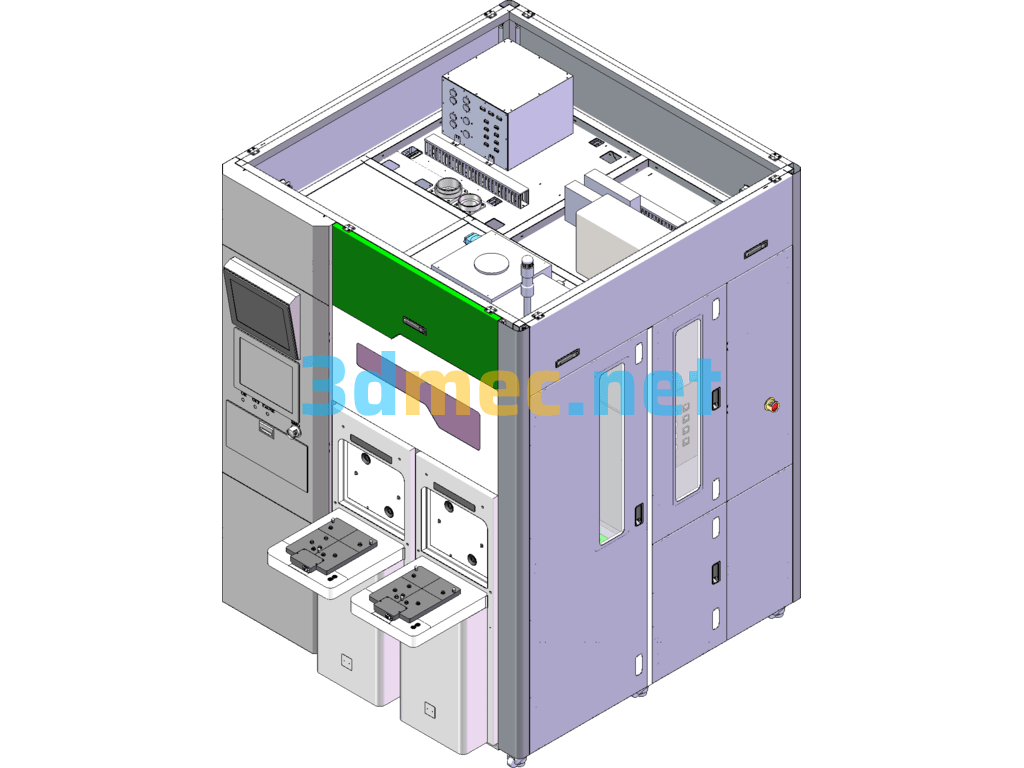

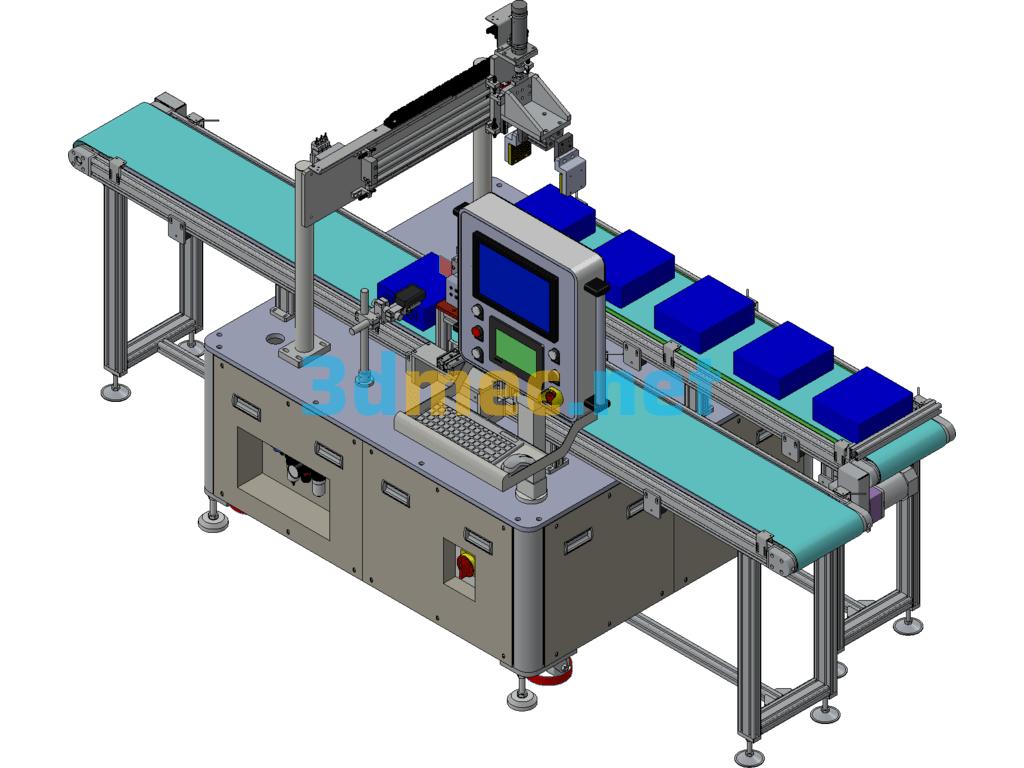

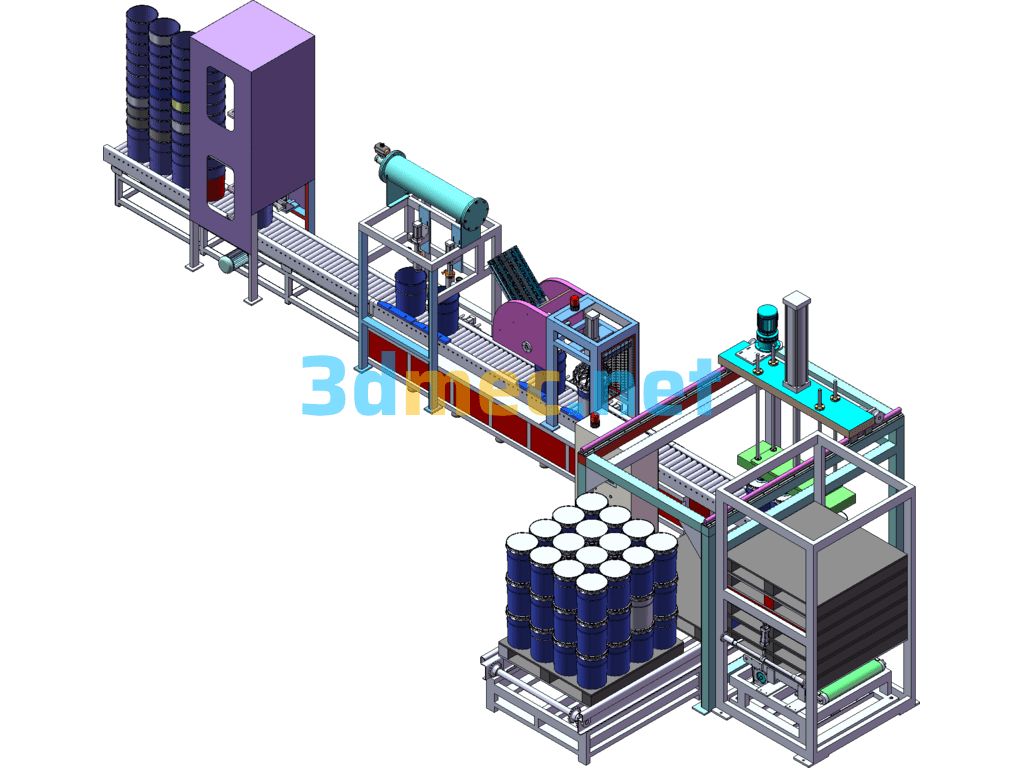

The cup-shaped mask edge sealing and trimming machine can automatically complete multiple processes from feeding, edge sealing, cutting and unloading. Compared with traditional manual feeding, unloading and cutting, it can save 3-5 manpower and produce 20-26 masks per minute. It adopts PLC control system and touch screen setting. The operation is simple and fast. It can be used by one person and one machine. Only manual feeding and taking are required. It greatly improves production efficiency.

The equipment mainly uses the principle of ultrasonic automatic welding and edge sealing to complete the special-shaped cutting and welding of slices. The machine solves the shortcomings of traditional lace machines such as inaccurate positioning, inaccurate size control, low production efficiency and high labor costs. It integrates many processes such as feeding, ultrasonic cutting, waste separation, finished product segmentation, etc., which greatly improves production efficiency, reduces production costs, and makes products more standardized, more stable in quality and more beautiful in appearance.

N95 cup-shaped mask edge sealing and trimming machine 3D model + engineering drawing

Specification: N95 Cup Mask Edge Sealing And Trimming Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “N95 Cup Mask Edge Sealing And Trimming Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.