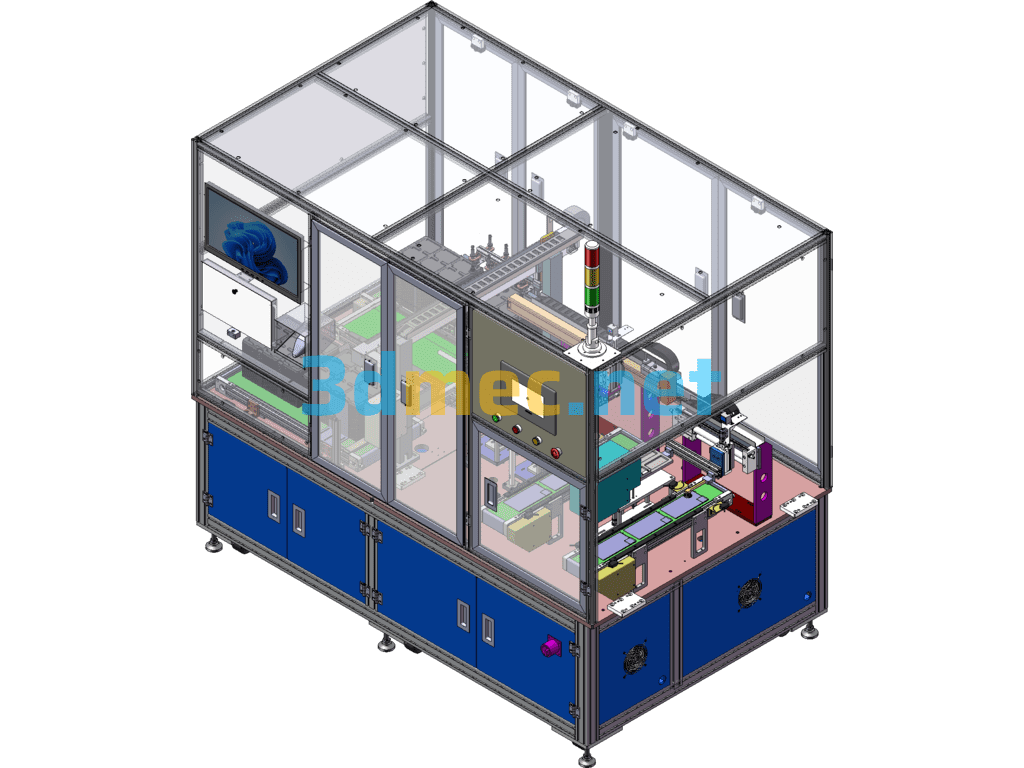

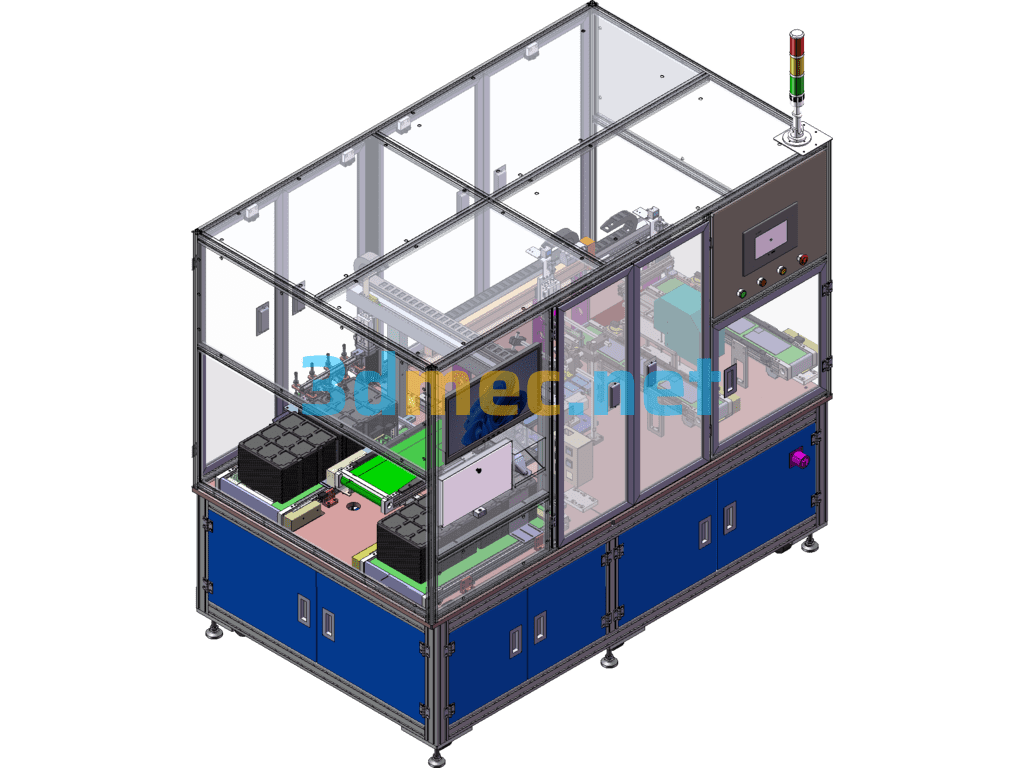

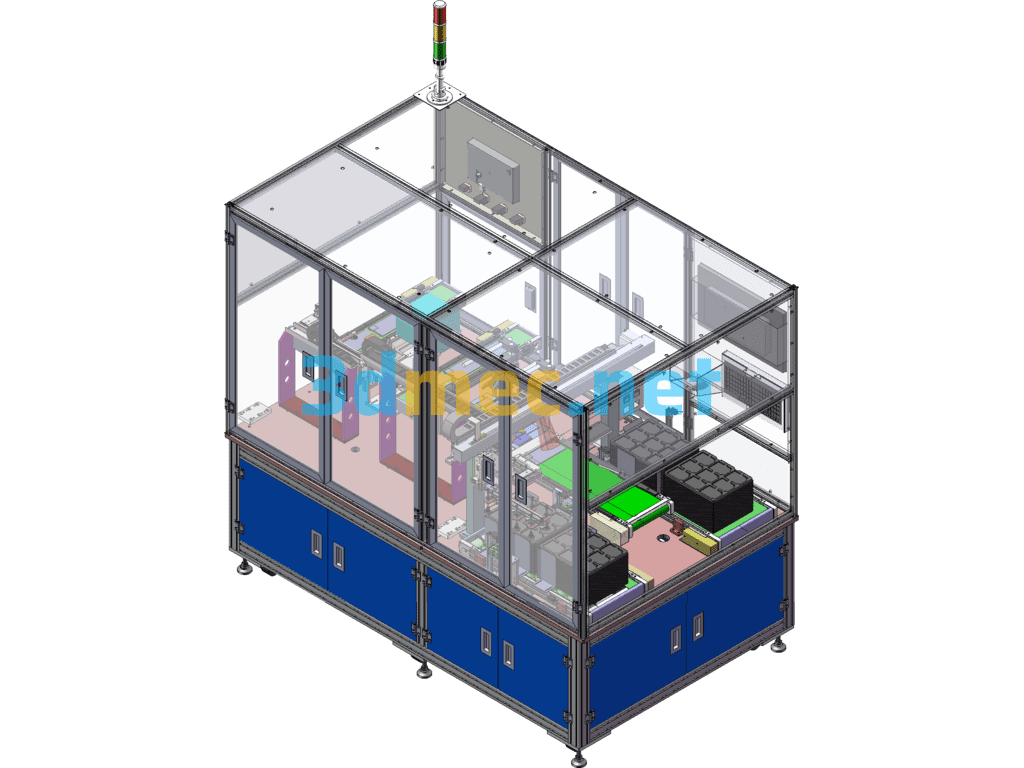

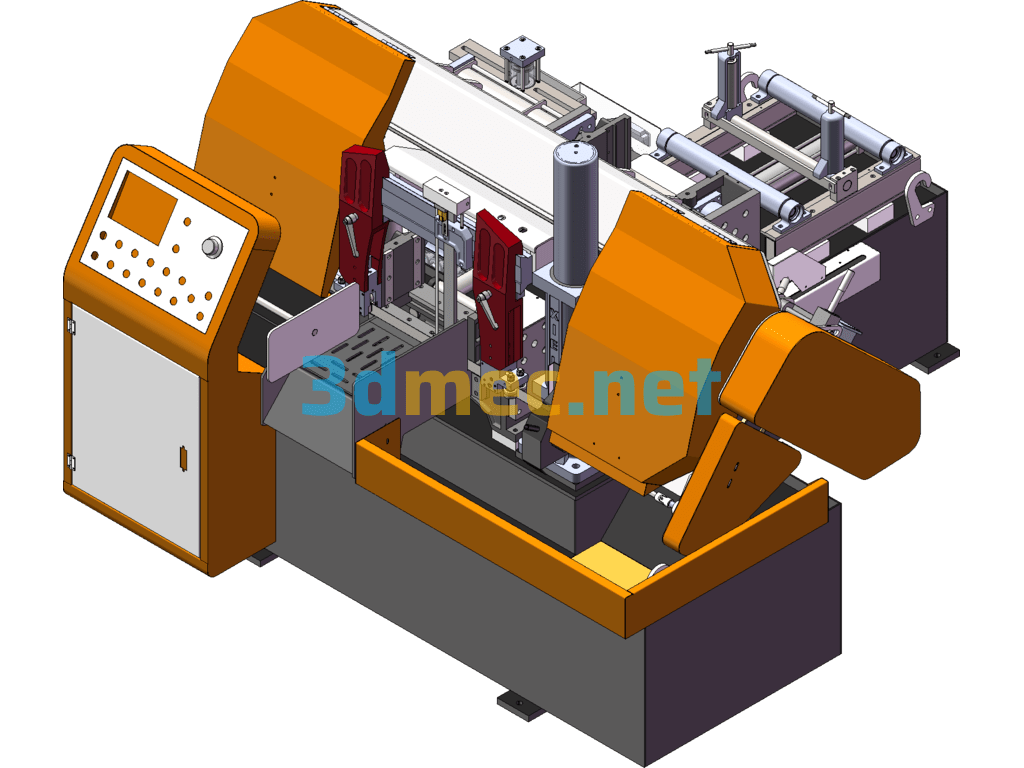

Lithium Battery Edge Voltage And Thickness Dimension Testing Machine – 3D Model SolidWorks

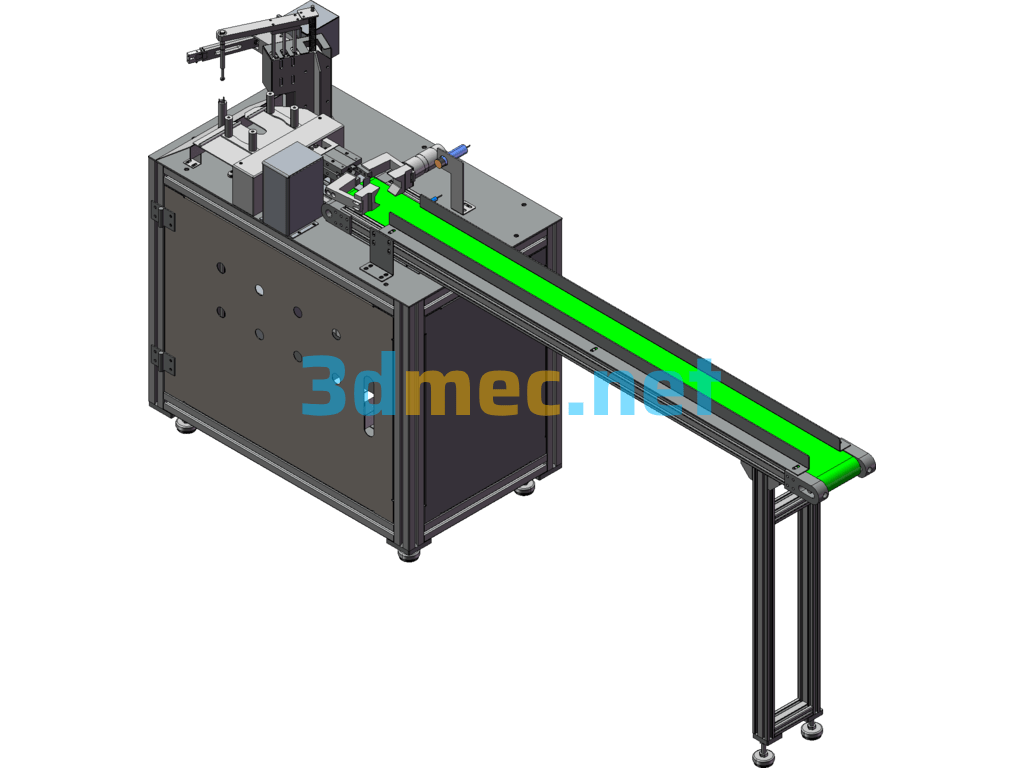

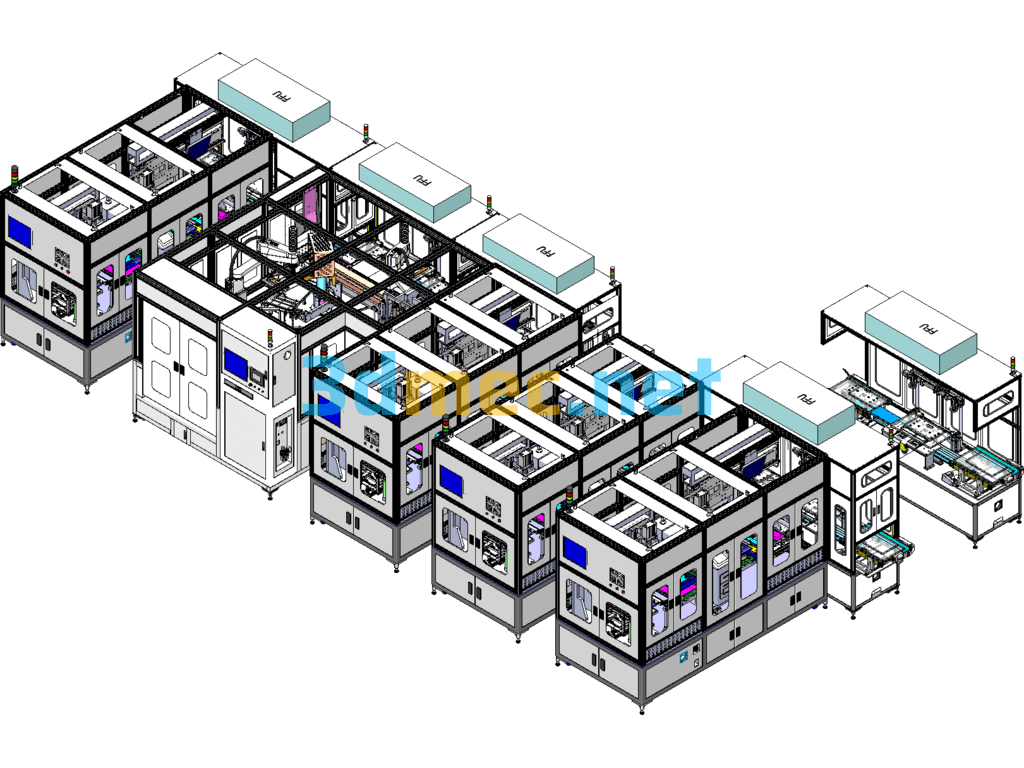

This machine is a battery PACK segment of a battery side voltage thickness detection device, the drawings of the device are 300MB, large and small parts drawings add up to almost 500, the 3D model of the device is designed with SolidWorks 2012 software, a full set of drawings are original design drawings, the quality of the drawings is better than other members of the drawings are all original download can be directly opened with SolidWorks, the device is a soft pack battery side voltage thickness detection device, its main function is to perform side voltage thickness testing on the battery and other work, and finally grab the tested battery to the unloading station, the test of the defective catch the bad belt out, the equipment is fully automatic operation, its main structural components include the following: 1. Automatic lifting feeding tray assembly 2. Automatic handling robot 3. Feeding belt module 4. Battery side voltage test, 4. Battery automatic scanning module, 5. Battery leakage detection module, 6. Battery handling robot, 7. Detection of bad belt line, 8. Battery thickness detection module, 9. Battery thickness detection bad and unloading robot. The working principle of the equipment is introduced: the battery loading is blister tray loading, and many trays can be stacked at one time. The stacking loading method is adopted so that the material does not need to be changed frequently. The tray is transported in by the feeding belt line. When it is detected in place, the lifting mechanism at the bottom lifts up one tray at a time, and then the robot takes the battery in the tray for loading. After the battery is grabbed, the empty tray is grabbed by the robot to the other side for recycling. Then the next tray is lifted up and the battery in the next tray is taken out. The battery is moved by the robot to the feeding belt. The battery is sent from the belt to the loading station for secondary positioning. The positioning mechanism is at the rear end of the feeding belt by a cylinder and an induction After the device completes the pushing and positioning action, the next robot grabs the battery for edge voltage and leakage test. If there is a bad test, it will be placed in the bad discharge belt line and flow out. If the test is OK, it will be transported to the thickness detection station for battery thickness test. After the test is completed, the robot grabs the battery to the unloading station. Similarly, the defective products are directly discharged, and the good products are sent to the next station for packaging and receiving. The above is the complete introduction of the mobile phone battery edge voltage thickness detection machine. Because the drawings contain more content, the detailed structure and details need to be downloaded before you can better understand it. This equipment is used in the soft pack battery PACK processing line. You are welcome to download and learn from it. It is very good.

Specification: Lithium Battery Edge Voltage And Thickness Dimension Testing Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “Lithium Battery Edge Voltage And Thickness Dimension Testing Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.