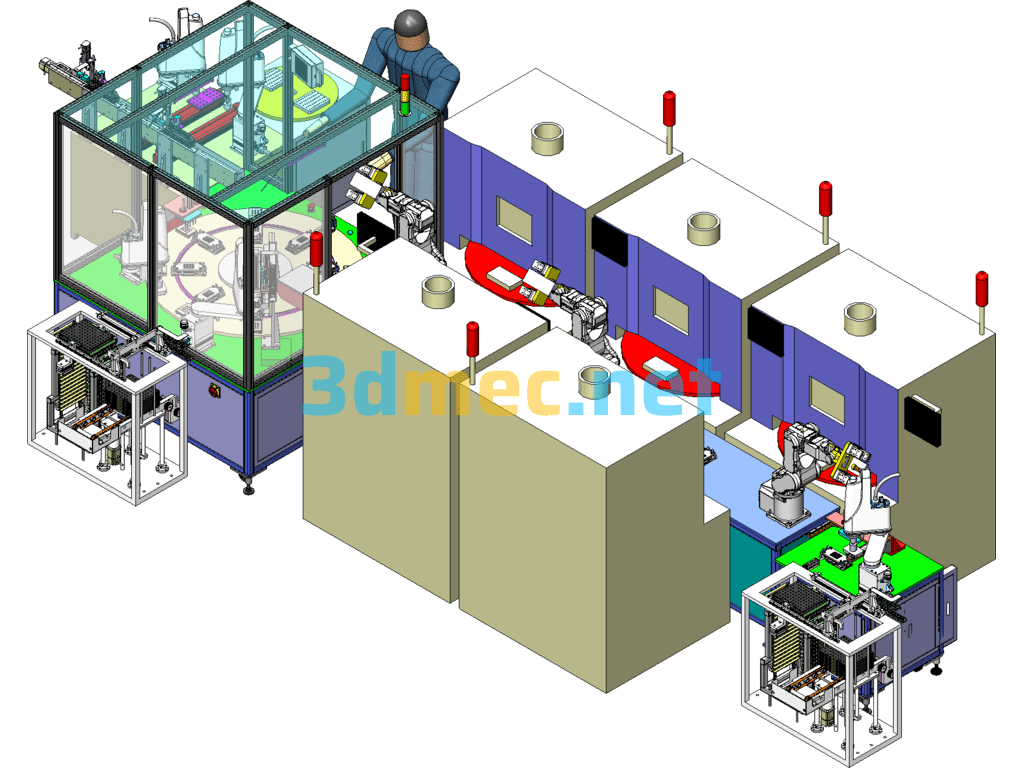

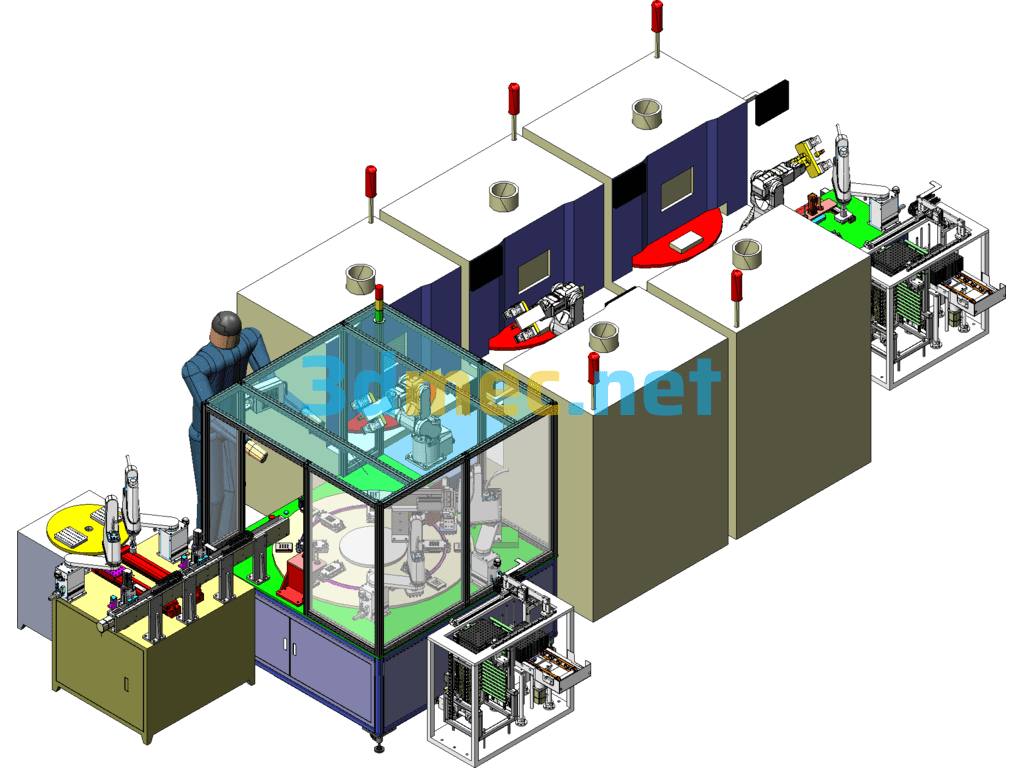

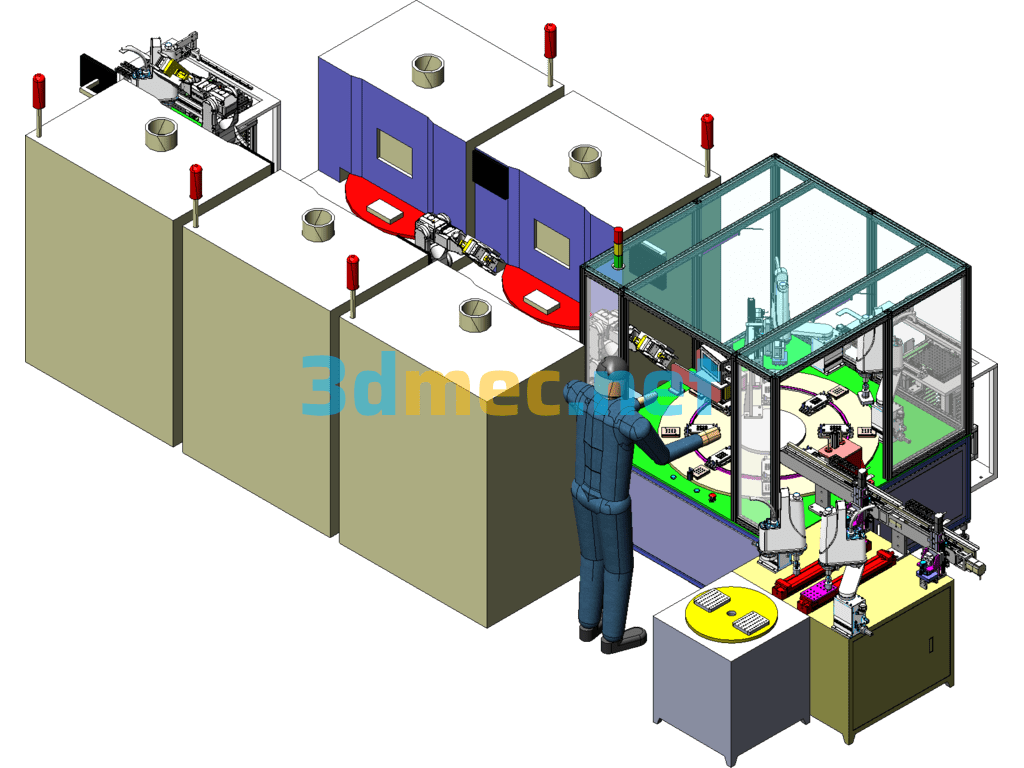

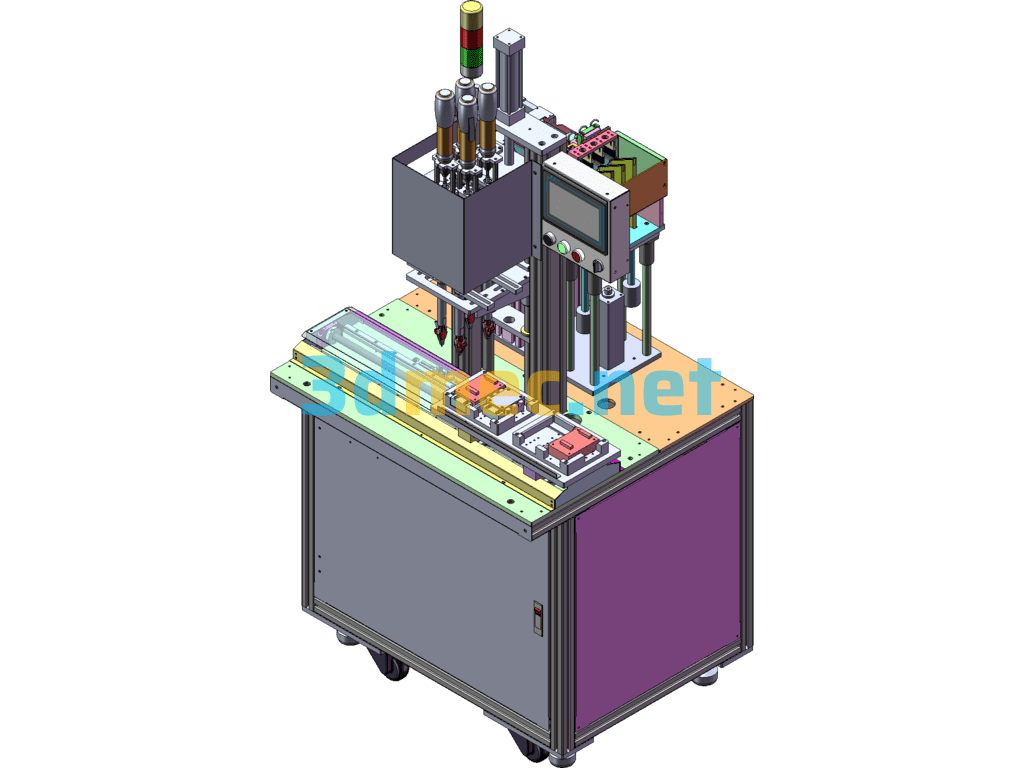

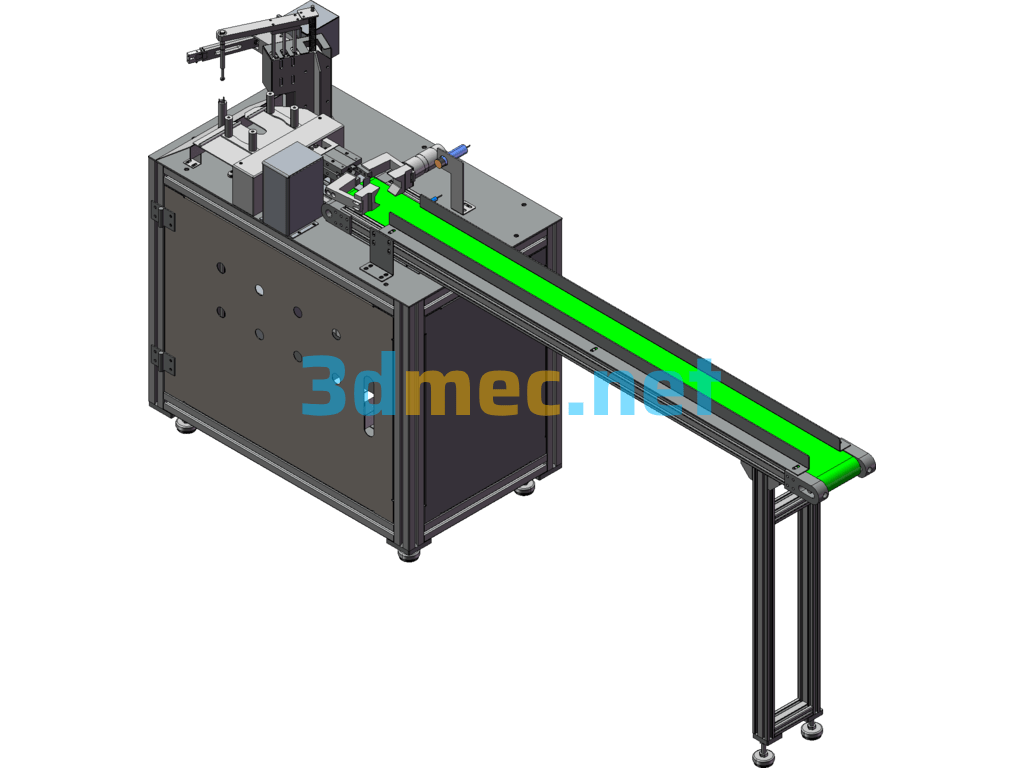

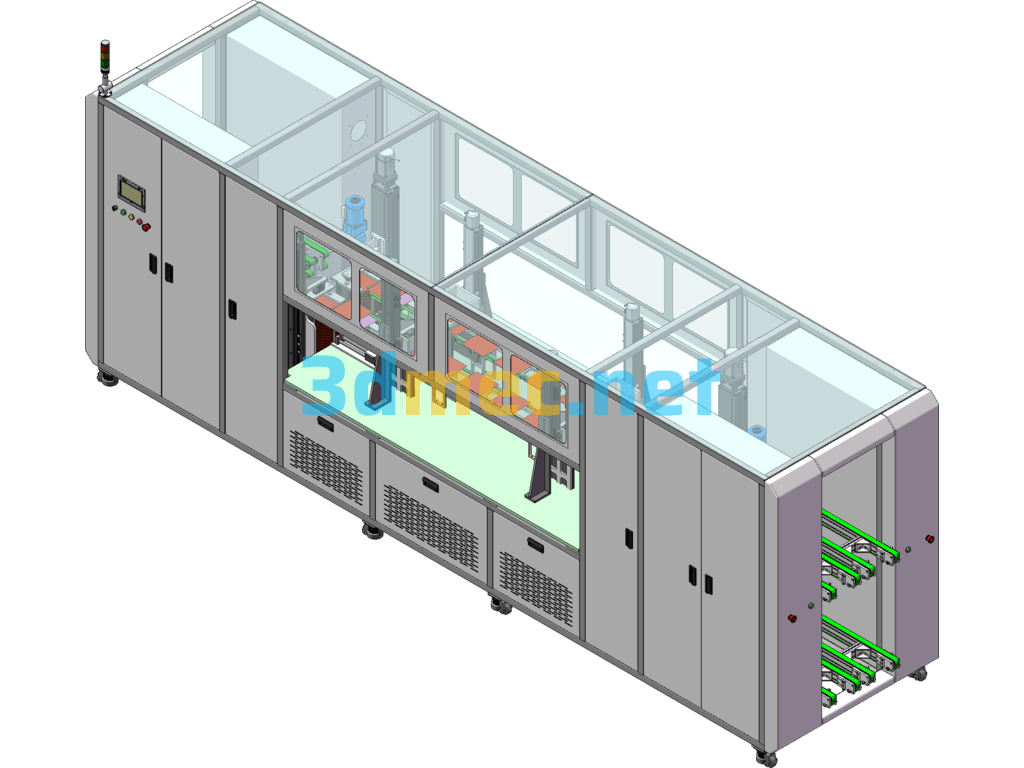

LED Shell Dispensing Detection And Pressure Holding Equipment (Already Produced) – 3D Model SolidWorks

LED shell dispensing detection pressure holding equipment (already produced) action description:

1. Enter the assembly station through the indexing plate;

2. Manually load the LED Tray into the equipment through the Tray feeding cylinder;

3. The X, Y module carries the Z-axis cylinder to the Tray to absorb the LED and rotate

(Rotate at the same angle as the assembly station) and move to the CCD module to shoot

Position the relative position with the assembly station;

4. The module moves to the assembly station, and the Z-axis cylinder cooperates with the buffer to assemble the LED;

5. The unloading module moves the assembled HSG to the pressure holding fixture 10Pcs;

6. The cylinder feeds in and out and sends the pressure holding fixture to the pressure holding station, and the pressure holding cylinder works;

(The pressure holding head is pressure-maintained, and the product is protected by the buffer spring)

Specification: LED Shell Dispensing Detection And Pressure Holding Equipment (Already Produced) – 3D Model SolidWorks

|

User Reviews

Be the first to review “LED Shell Dispensing Detection And Pressure Holding Equipment (Already Produced) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.