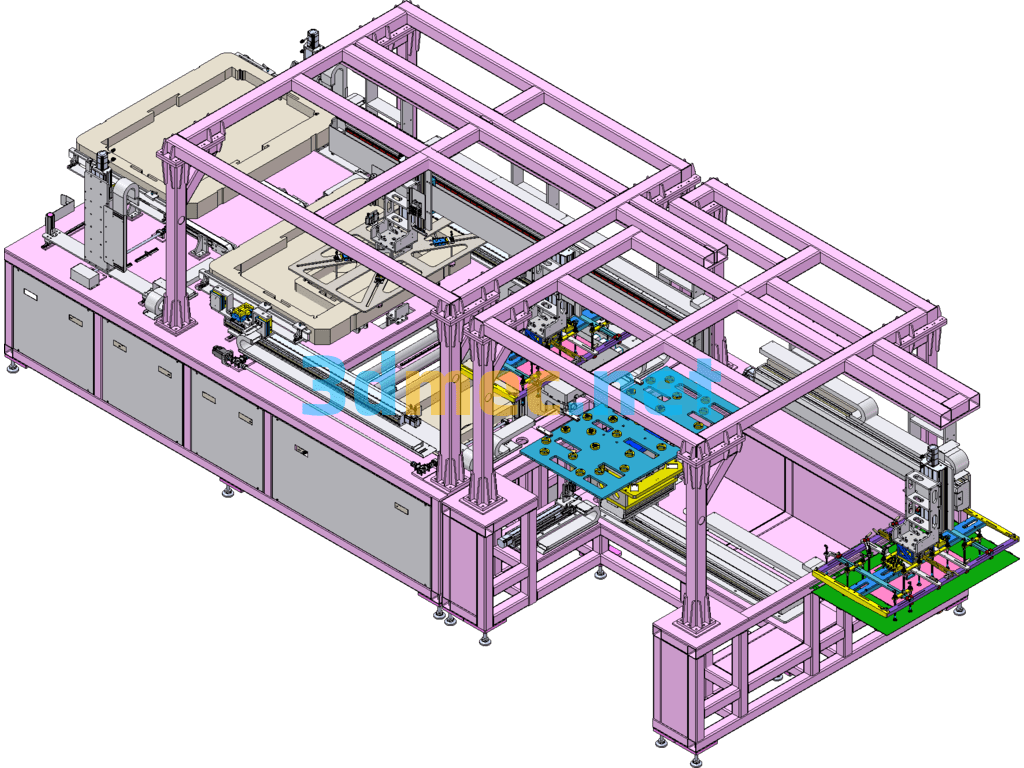

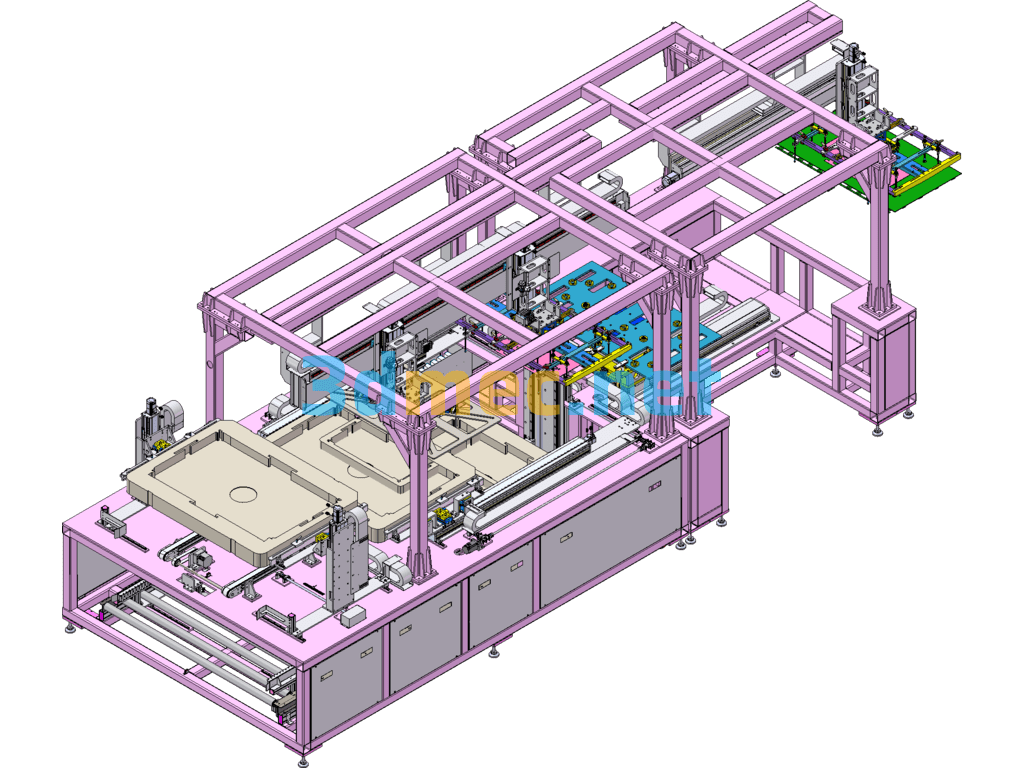

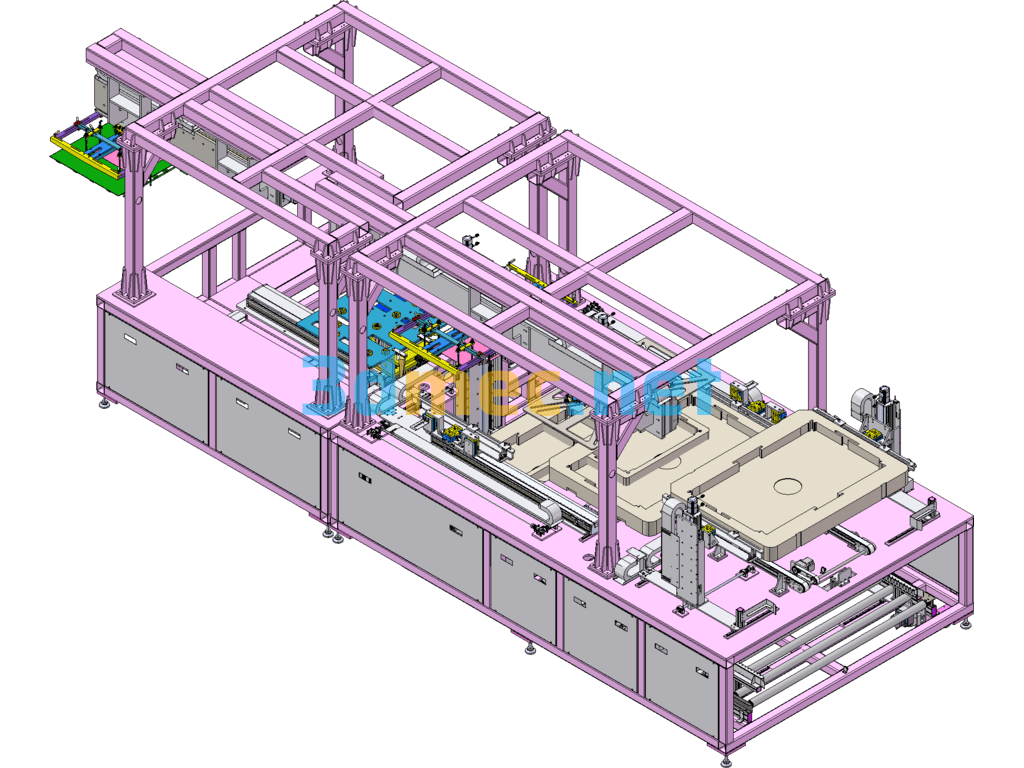

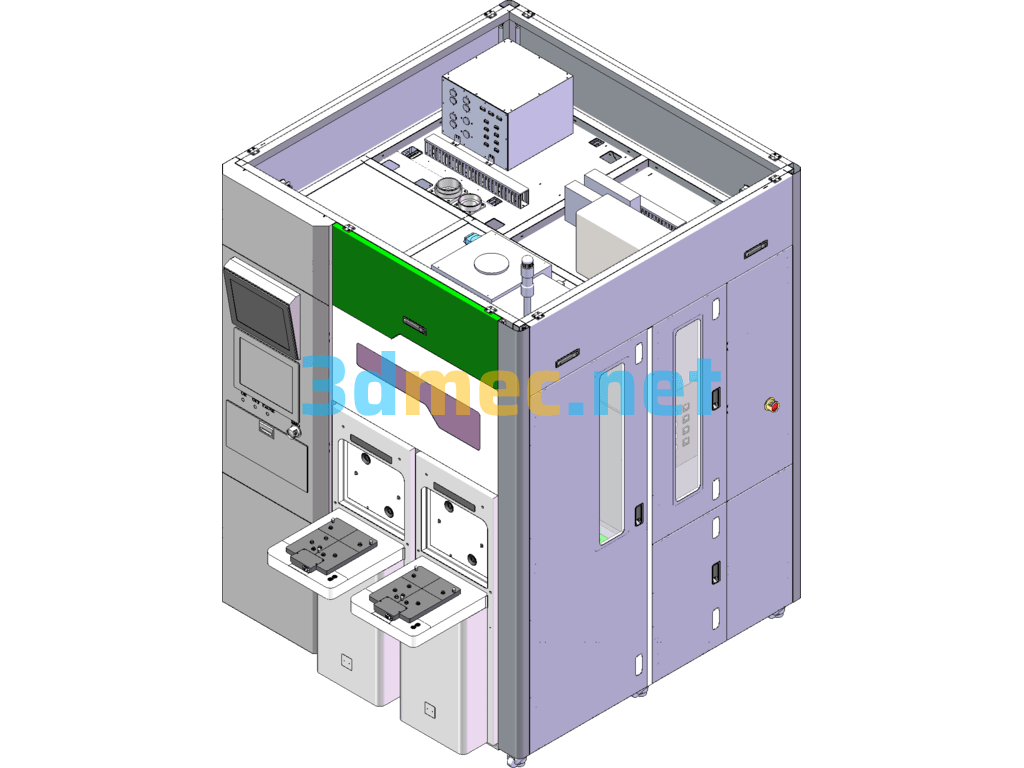

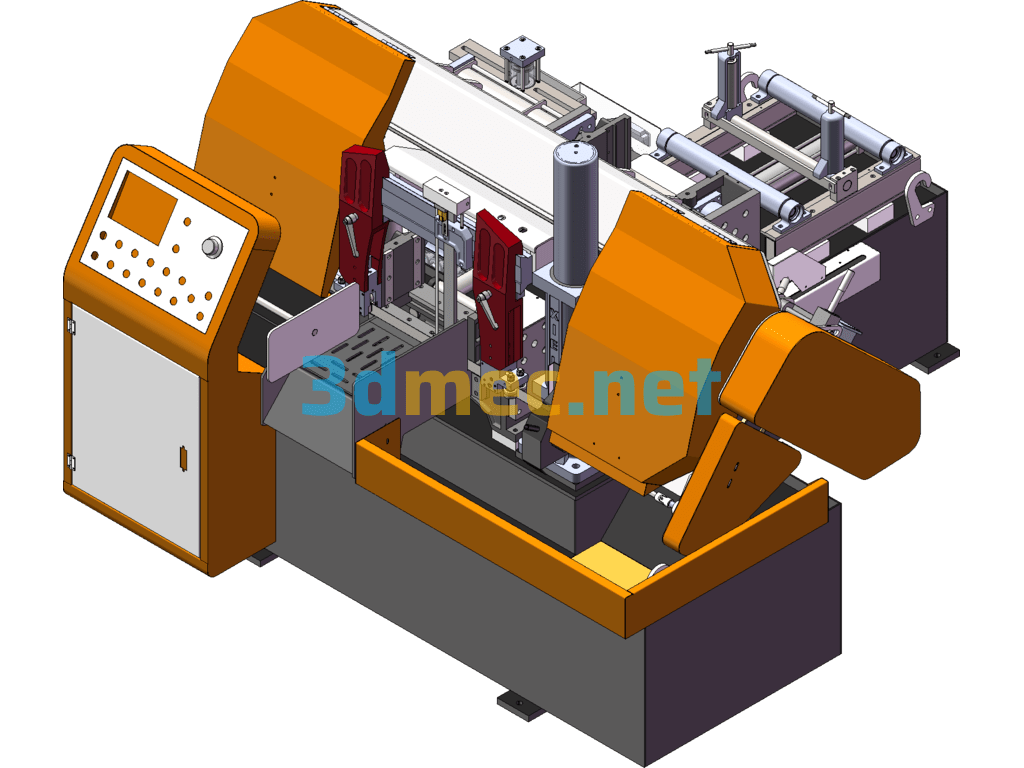

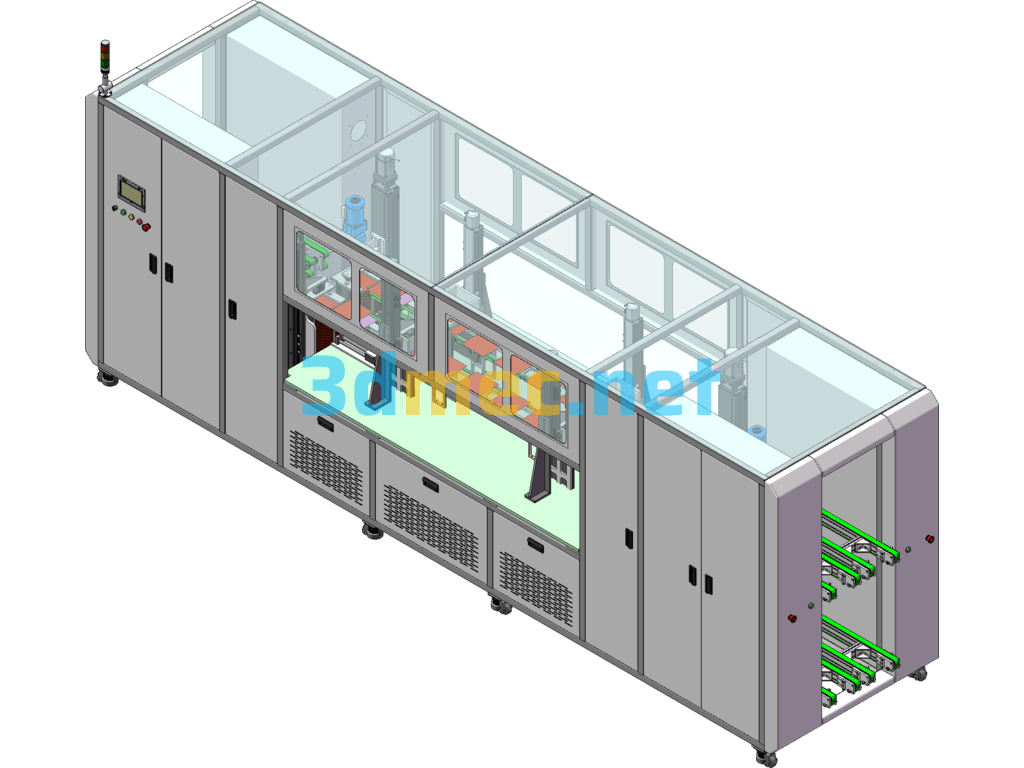

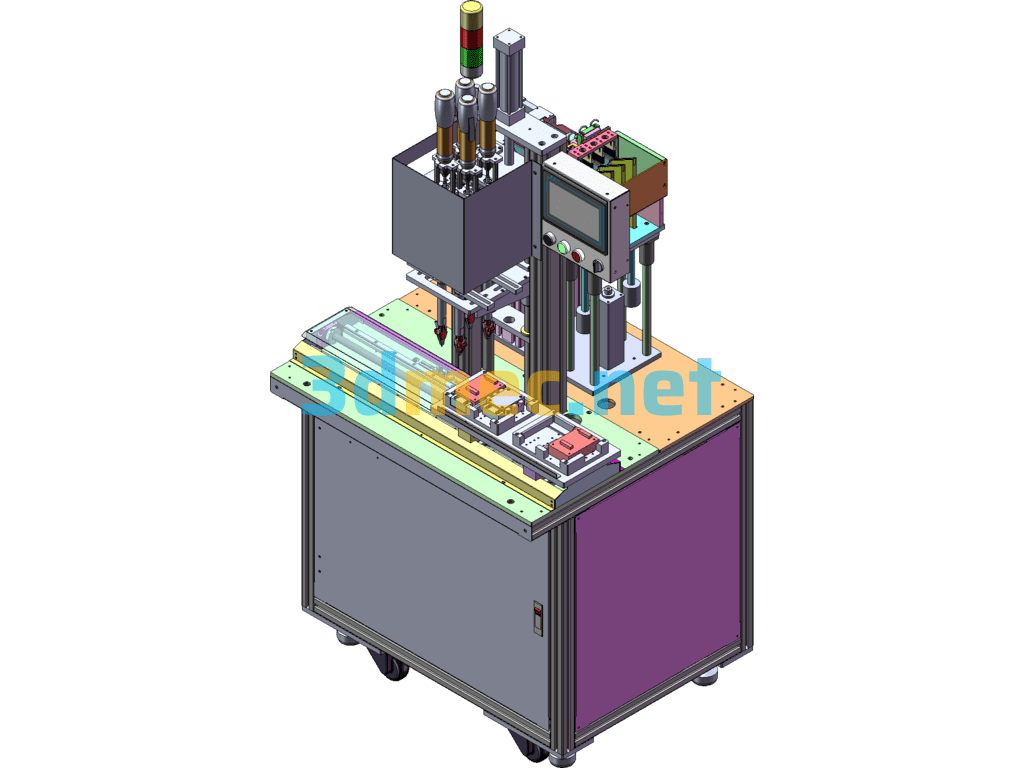

LCD Panel Production Line – 3D Model SolidWorks

This project is mainly used for 8.5-generation high-generation LCD production lines. Liquid crystal glass is fed in boxes, and the liquid crystal glass box is stored with a piece of glass and a piece of sponge. Linear motors are used as handling actuators to improve efficiency. The mechanism has a self-actuated disassembly mechanism and a CCD centering mechanism. Boxes of liquid crystal glass are transported to the designated location, and two manipulator installation stations are set on the linear motor. One is responsible for sucking the sponge and placing it in another BOX, and the other is responsible for sucking the glass panel onto the positioning platform. When a box of liquid crystal glass is sucked, the empty box is automatically discharged to the stacking mechanism for automatic stacking. The centering step is completed by the CCD centering mechanism, and a single-axis manipulator is used to transport it to the designated location. The STAGE handling manipulator is transferred to the next workstation.

Specification: LCD Panel Production Line – 3D Model SolidWorks

|

User Reviews

Be the first to review “LCD Panel Production Line – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.