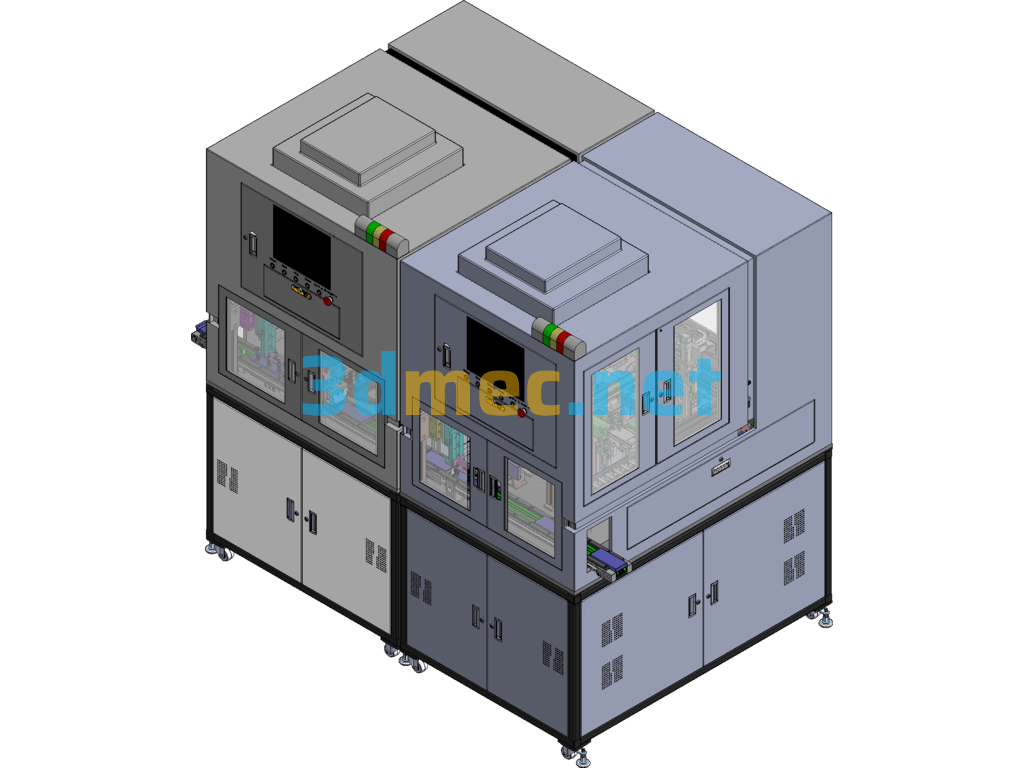

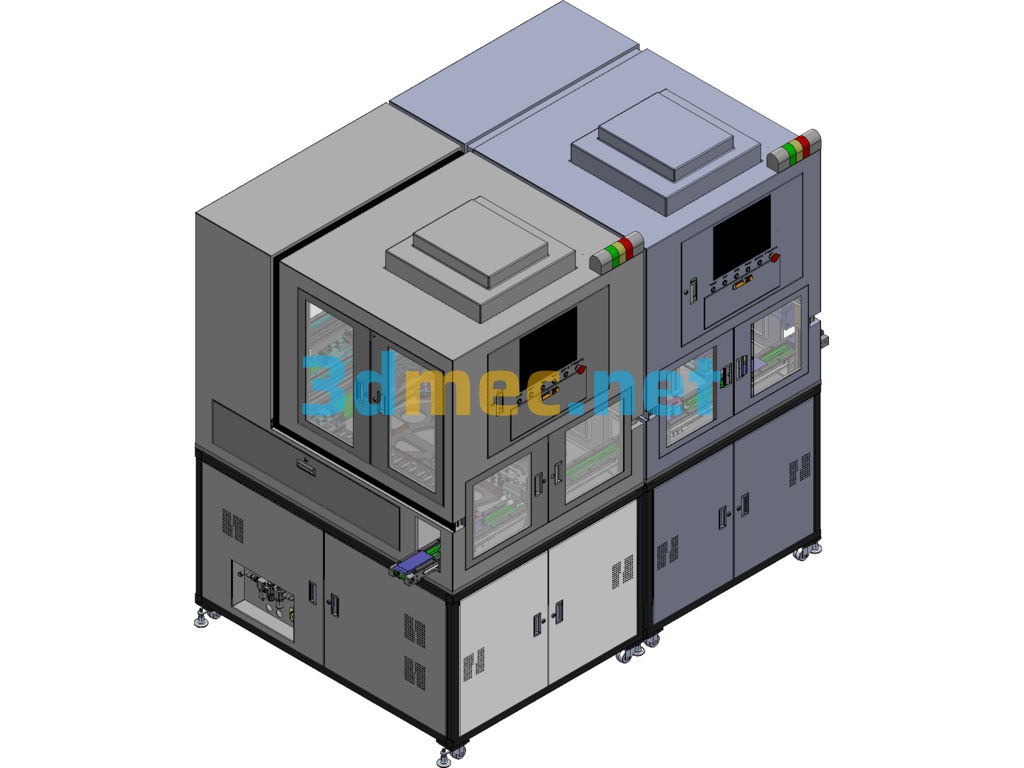

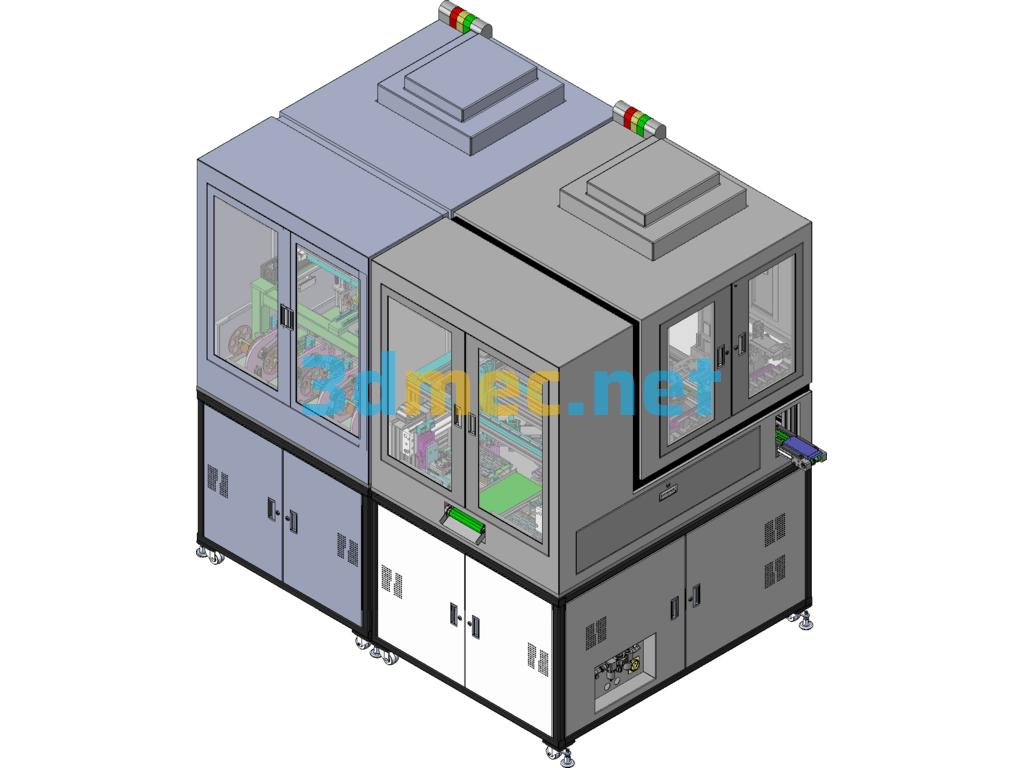

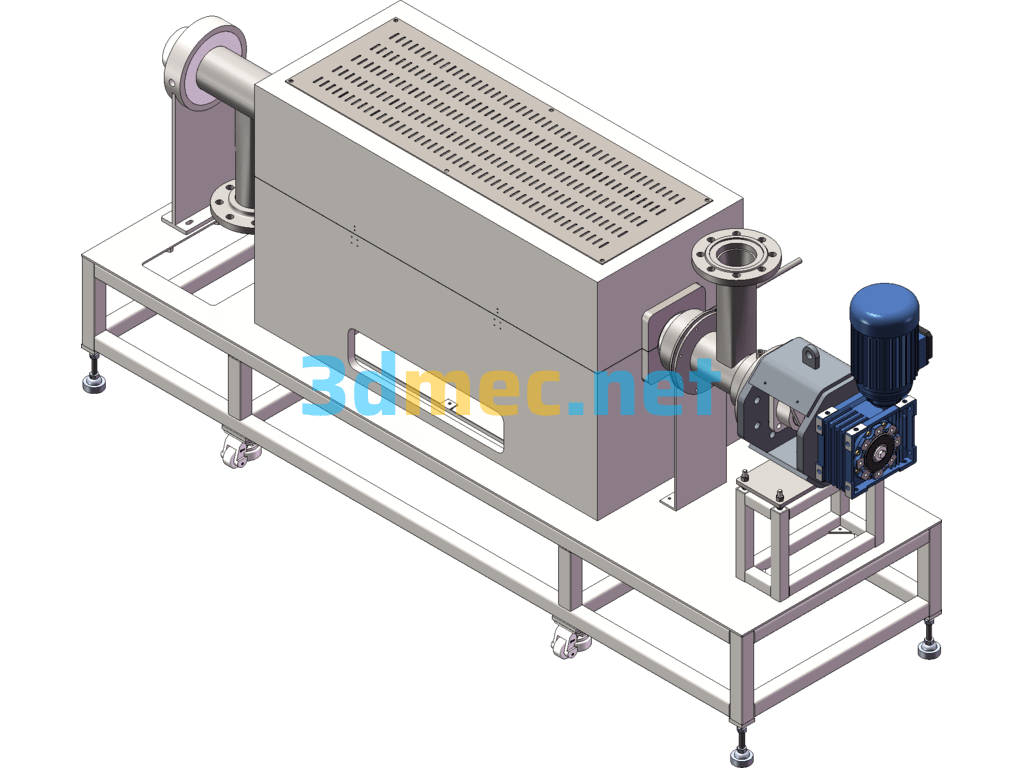

Labeling And Sealing Equipment – 3D Model SolidWorks

Labeling and sealing equipment

Working principle:

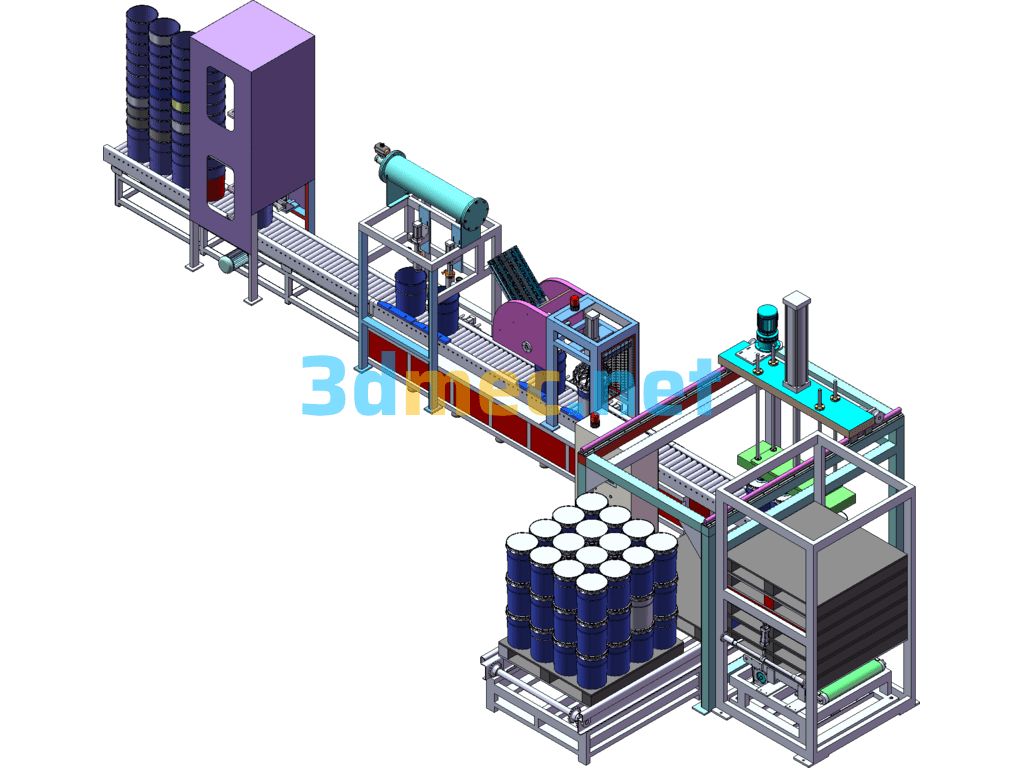

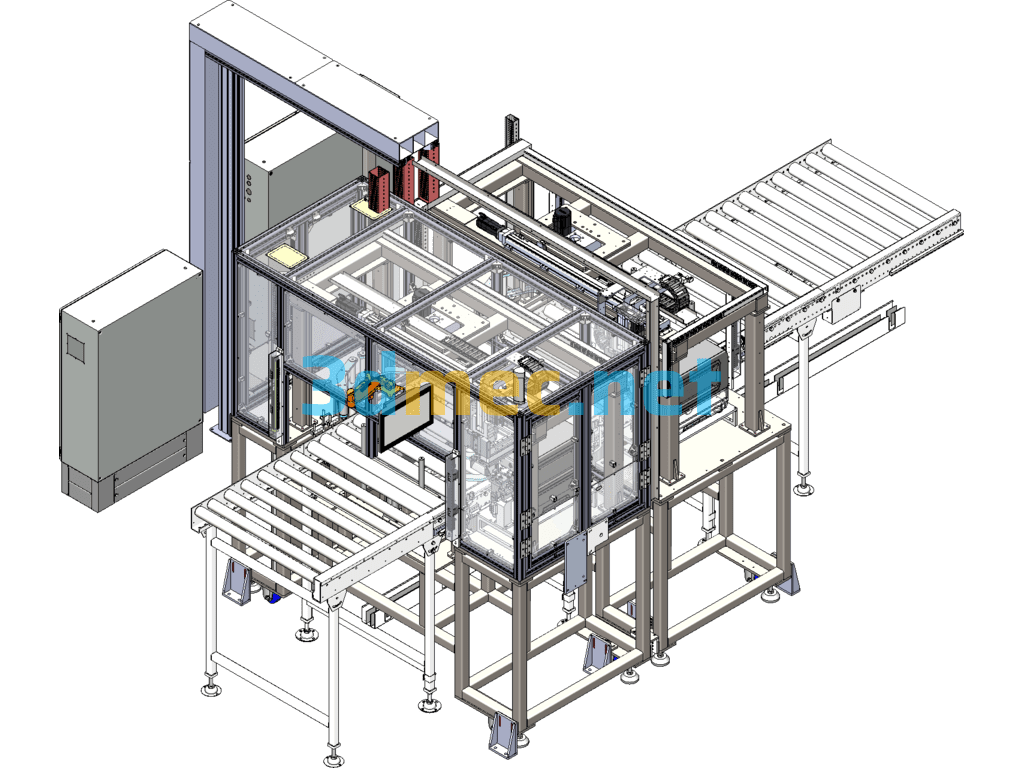

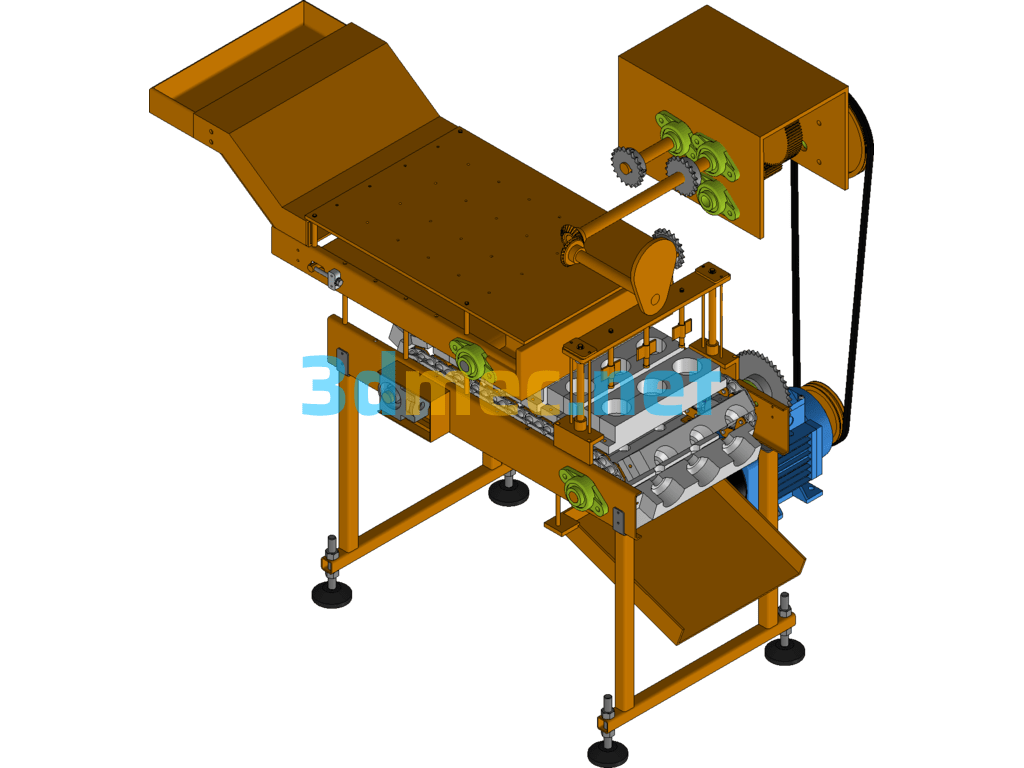

Automatic discount: 1. Put the box on the production line manually or by machine 2. The box is transported to the material picking point, and the material picking module picks it up and puts it on the indexing turntable 3. The cylinder positions the box, and the suction cup sucks the box tightly 4. The cylinder pushes the accessories inside the box tightly 5. The module automatically sticks a large label on the box 6. The module automatically folds the box and seals it 7. Tear off the small centrifugal paper on the large label 8. Stick the small lip on the large label on the box 9. The module automatically unloads the box onto the production line 10. Follow the production line Flow out of this workstation

Automatic labeling: 1. The box flows into this workstation from the previous workstation along the assembly line. 2. The box is transported to the material picking point, and the material picking module takes it and places it on the upper box rotating module. 3. The upper box rotating module flips the box 90 degrees along the width, and the side that needs to be labeled faces up. 4. The box moving module places the turned box on the box moving positioning module. 5. The box moving positioning module brings the box to the labeling position, and after positioning, the side label is affixed. 6. The bottom rotating module clamps the paper box and rotates the box 90 degrees along the length direction, with the bottom side that needs to be labeled facing up. 7. After rotating into place, the carton is taken away by another module and moved to the coding position, and the labeling component comes over to stick the barcode on it. 8. After sticking the barcode, the carton is taken away and rotated 90 degrees along the length direction, and then put into the lower box rotating module. 9. The lower box rotating module rotates the carton 90 degrees again with the carton to restore the posture when the box is loaded. 10. The unloading robot puts the box with the barcode and label paper into the assembly line. 11. The box flows out of this station along the assembly line.

Specification: Labeling And Sealing Equipment – 3D Model SolidWorks

|

User Reviews

Be the first to review “Labeling And Sealing Equipment – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.