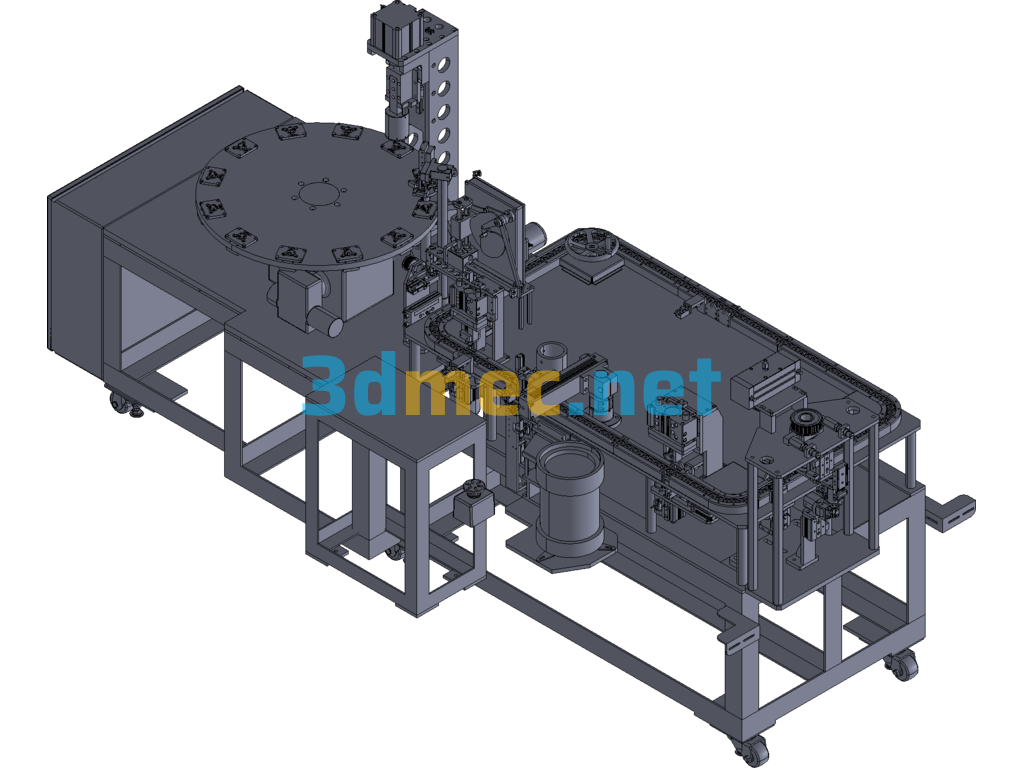

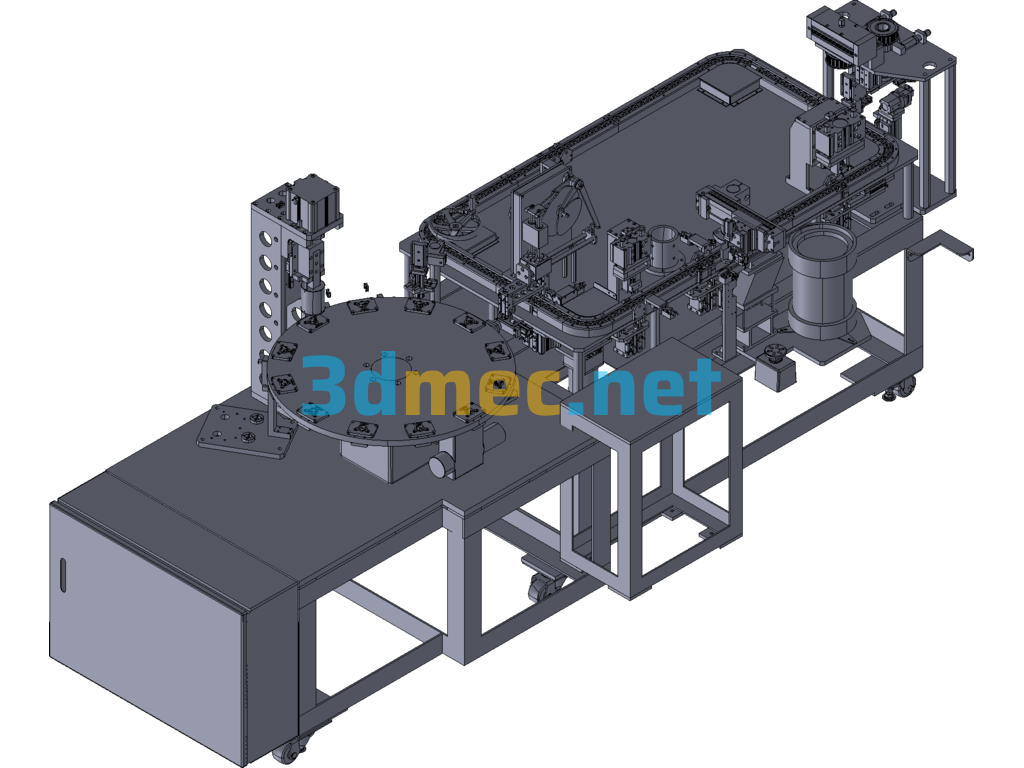

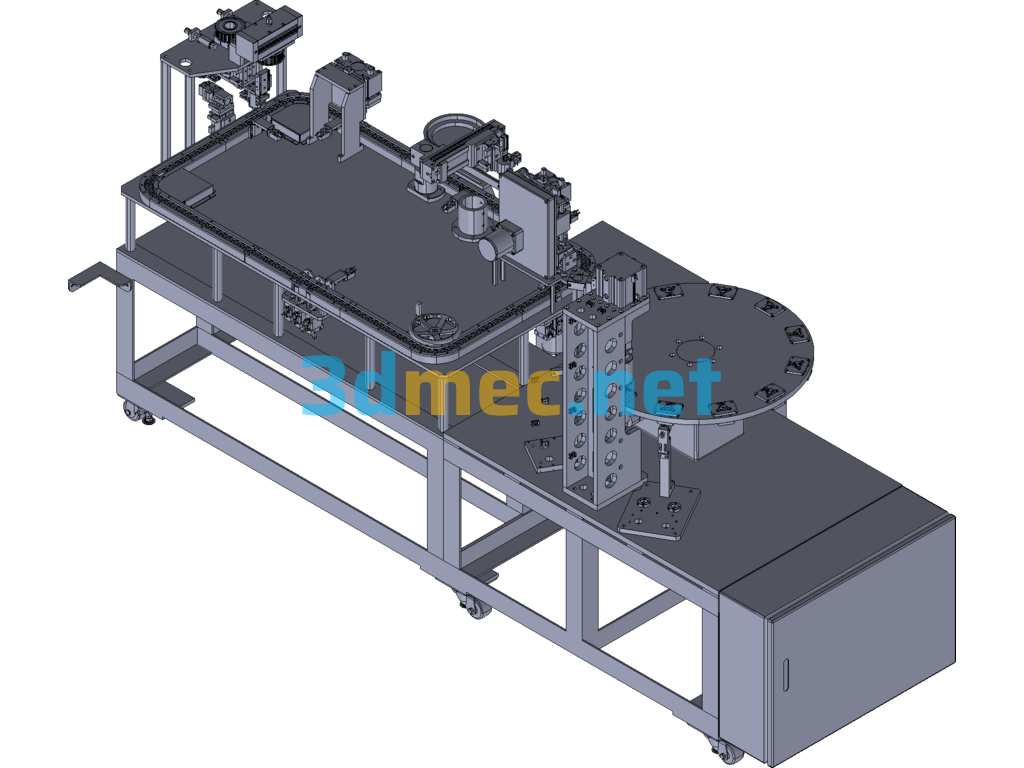

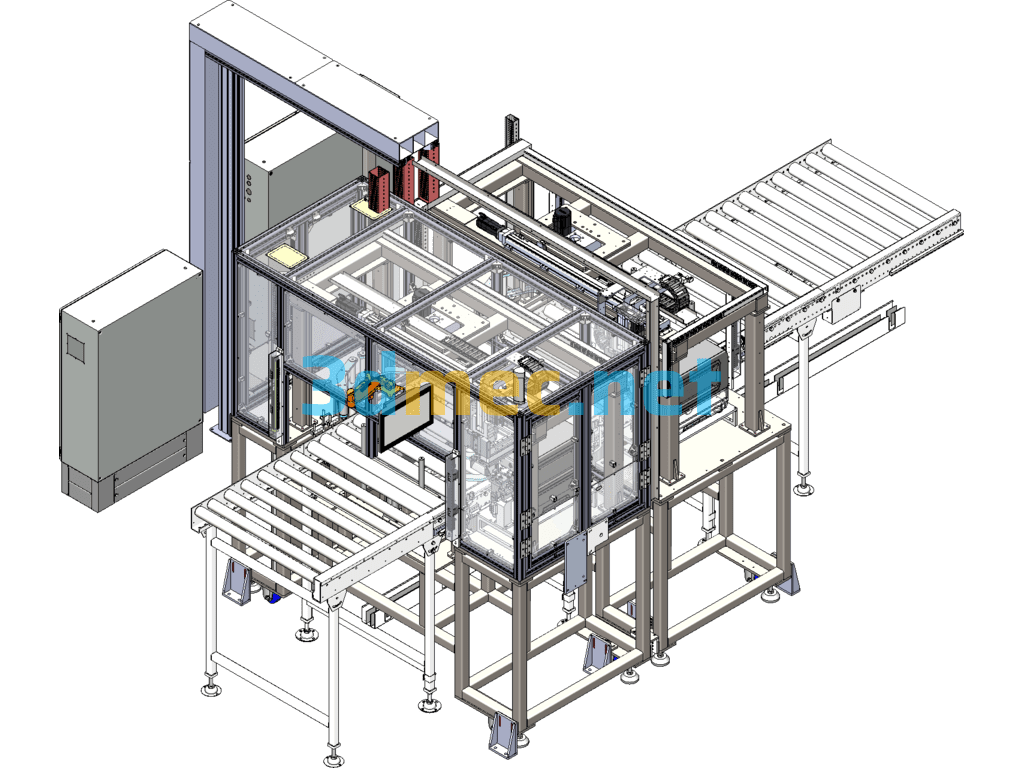

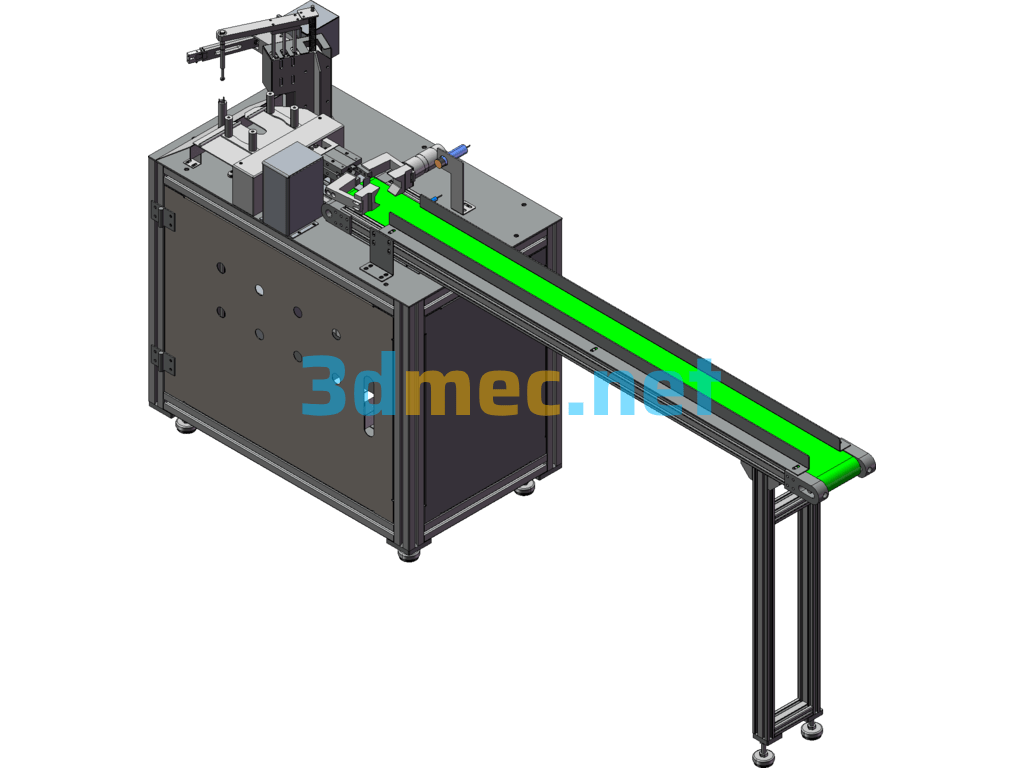

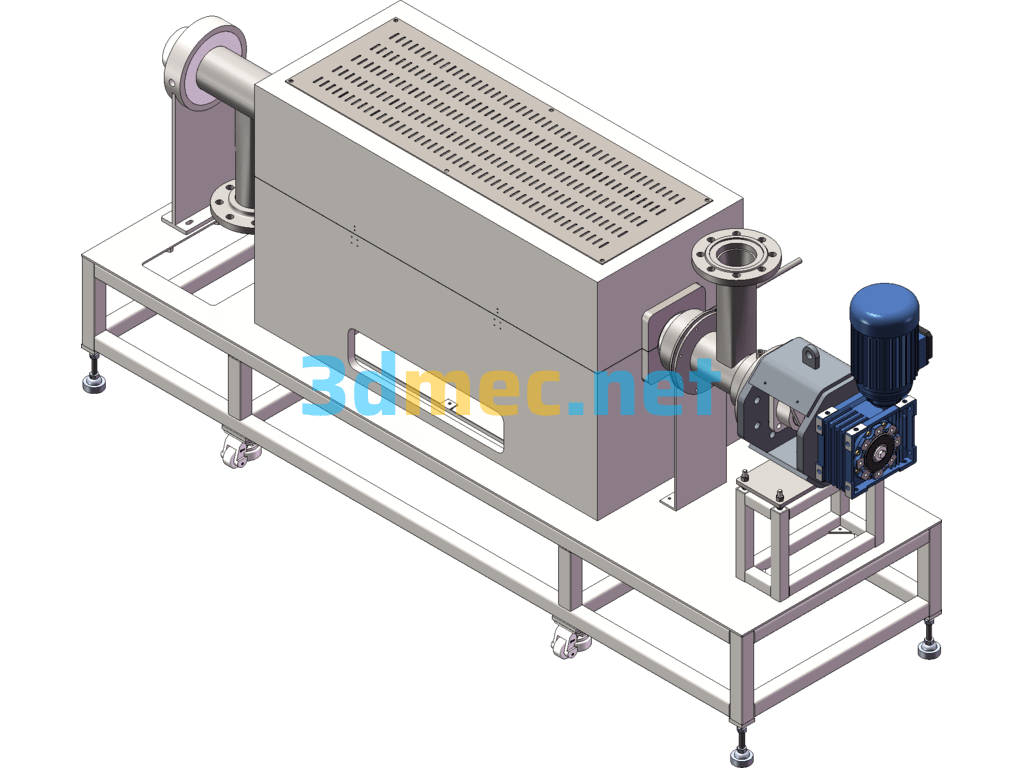

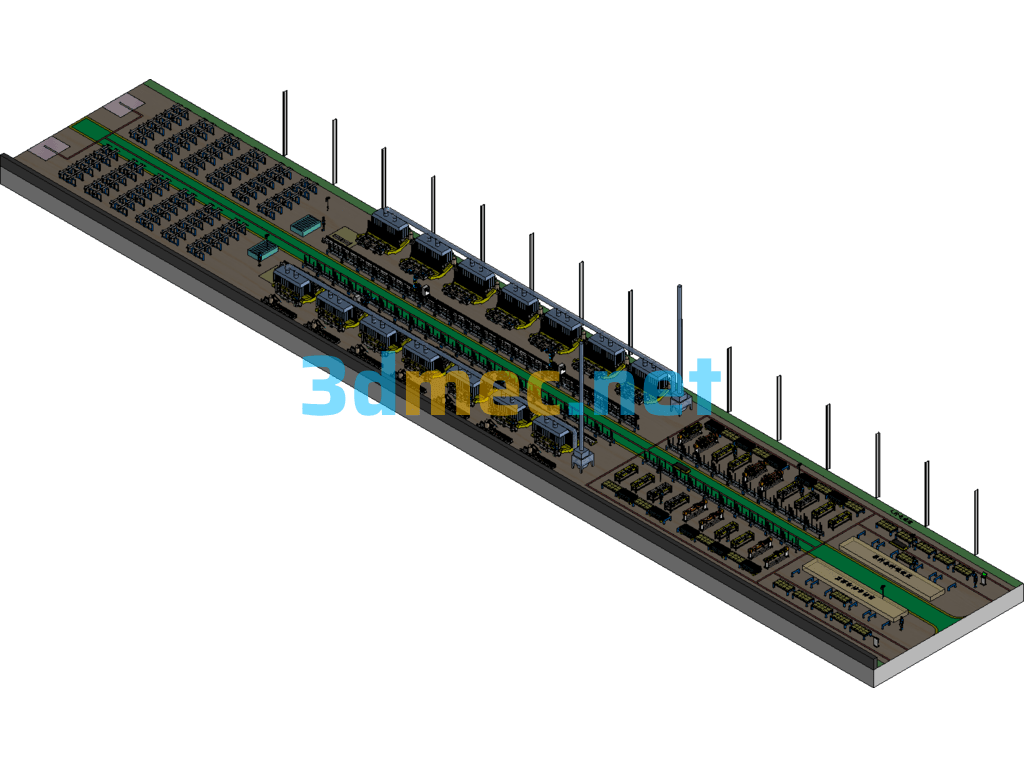

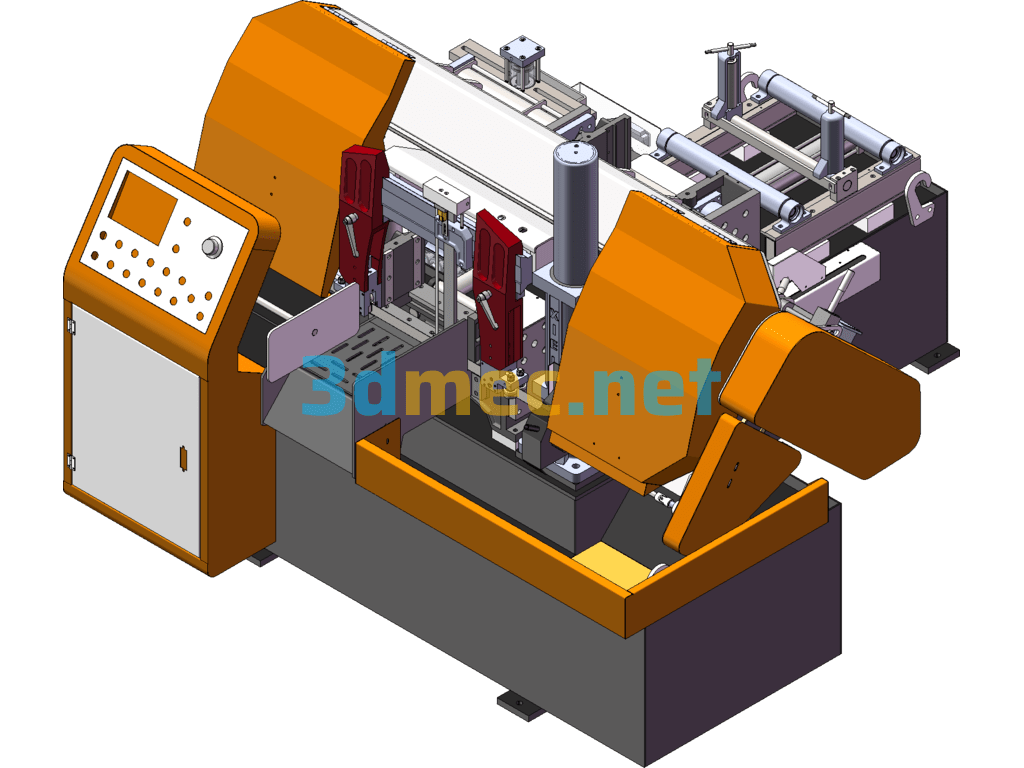

By setting up the annular transport device, the position of the workpiece can be adjusted. At this time, the workpiece is transported by the loading component 2, so that the part can be located in the annular slide rail, and then the workpiece passes through the pressing component and the welding component to complete the welding work of the workpiece, so as to avoid the position of the workpiece from being offset during welding, thereby ensuring the smooth operation of the welding work. Then, the workpiece that has completed the welding work passes through the movement of the transport mechanism, and the transport mechanism can transport the workpiece to a predetermined area, and then the rotating component can flip the workpiece to a certain angle, and place the workpiece on the detection mechanism to complete the detection of the workpiece.

Specification: Inspection Device For Welded Parts/Finished Products – 3D Model Exported

|

User Reviews

Be the first to review “Inspection Device For Welded Parts/Finished Products – 3D Model Exported”

You must be logged in to post a review.

There are no reviews yet.