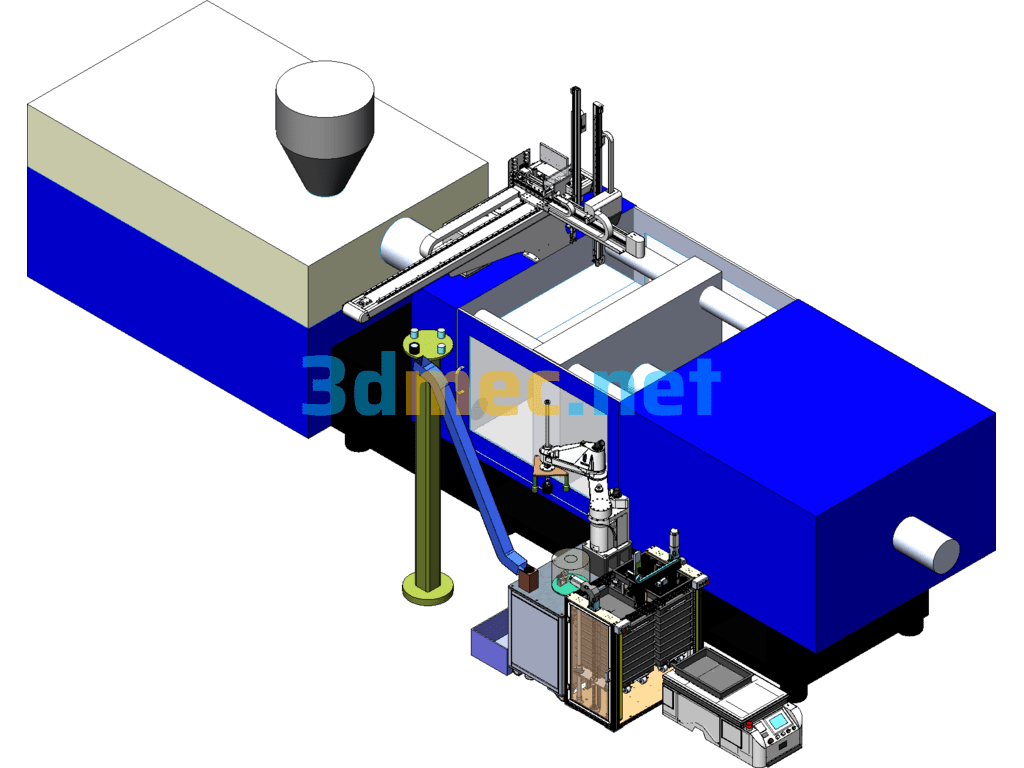

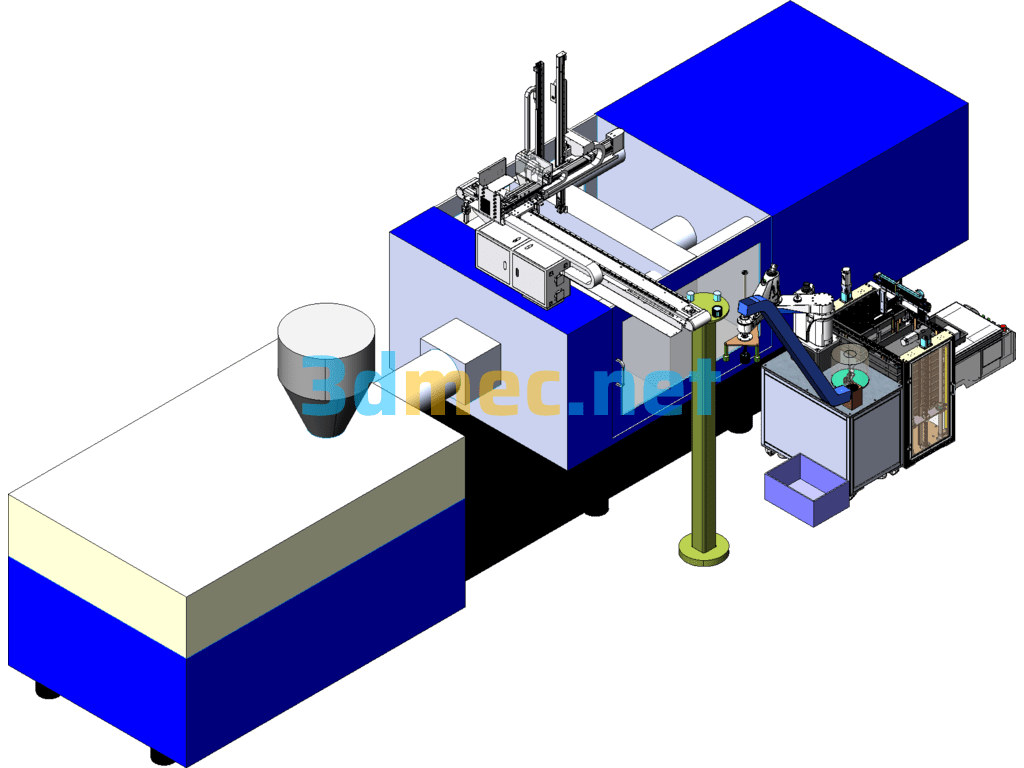

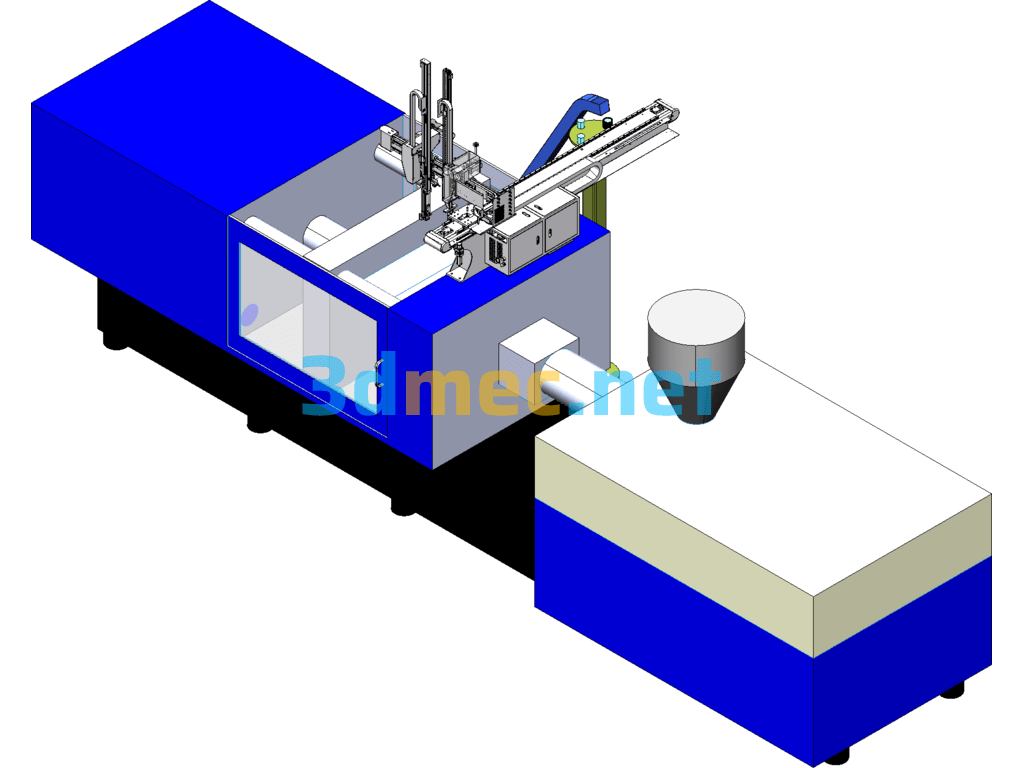

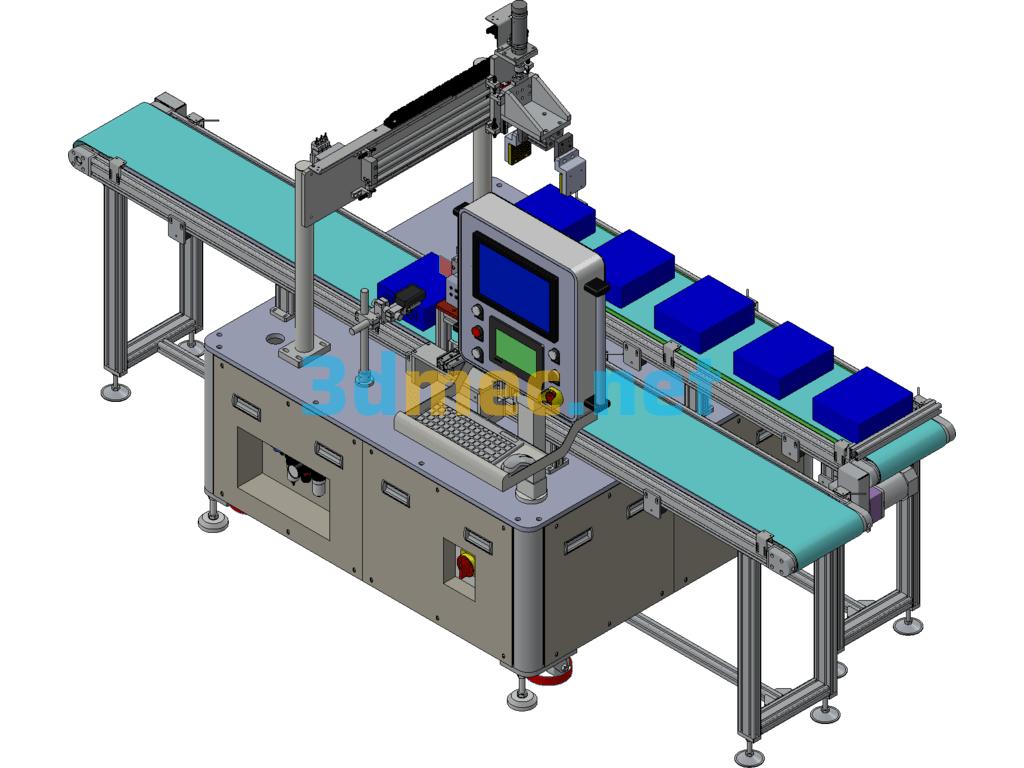

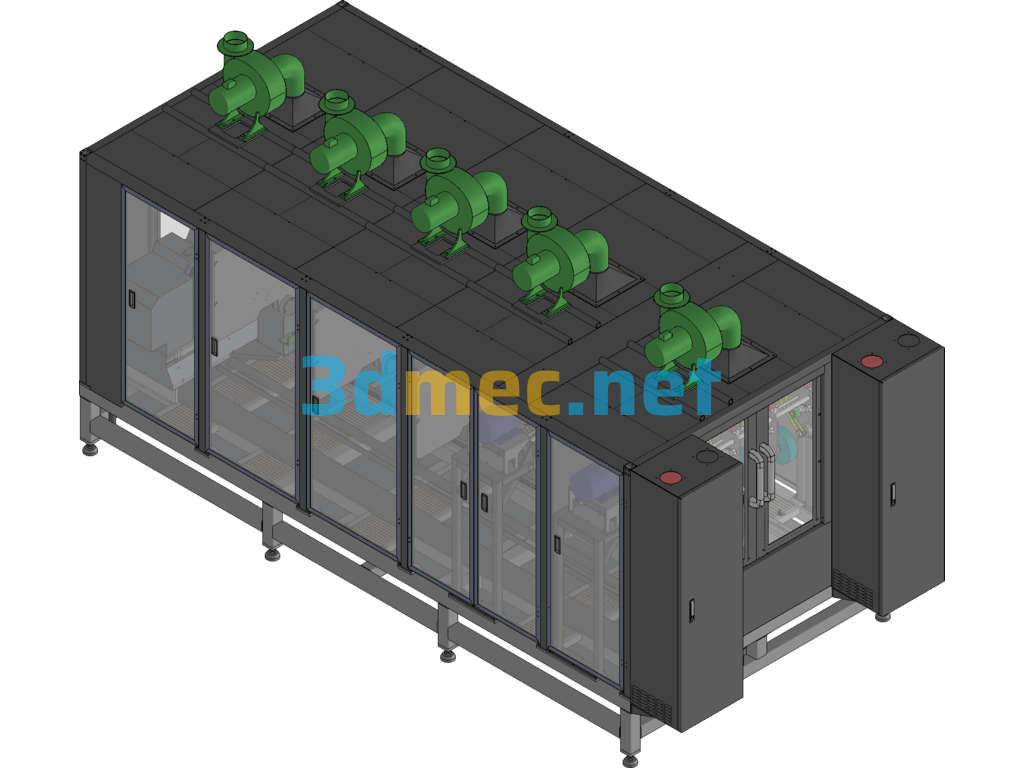

Injection Molding Product Inspection And Palletizing Equipment (Including Detailed PPT Instructions) – 3D Model SolidWorks

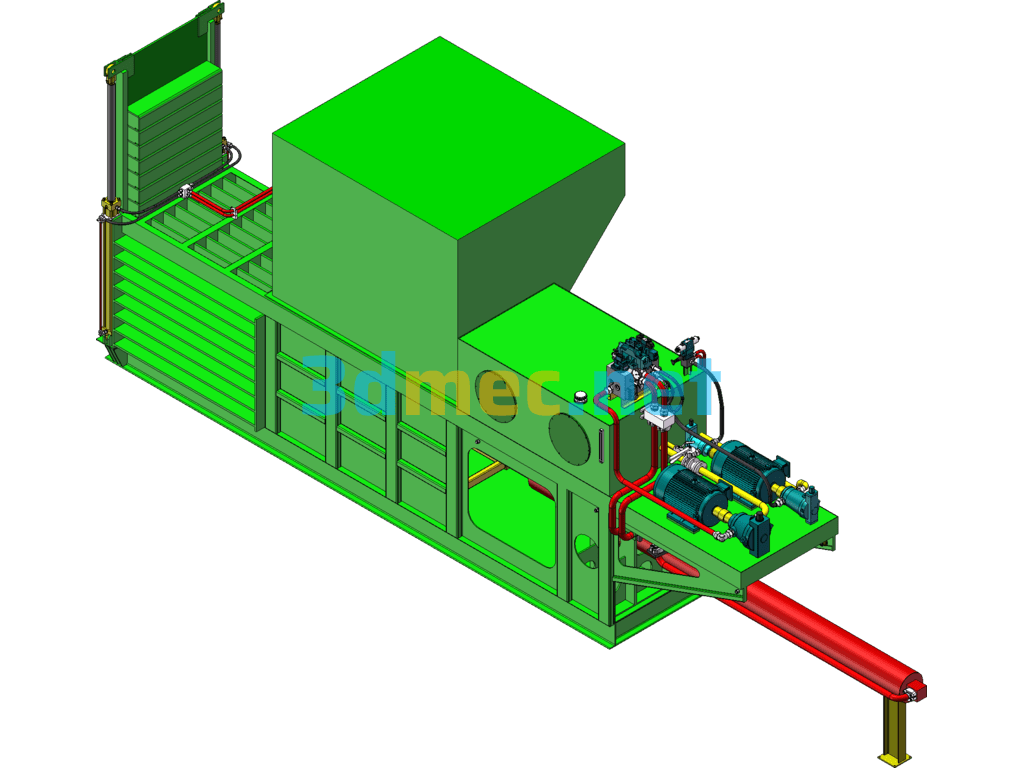

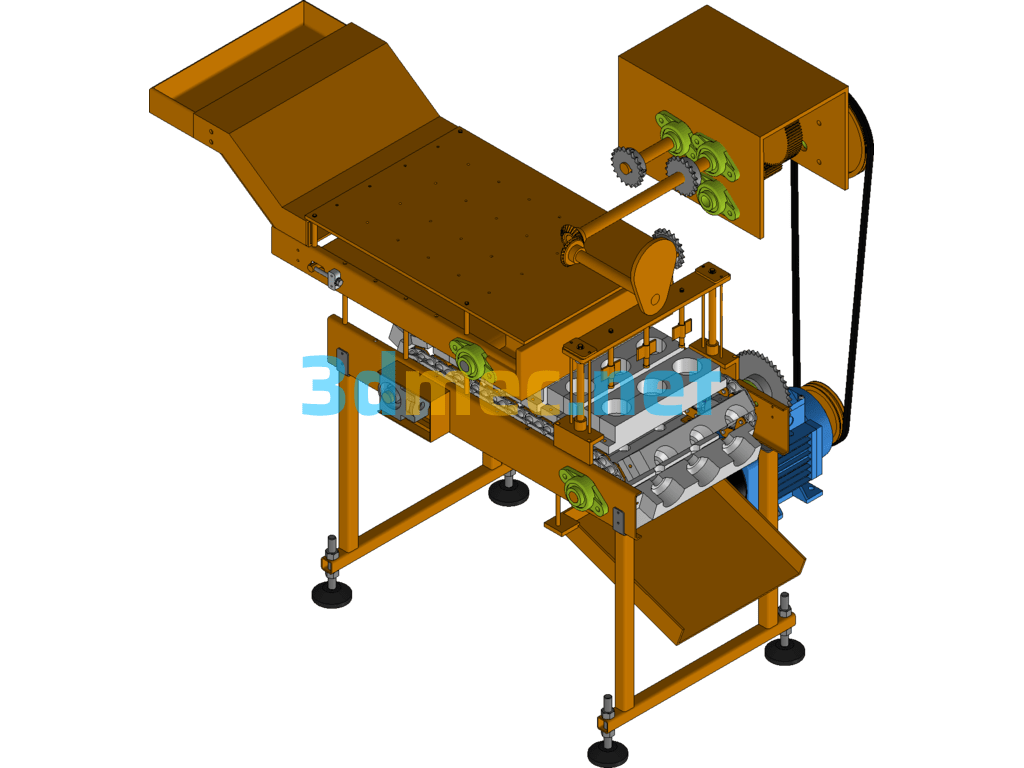

The injection molded products are unloaded by the injection molding robot and moved to the detection and grasping robot. The robot grasps and rotates to detect whether there is a lack of material, flash, etc. After completion, they are loaded into the material box for palletizing. The material box is moved by the AGV car to change the material.

Equipment action flow:

1.Product feeding and positioning;

2.The robot grips the product CCD to take pictures;

3.OK products are moved to the palletizing area for placement:

4.NG is moved to the NG material box for unloading;

5.The robot absorbs the empty material tray and transfers it to the palletizing area;

6.AGV feeds the empty material tray;

7.Full material trays are unloaded to the AGV car;

8.The above actions are cycled.

Specification: Injection Molding Product Inspection And Palletizing Equipment (Including Detailed PPT Instructions) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Injection Molding Product Inspection And Palletizing Equipment (Including Detailed PPT Instructions) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.