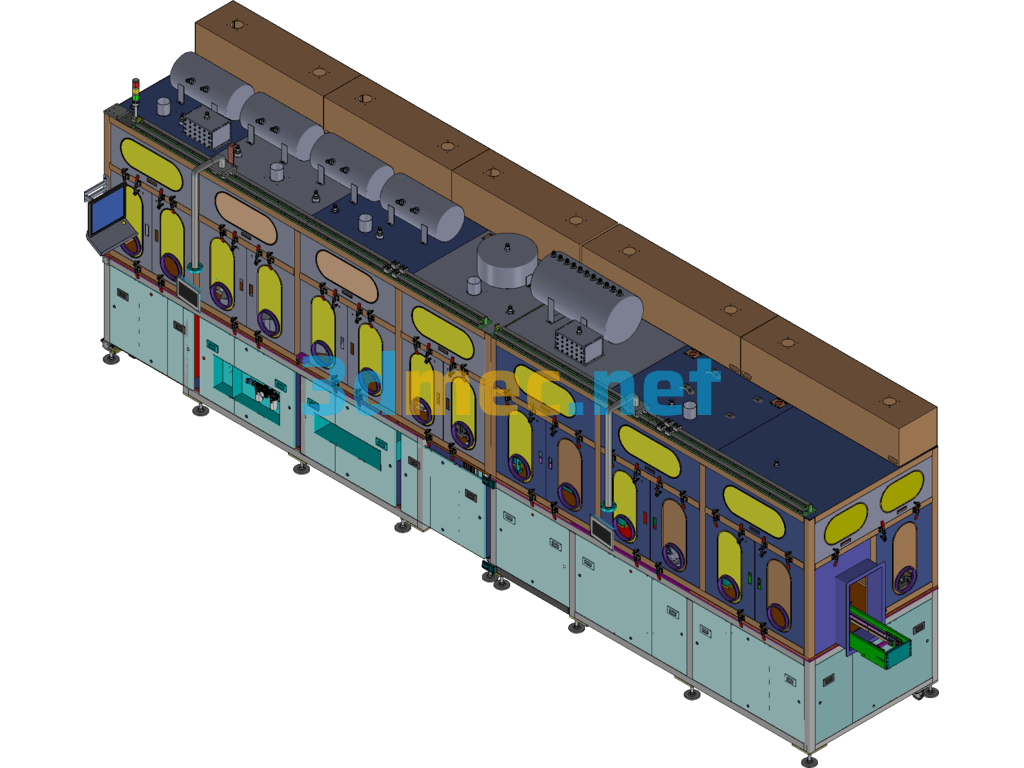

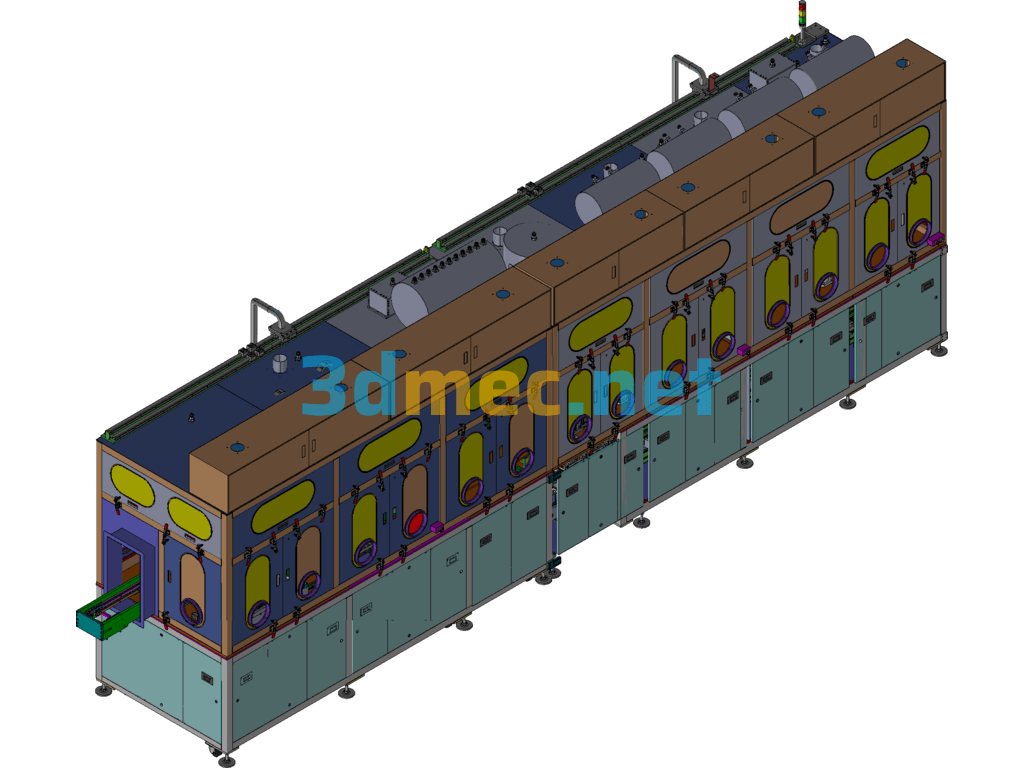

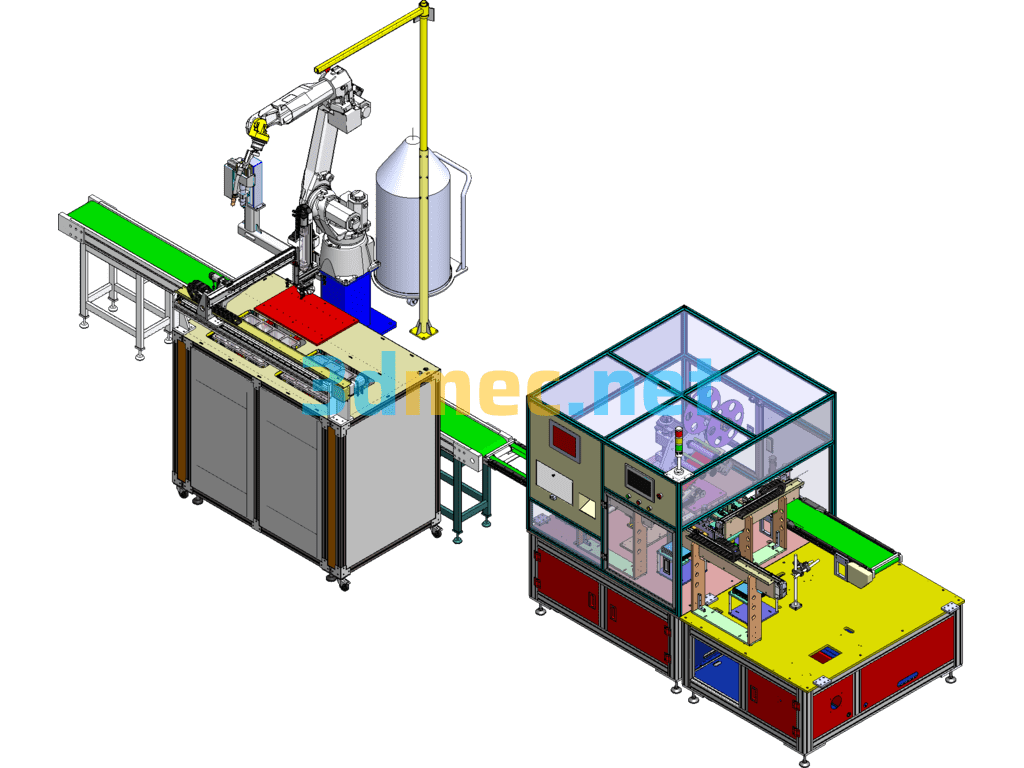

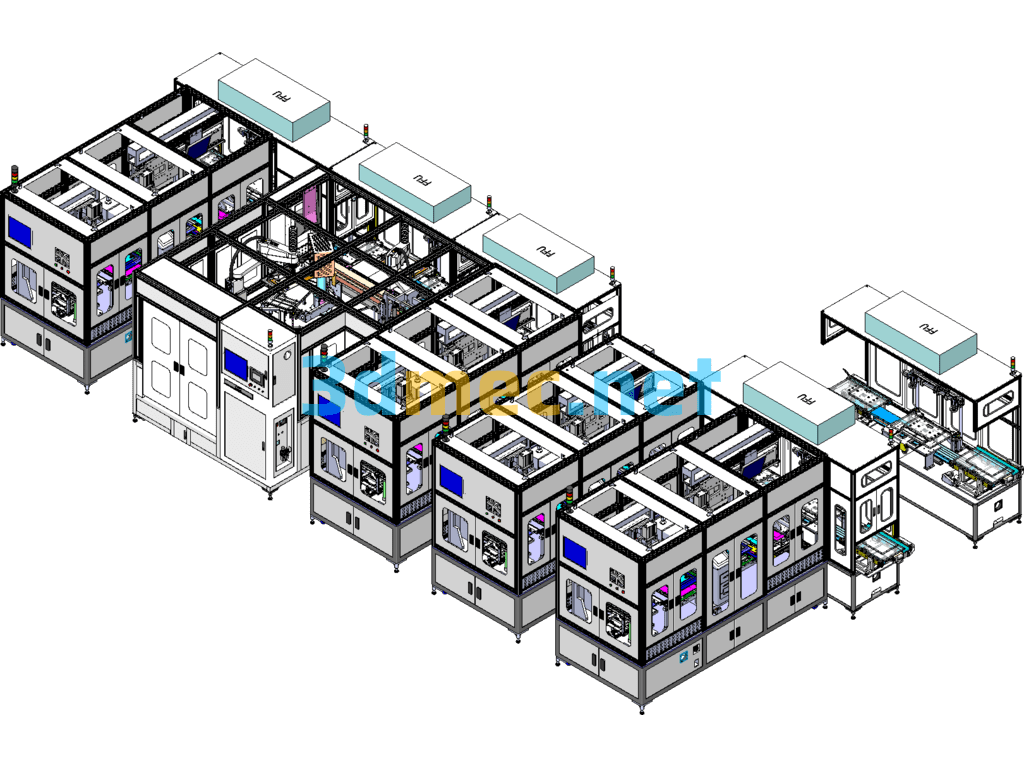

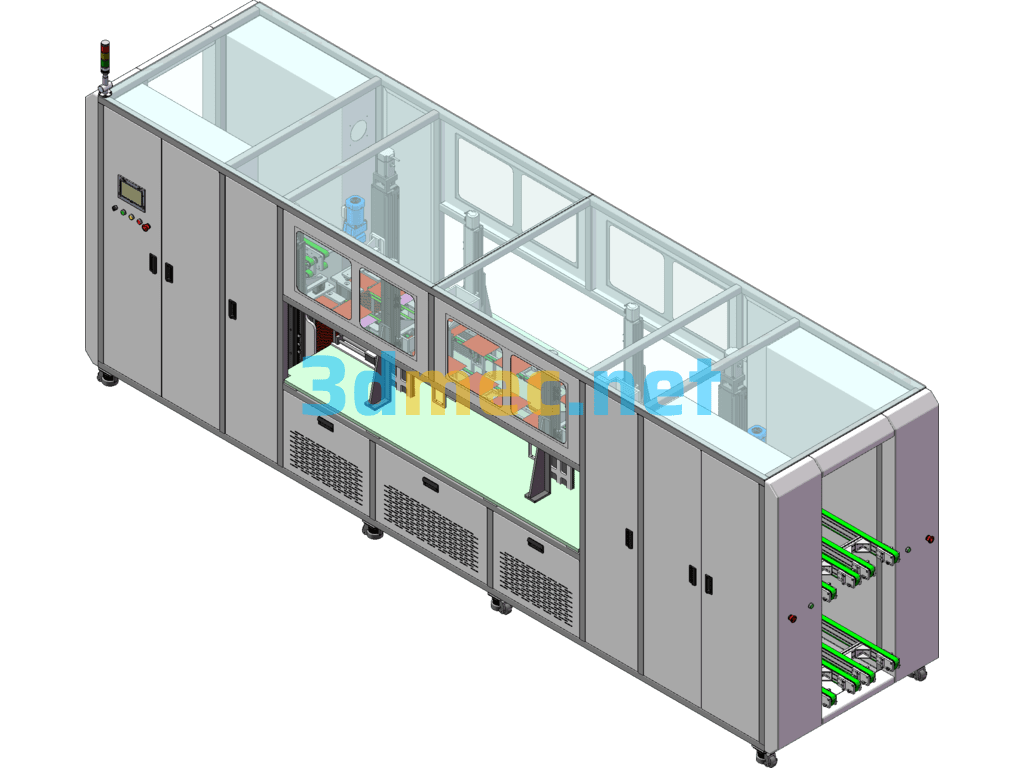

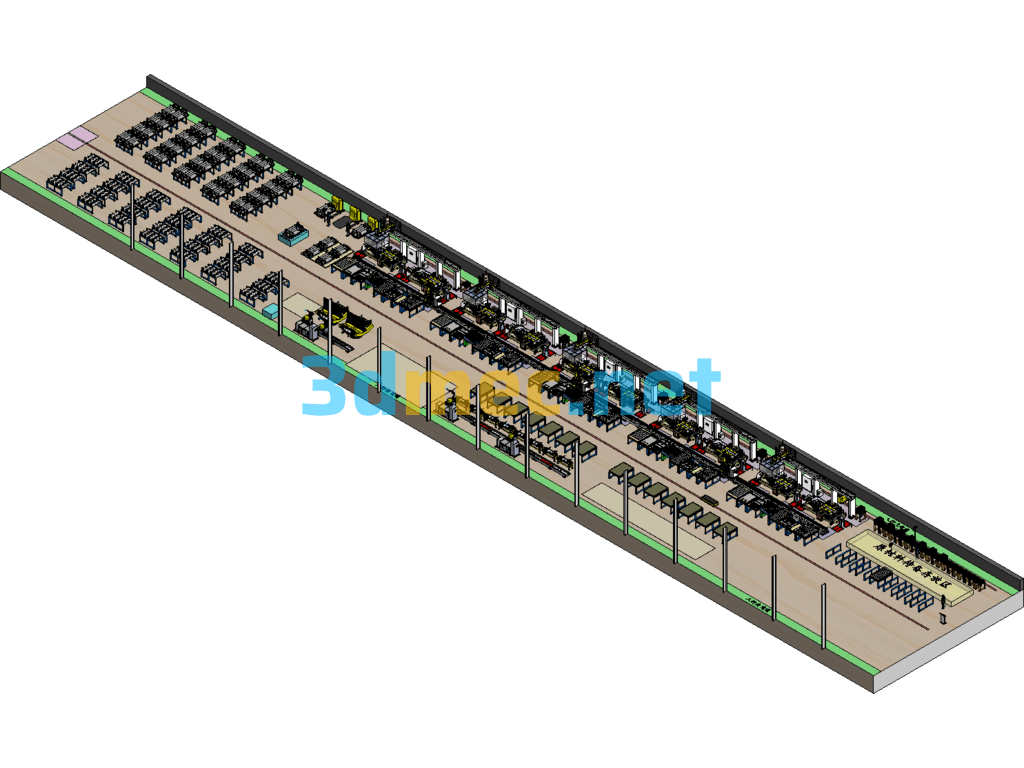

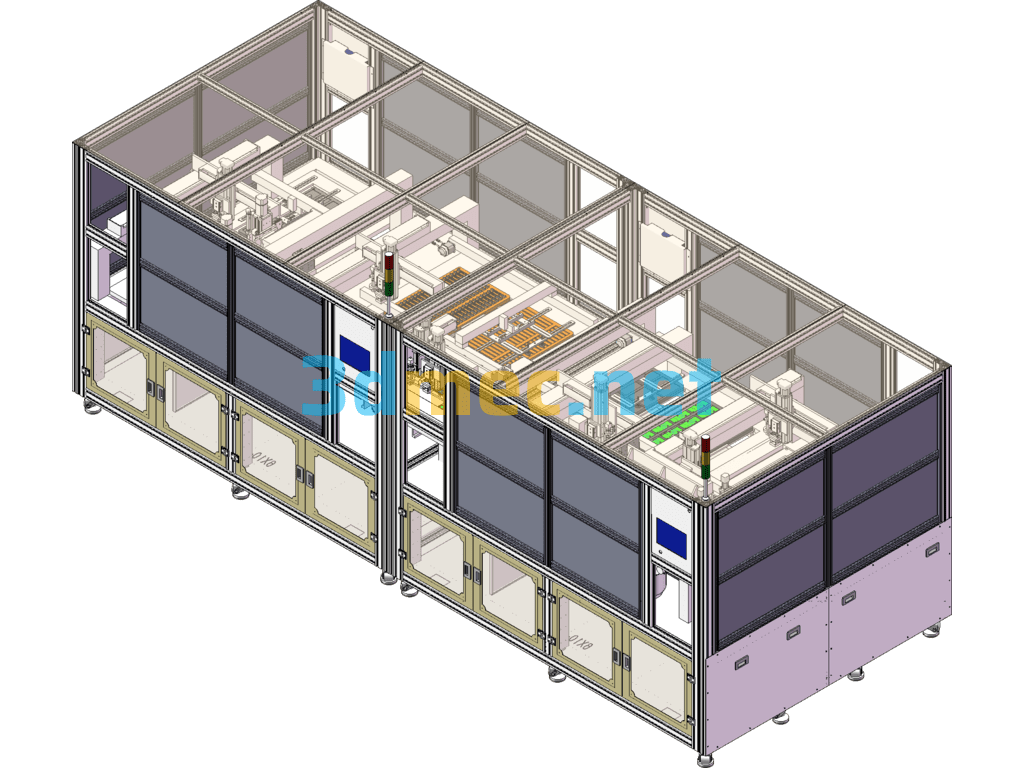

The equipment is mainly used for cell phone soft pack lithium ion battery and power battery common automatic liquid injection machine, the main process is, automatic feeding sealing process. Realize for soft pack battery liquid injection before weighing, automatic liquid injection, automatic static, automatic vacuum sealing, liquid injection after automatic heating and encapsulation, automatic sorting liquid injection defective products, automatic discharging and other functions, the equipment is a soft pack lithium battery vacuum injection machine in the higher efficiency, it is according to one out of six structural design, institutional precision dexterity, from the automatic loading, scanning bad discharge, vacuum liquid injection, three-stage static, vacuum hot pressing, encapsulation, discharging and other processes are automated. Encapsulation, discharging and other processes are all automated. Starting from the front-end loading, circulating jig, to the liquid injection station, three-stage static, vacuum encapsulation, material, complete structure, the frame using a square welded plus aluminum shroud, from the figure can be seen to hide the outer cover inside the structure is very complex, the core grabbing and handling robots, and the core feeding and conveying to the design of the work tooling are very valuable to learn, first of all, before the liquid injection of the battery cavity to be pumped -96 ~ -100kPa high vacuum; -100kPa high vacuum; -100kPa high vacuum; -100kPa high vacuum; -100kPa high vacuum. -100kPa high vacuum; Secondly, the liquid injection to maintain a differential pressure laminar flow injection, to avoid injection nozzle spraying, spraying, after the liquid injection set up a number of vacuum pumping cycle, which in order to prevent excessive volatilization of the electrolyte, the pumping pressure is set at -65 ~ -76kPa; Due to the need for liquid injection of the vacuum before the pumping of a dry vacuum, liquid injection pumping after the pumping of the pumping cycle process needs to be pumped in a low vacuum, in order to increase the stability of the equipment, specially added four sets of vacuum systems, three vacuum pumps and four gas storage and transport equipment. Three vacuum pumps and four gas storage tanks. One vacuum system consists of one TRP24 vacuum pump specialized in high vacuum pumping; the other vacuum system consists of two TRP48 vacuum pumps, and adopts the international advanced vacuum differential pressure liquid injection process to ensure the precision of liquid injection, production stability, and full infiltration of the battery electrolyte, taking into account the clean production and easy maintenance of equipment inspection points.

Specification: High-Efficiency Vacuum Liquid Filling And Sealing Machine For Soft Pack Lithium Batteries Exported 3D Model

|

User Reviews

Be the first to review “High-Efficiency Vacuum Liquid Filling And Sealing Machine For Soft Pack Lithium Batteries Exported 3D Model”

You must be logged in to post a review.

There are no reviews yet.