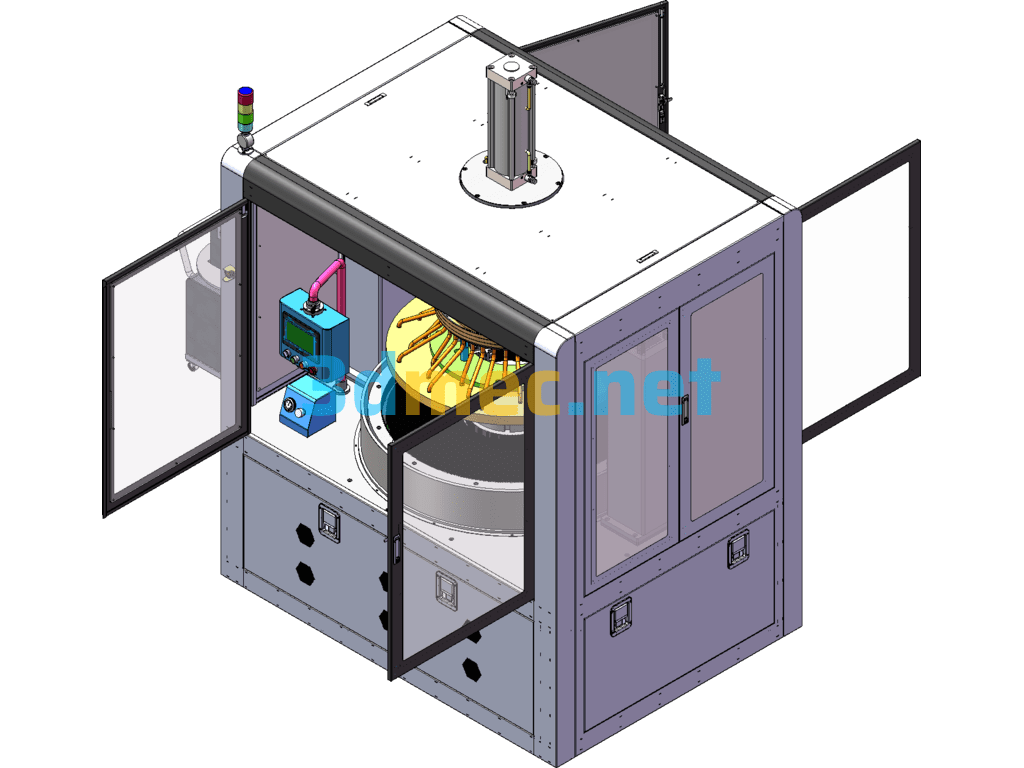

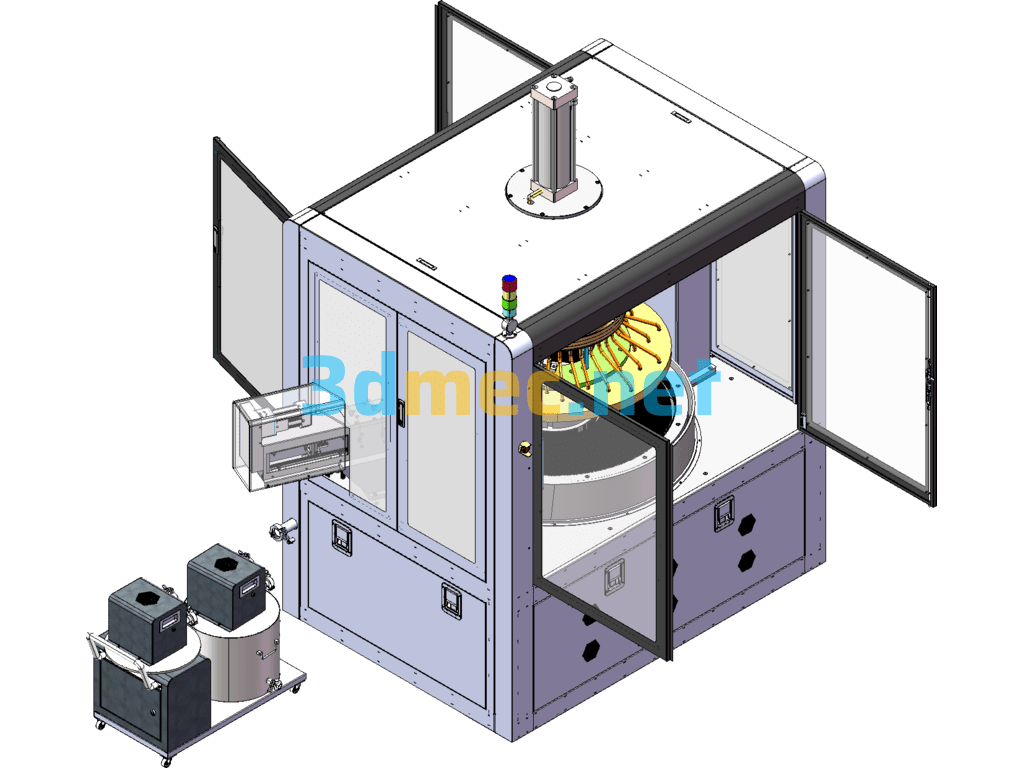

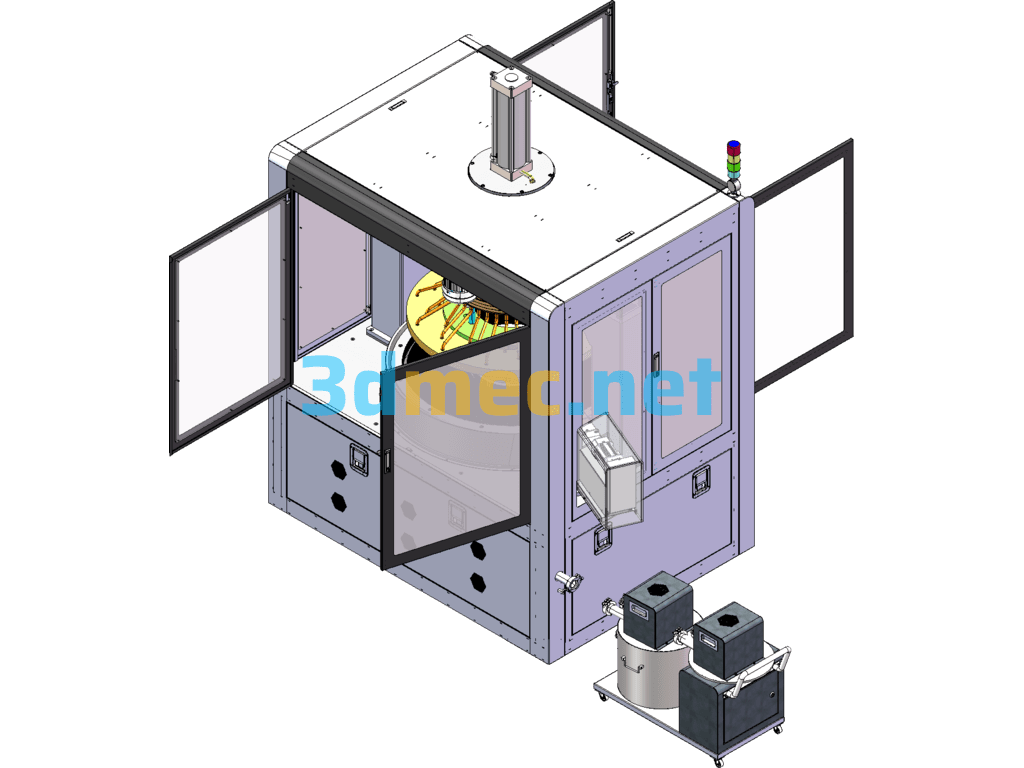

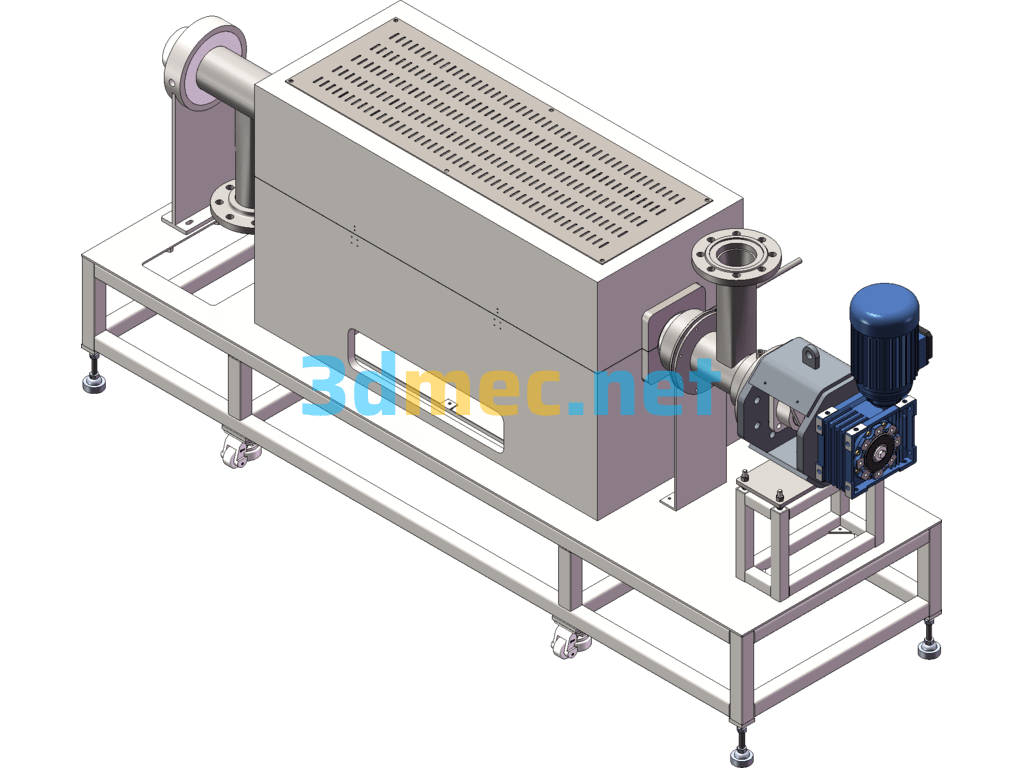

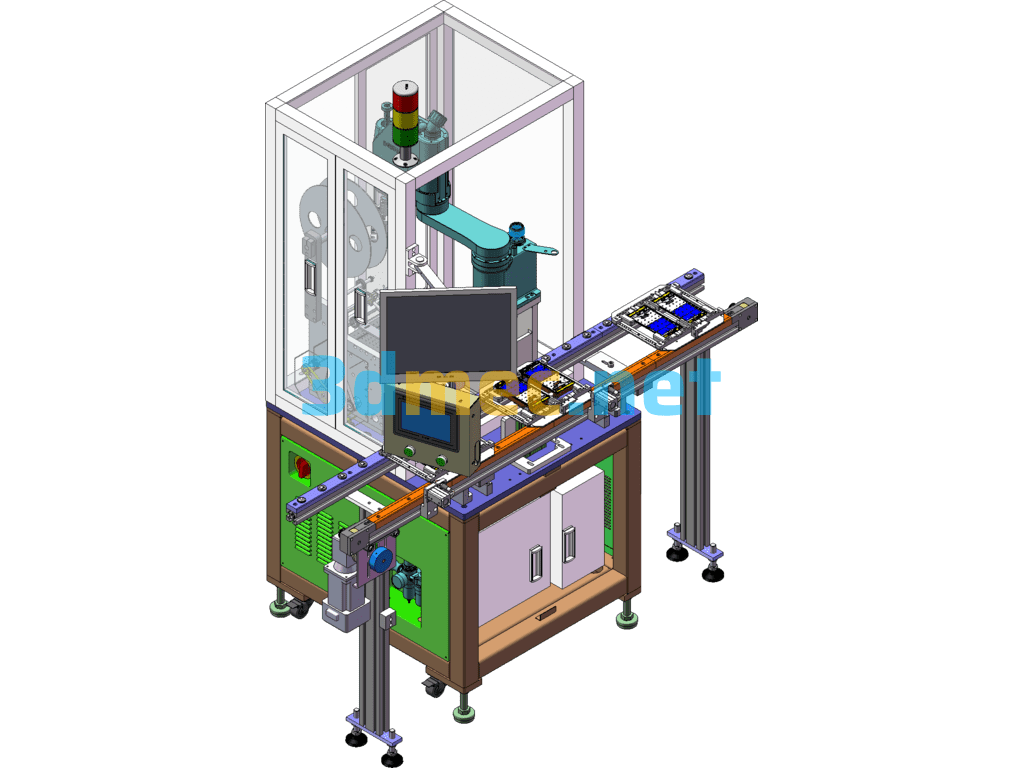

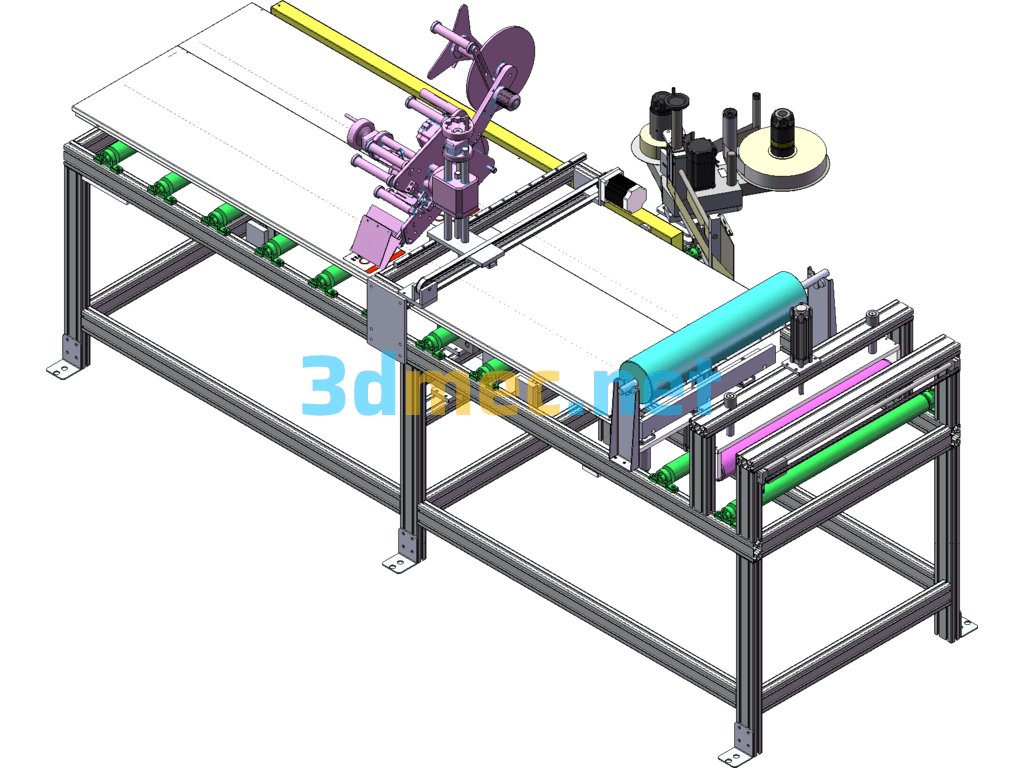

Glass Double-Sided Grinding Machine – 3D Model SolidWorks

Double-sided grinding machine

1. Main uses

Mainly used for high-precision double-sided grinding/polishing of sapphire, blue glass, ceramic sheets, crystals, semiconductors and other hard and brittle materials, especially for the processing of ultra-thin workpieces.

II. Main features

1. Precision pressure control: PLC+PT+electric proportional valve+low-friction cylinder realizes high-precision pressure closed-loop control;

2. Upper plate damping device: a vibration-damping elastic connection method suitable for both dynamic and static conditions;

3. Precision transmission system: high-precision small tooth gap full gear transmission;

4. Lower plate support: high-precision plane fluid bearing support, large load-bearing capacity, stable operation, maintenance-free;

5. Pin gear transmission: internal and external teeth adopt pin gear transmission to extend the service life of the carrier and facilitate maintenance. Involute gear transmission can also be adopted;

6. Transmission system: three motors are driven synchronously, and the speed of the upper plate, lower plate, gear ring and sun gear (can be forward or reverse) can be set arbitrarily, with formula function.

Specification: Glass Double-Sided Grinding Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “Glass Double-Sided Grinding Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.