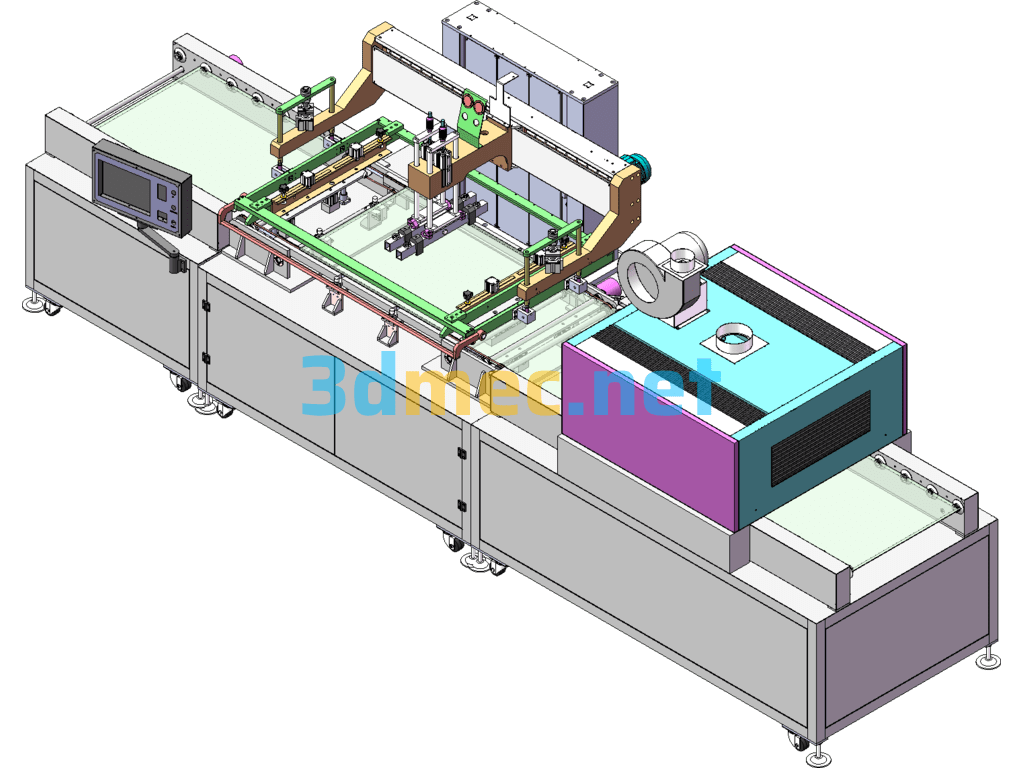

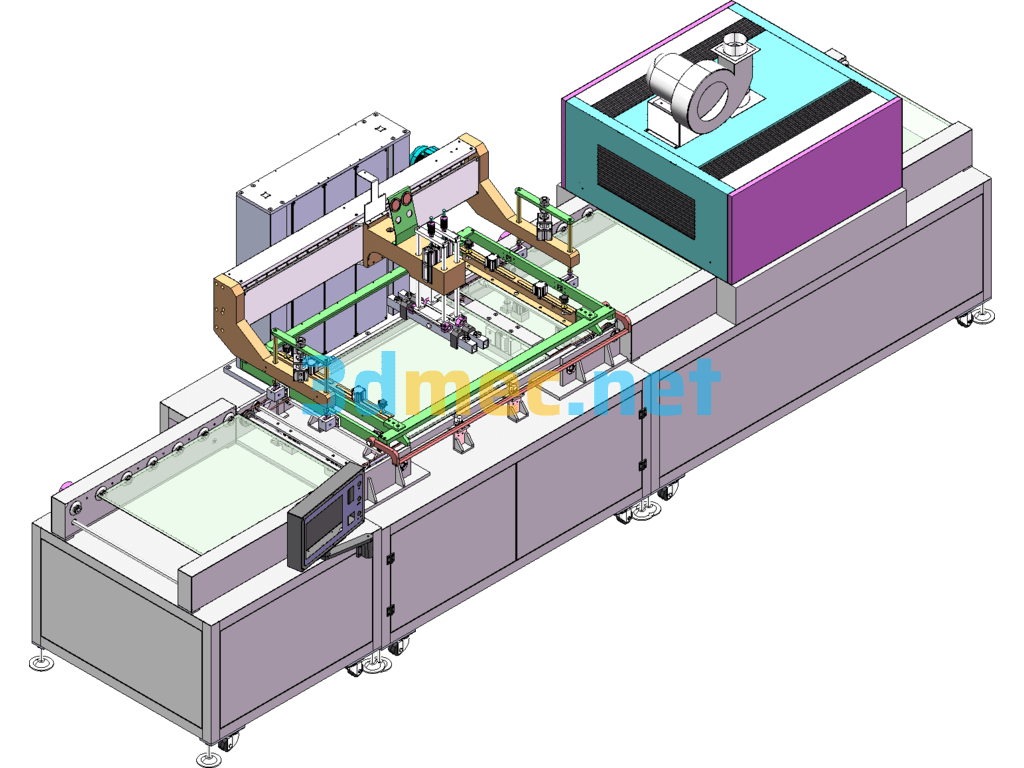

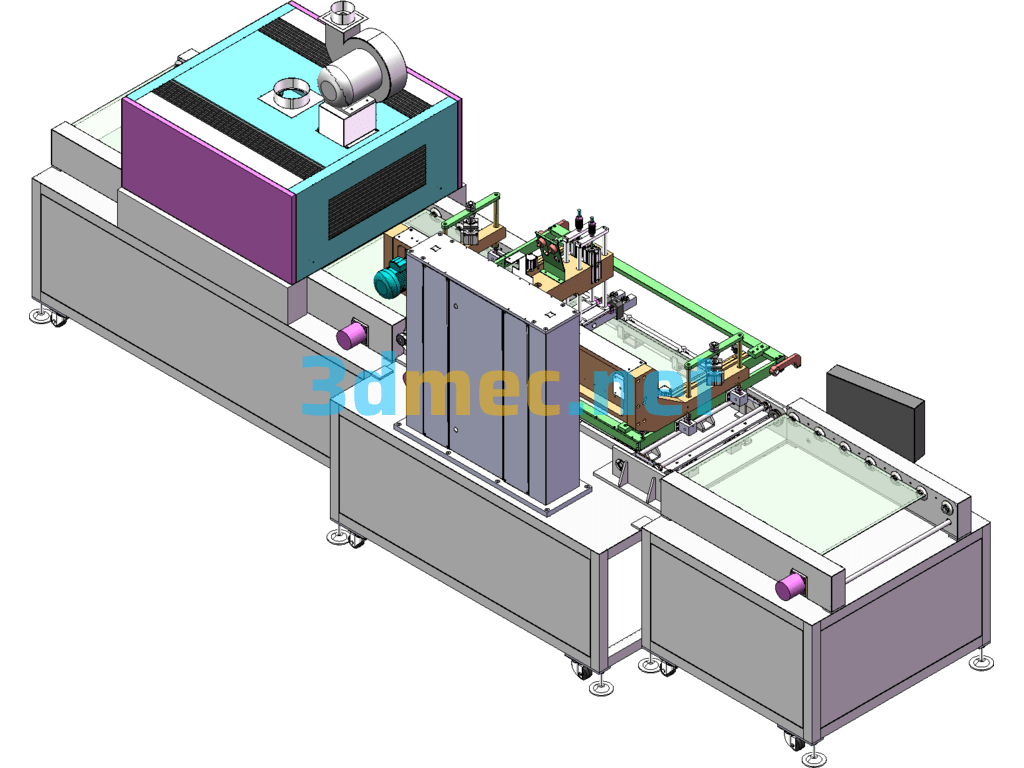

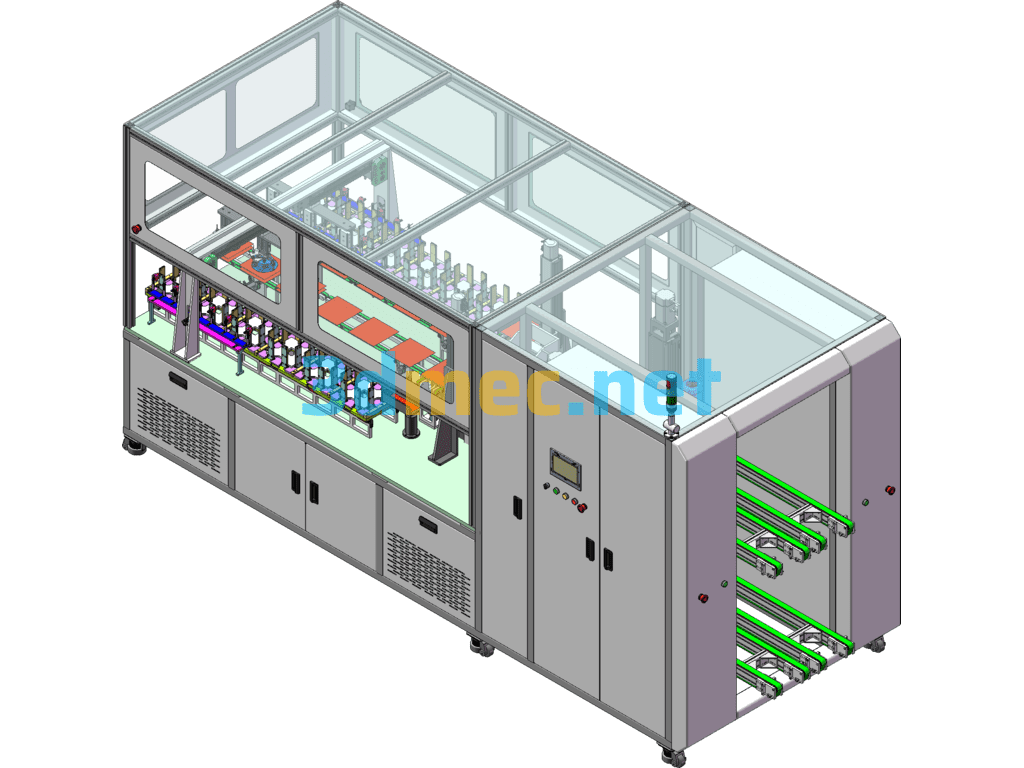

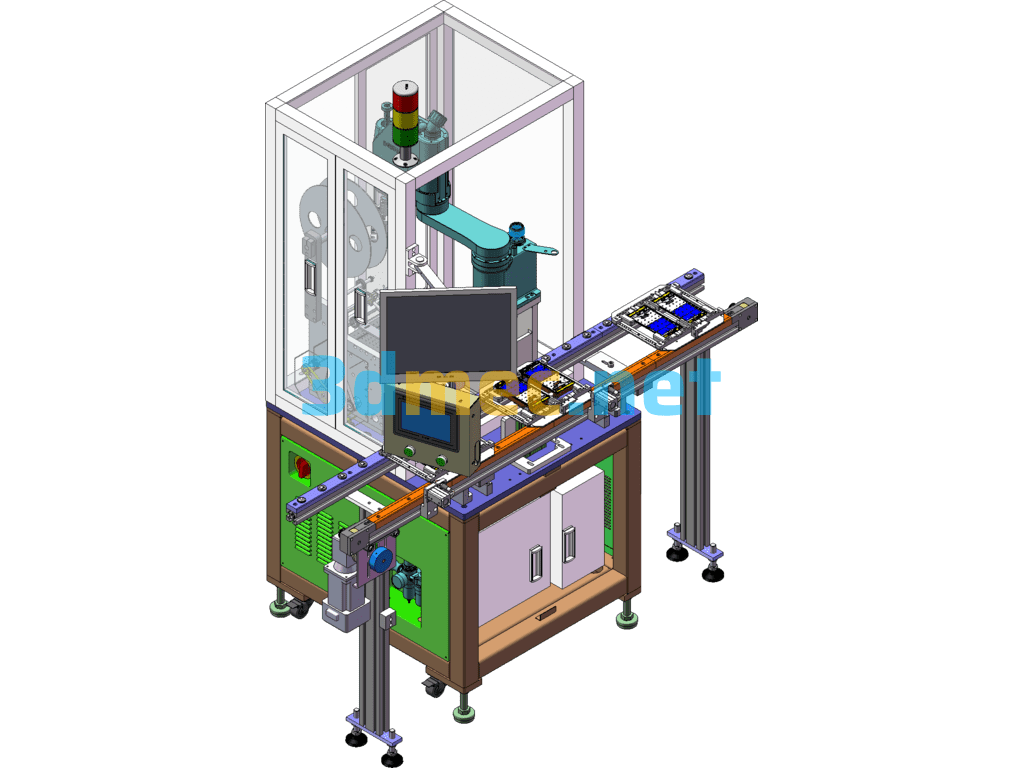

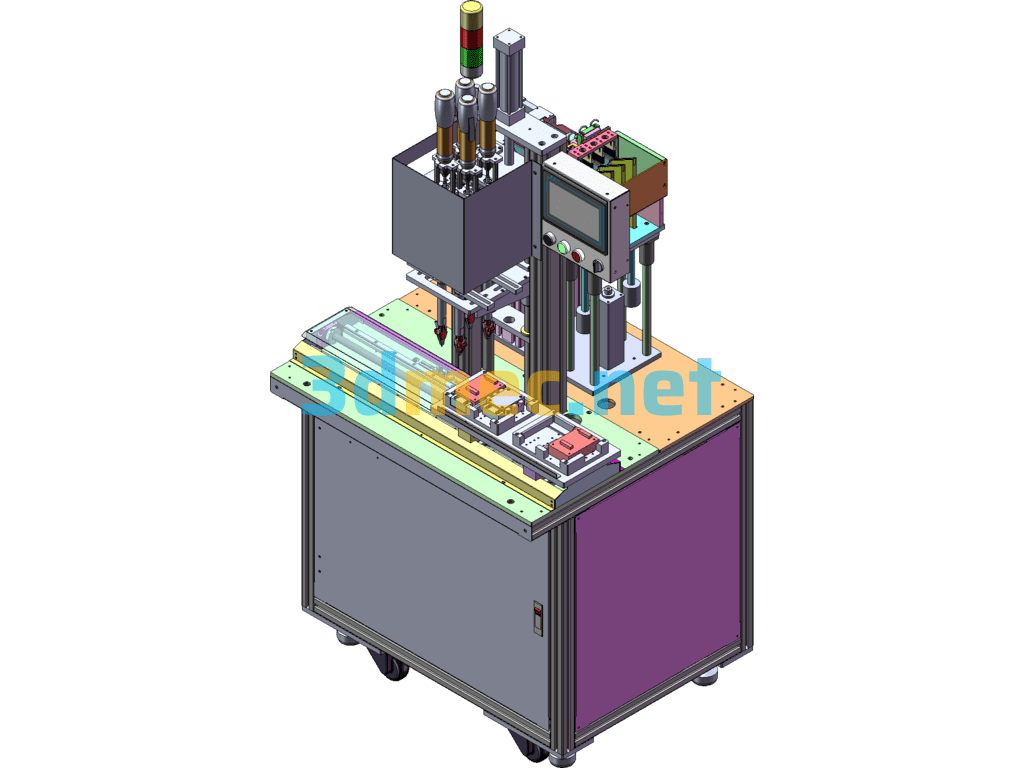

Fully automatic screen printing machine 3D model, fully automatic screen printing machine, maximum printing area 800*600, the main features of the equipment are 360° stop and turn drum, ultra-high printing accuracy; LCD human-machine dialogue interface; 4-9mm adjustable network (screen and drum spacing); pull-out screen frame, easier to check the paper feeding status and clean the screen; PLC controlled centralized lubrication oiler to ensure lubrication of the transmission part, reduce the key parts from being easily damaged and extend the service life; photoelectric monitoring of the empty and skewed state during the printing process, effectively reducing the scrap rate. Process flow: raw materials—automatic feeding (double-sided dust removal, tearing protective film, removing static electricity)—automatic printing (punching positioning holes, quality inspection lights)—automatic baking and rewinding (automatic glazing, protective film, laminating tape, release paper, etc.)—subsequent processes can realize automatic punching—finished products. Fully automatic only requires 1-2 people to operate, and a set of fully automatic only requires 15-20 square meters. A proposal for the design of a fully automatic screen printing machine is included.

Specification: Fully Automatic Screen Printing Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “Fully Automatic Screen Printing Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.