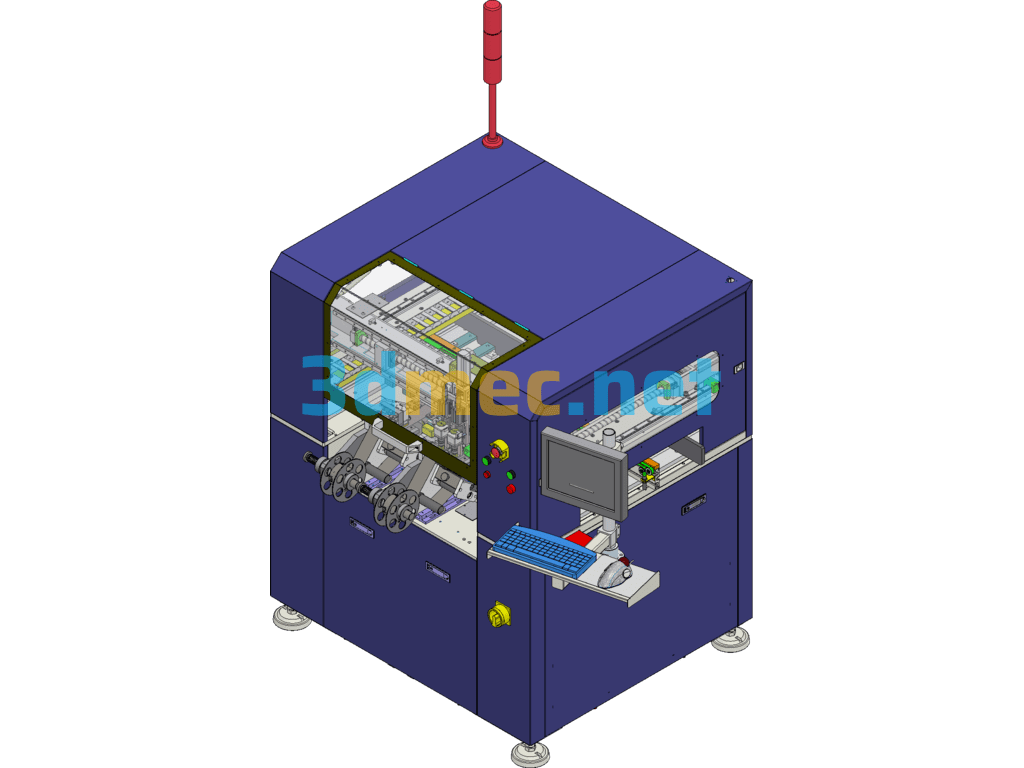

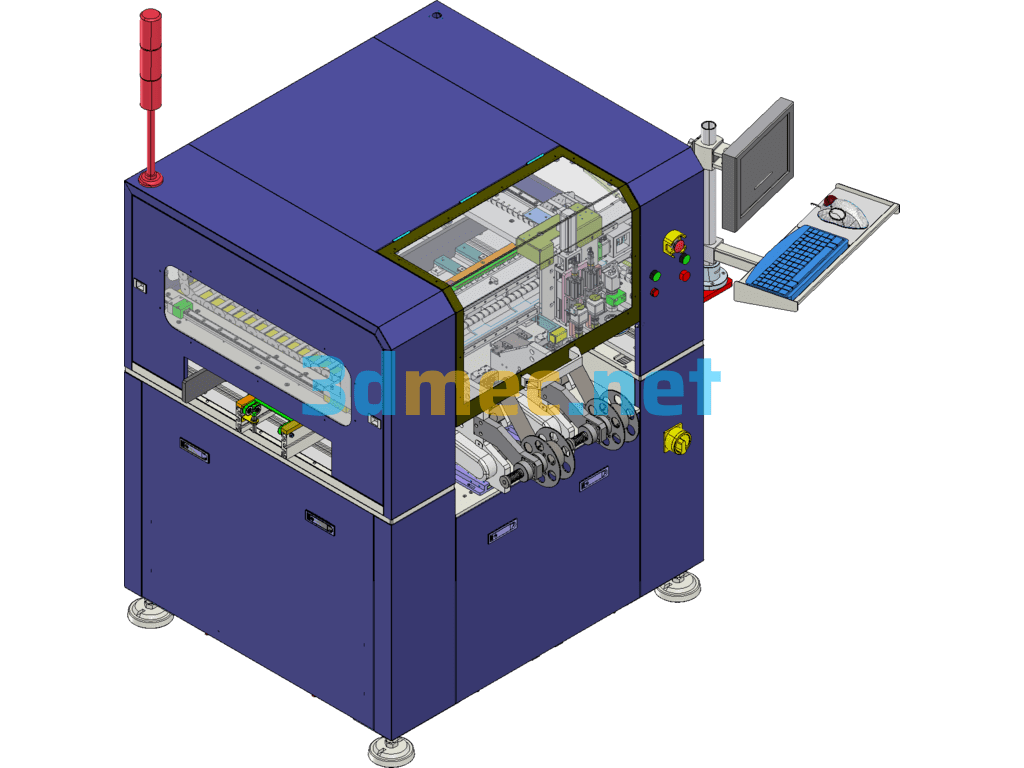

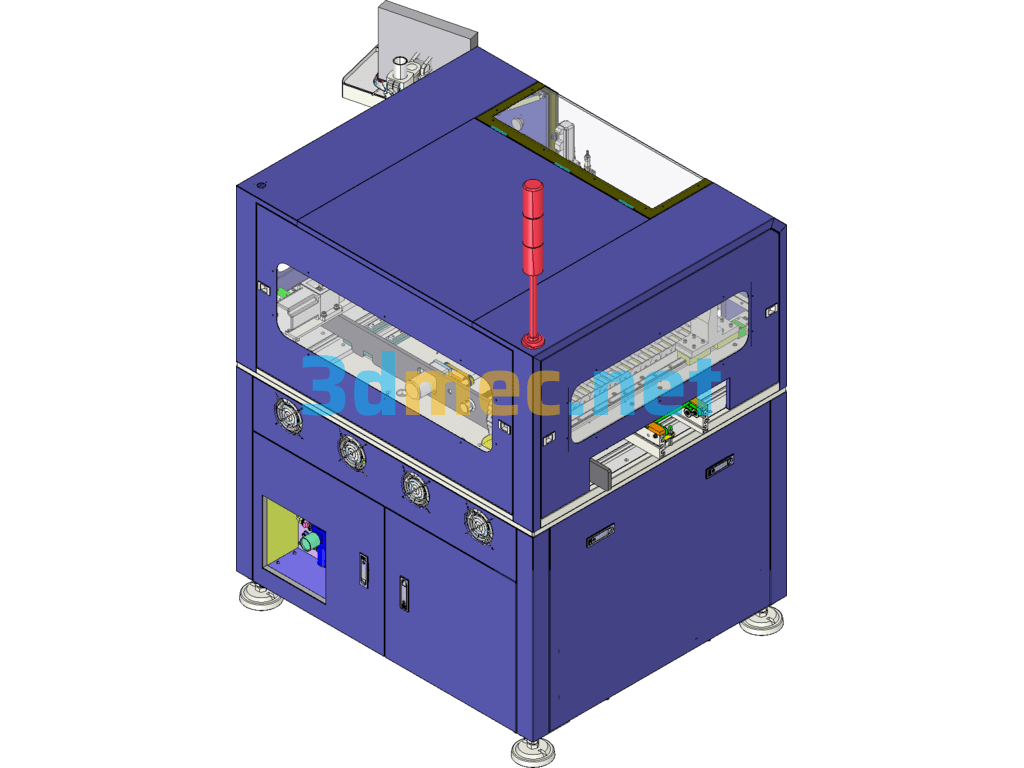

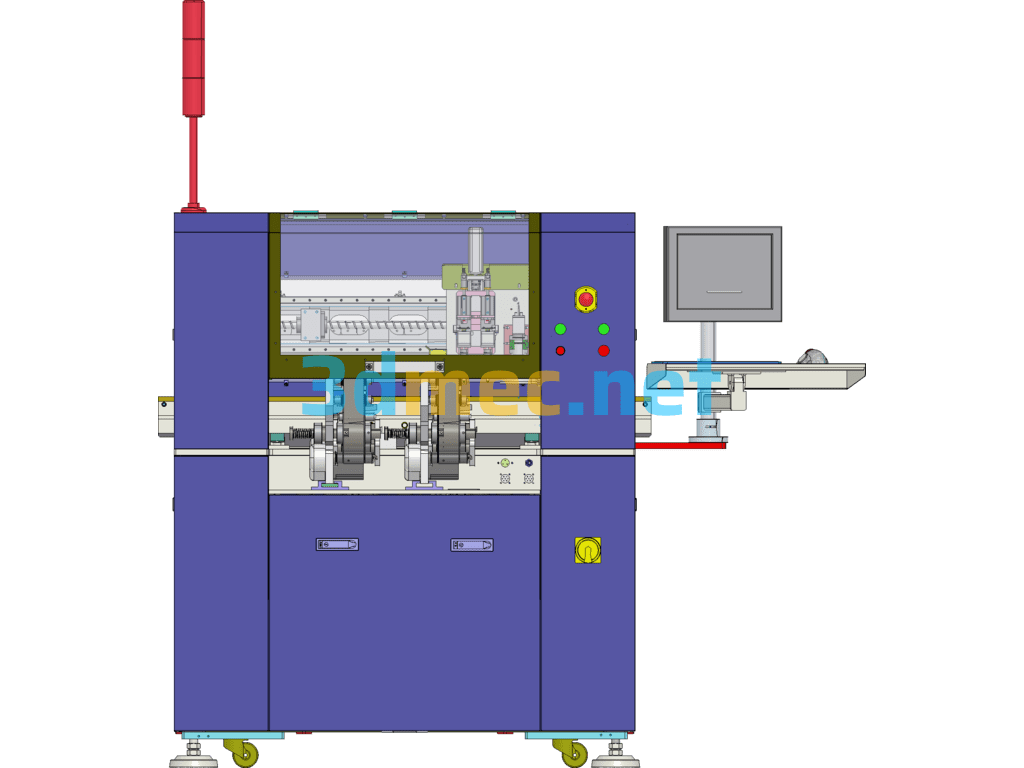

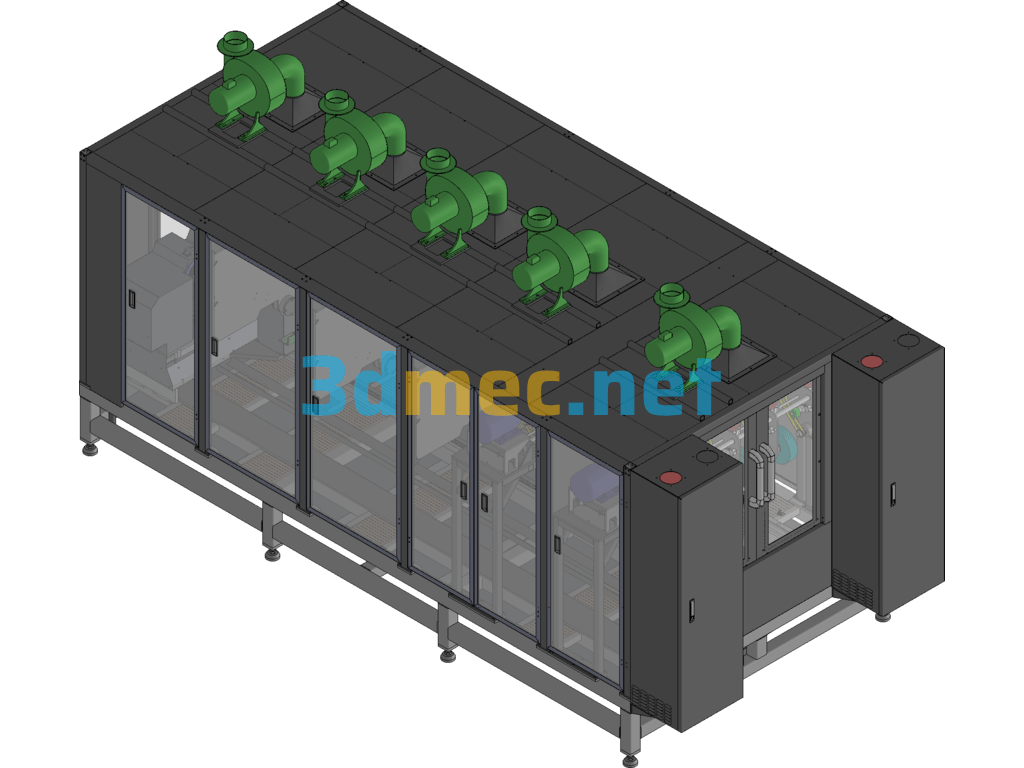

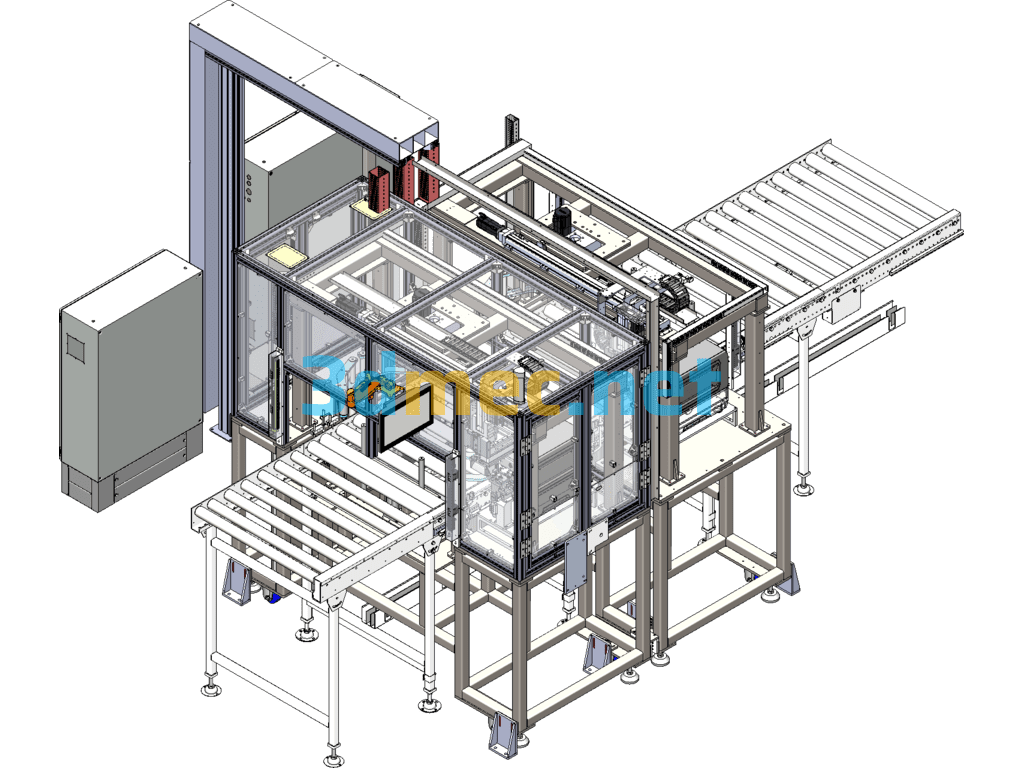

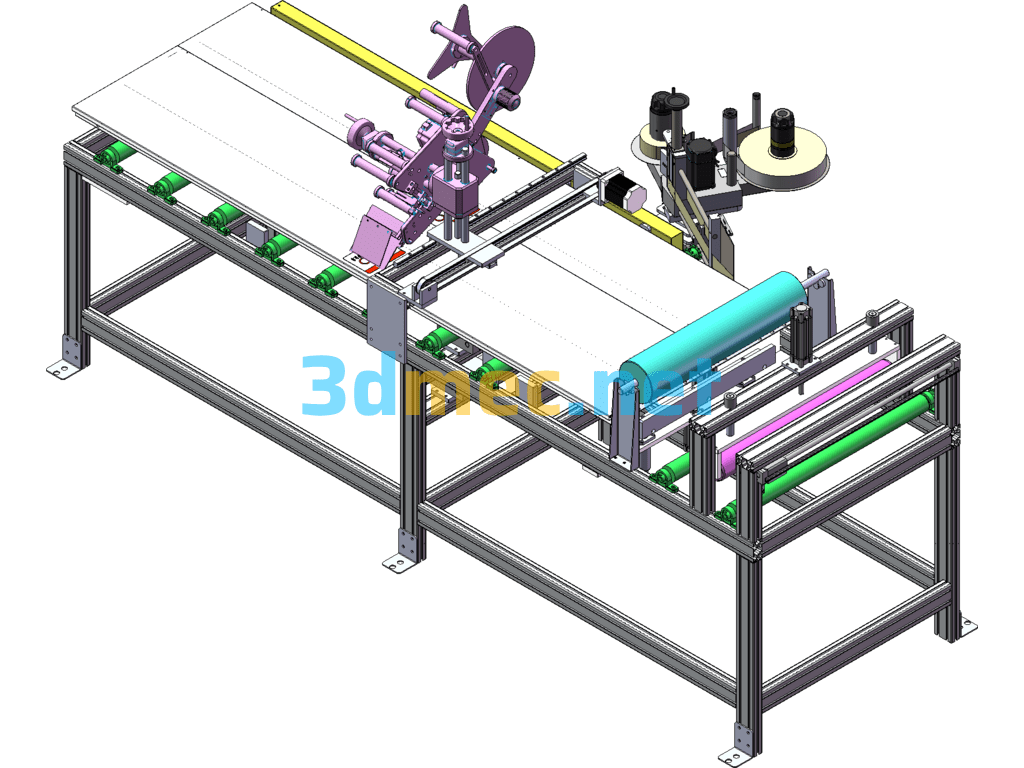

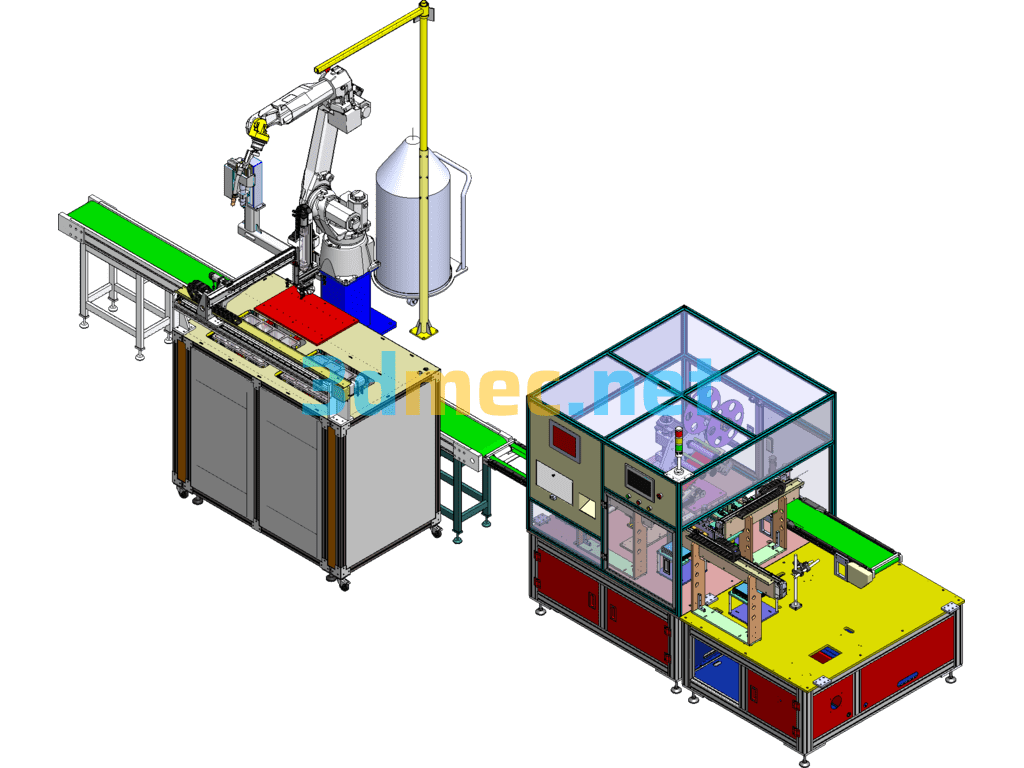

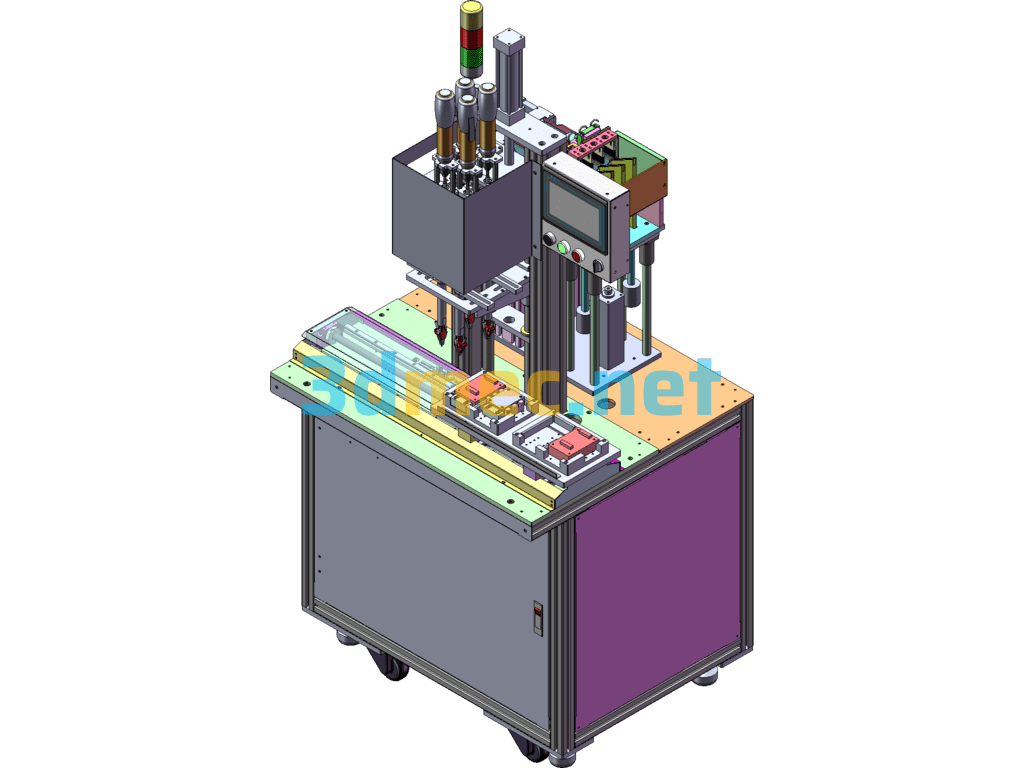

SMT high-speed barcode labeling machine for SMT line automatic barcode labeling, is a set of automatic feeding, automatic barcode labeling, automatic barcode reading in one of the new high-performance intelligent automatic barcode labeling equipment, this SMT high-speed barcode labeling machine for the double suction head to take the labeling structure of the suction head can be replaced, can be individually rotated to take a separate angle of the label, take the labeling and labeling accuracy by the CCD vision camera to achieve high-speed high-precision positioning Labeling, labeling accuracy of plus or minus 0.05MM, feeding conveyor width can be adjusted, according to the size of different boards and adjust the width, this drawing can be made into a mounter through the transformation of the current set of drawings uploaded to everyone to learn, misuse for commercial purposes, you want to more drawings, please enter my home page to download thank you, the total assembly body name: smttbj-000001 equipment parameters Category . Specifications Dimensions 1200*1000*1900 Input Voltage AC 220V 50Hz Maximum Power 1.8KW 7A Weight: ≈400kg Input Air Pressure 0.5-0.7 Mpa Air Consumption ≈20L/min Production Efficiency (C/T) ≤2/PCS Equipment Load and Use Ratio ≥95% (Including loading and unloading, adjusting the machine, etc.) Processing Methods Automatic feeding, automatic feeding, automatic barcode sticking, automatic barcode reading, automatic discharging PCB board feeding method Conveyor belt automatic feeding PCB board board maximum size 250*250 XY axis maximum stroke 400*330 Positioning method High-precision photoelectric sensors (driven by Panasonic servo motors, can be adjusted to the position) Positioning of the suction head CCD camera positioning The suction head rotating angle of the most 180o 90o Rotation mode Stepping motor rotation Labeling picking and labeling mechanism Labeling picking mode XYZ-axis manipulator driven cylinder suction cups to pick up the material Positioning adjustment mode High-precision photoelectric sensors can be adjusted at will Stroke arm movement speed Maximum 800mm/s Up and down adjustment Z-axis Stroke Adjustment Barcode sticking two-dimensional code equipment SMT on-line barcode labeling equipment – with CCD vision positioning mounter principle -Original design

Specification: Fully Automatic Online Barcode Labeling Equipment SolidWorks 3D Model

|

Project's Download Info

User Reviews

Be the first to review “Fully Automatic Online Barcode Labeling Equipment SolidWorks 3D Model” Cancel reply

You must be logged in to post a review.

There are no reviews yet.