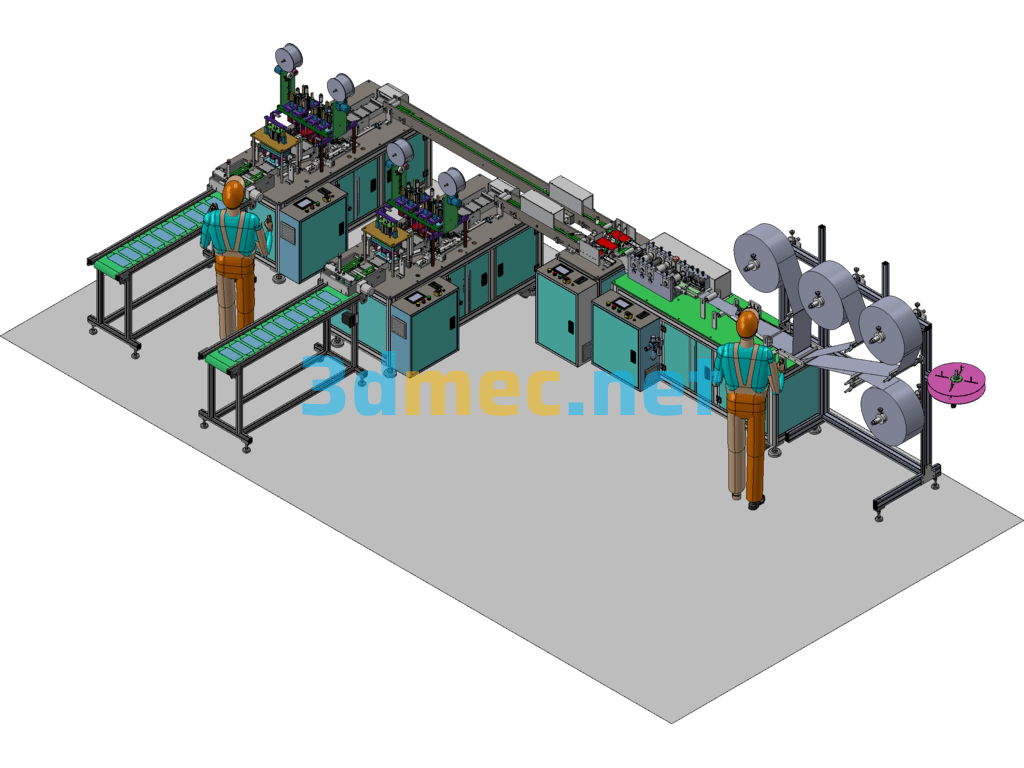

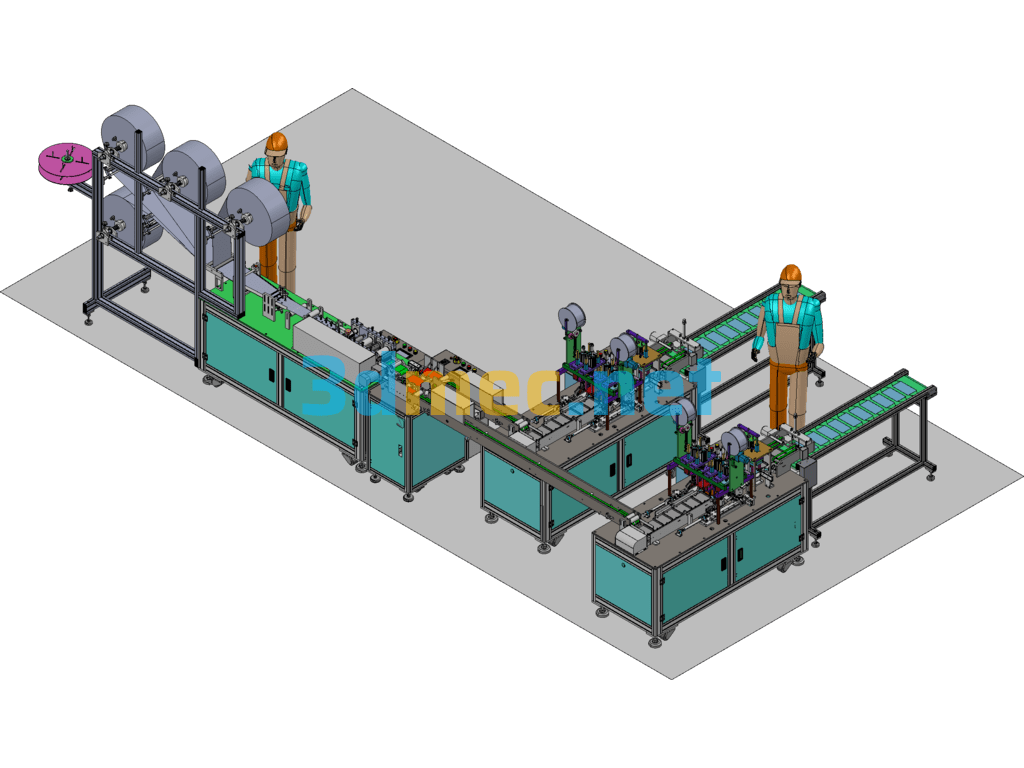

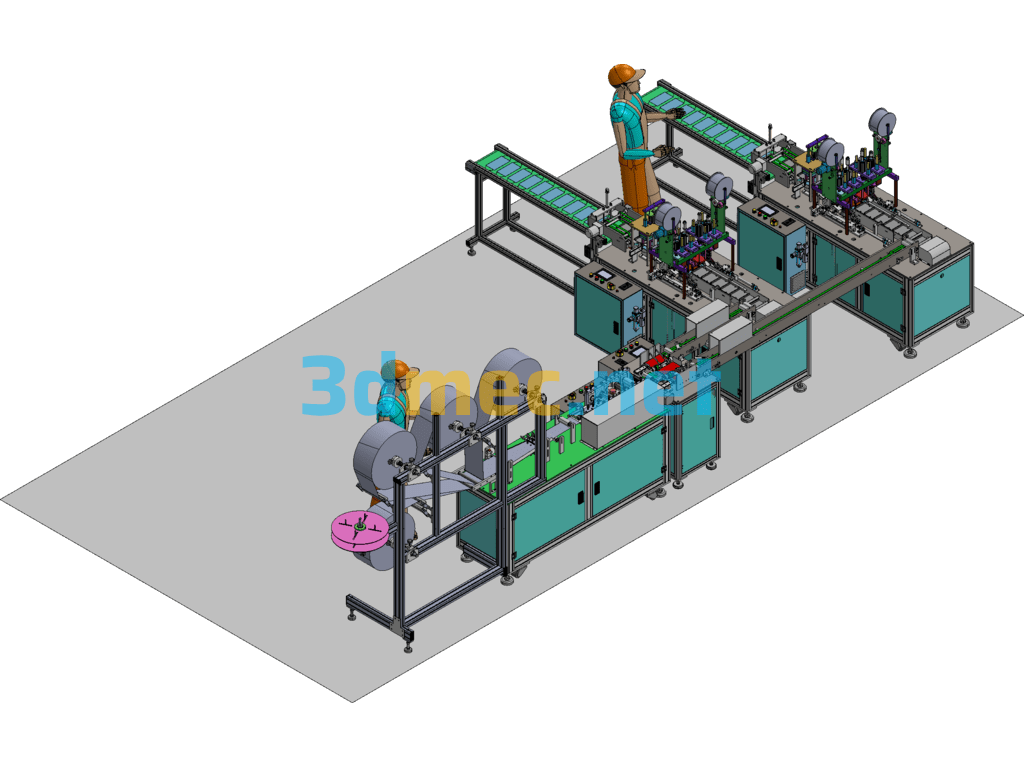

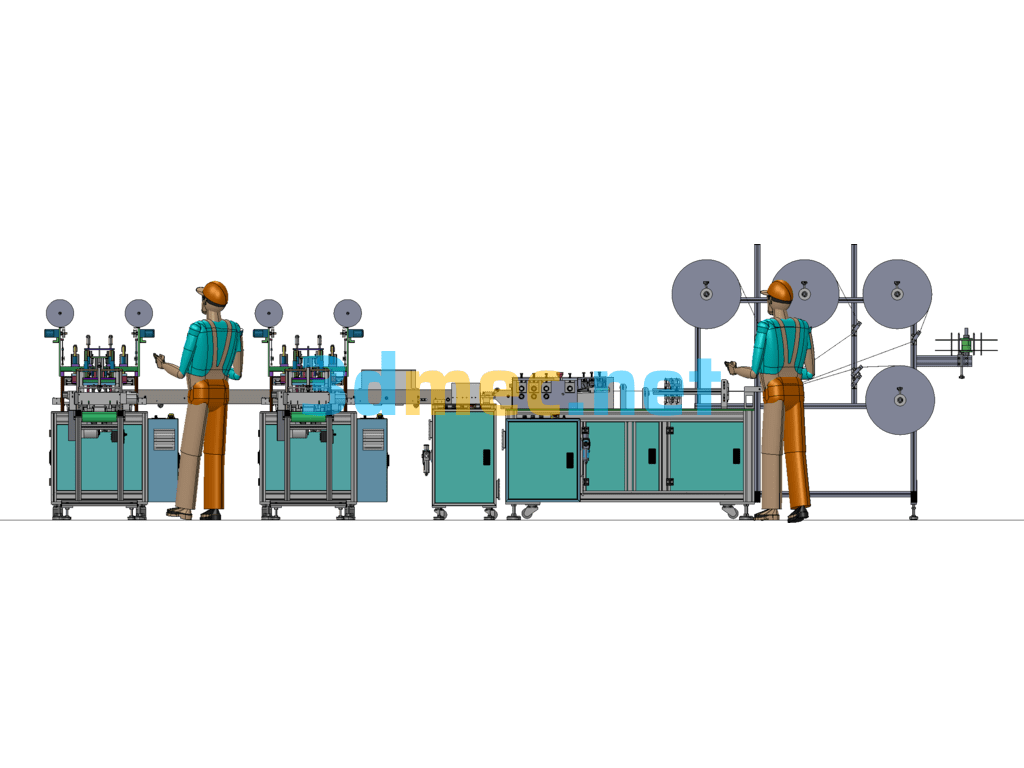

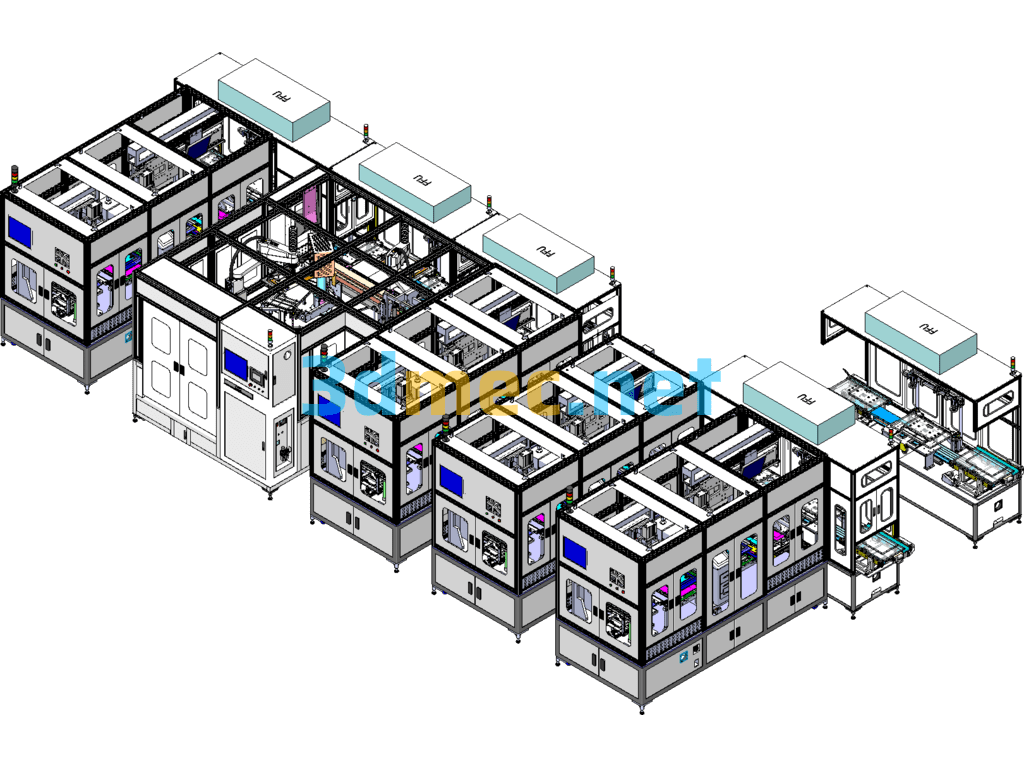

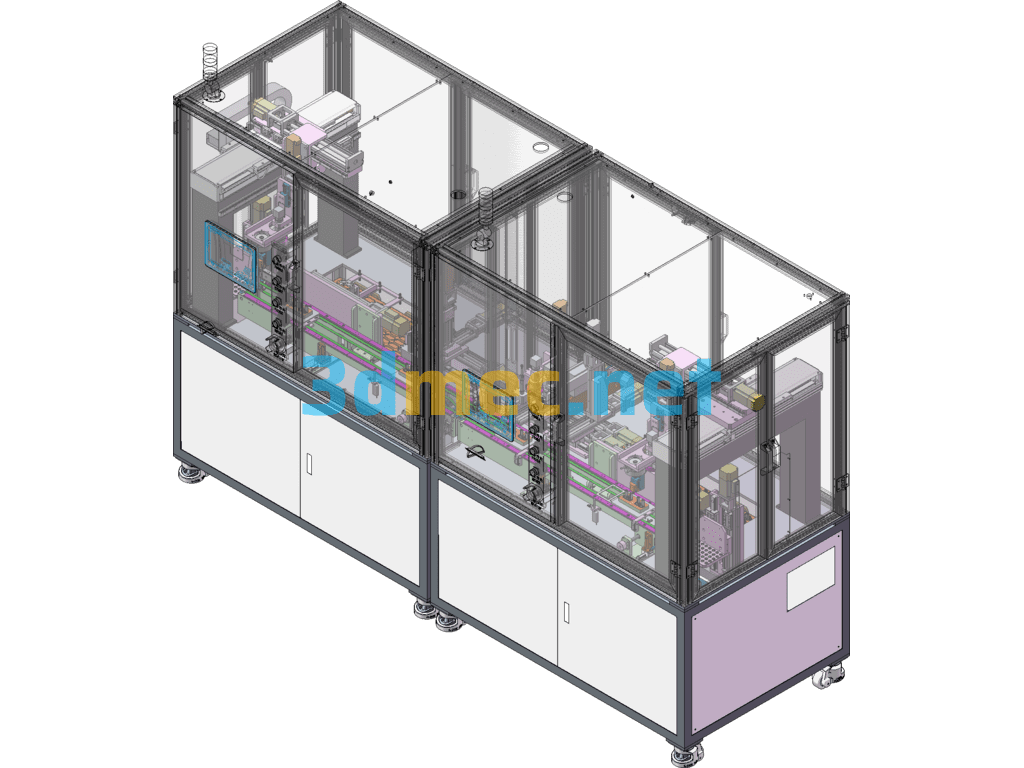

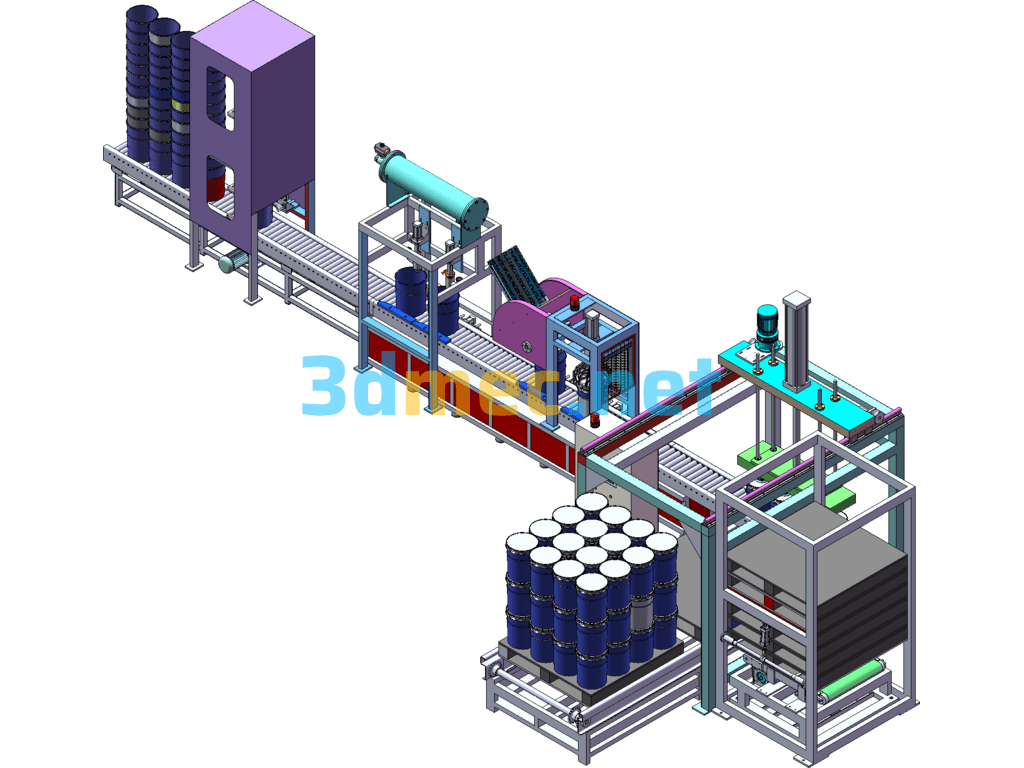

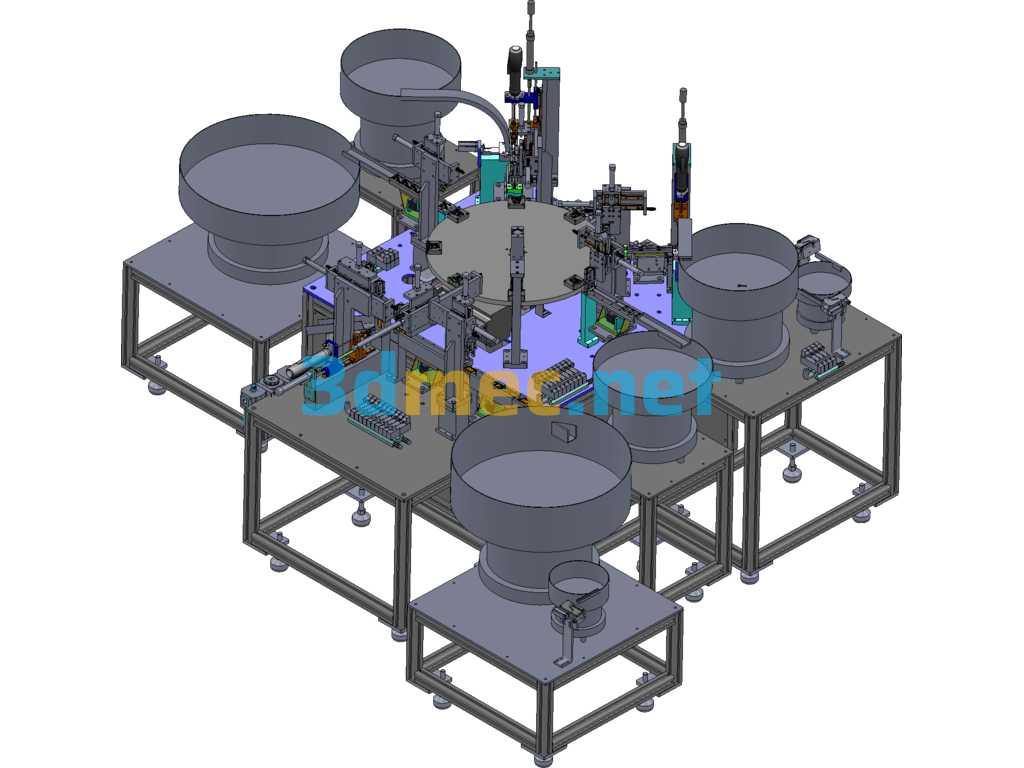

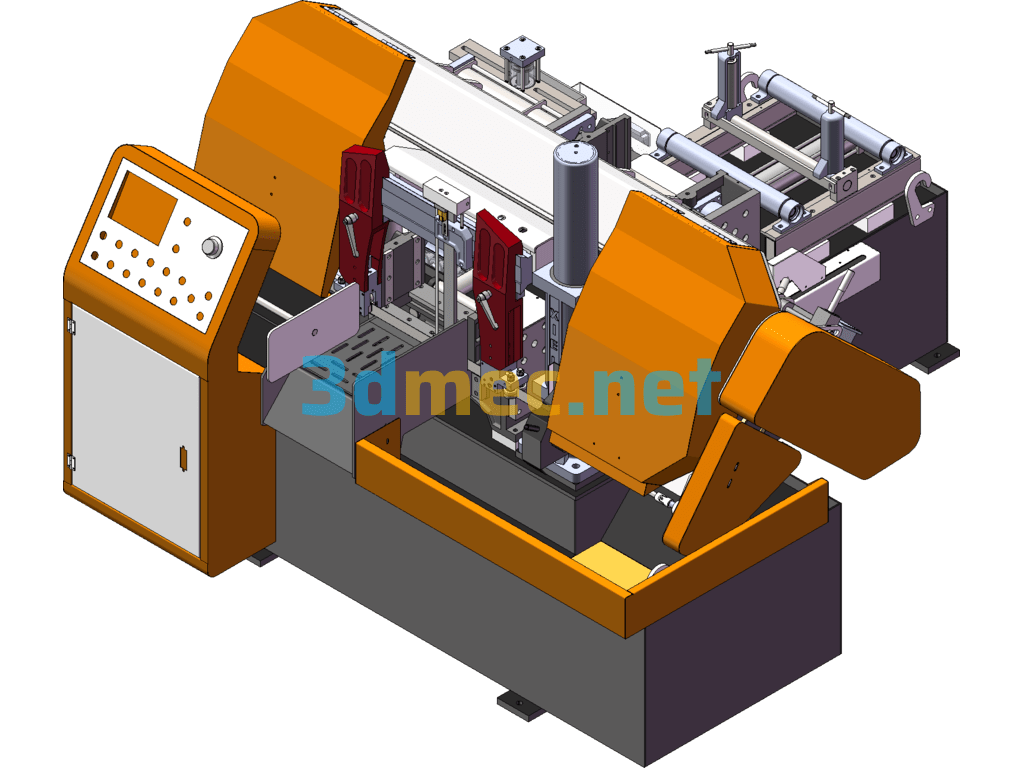

Full automatic one tow two plane mask machine production line is a full automatic high speed plane type ear strap mask production line from Xintaiming, including automatic raw material feeding, automatic conveying, cutting off nose strip, mask edge welding, folding, ultrasonic fusion, molding, cutting off and so on full process automation, completing the whole production process from the raw material of the rolls of material to the finished product of the mask. n The high-speed automatic one-two flat mask machine production line is connected by one body machine and one ear band machine. After outputting the mask body from the body machine, the conveyor belt structure conveys the mask body piece to the flipping mechanism, and through the flipping mechanism, the mask disk is flipped to the conveyor belt connected to the ear band machine, and then through the conveyor belt, the mask piece is conveyed to the front of the ear band machine on the top of the first mask disk, and finally through the pneumatic cylinder downward pressure the mask piece is placed in the mask disk of the ear band machine, and then the ear band machine completes the fusion of ear band of masks, wrapping and other actions, thus completing the production of an ear band mask product. Then the ear band machine will complete the production of one ear band mask product. n The high-speed automatic one-two flat mask machine production line is mainly used for automatic molding of flat masks: the whole roll of fabric is unrolled and then driven by rollers, and the fabric is automatically folded and wrapped; the whole roll of nose strip is hauled and unrolled, and then cut at a fixed length and imported into the wrapped fabric, and then both sides are welded by ultrasonic welding to the closure and then ultrasonically sealed sideways, and then cut and shaped by the cutter; the masks are transported through the assembly line to the two earband welding stations, and then ultrasonically welded and ultimately welded to the final earband welding station. The masks are conveyed to the two mask ear band fusion stations through the assembly line, and the final masks are formed through ultrasonic welding; when the masks are made, they are conveyed to the flat belt line for collection through the assembly line.

Specification: Fully Automatic One-Two Flat Mask Machine (3D Supplementary Version) Exported 3D Model

|

User Reviews

Be the first to review “Fully Automatic One-Two Flat Mask Machine (3D Supplementary Version) Exported 3D Model”

You must be logged in to post a review.

There are no reviews yet.