Johnathan Marks

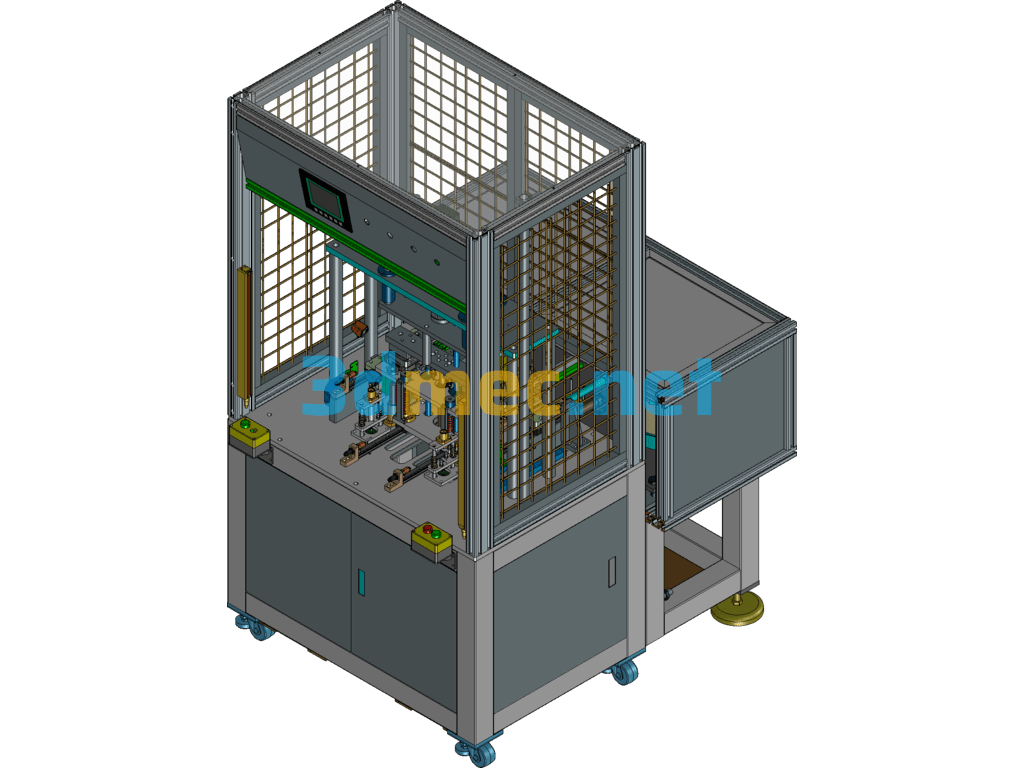

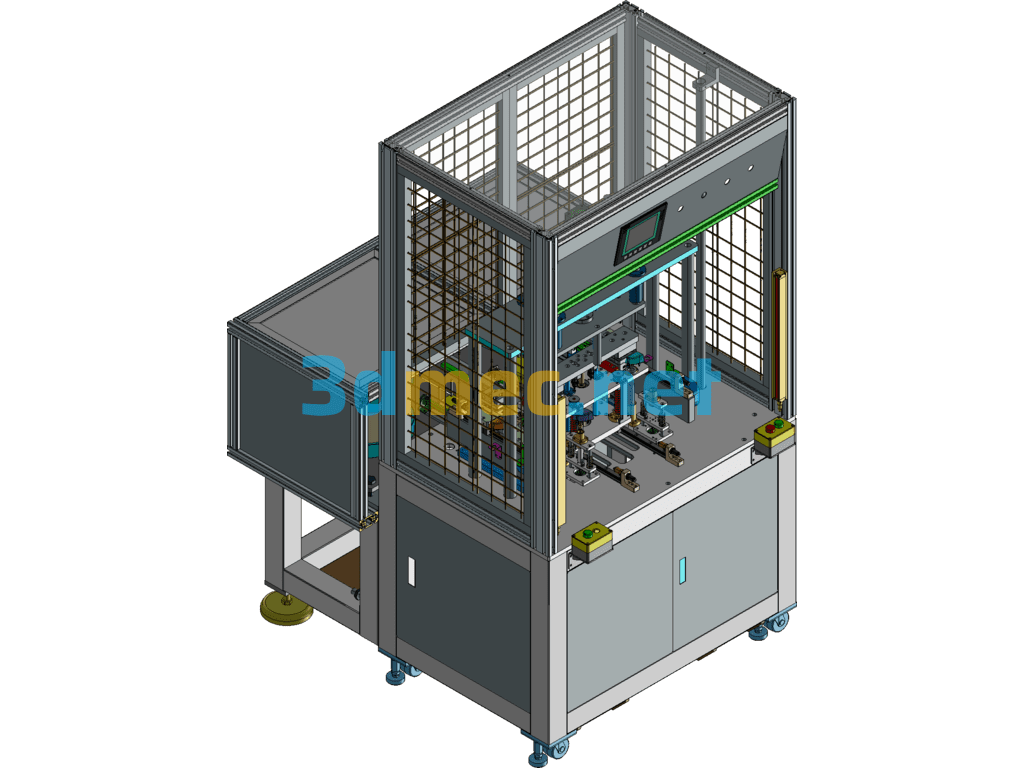

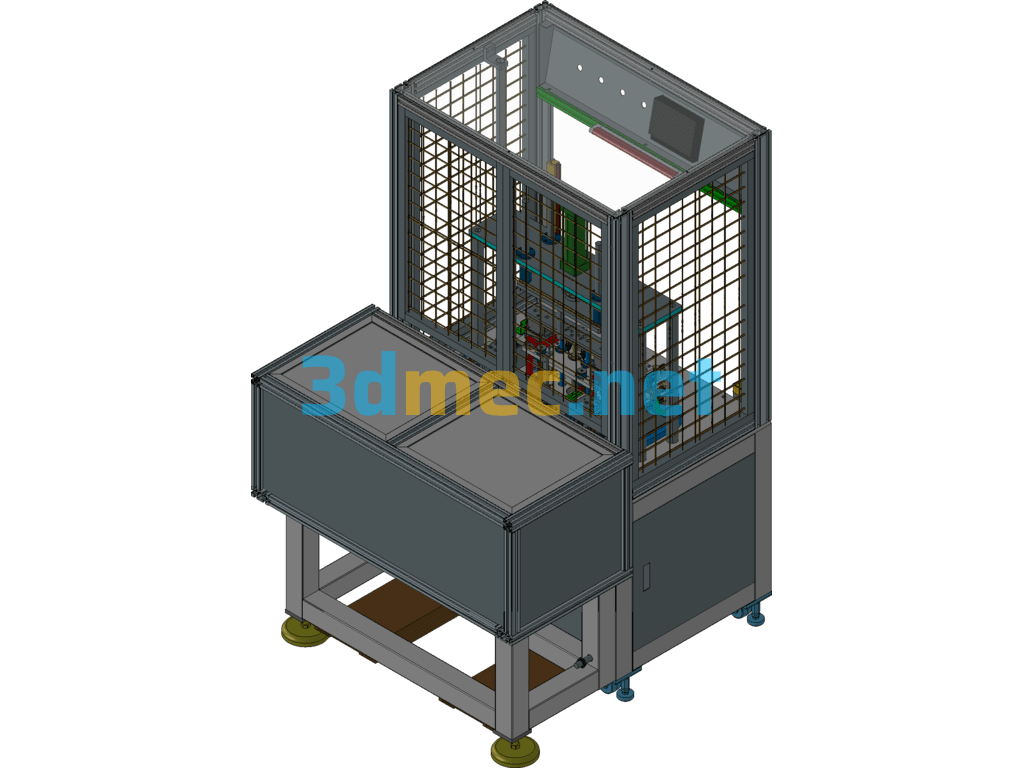

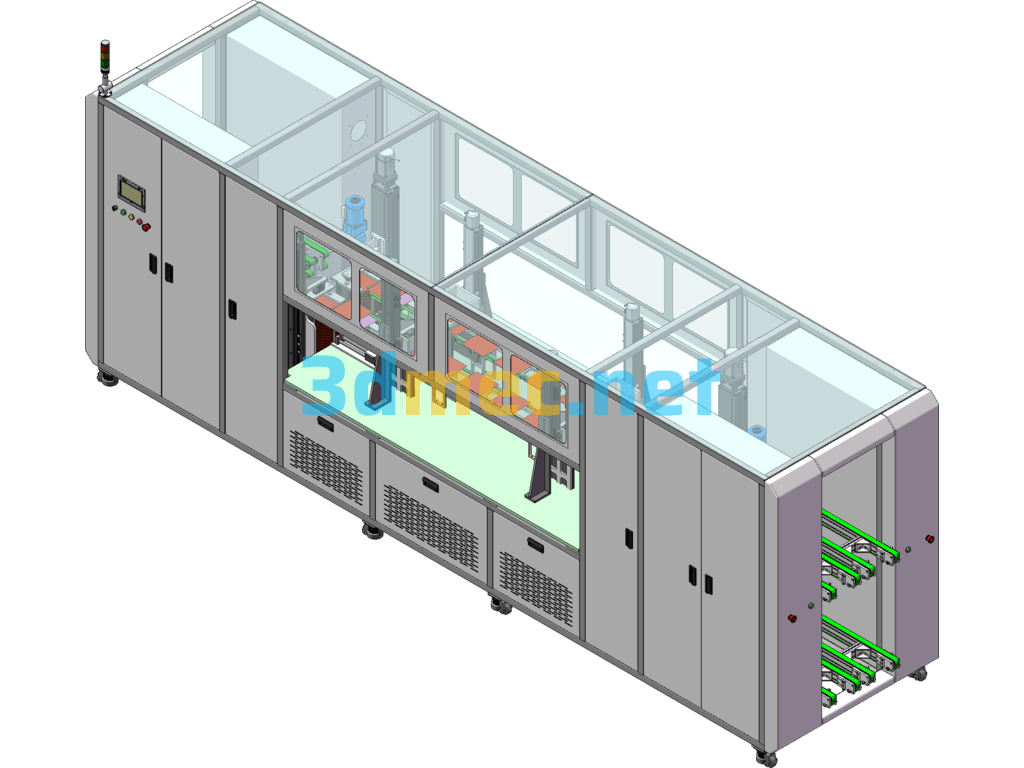

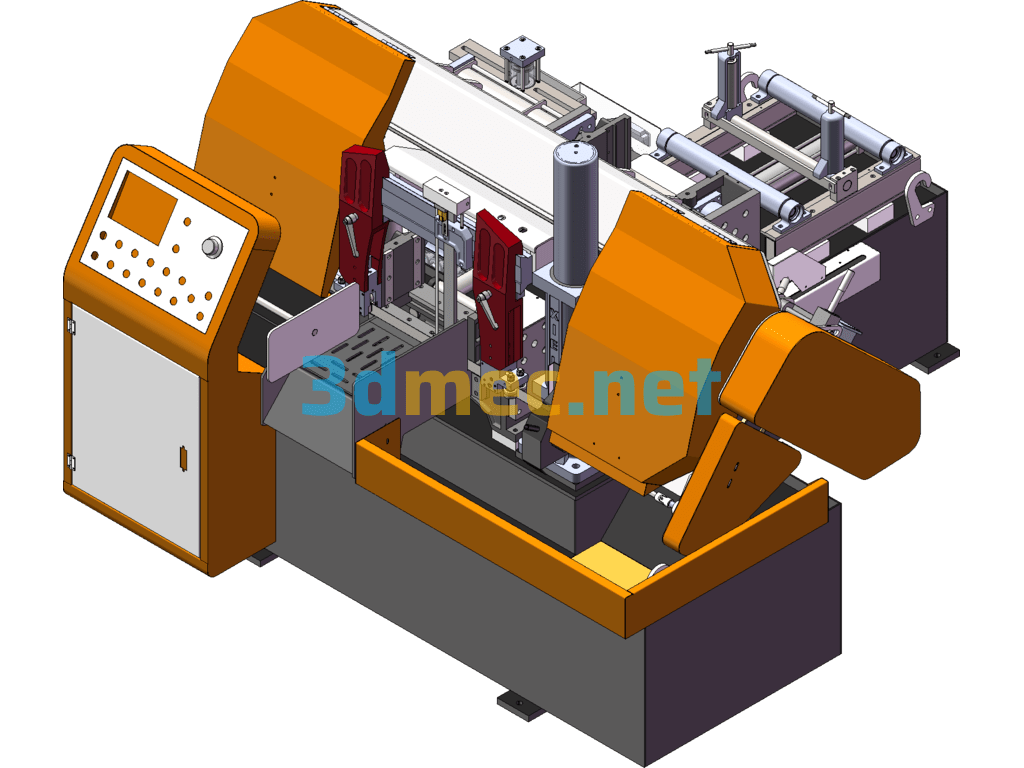

[Equipment independently developed by the automation company] Automatic nut implantation equipment, also known as fully automatic nut implantation machine, is often used in electronic industry equipment. This equipment has been put into production and can be directly copied and used. The equipment structure is classic and compact. , beautiful appearance, the device has a total of 581 files, all of which are SW source files and XT universal 3D files.

Automatic nut implanting equipment. Automatically insert the nut through the propagation of the welding head and appropriate pressure to instantly squeeze the metal parts (such as nuts, screws, etc.) into the reserved plastic holes and fix them at a certain depth. After completion, both pulling force and torsion are comparable to the strength of traditional in-mold molding, which can avoid the shortcomings of damage to the injection mold and slow injection (automatic nut implantation equipment). Nut hot-melt embedding equipment is suitable for the inlaying and welding of metal mechanical components and plastic mechanical components, and the hot-melting and embedding of screws, nuts and other hardware. Nut hot-melt implantation equipment is widely used in the welding of copper nuts fixed to digital camera memory cards, speaker grilles, MP3s, computer built-ins, Bluetooth, and mobile phone cases (automatic nut implantation equipment).

Hot-melt nut embedding has high production efficiency and quick production changeover. Once the machine is debugged once, it will be very fast to change production anytime. Just find the product program in the corresponding folder and put it into the corresponding mold to use (automatic nut implantation equipment).

The operation process of nut hot-melt embedding equipment: first put the products to be welded into the mold respectively, align the positions, adjust the required heating temperature and welding time, etc. Turn on the start button, and the nut is hot-melt embedded. The implantation equipment enters fully automatic operation. The product is heated by the middle heating plate first, and then exits the heating plate when it reaches the specified temperature and time, and then uses the cylinder to weld the upper and lower plastic parts to be welded. (Automatic nut implantation equipment).

Specification: Fully Automatic Nut Embedding Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “Fully Automatic Nut Embedding Machine – 3D Model SolidWorks” Cancel reply

You must be logged in to post a review.

There are no reviews yet.