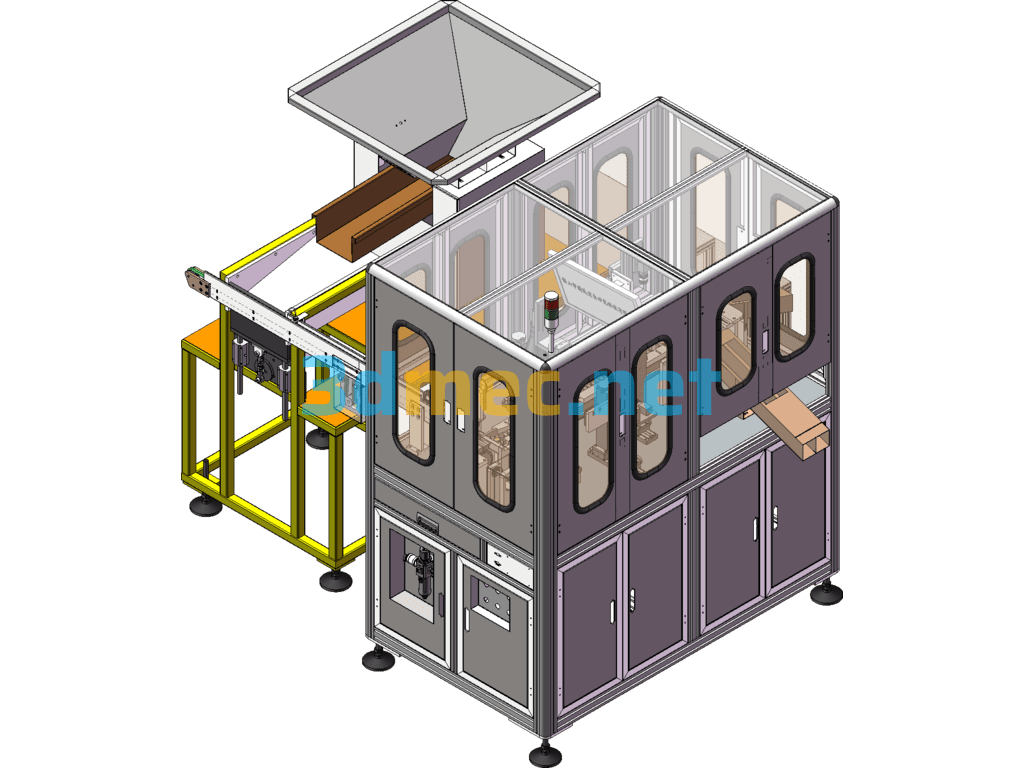

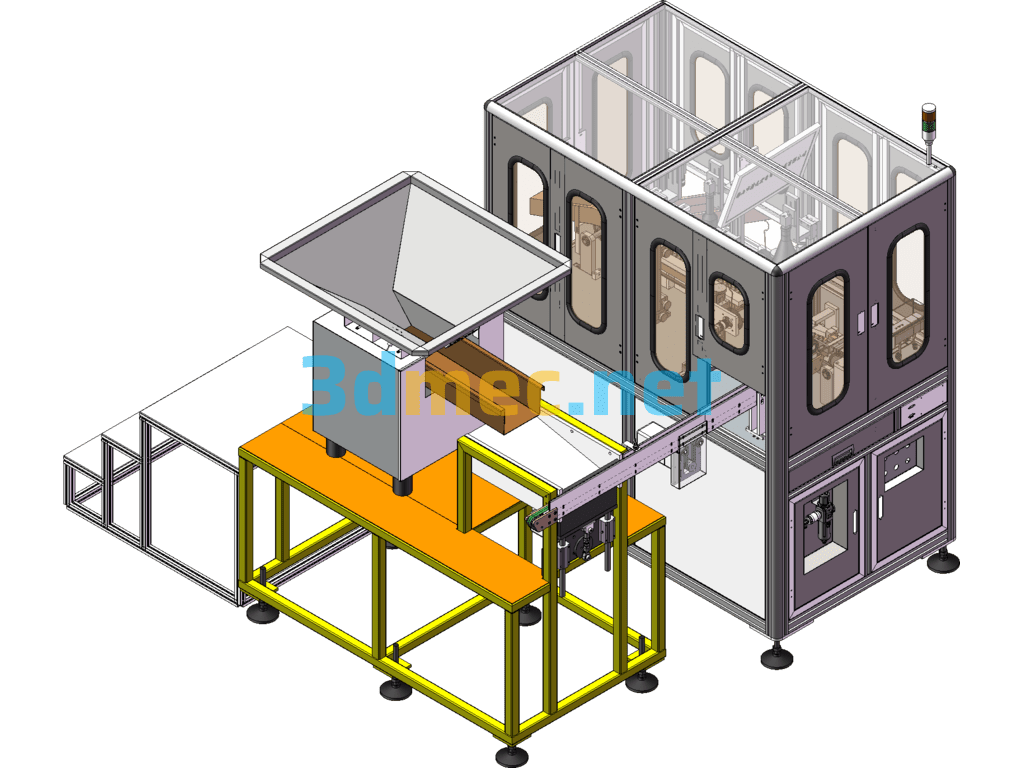

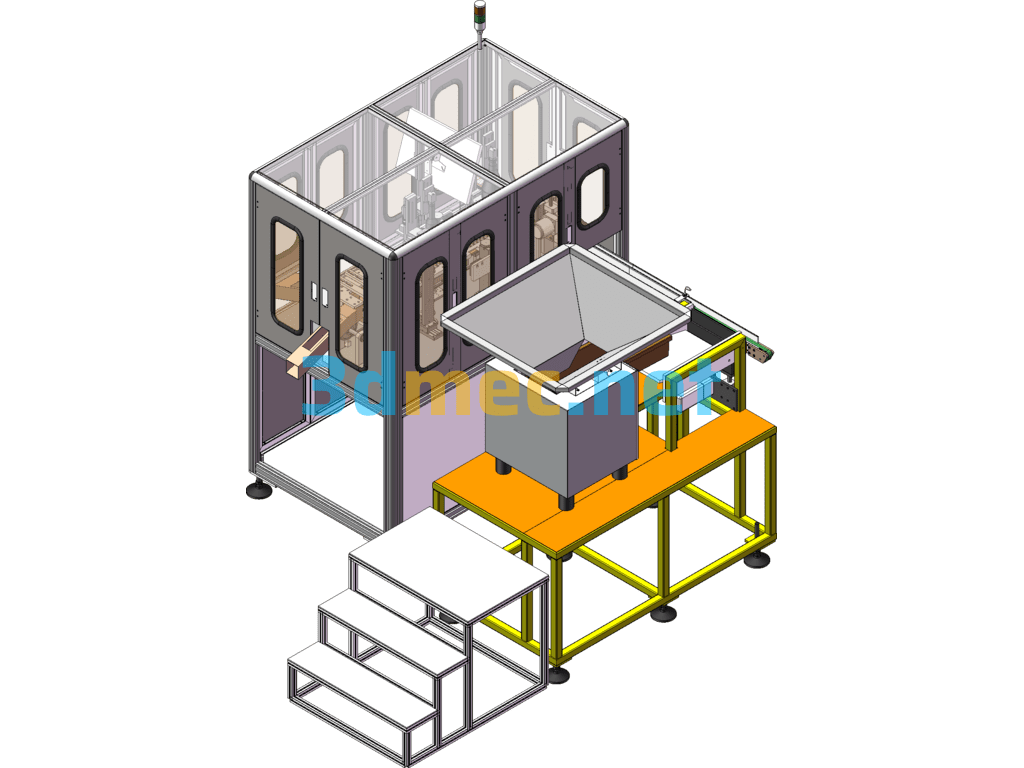

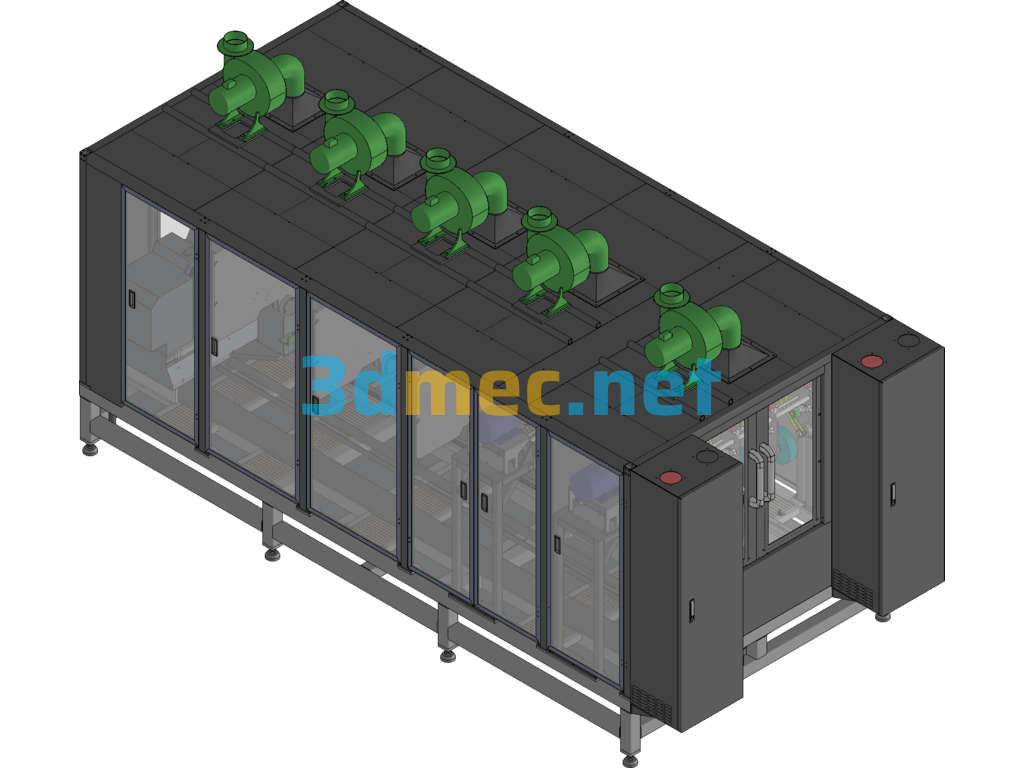

Fully Automatic Catheter Inspection Machine 3D Digital Model + BOM + Design Instructions – 3D Model SolidWorks

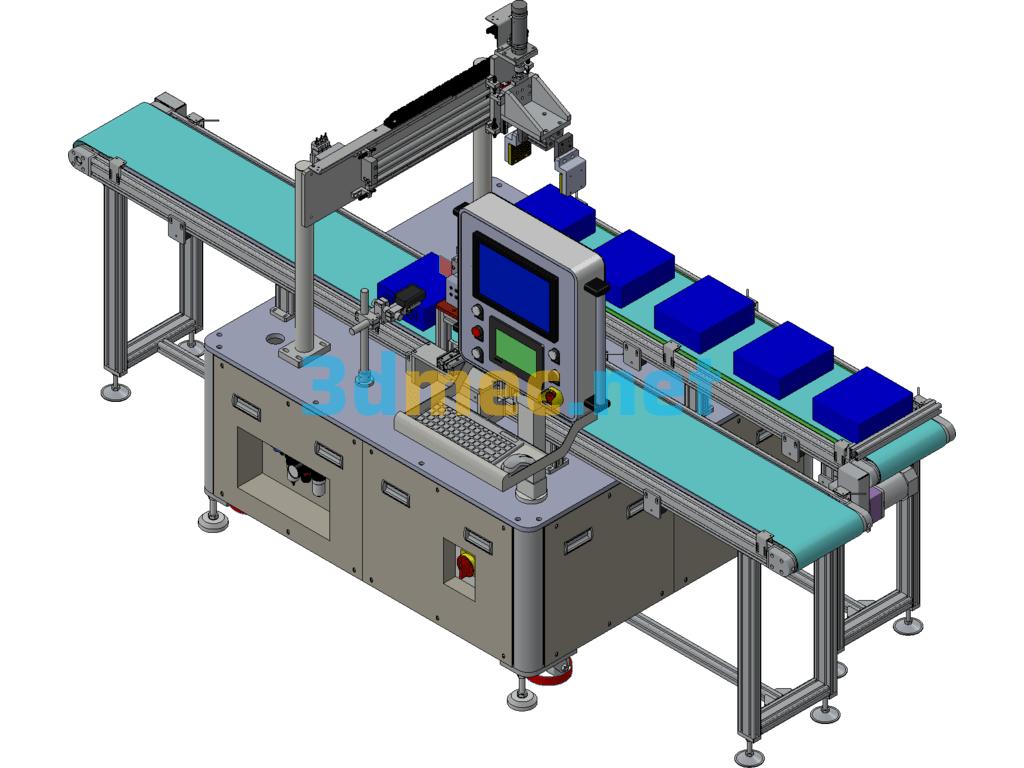

Fully automatic catheter inspection machine machine functions:

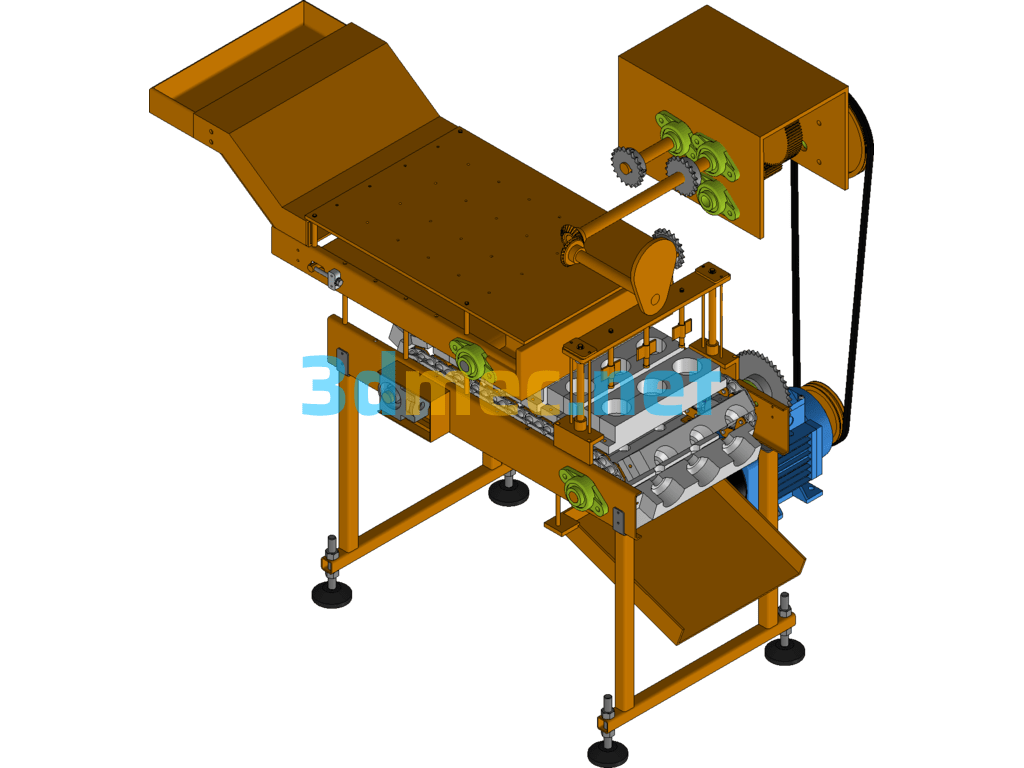

1. Automatic feeding system: Pour the catheter into a large funnel, and gradually send a small amount of product to the slot of the insert plate feeder through vibration waves; the insert plate feeder sends the products horizontally to the conveyor belt one by one;

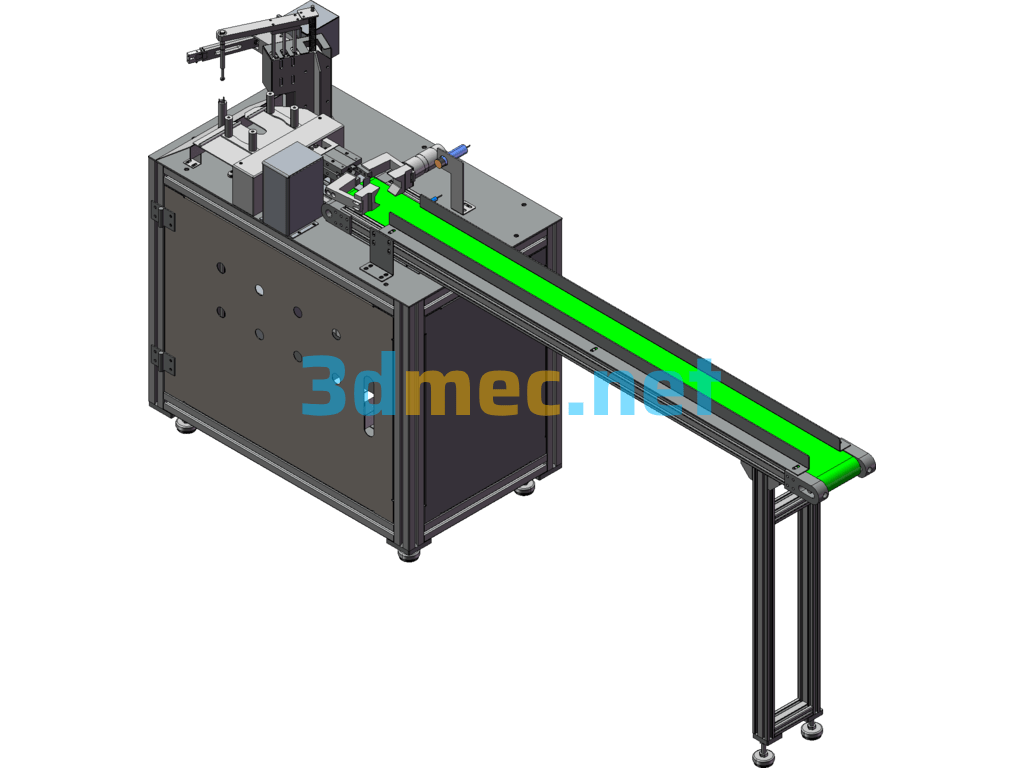

2. Top CCD1 detection, that is: the size detection of items A, B, C, D, E, F, and G in the attached “Inspection Content Description Figure”;

3. Side CCD2 and CCD3 detection, respectively used to measure the inner diameter, outer diameter, surface indentation, and lack of material detection. The visual system has an automatic faceting function, that is: the H, I, and J items in the attached “Inspection Content Description Figure” detection;

4. Discharge sorting system: After the software determines the properties of the catheter, the PLC electrical control system discharges the current product according to the properties of the current product recorded by the software (good products/waste products). Qualified products are discharged to the qualified discharge port, and defective products are discharged to the defective discharge port. This system is equipped with two good product discharge ports, one bad product discharge port, and one untested discharge port; the discharge height meets the interface standard of the later packaging machine.

Included: design manual + BOM + original file + neutral format

Specification: Fully Automatic Catheter Inspection Machine 3D Digital Model + BOM + Design Instructions – 3D Model SolidWorks

|

User Reviews

Be the first to review “Fully Automatic Catheter Inspection Machine 3D Digital Model + BOM + Design Instructions – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.