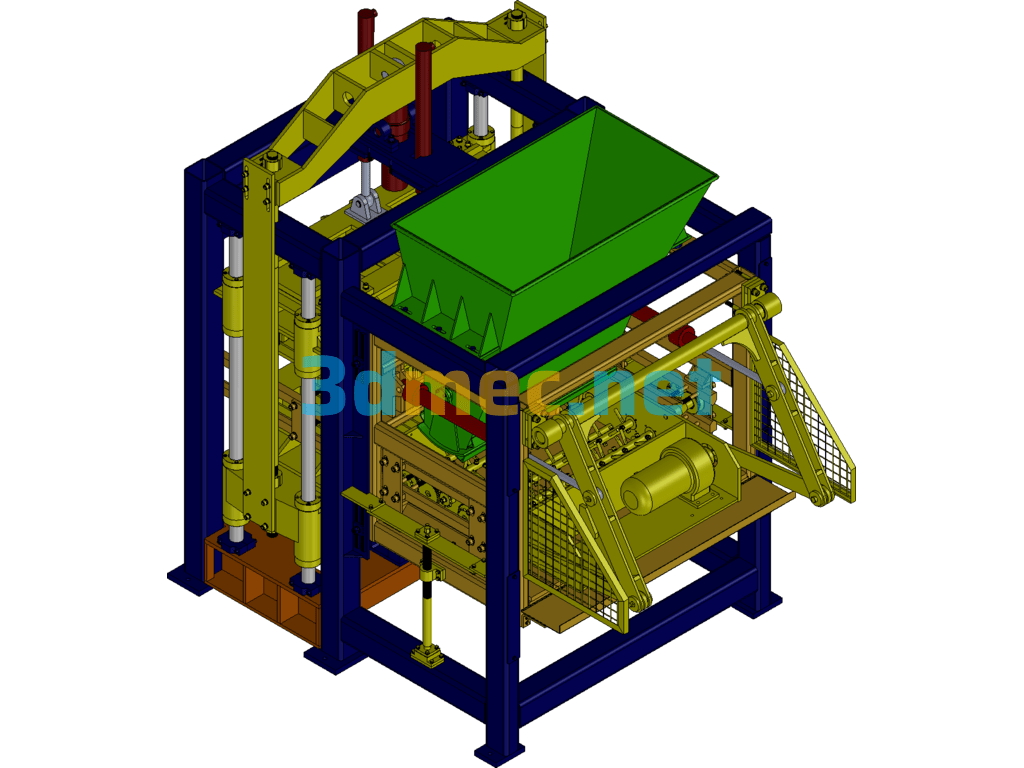

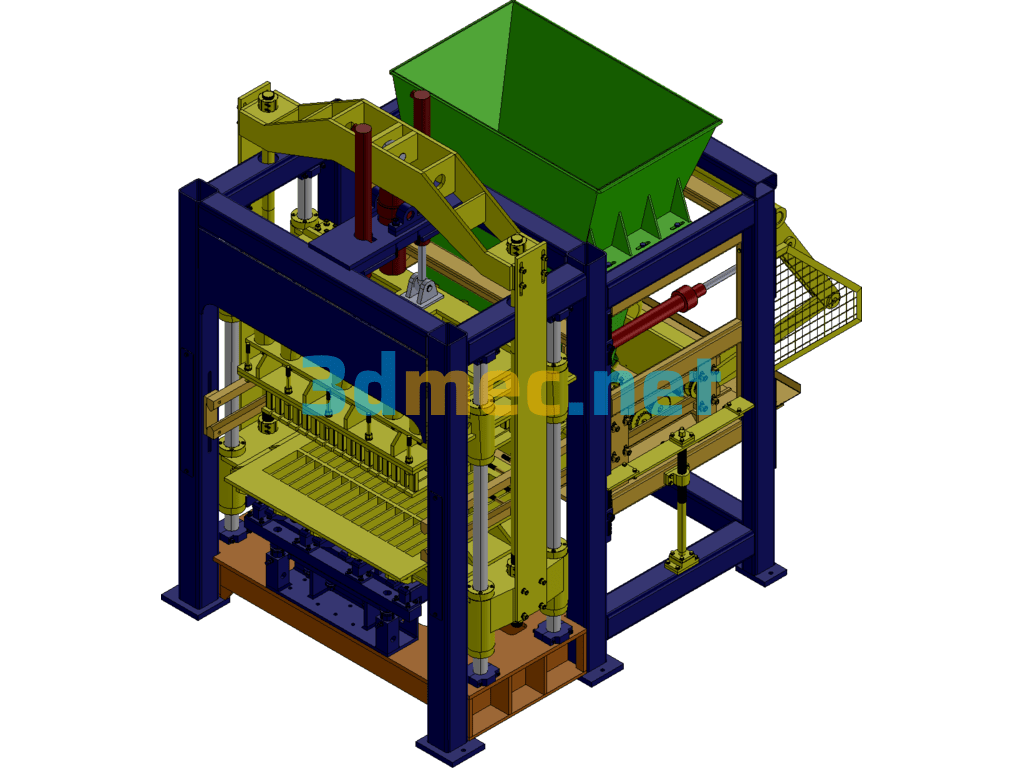

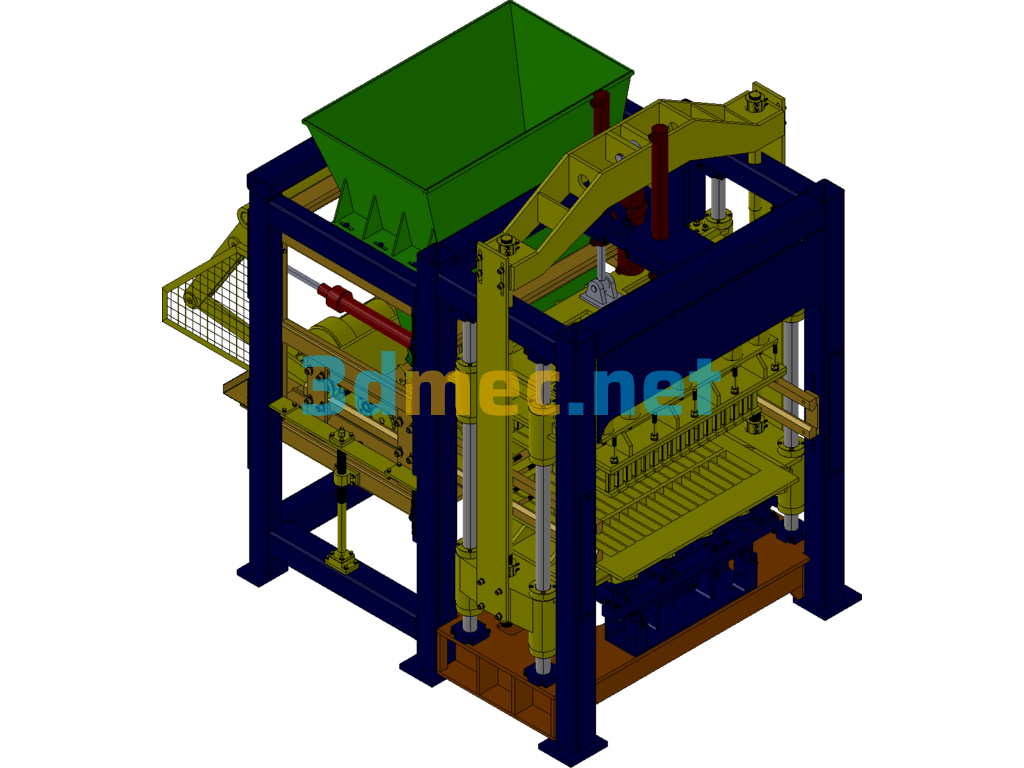

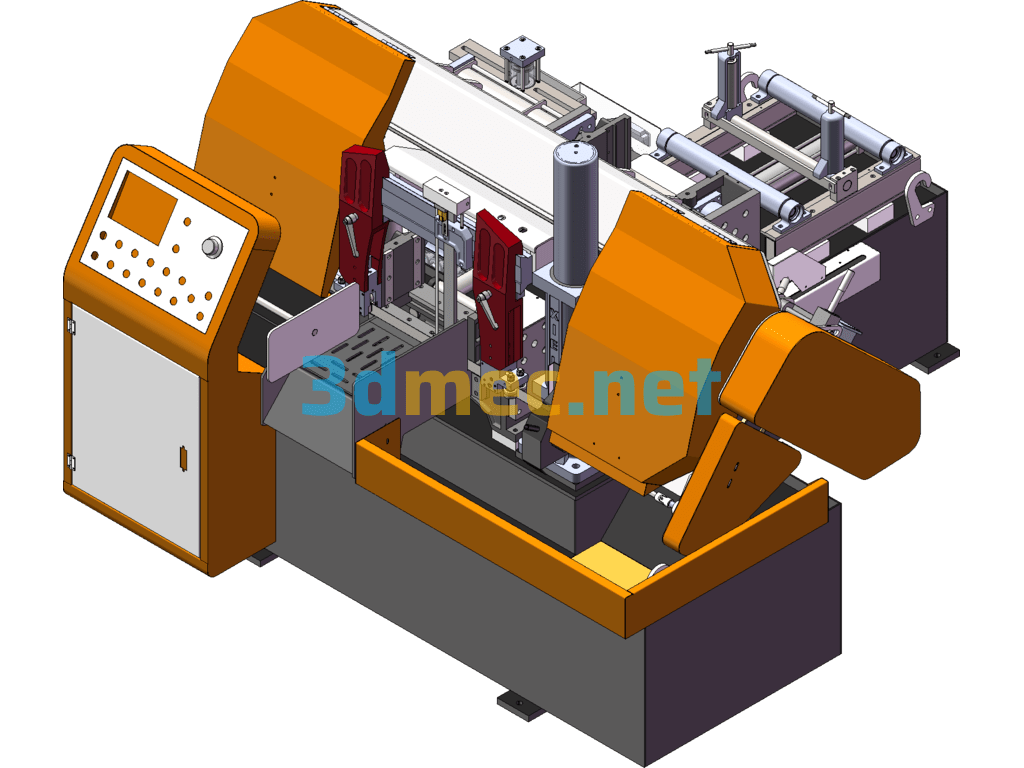

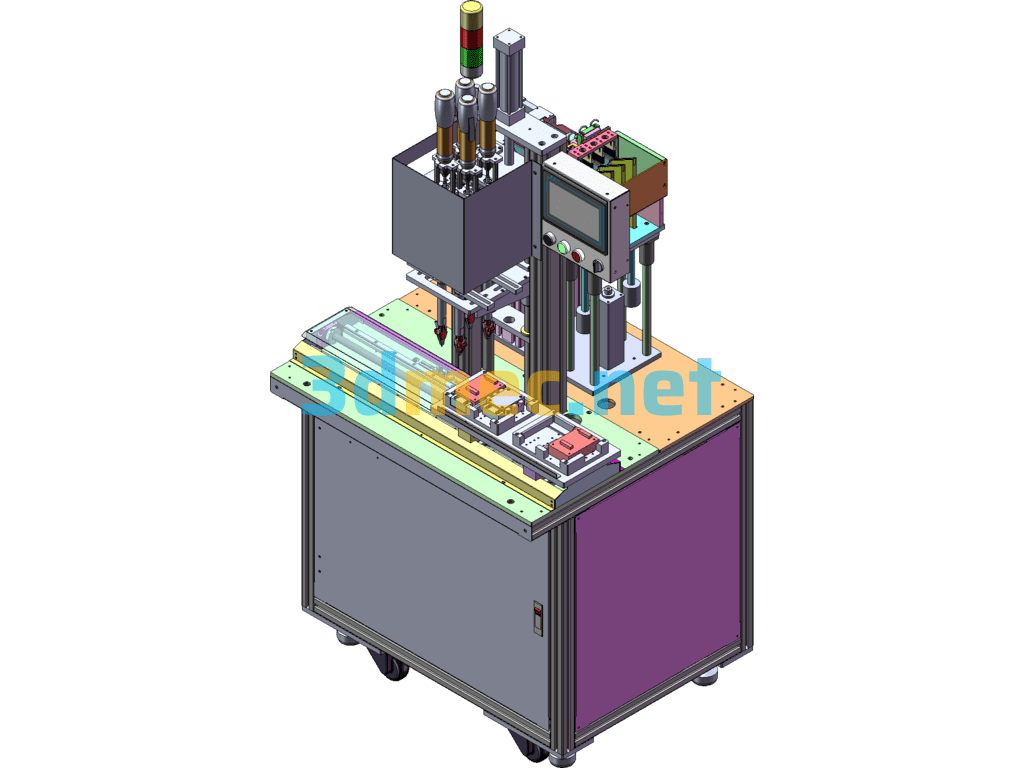

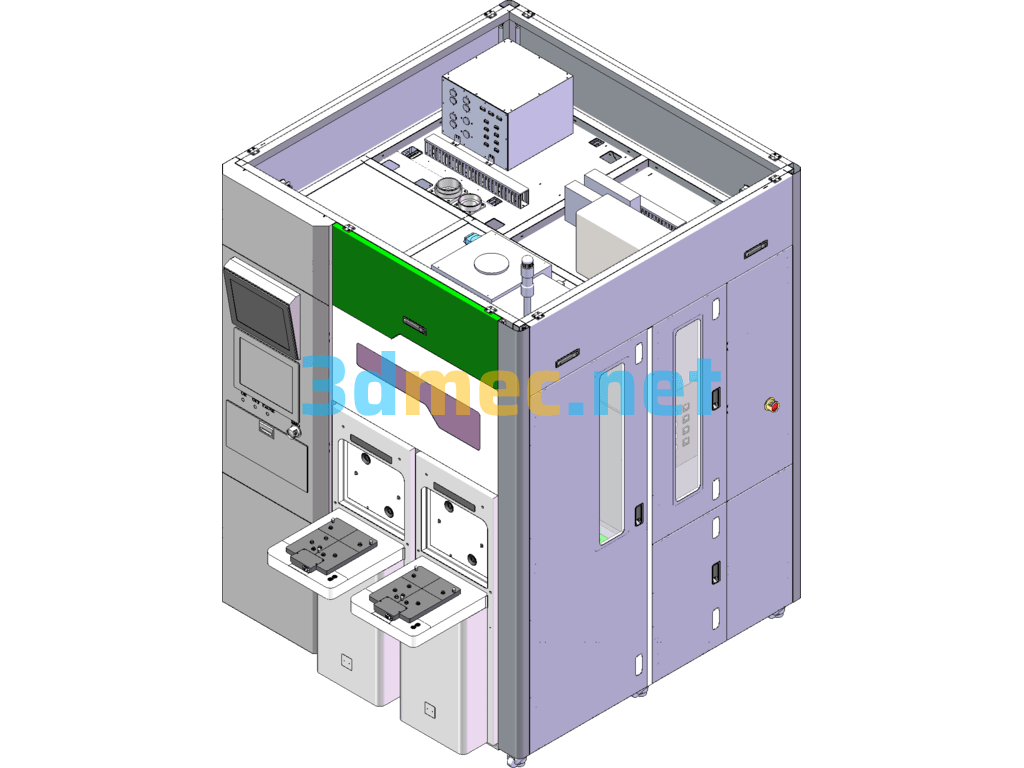

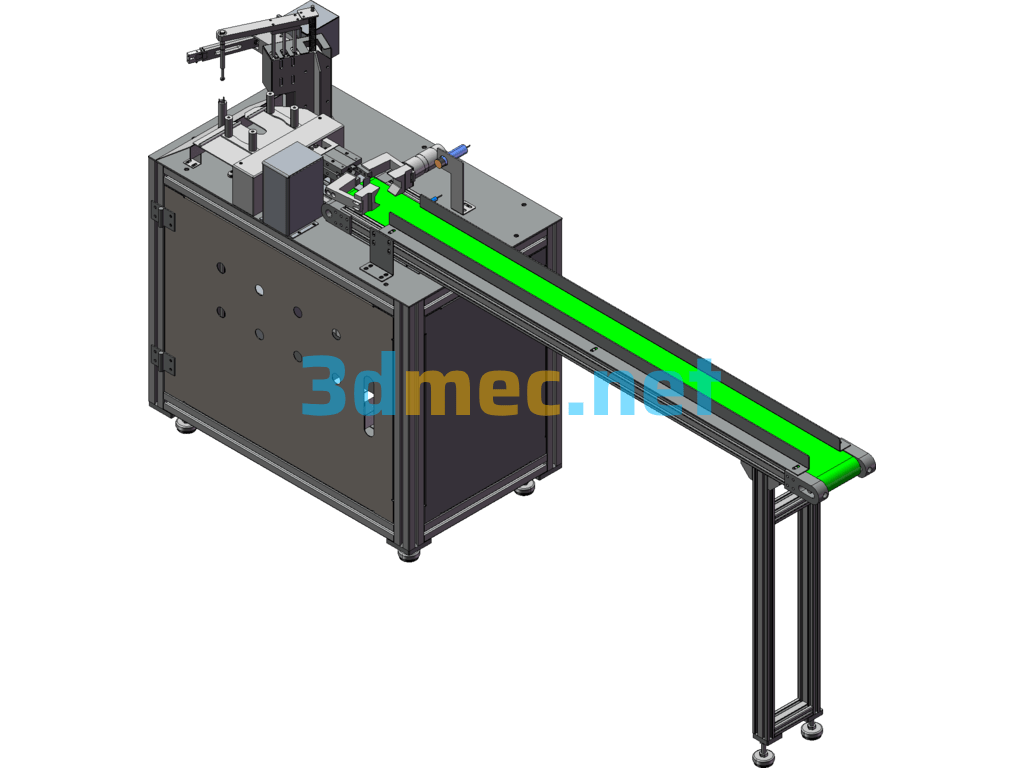

Fully Automatic Brick Making Machinery, Complete Brick Making Industrial Equipment – 3D Model SolidWorks

The fully automatic brick making machine drawing is a complete set of brick making industrial equipment, which is awesome. Fully automatic brick-making machinery drawings, in solidworks format, including general assembly drawings, component assembly drawings, parts drawings, and standard parts drawings. It is a complete set of mechanical drawings. Manufacturers can directly produce according to the drawings, and those in the machinery industry can also refer to the structure inside. Brick making machine is a general term for brick-making machinery and equipment in the building materials industry that manufactures colored bricks, cement bricks and other series of products.

1. Adopting the advanced technology of German block making machine, it is thick and stable, weighing 30% more than the weight of domestic models of the same production, and has remarkable shock-absorbing effect.

2. It adopts Japanese Mitsubishi computer control system, LCD touch screen to adjust parameters, and is equipped with data input and output devices to realize human-machine dialogue.

3. The computer control system has a self-locking function. If the previous action is not in place, the next action cannot be executed, thus avoiding the occurrence of malfunctions and damage to the machine. And remote fault diagnosis can be realized through telephone lines.

4. The machine body is made of thick-walled square tubes and extra-long guide sleeves to ensure that the machine body is strong and shock-resistant, and the indenter movement is accurate.

5. The center of gravity is extremely low, and the vibration table is 486MM from the ground, ensuring that 90% of aftershocks are introduced into the ground, extending the life of the equipment.

6. Good synchronization. The indenter and demoulding frame are all equipped with adjustable synchronous swing arms to ensure that the indenter and demolding errors are within +1MM.

7. Wide range of products. With the addition of secondary distribution equipment, it can simultaneously produce hollow blocks, multi-row holes, hollow bricks, curb stones, split blocks, colored pavement bricks, grass-planted bricks, washed bricks and other products.

8. Vibration pressure separation technology. Install a vibration support plate and a auxiliary pressure head with a shock-absorbing rubber pad to completely block vibration and pressure interference.

9. Taiwan hydraulic valves and coolers are used to ensure reliable operation of the hydraulic system and low failure rate.

10. The claw-forced unloading device is used to completely solve the problem of difficult unloading of thin-walled products (wall thickness less than 20MM).

11. The vibration spindle adopts universal joint transmission shaft transmission method to ensure accurate transmission speed. The long service life avoids the trouble of frequently replacing belts in belt drives.

12. All models use frequency converters to completely realize non-stop rotation of the spindle motor, thereby fundamentally solving the problem of spindle motor temperature rise.

13. The only manufacturer in the same industry in the country that adopts a vibration force adjustment system. Each block host has a variety of adjustable vibration forces, thereby shortening the vibration time, improving product density, and saving cement.

14. Using the overall frame adjustment method of the casing, all parameters can be adjusted by simply rotating two screw machines and adjusting the proximity switch distance.

15. The excitation force is strong, the amplitude reaches 2Mm, and the excitation acceleration reaches 15g, allowing the material to be quickly formed in about 2 seconds, and the cement is fully liquefied. Under normal weight ratio conditions, the loading strength can be increased by one level.

Specification: Fully Automatic Brick Making Machinery, Complete Brick Making Industrial Equipment – 3D Model SolidWorks

|

User Reviews

Be the first to review “Fully Automatic Brick Making Machinery, Complete Brick Making Industrial Equipment – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.