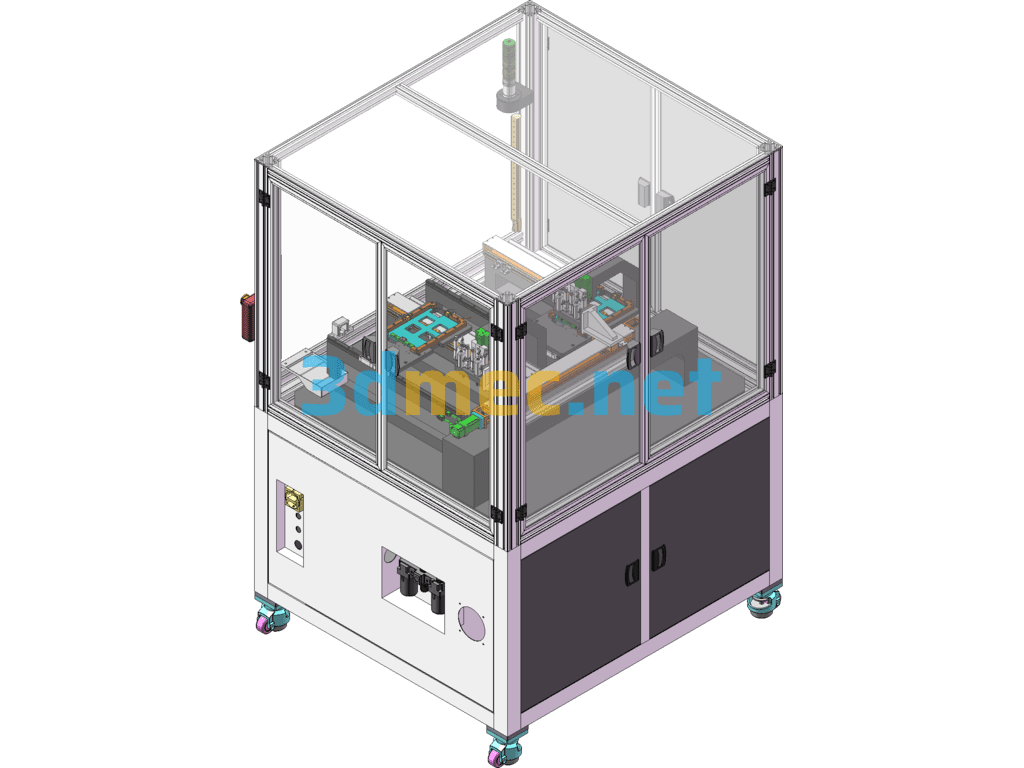

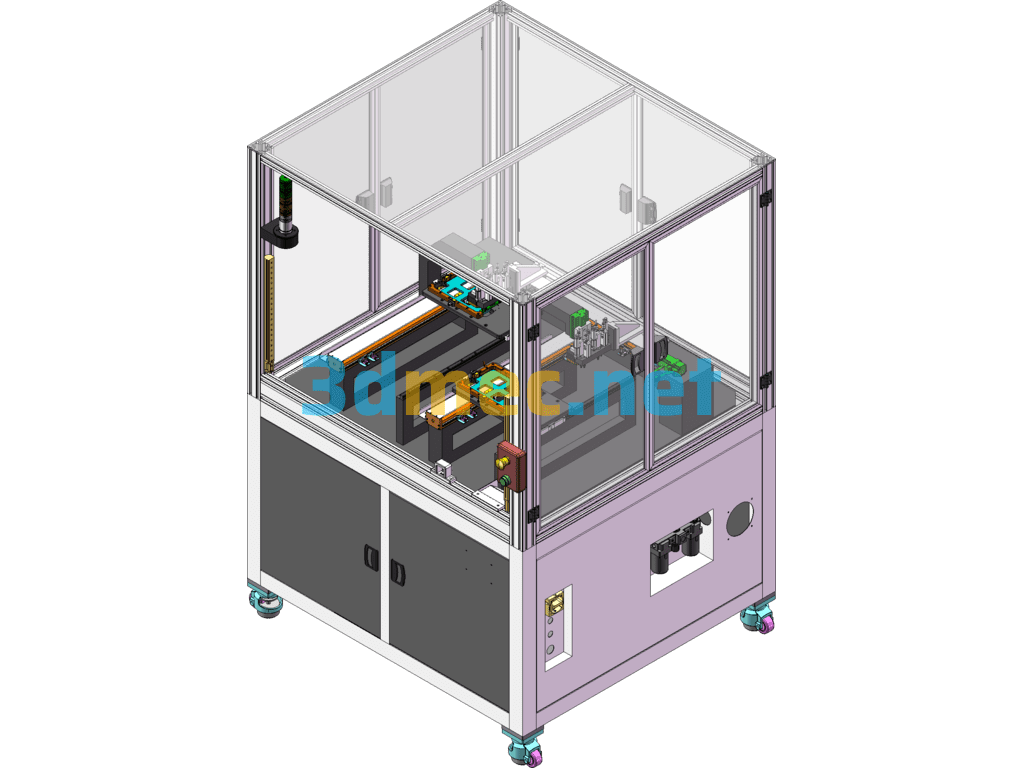

Flat Panel Step Detection Equipment (Including DFM, BOM) – 3D Model SolidWorks

The action flow of the flat plate step detection equipment:

1. Test the internal height of the flat plate product, divided into two groups of left and right fixtures to switch the feeding, saving the equipment CT to provide production capacity;

2. Manually put the product into the fixture to fix the positioning side clamp.

3. The Y axis enters the test area, and the Z axis cylinder presses down to fix the product to place and move.

4. The GT test cylinder drives the GT test head to test the product height.

Specification: Flat Panel Step Detection Equipment (Including DFM, BOM) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Flat Panel Step Detection Equipment (Including DFM, BOM) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.