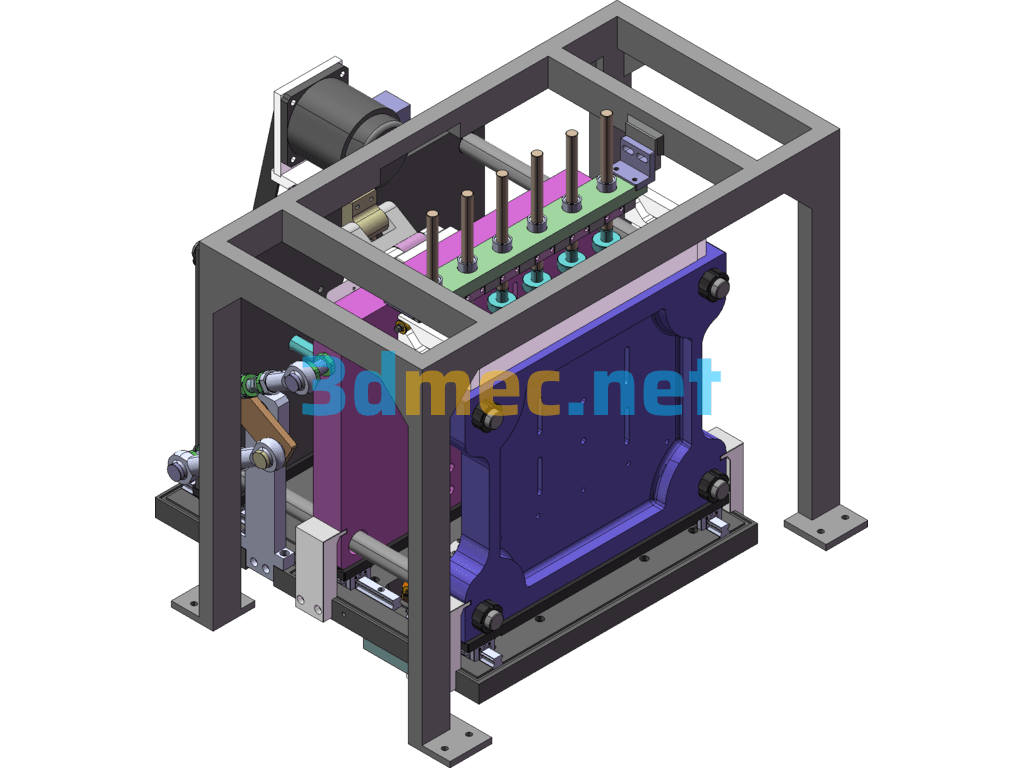

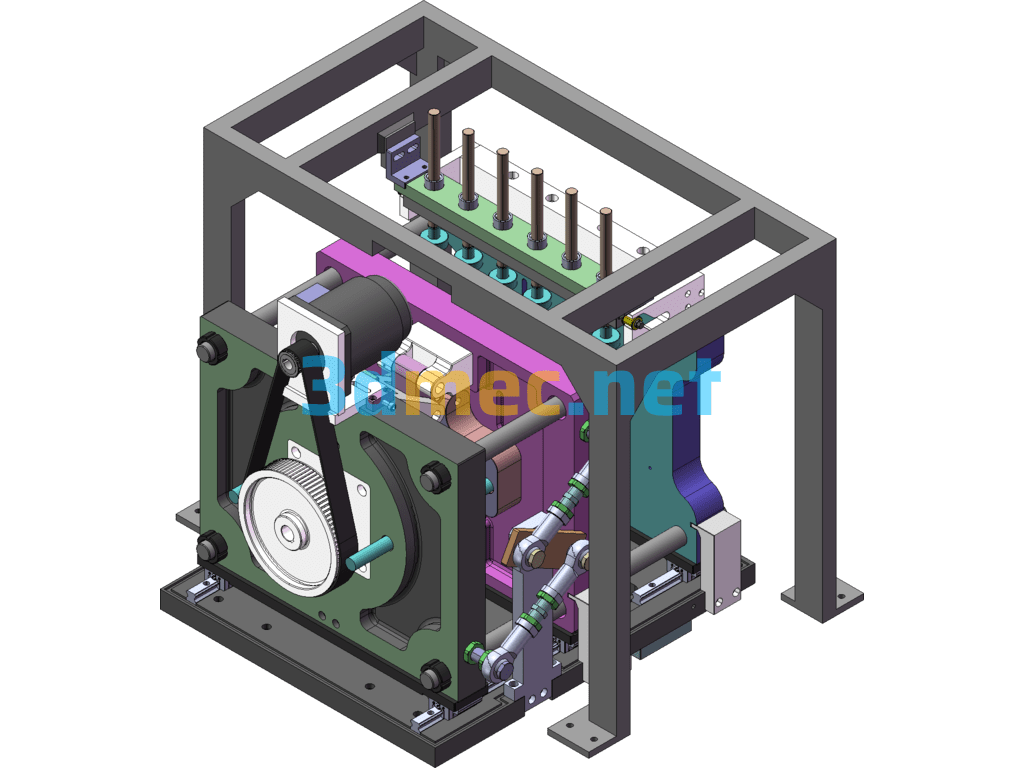

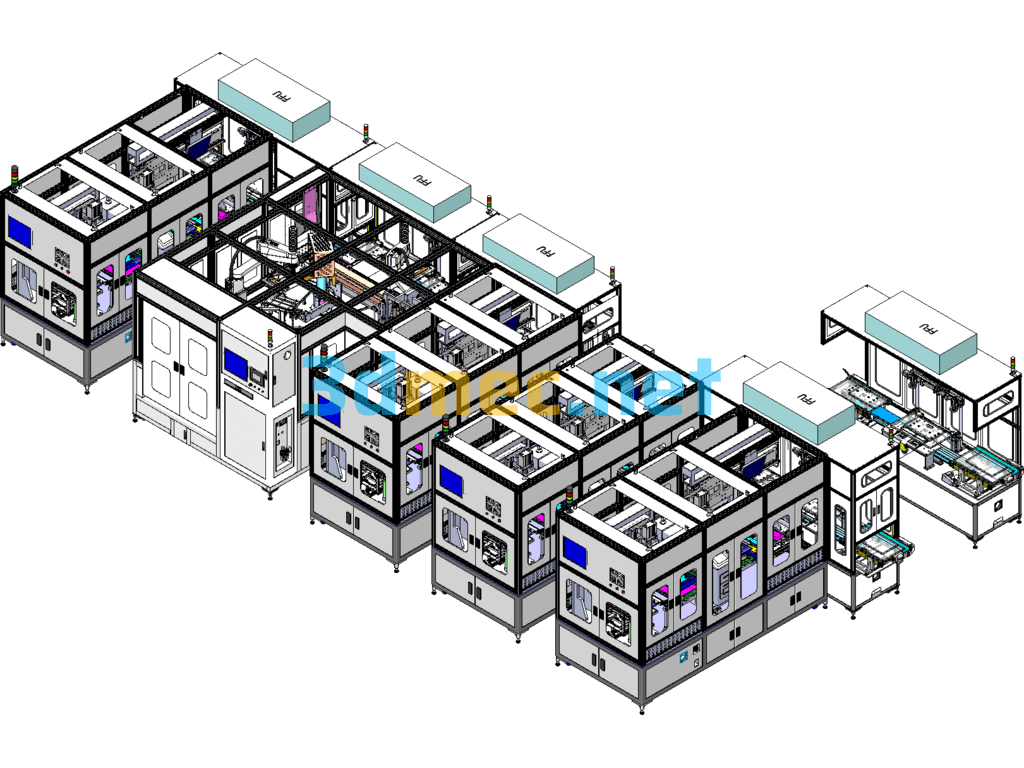

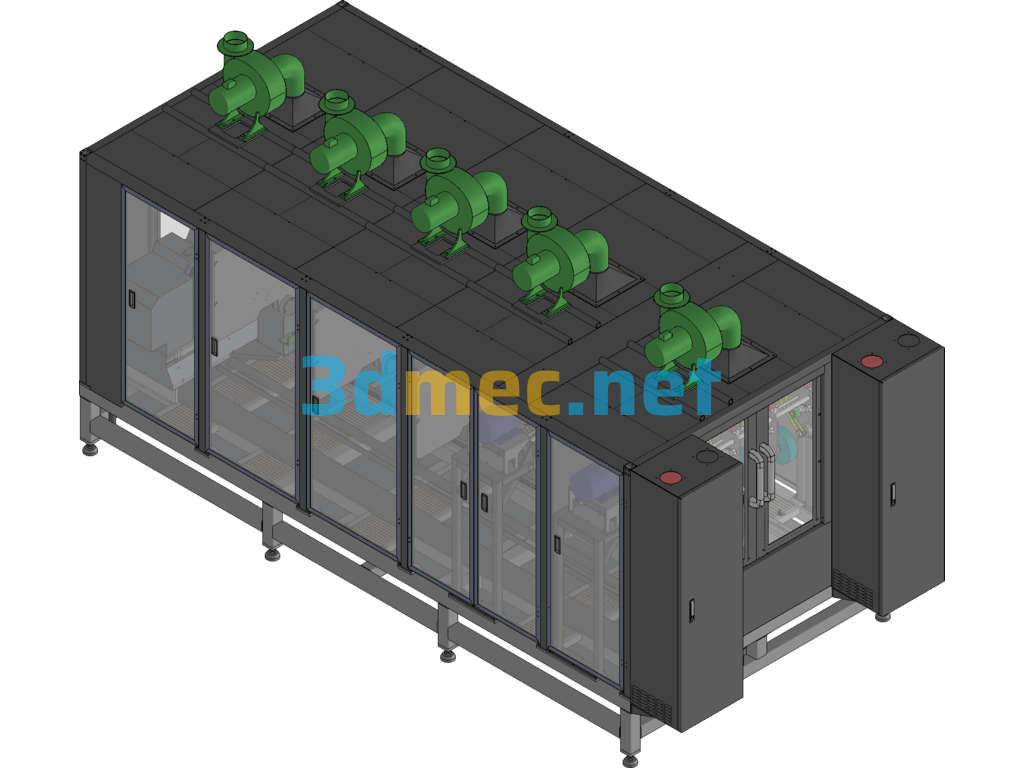

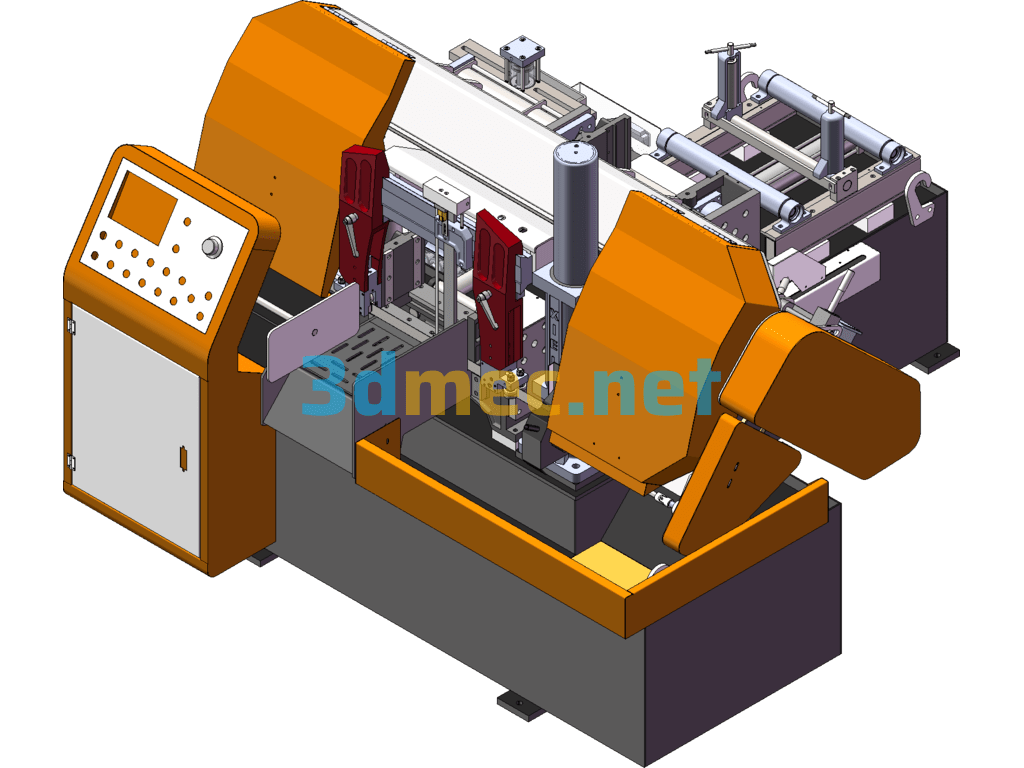

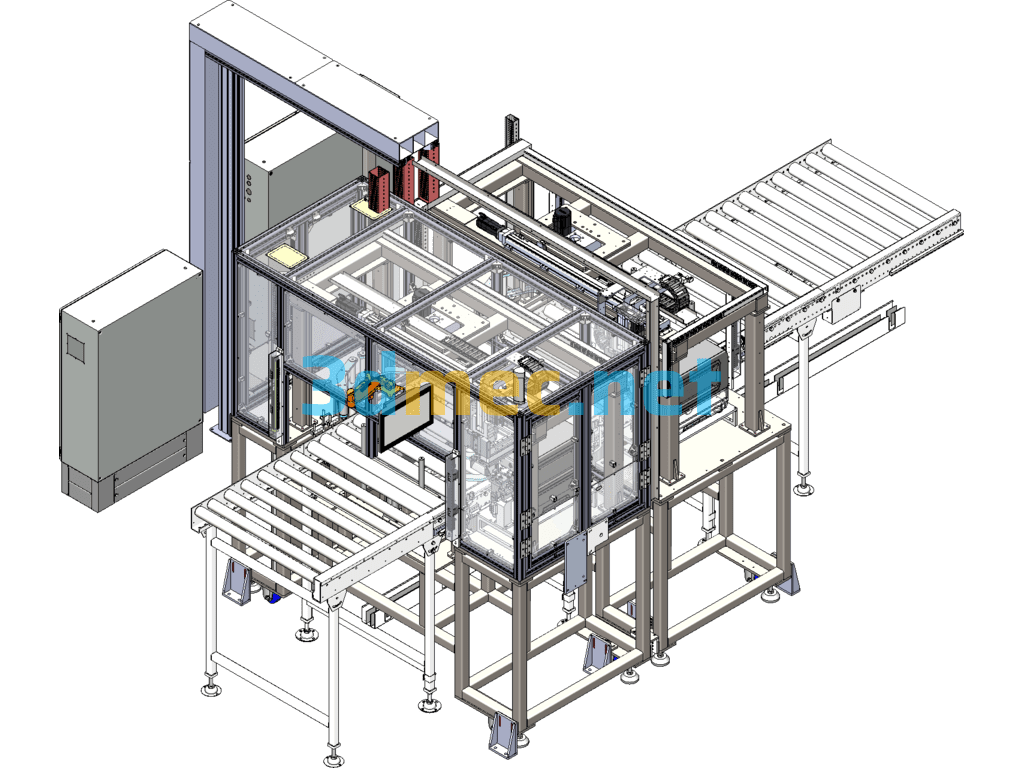

Electric Mold Clamping Mechanism For Bottle Blowing Machine – 3D Model SolidWorks

The electric mold clamping mechanism of the blow molding machine

The mold clamping machine is a professional mold research and testing equipment, which is mainly used for the upper and lower molds in the later stage of mold production, and the required pressure is used to pressurize and clamp the mold. It adopts a variety of reliable devices, equipped with a mobile workbench mold clamping positioning device, an upper mobile flip locking device, a mechanical flip device, a hydraulic ejector, a mold slide control, a safety anti-fall device, etc.

The mold clamping device refers to an injection molding machine composed of an injection device, a mold clamping device, a hydraulic control system, etc. The injection device injects a certain amount of molten material into the mold cavity at a certain pressure and speed; the mold clamping device realizes the opening and closing of the mold to ensure reliable mold closing and ejection of the product; the hydraulic control system ensures the predetermined pressure, speed, temperature, time and action program.

Specification: Electric Mold Clamping Mechanism For Bottle Blowing Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “Electric Mold Clamping Mechanism For Bottle Blowing Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.