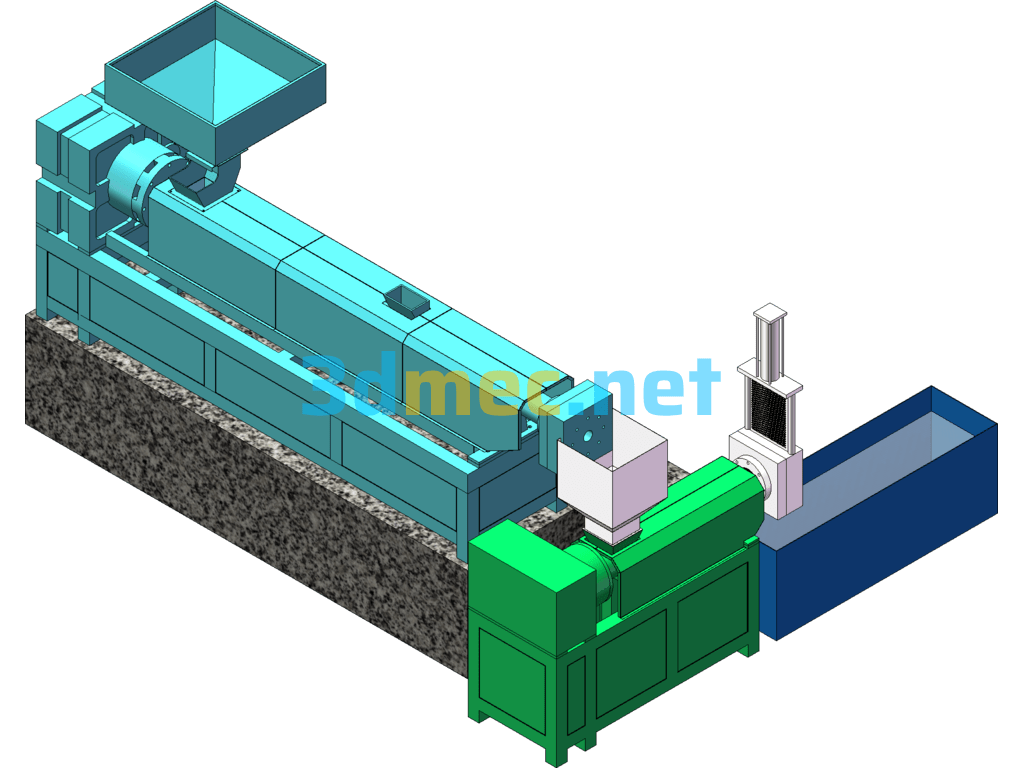

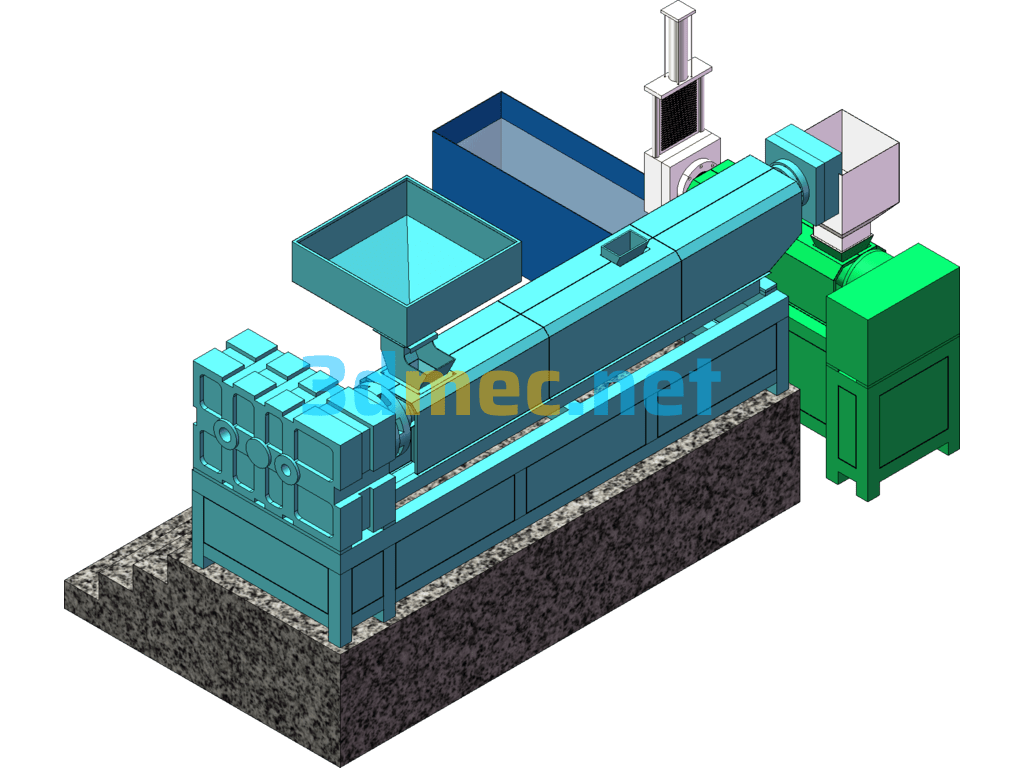

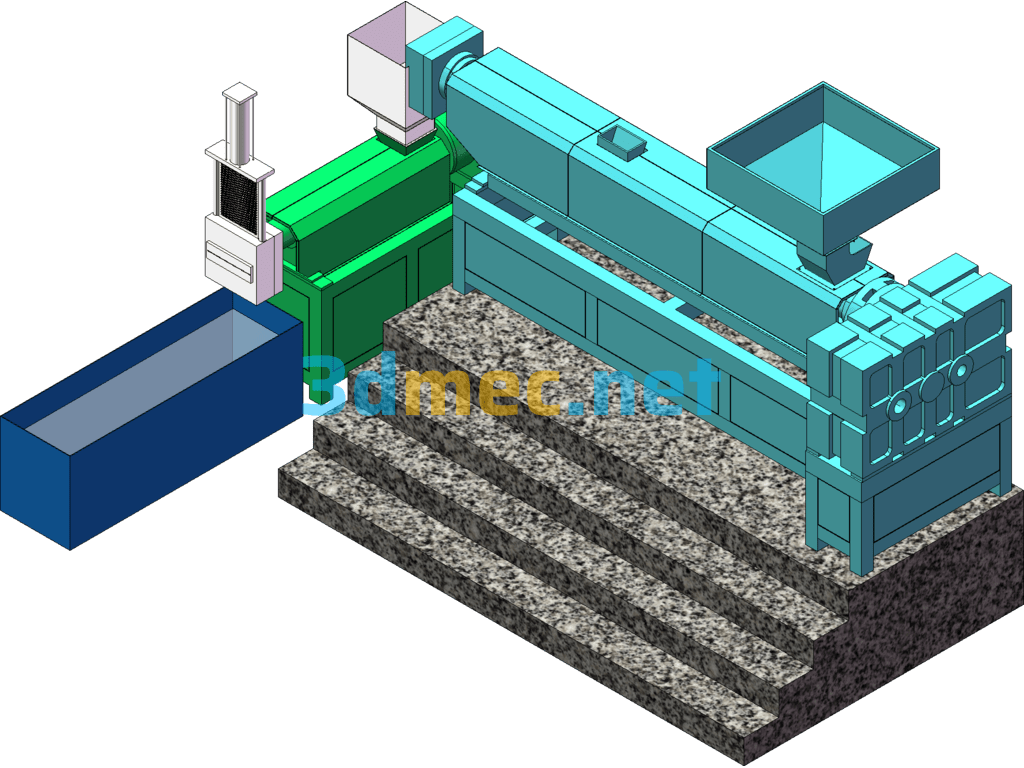

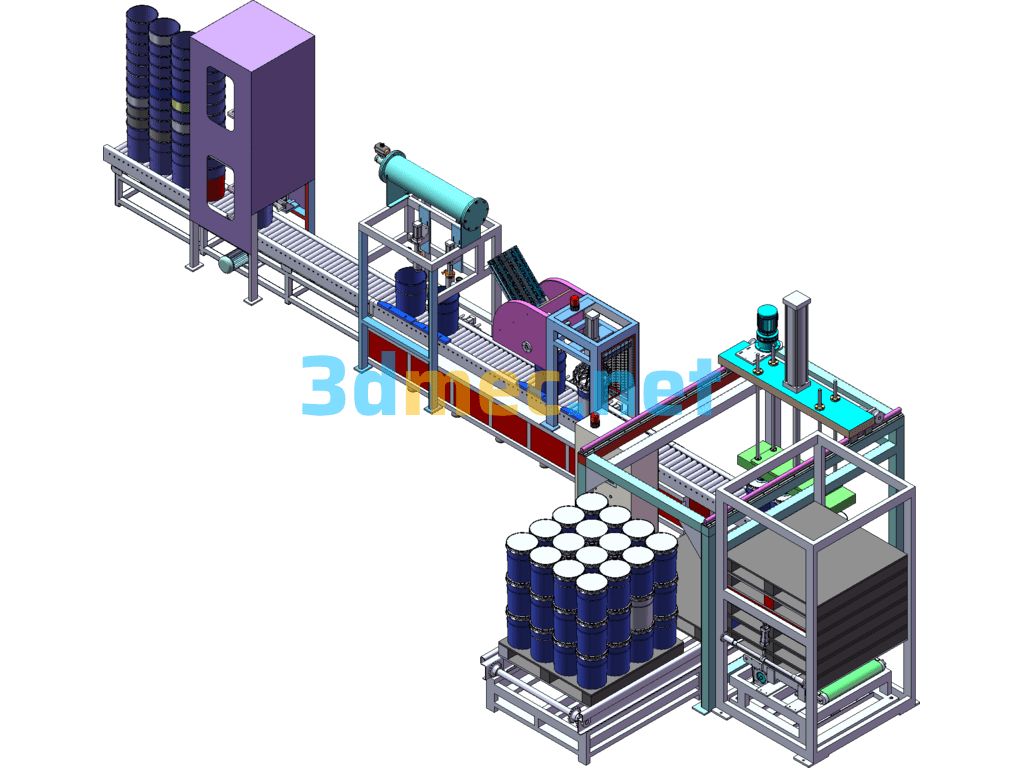

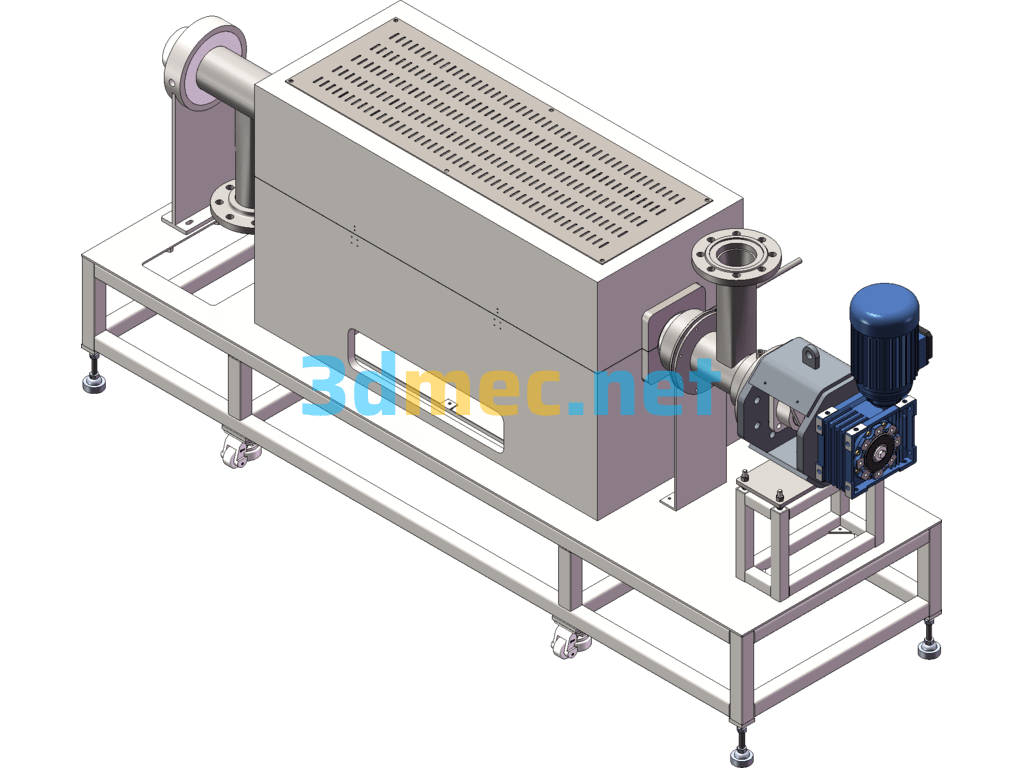

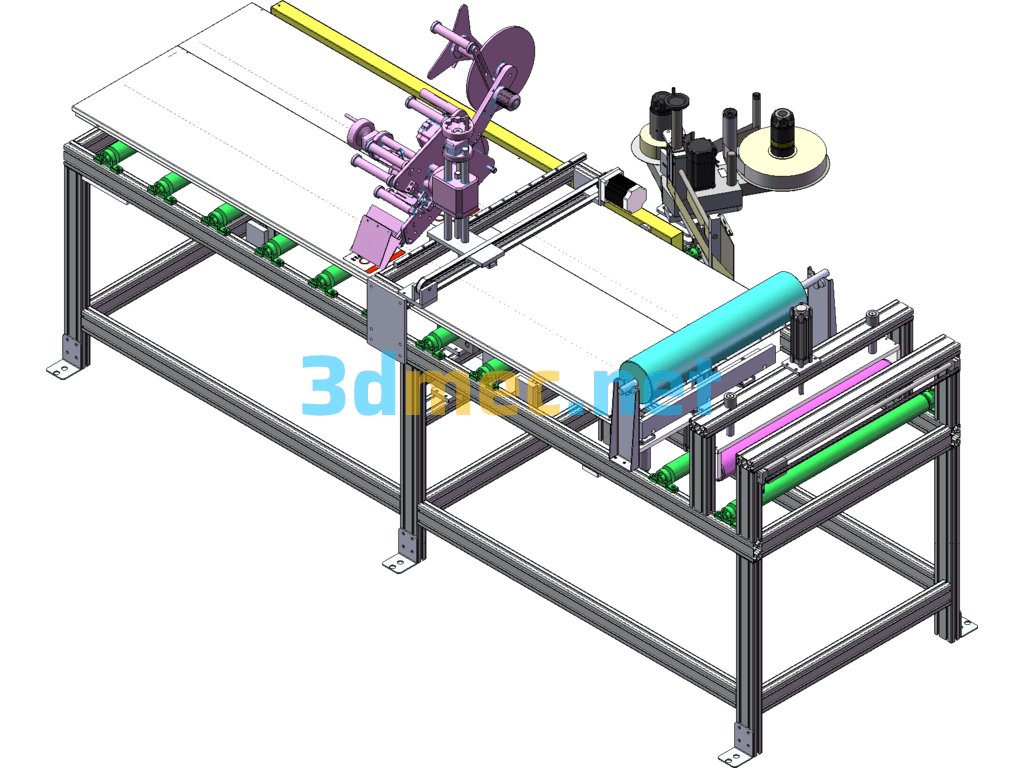

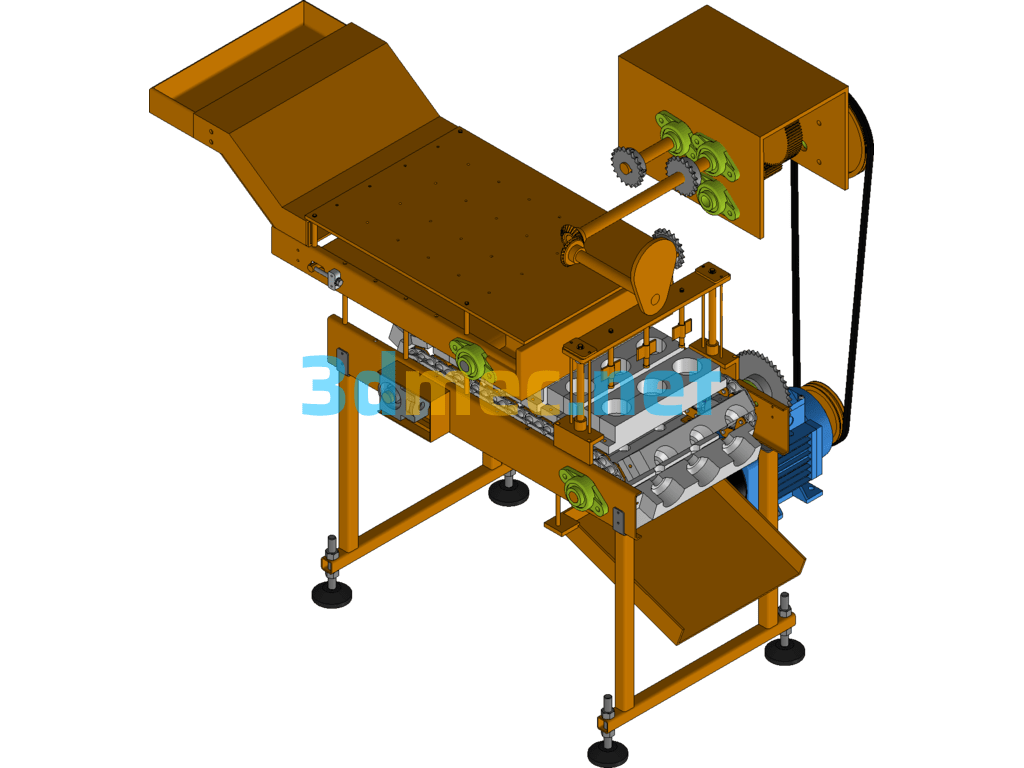

The working principle of the double-die granulator unit is that the raw material is put into the hopper, and it falls smoothly onto the screw from the hopper and is entangled by the screw. As the screw rotates, it is forced forward by the screw. While being heated by the heating furnace, the plastic itself is compressed and the stirring movement generates heat. Under the action of external and internal forces, the temperature of the plastic rises rapidly, causing it to melt into a liquid form and be evenly extruded from the barrel. Then, it enters the negative machine for stirring and extrusion. Due to the action of the resistance of the road network diverter plate and the die head, a strong extrusion pressure is formed in the process, which presses the material very densely, so that the plastic can be evenly discharged from the pores in strips, and then falls into the water pool for cooling. Afterwards, it enters the pelletizer and is cut into pellets. This model only demonstrates the main negative machine model. You can search for the general model of the pelletizer yourself.

Specification: Double Die Head Granulator – 3D Model SolidWorks

|

User Reviews

Be the first to review “Double Die Head Granulator – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.