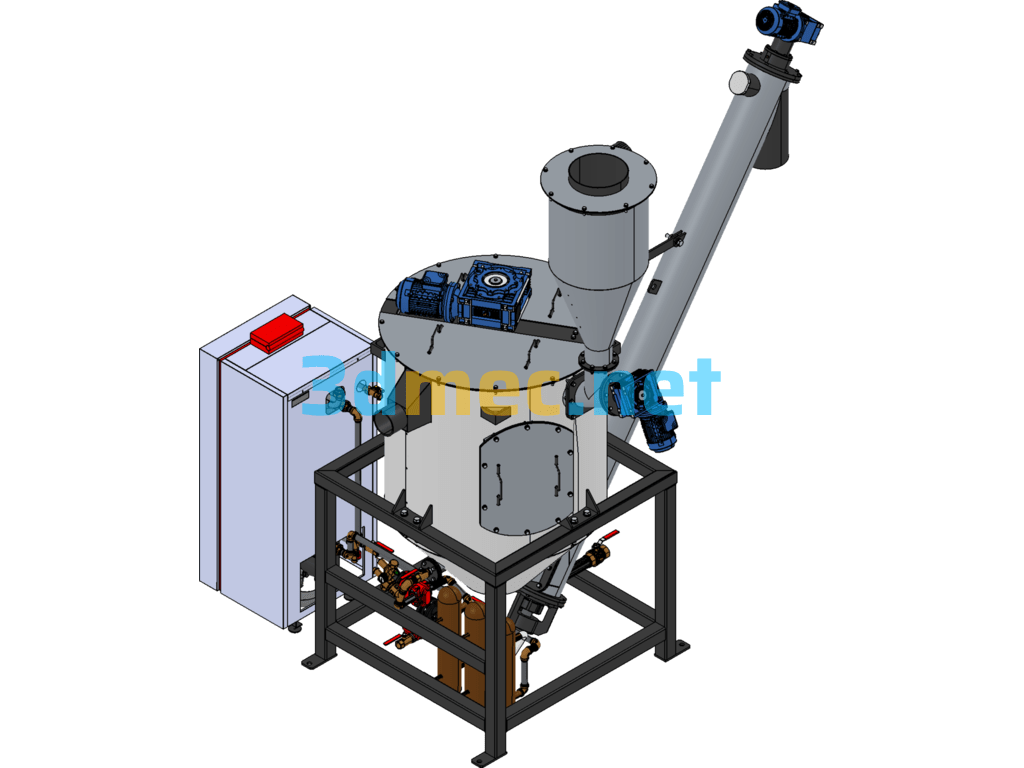

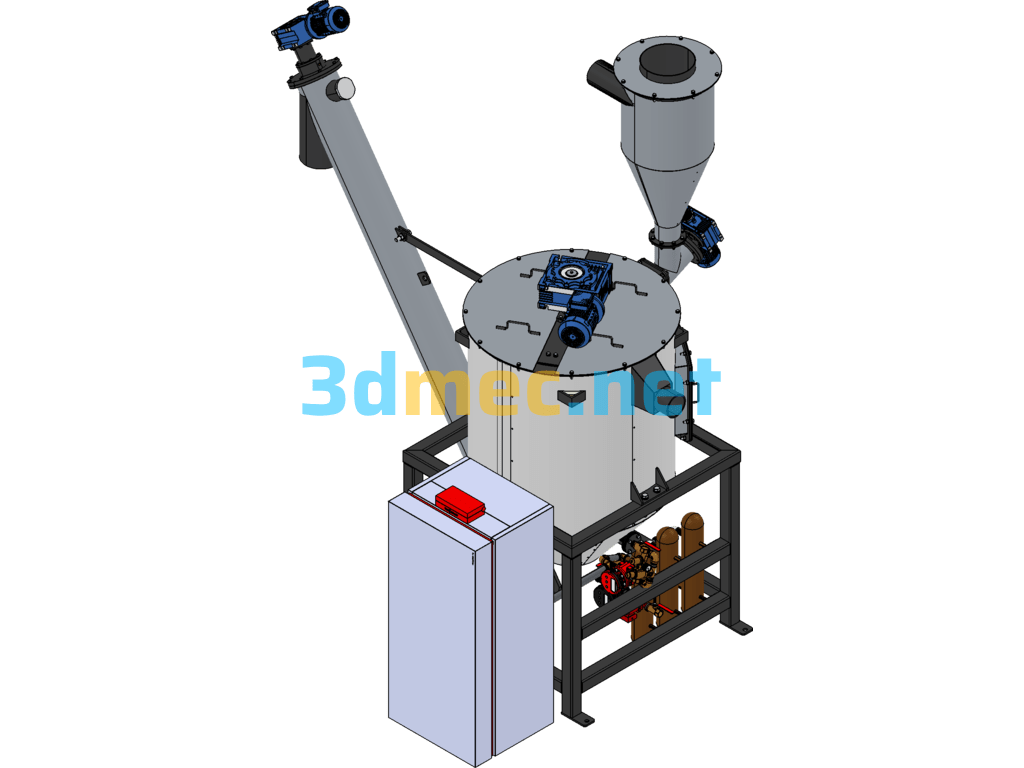

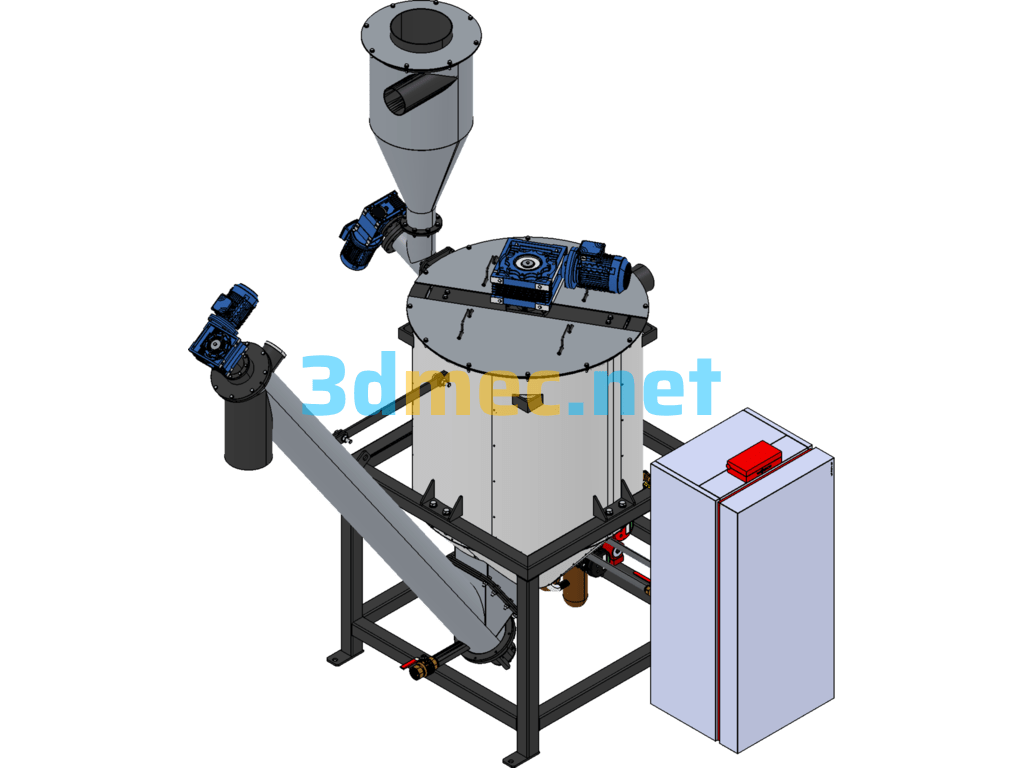

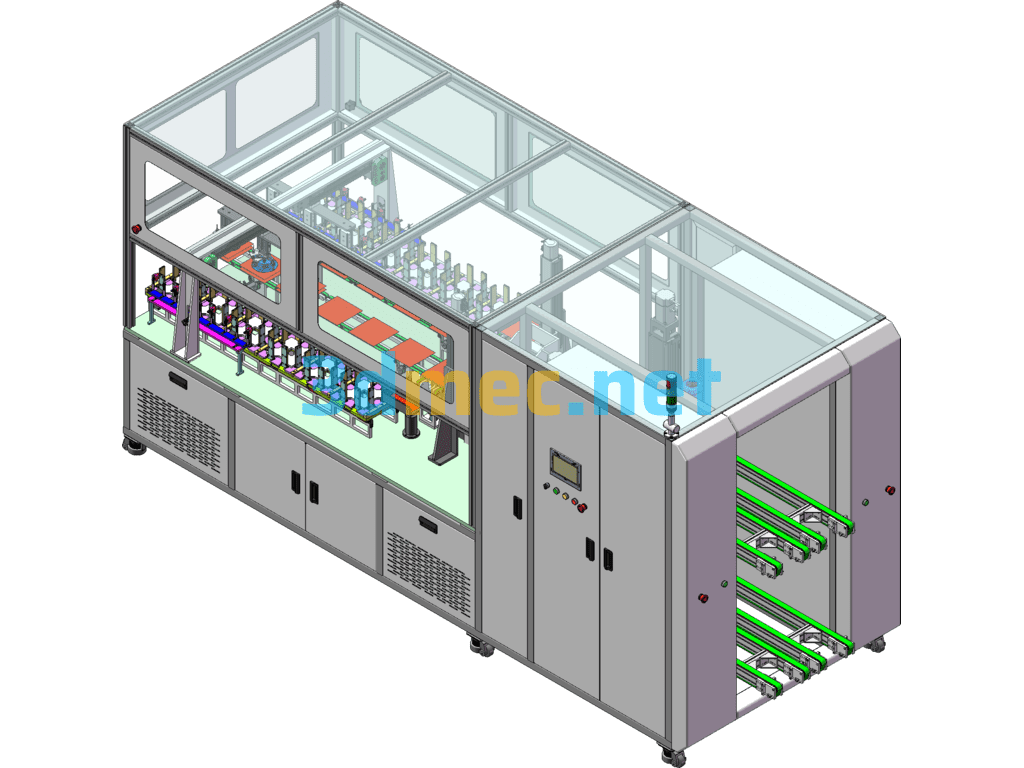

During the working process, this is a tank filled with water (with a special cleaning agent). The water/solution has a temperature between the polymerization temperature and the boiling temperature. Hot water softens the adhesive and keeps it in contact with the surface of the polymer. The ground pat is constantly entering and constantly unloading. During the process, the crew is designed in such a way that the pat lasts as long as possible and a maximum of hot water is obtained. This is a warmer that reduces electricity in the hot water. The water heated in the polymer can be driven by different energy sources selected by the user. By default, we will include water towers and ring heaters.

Process features:

There is a device on the market that is similar to our development, however, we have some constructive and technical features that must be noted when comparing:

This is not just a container of water, it is a water that enters directly into the tank. Unlike other producers, our device is equipped with a disc brake system that provides as much time as possible in the hot solution, while the device remains continuous.

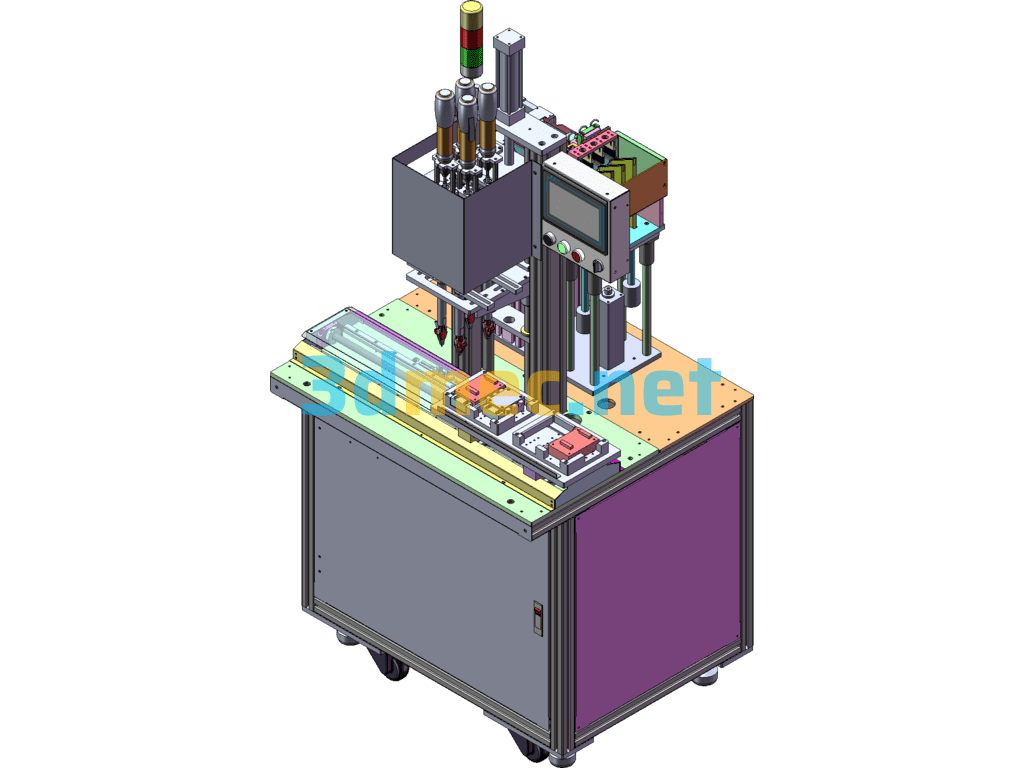

Specification: Dip Washing Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “Dip Washing Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.