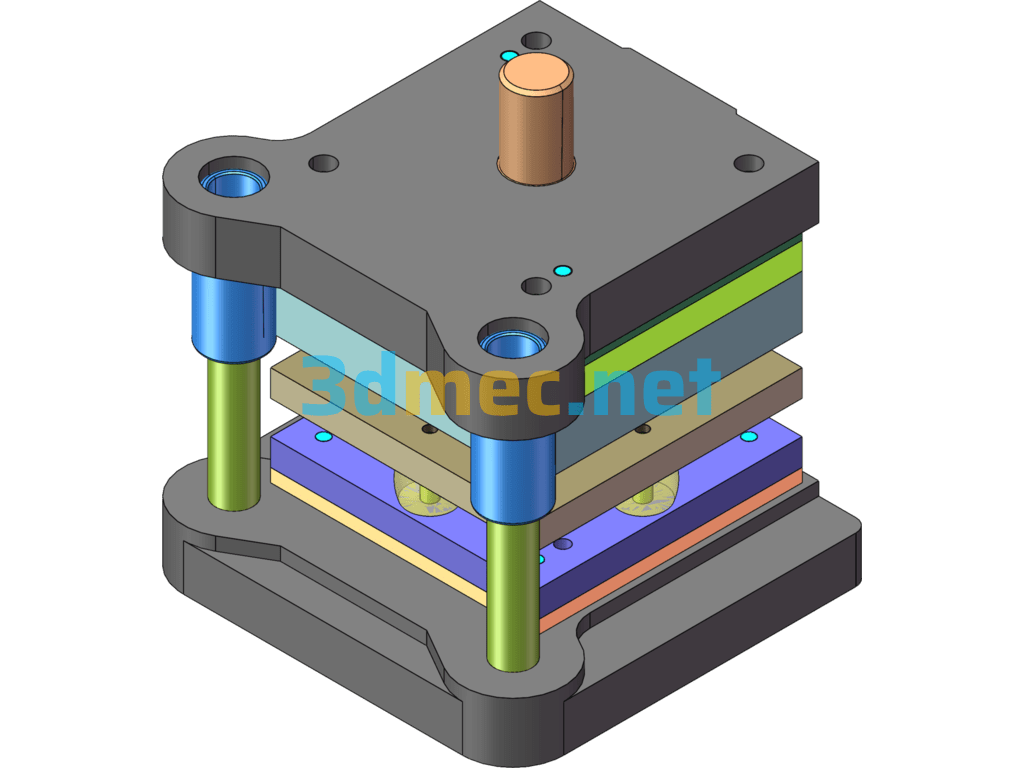

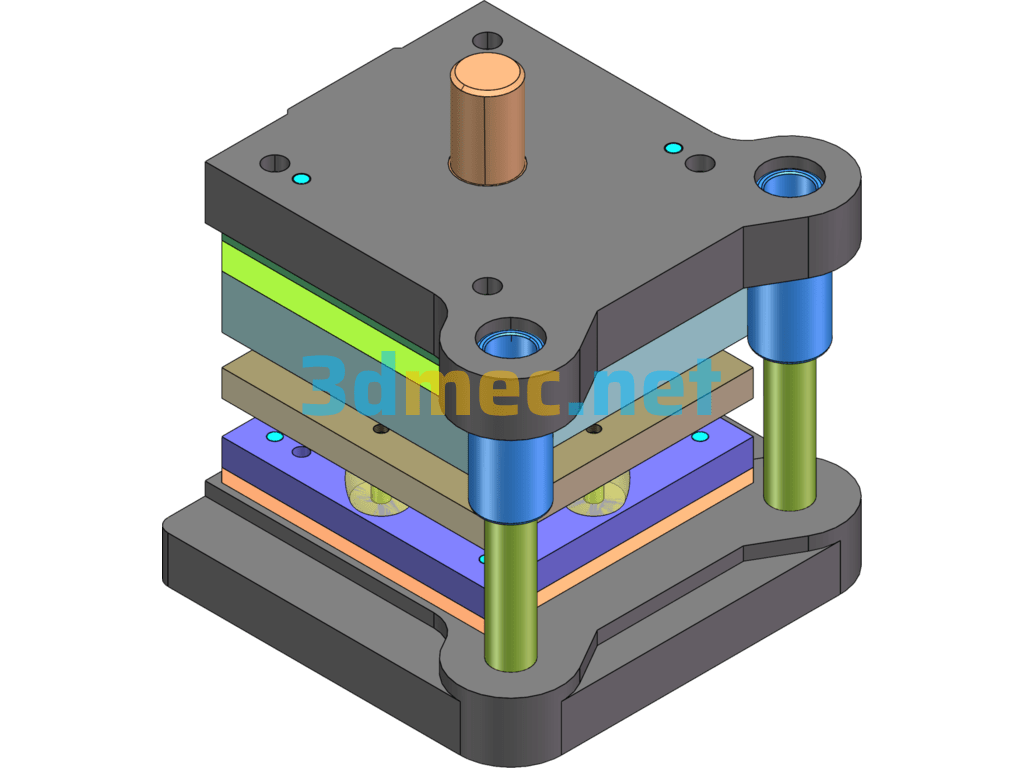

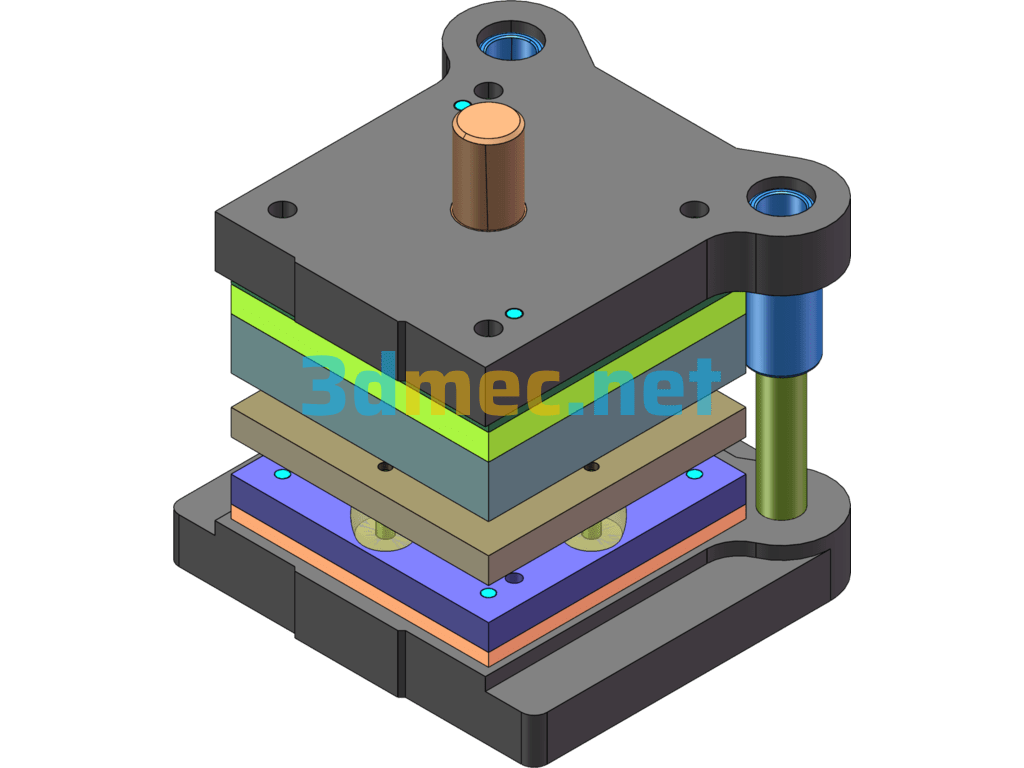

Design Of Compound Mold For Connecting Plate – 3D Model SolidWorks

Material: 08 steel material thickness: 2.0mm Batch: Large batch without dimension tolerance IT6

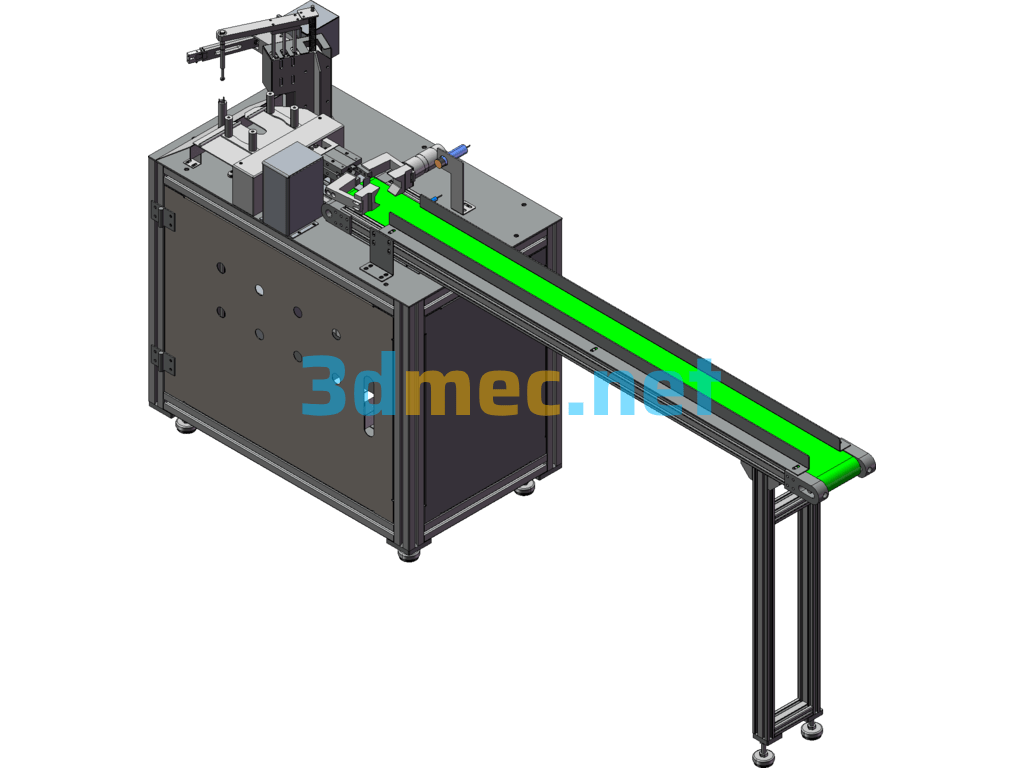

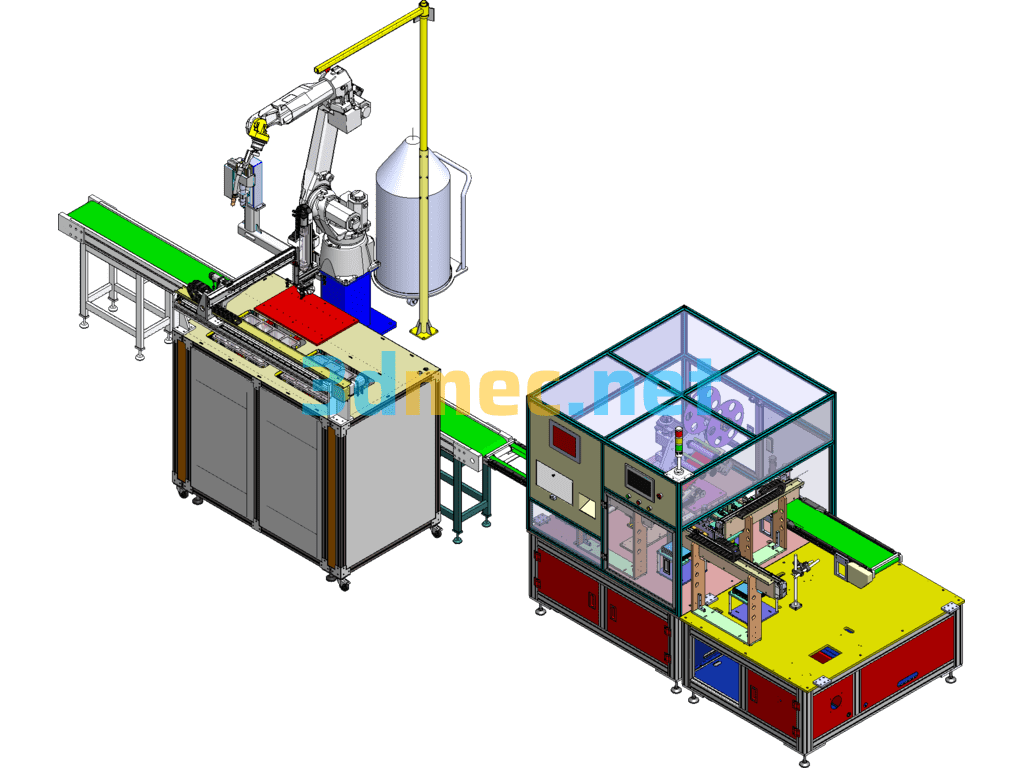

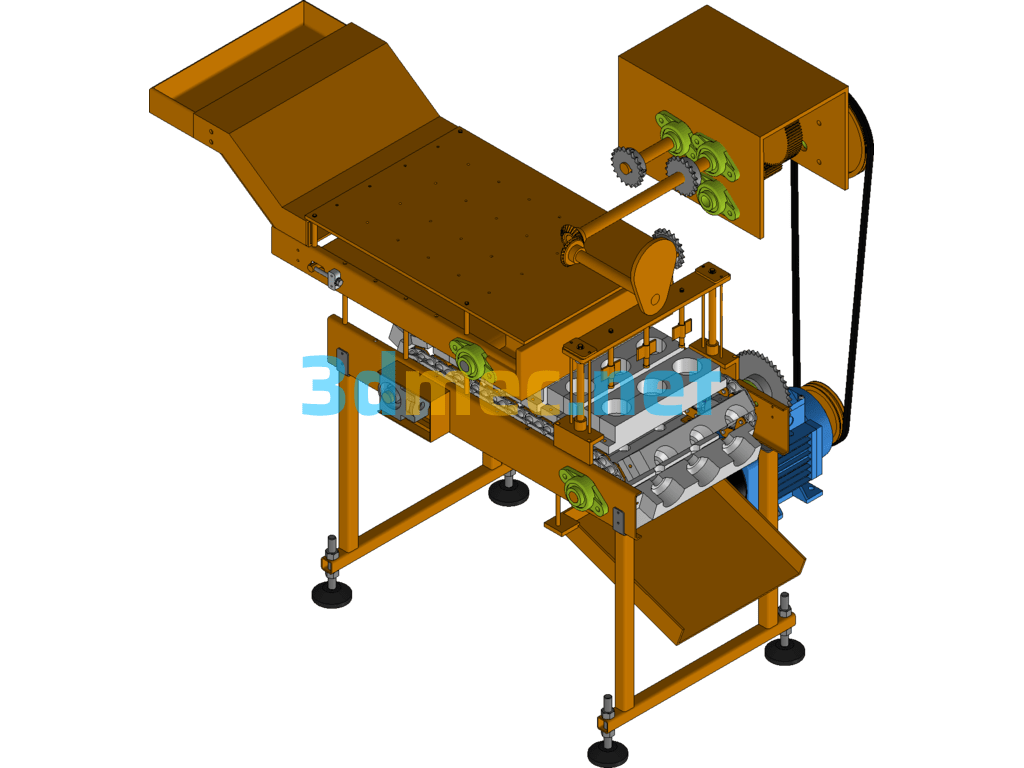

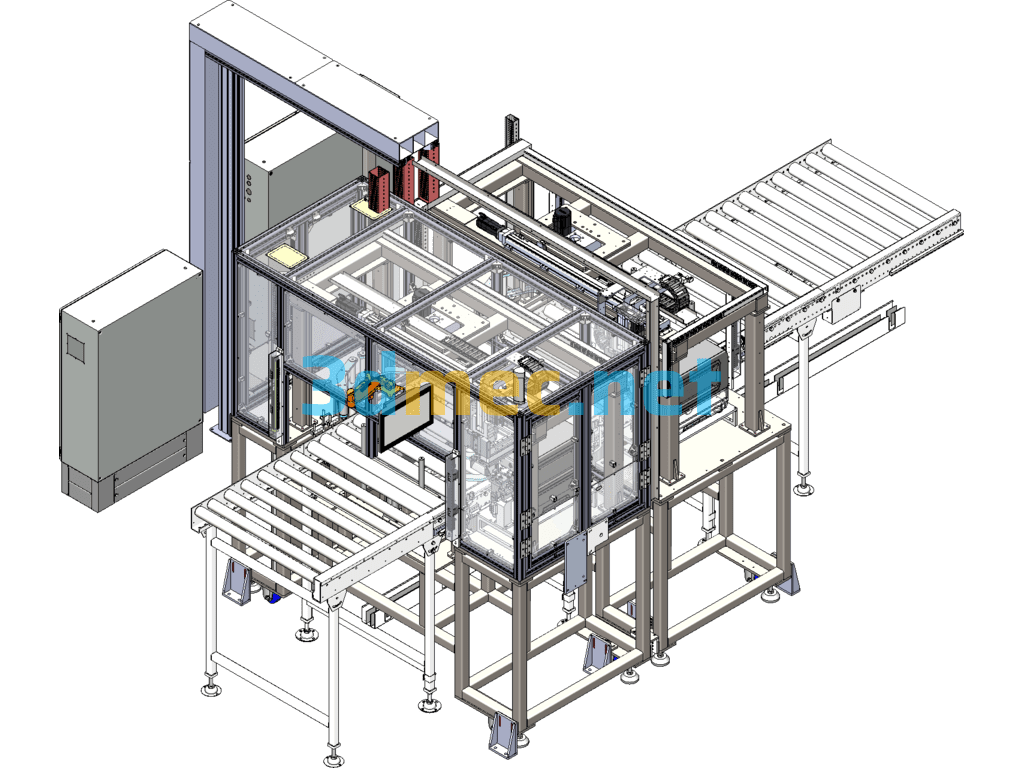

This set of molds is a composite mold for connecting the power strip. The drawings include CAD assembly drawings and parts drawings, UG three-dimensional drawings, complete drawing parts, and drawing specifications.

1. The punch is installed by pressing in. First grind the punch and then connect it with the pad;

2. The guide sleeve and the guide column are clearance fit H7/h6. Pay attention to correcting the verticality of the guide column, guide sleeve and template when pressing in; the distance between the fixed end face of the assembled guide column and the upper and lower die seat planes is 1~3mm;

3. The guide column and the lower die seat are interference fit H7/r6; the guide sleeve and the upper die seat are H7/r6;

Specification: Design Of Compound Mold For Connecting Plate – 3D Model SolidWorks

|

User Reviews

Be the first to review “Design Of Compound Mold For Connecting Plate – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.