D180x300V Lathe – 3D Model SolidWorks

Your custom info text here.

Loading 3D Preview...

Due to web version limitations, it may not display completely. You can download this Project to use the full data

Description

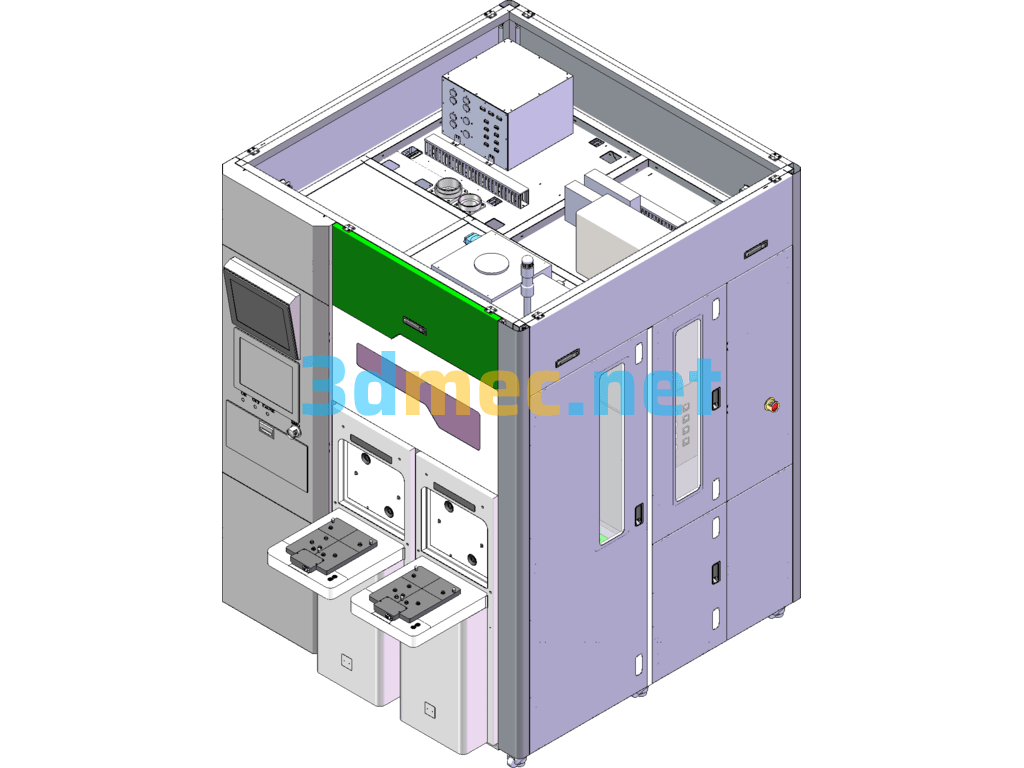

lathe is a machine tool that mainly uses a turning tool to turn a rotating workpiece. Drills, reamer drills, reamers, taps, dies and knurling tools can also be used on the lathe for corresponding processing.

Its components include:

Spindle box: also known as the headstock box, its main task is to pass the rotational motion transmitted by the main motor through a series of speed change mechanisms so that the spindle can obtain the required forward and reverse rotation speeds. At the same time, the spindle box divides part of the power to transmit the motion to the feed box.

Feed box: also known as the tool box, the feed box is equipped with a speed change mechanism for the feed motion. By adjusting its speed change mechanism, the required feed amount or pitch can be obtained, and the motion is transmitted to the tool holder through a light rod or a lead screw for cutting.

Lead screw and light rod: used to connect the feed box and the slide box, and transmit the motion and power of the feed box to the slide box, so that the slide box can obtain longitudinal linear motion. The lead screw is specially used for turning various threads. When turning other surfaces of the workpiece, only the light rod is used, not the lead screw.

Slide box: It is the control box of the lathe feed motion. It is equipped with a mechanism that converts the rotational motion of the light rod and the lead screw into the linear motion of the tool holder. The longitudinal feed motion, lateral feed motion and rapid movement of the tool holder are realized through the light rod transmission. The tool holder is driven to make longitudinal linear motion through the lead screw to turn the thread.

Tool holder: It consists of two layers of slides (medium and small slides), a saddle and a tool holder body. It is used to install the turning tool and drive the turning tool to move longitudinally, transversely or obliquely.

Tailstock: It is installed on the bed rail and moves longitudinally along this rail to adjust its working position. The tailstock is mainly used to install the back center to support longer workpieces. It can also be installed with drills, reamers, etc. for hole processing.

Bed: It is a large basic component of the lathe with guide rails (mountain rails and flat rails) with high precision requirements. Used to support and connect the various parts of the lathe and ensure that the parts have accurate relative positions during operation.

Cooling device: The cooling device mainly uses a cooling water pump to pressurize the cutting fluid in the water tank and spray it into the cutting area to reduce the cutting temperature, wash away the chips, and lubricate the processing surface to improve the tool life and the surface processing quality of the workpiece.

The drawing contains source files and step formats

Specification: D180x300V Lathe – 3D Model SolidWorks

|

Related products

About 3DMec.net

3DMec.net is a sharing community of Mechanical Engineers, Where you can share and download mechanical drawing library, cad drawings, 3d model.

Including automation equipment, non-standard equipment, mold, robot, machine tool, conveyor, jig, manipulator, assembly machine, welding machine, packing machine, flow line, testing machine, dispensing machine, production line, labeling machine, conveyor, locking screw machine, feeder, former, lifting machine, cam Equipment, automotive and other large machinery and equipment drawings.

User Reviews

There are no reviews yet.