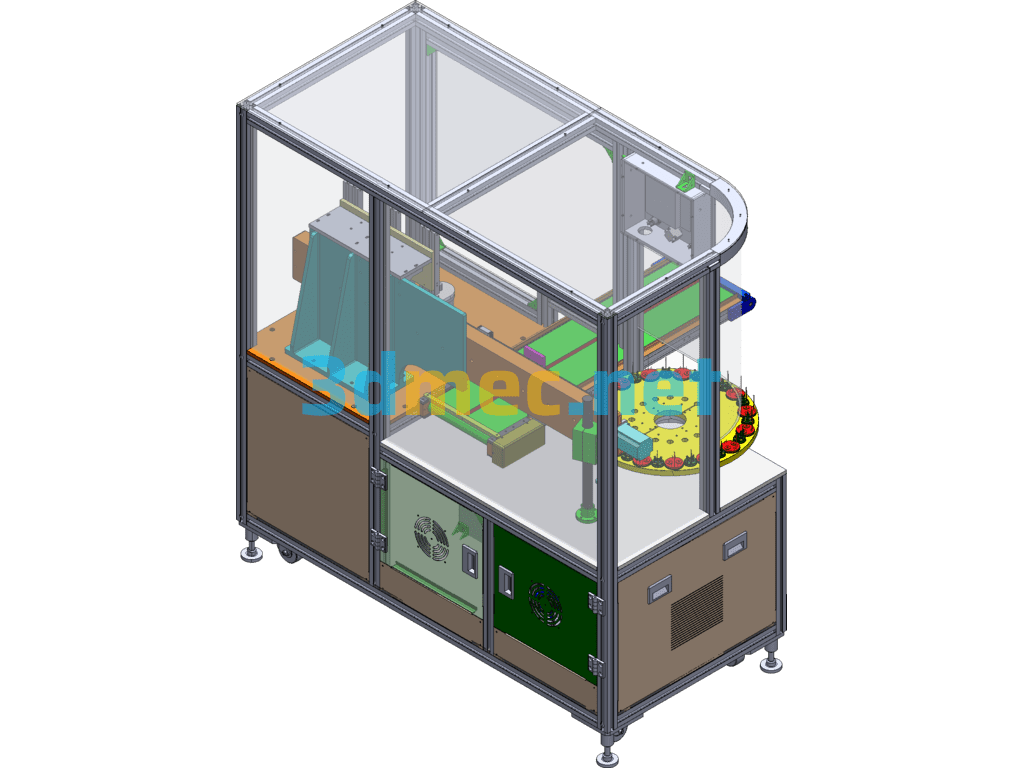

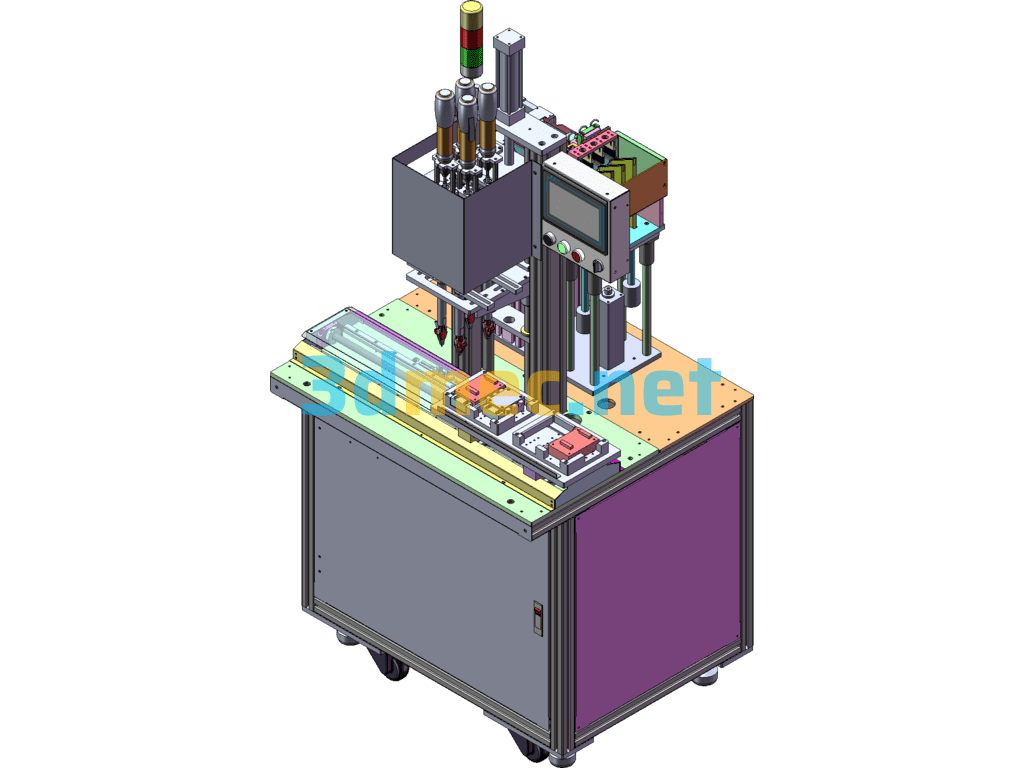

Ceramic Leak Detection Equipment (Including BOM List) – 3D Model SolidWorks

The ceramic leak detection equipment uses nitrogen to detect whether ceramic pieces have leaks; the manual turntable loads the materials, the robot grabs the products and puts them into the testing station, the fixture clamps and fills with nitrogen for testing (three stations test simultaneously), and after the test is completed, it distinguishes between OK and NG materials, including the BOM parts list and procurement list.

Specification: Ceramic Leak Detection Equipment (Including BOM List) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Ceramic Leak Detection Equipment (Including BOM List) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.