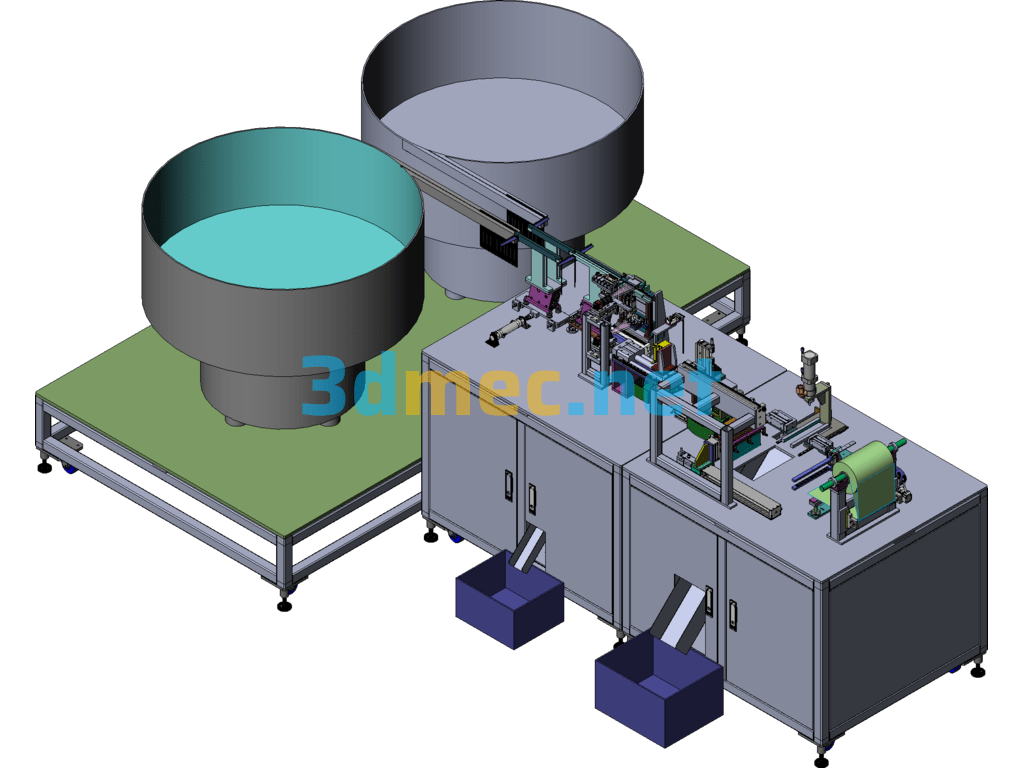

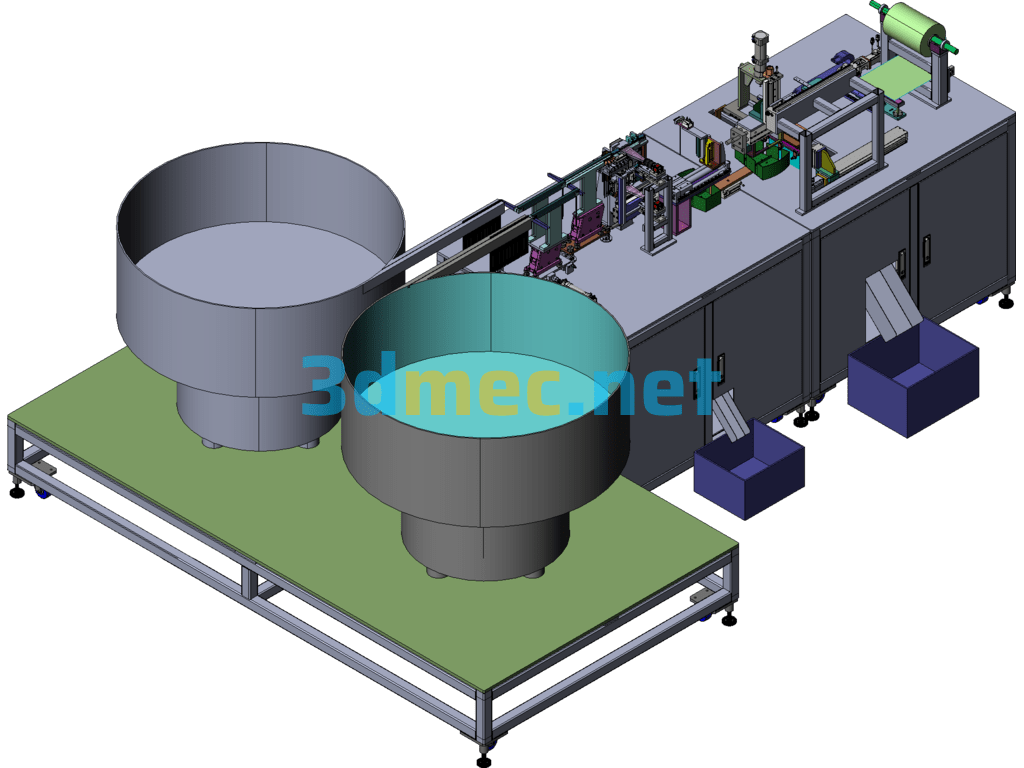

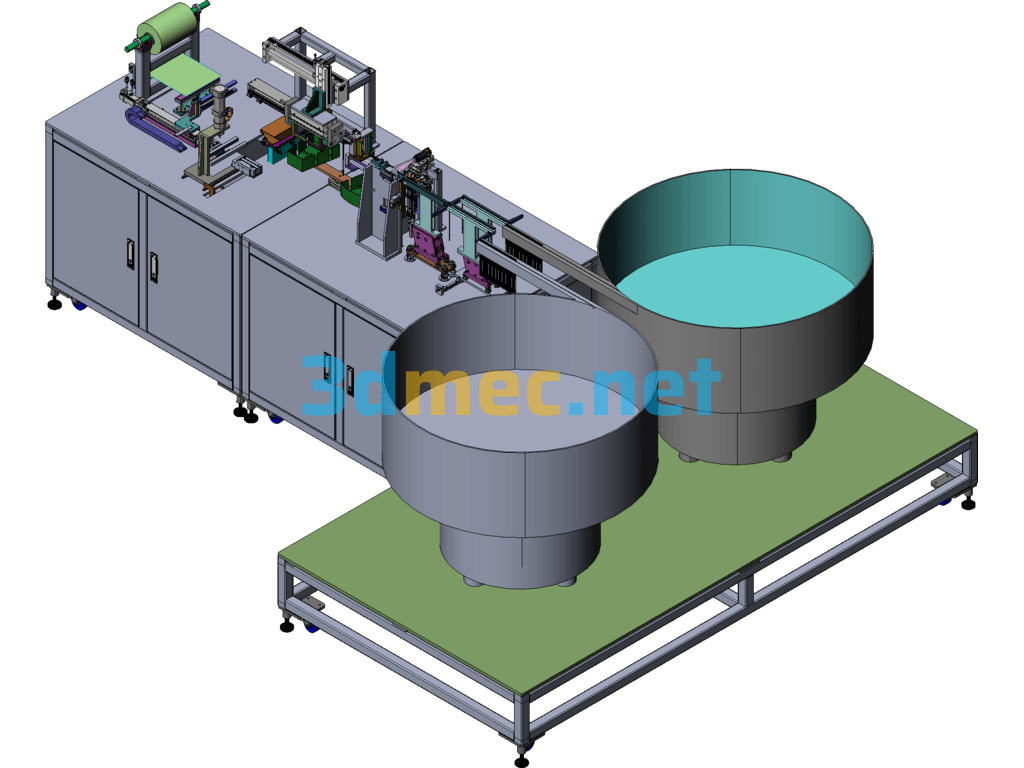

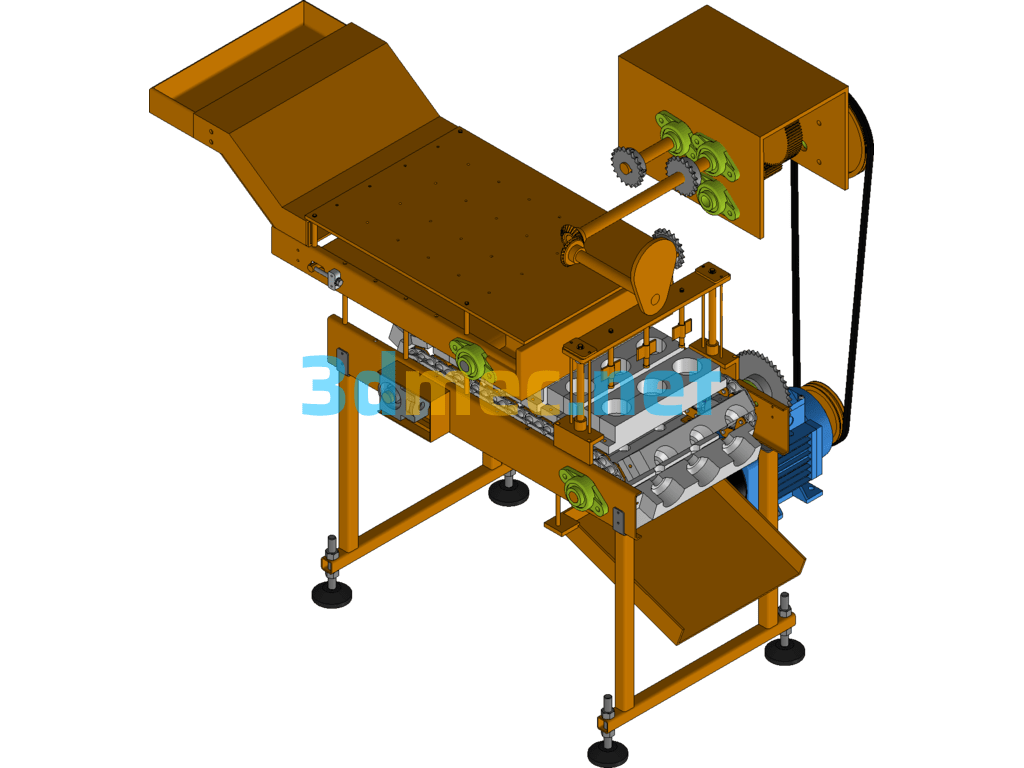

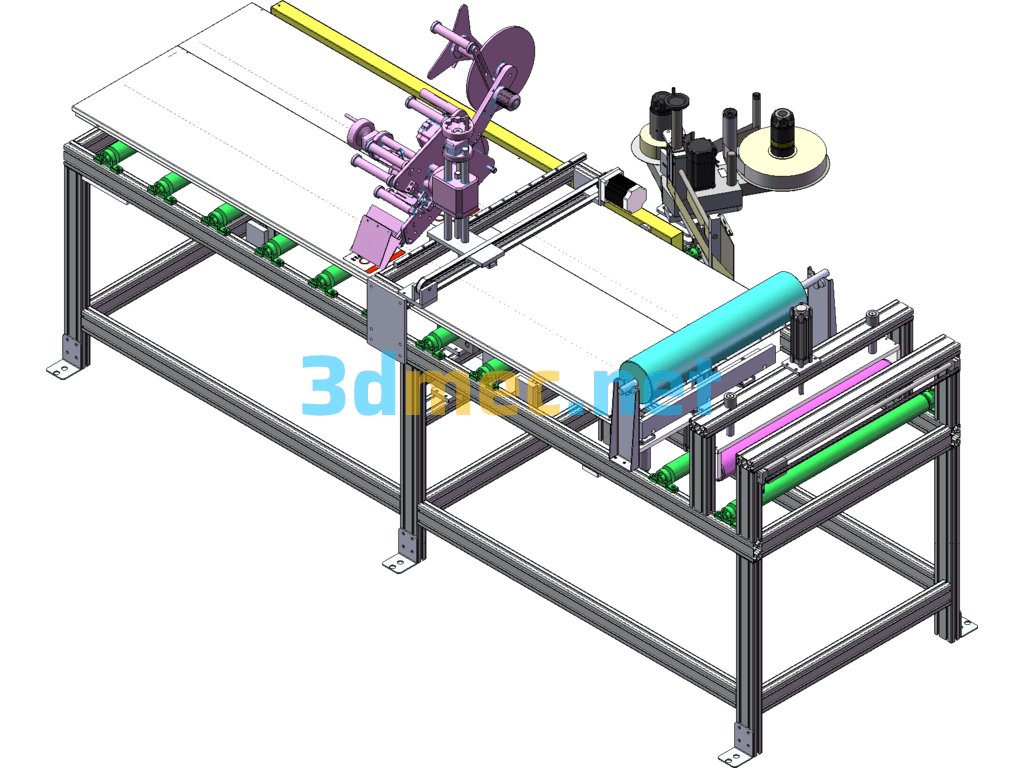

Cable Tie Detection And Automatic Packaging (PPT Detailed Explanation Of The Action Process) – 3D Model SolidWorks

The two sets of vibrations of the automatic cable tie detection and packaging machine switch the feeding respectively, the counting and material separation CCD detects whether the injection molding head inside the cable tie head is short of material, and the lower CCD detects whether the tail of the cable tie is short of material, counts and packages.

Introduction to the operation of the cable tie detection automatic packaging machine:

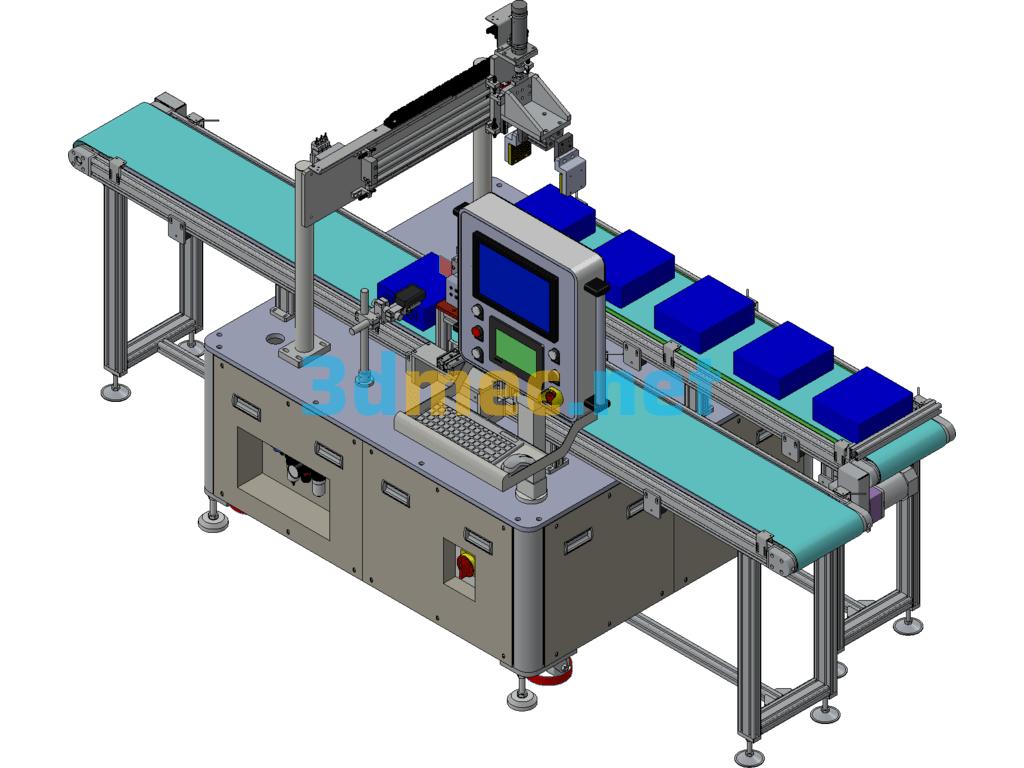

1. Manually put in the circuit board, and the inner cavity guides the positioning;

2. Manually put in two groups of chip trays;

3. After the photoelectric detection of the loading is in place, the equipment is ready, and the manual button starts the equipment;

4. The discharge lower pressure plate moves to avoid the position, and the suction nozzle changes the distance and moves to the tray to absorb the material. After the distance is changed, it is pressed down and loaded into the circuit board;

5. Reminder for unloading and changing materials;

6. Take out the empty tray and put in the new material tray. The equipment memorizes the quantity and position of the other tray;

7. The discharge position can be selected separately for every two rows;

Specification: Cable Tie Detection And Automatic Packaging (PPT Detailed Explanation Of The Action Process) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Cable Tie Detection And Automatic Packaging (PPT Detailed Explanation Of The Action Process) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.