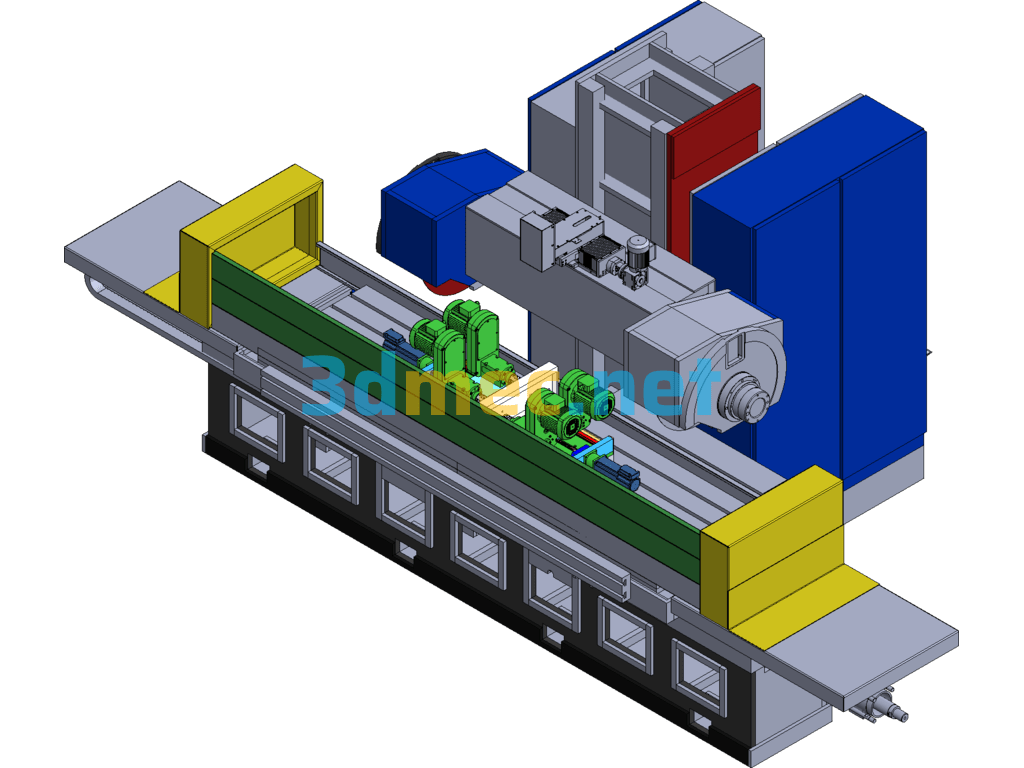

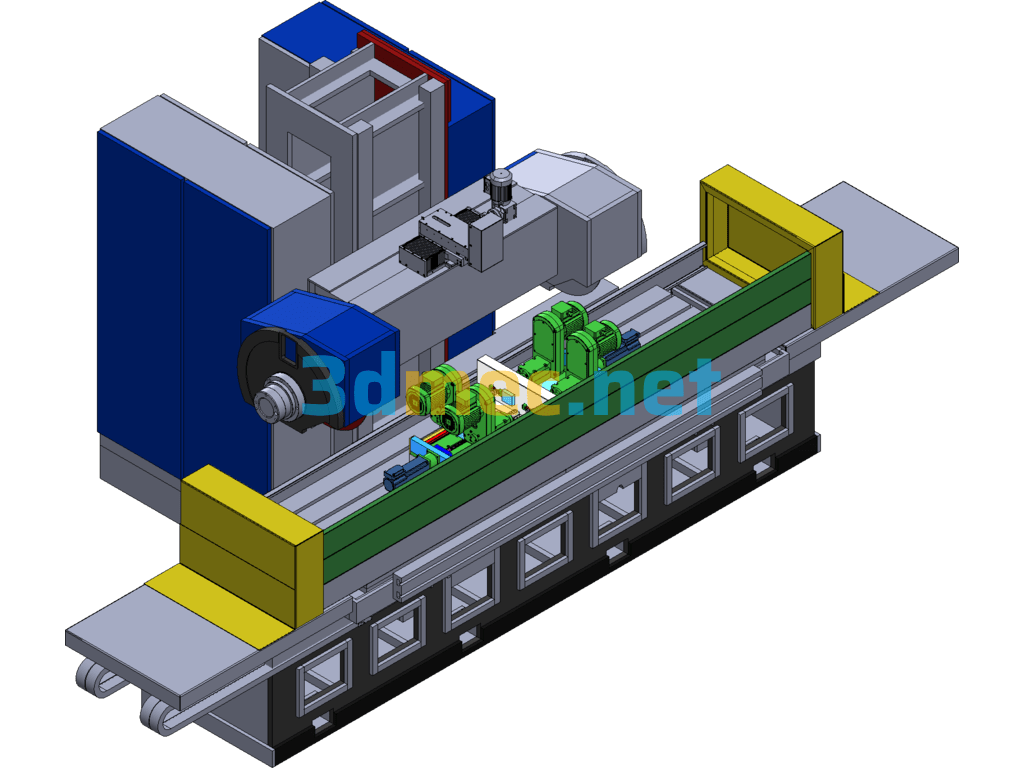

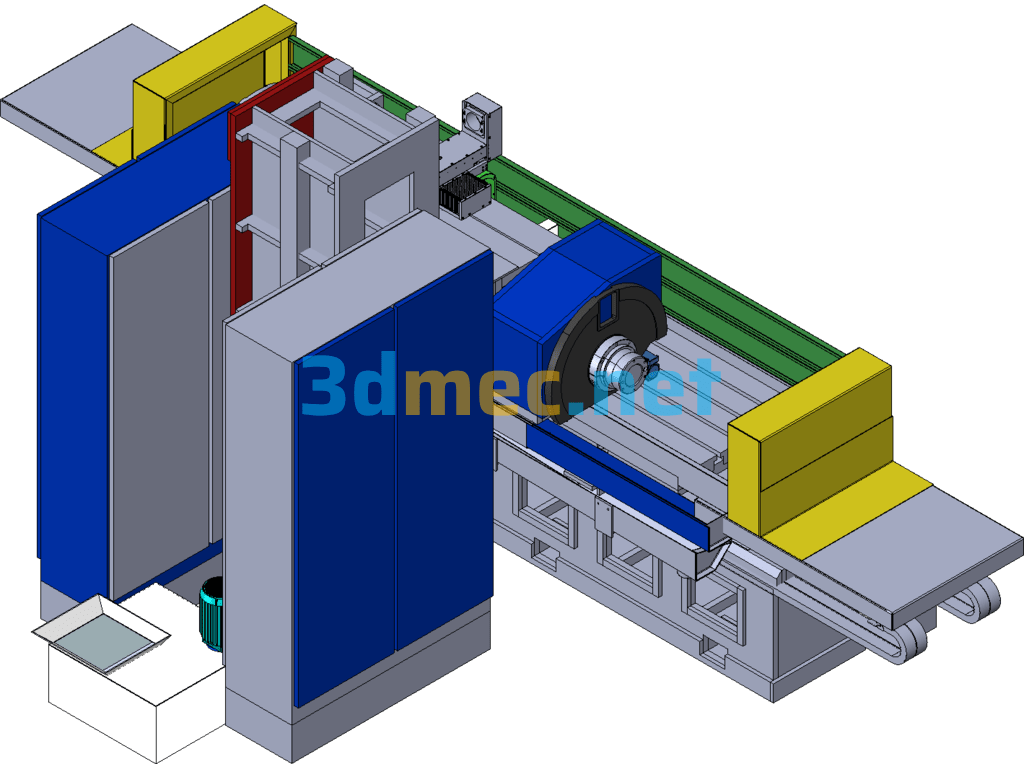

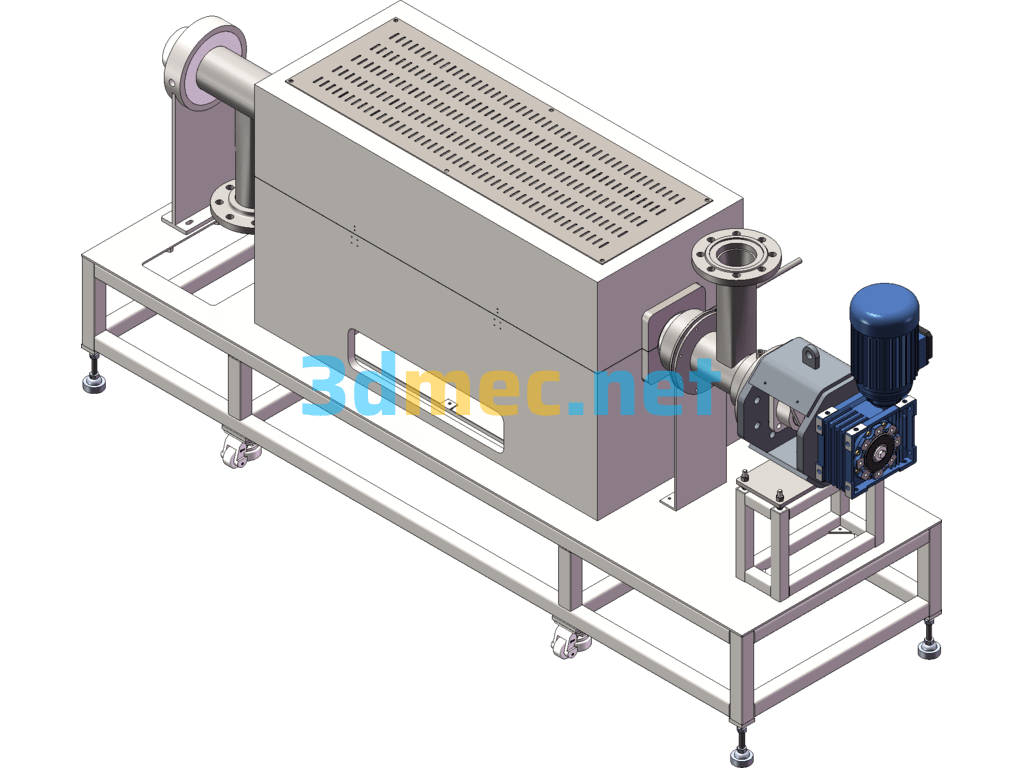

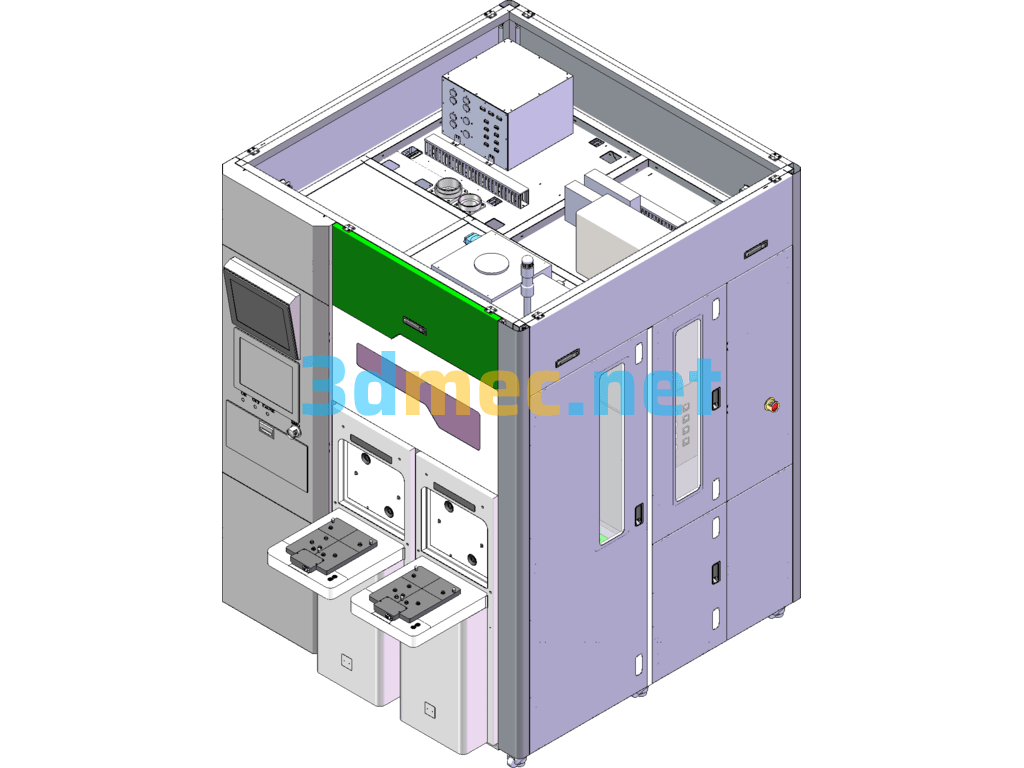

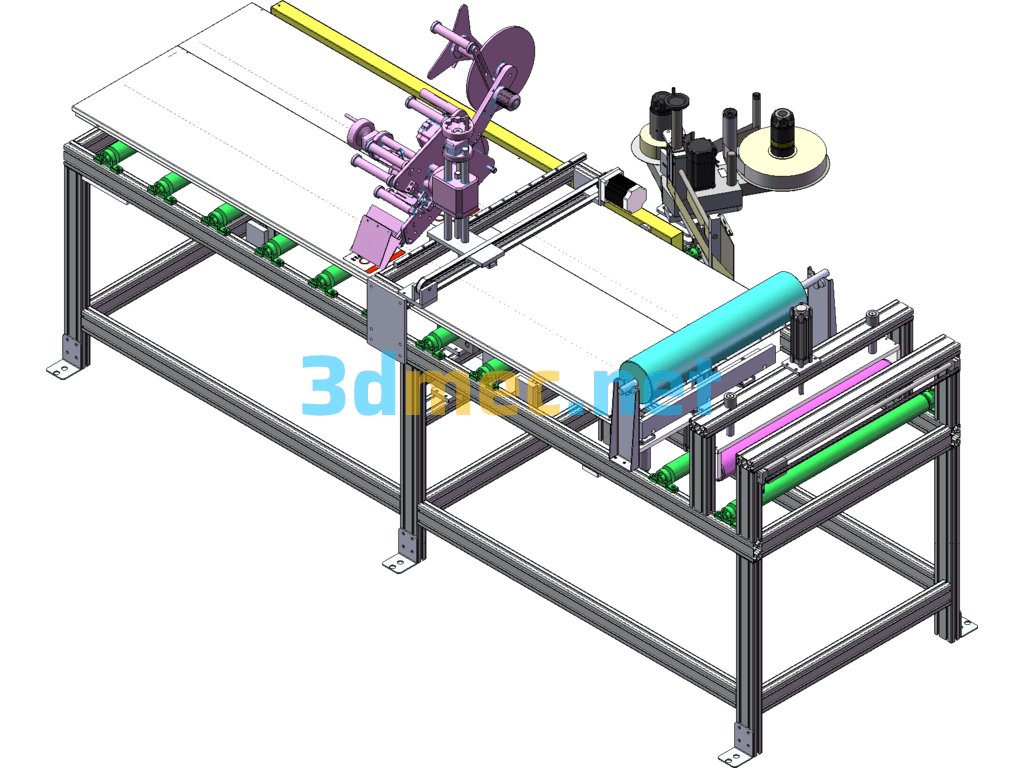

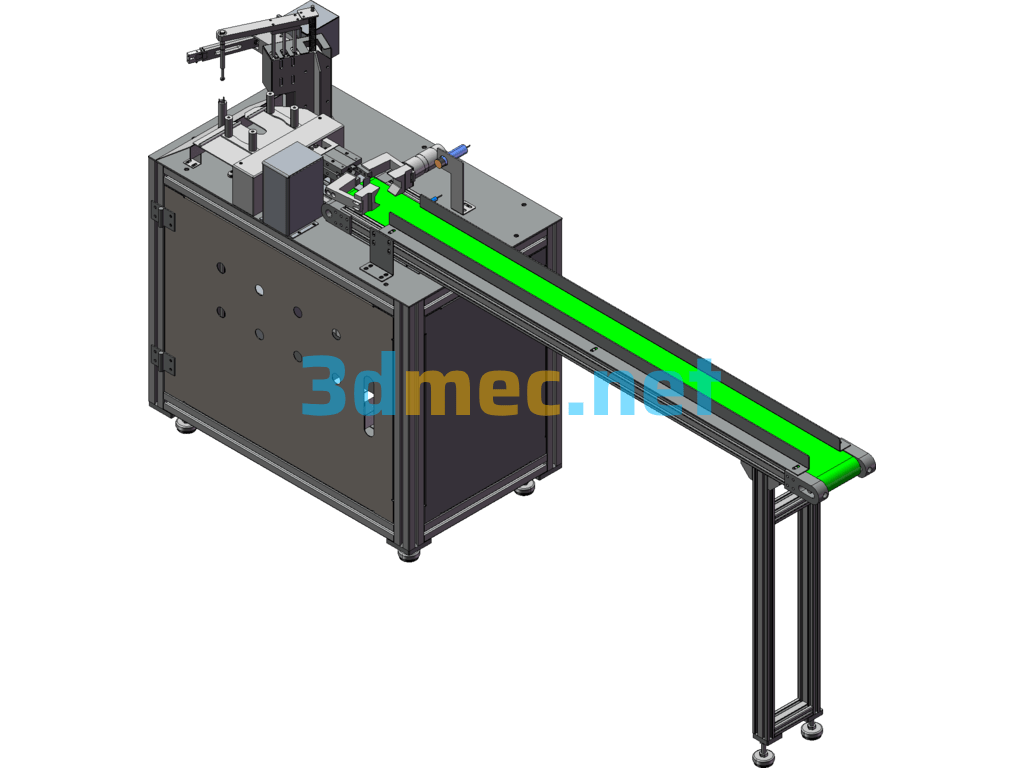

Bidirectional Heat Sink High Speed Cutting Equipment – 3D Model SolidWorks

The mechanism of this equipment is designed by SW2016 and includes editable part features. The worktable panel of the sawing equipment adopts patented design and special processing technology, which can effectively protect the cutting product and avoid scratching the material surface when feeding forward and backward; the equipment cutting tail is controlled at a short 80mm, which greatly controls the waste of tail; the use of dust suction and fully enclosed protective cover can better collect aluminum chips, facilitate 5S management and effectively reduce the sawing noise by more than 20 decibels. It is a low-noise aluminum profile sawing machine; the spindle accuracy is within 0.005mm, and the workpiece cutting accuracy is stably controlled within ±0.1mm, which is suitable for ultra-thin saw blades to achieve the purpose of saving materials; the feeding and feeding all use imported square ball linear guides to ensure the stability of the sawing process; the equipment motors are equipped with overheating and overload protection devices to prevent accidental damage to the motor. The sawing propulsion adopts a servo motor, and the sawing is smooth and jitter-free. Contains STP and UG universal editable formats.

Specification: Bidirectional Heat Sink High Speed Cutting Equipment – 3D Model SolidWorks

|

User Reviews

Be the first to review “Bidirectional Heat Sink High Speed Cutting Equipment – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.