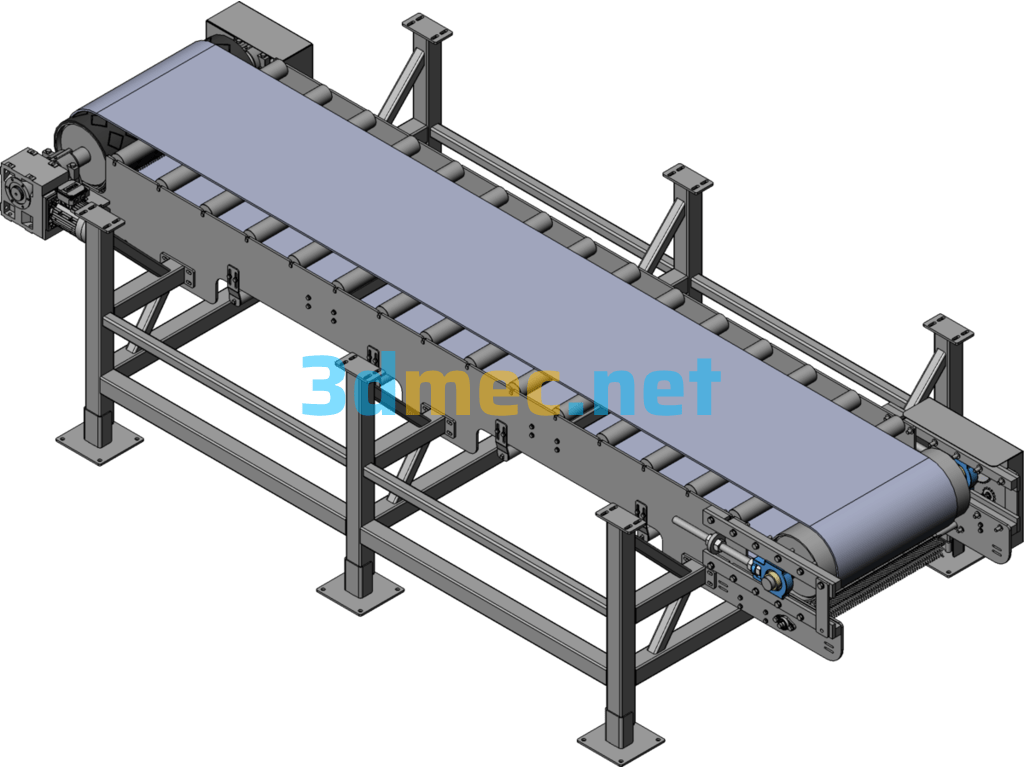

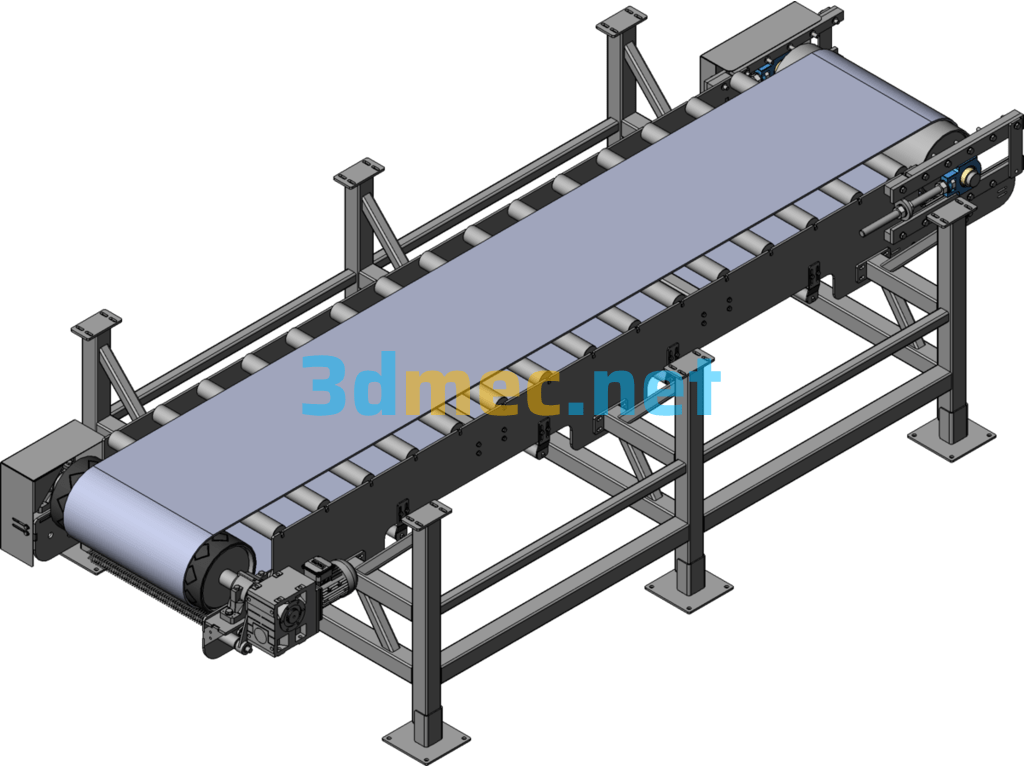

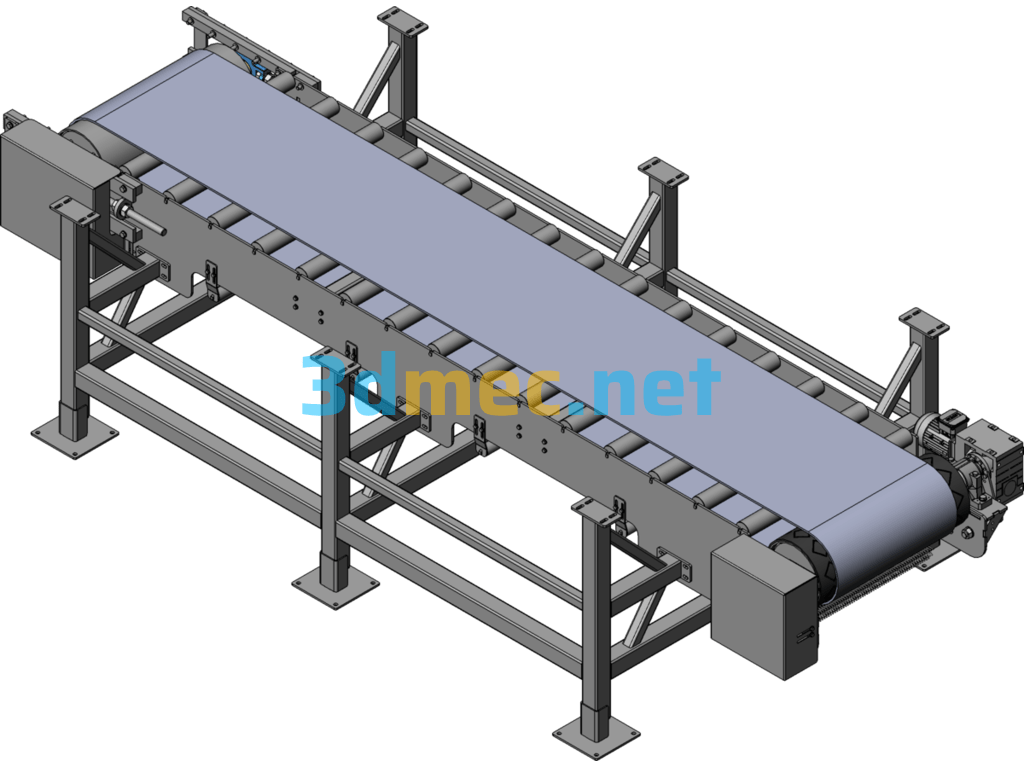

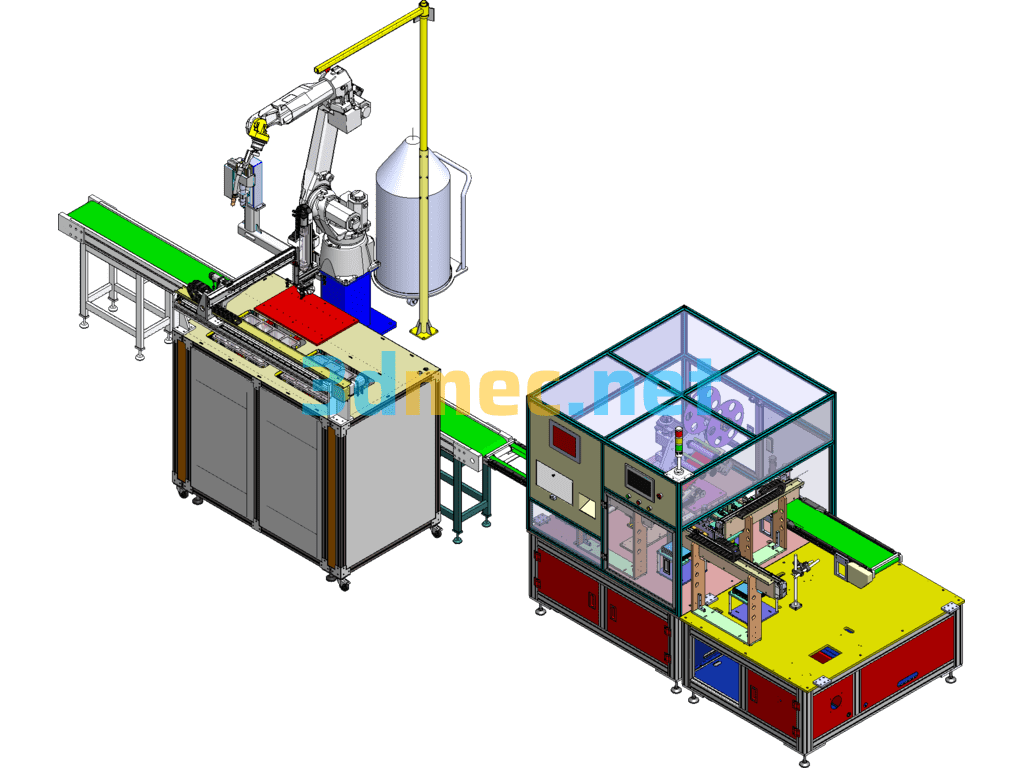

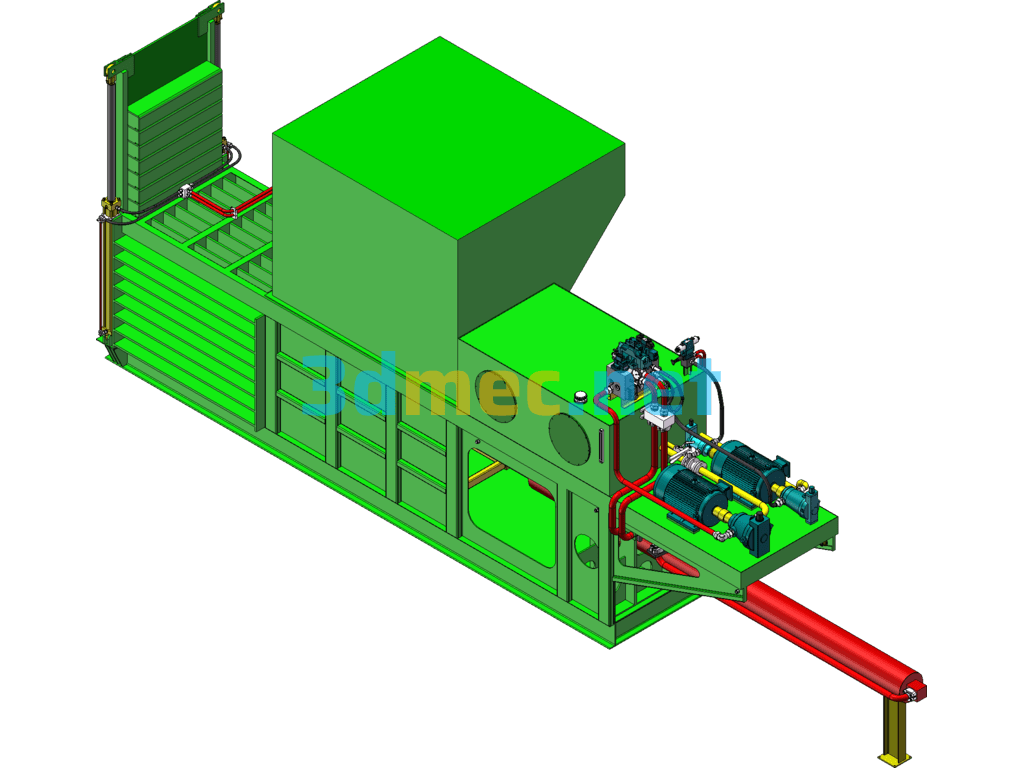

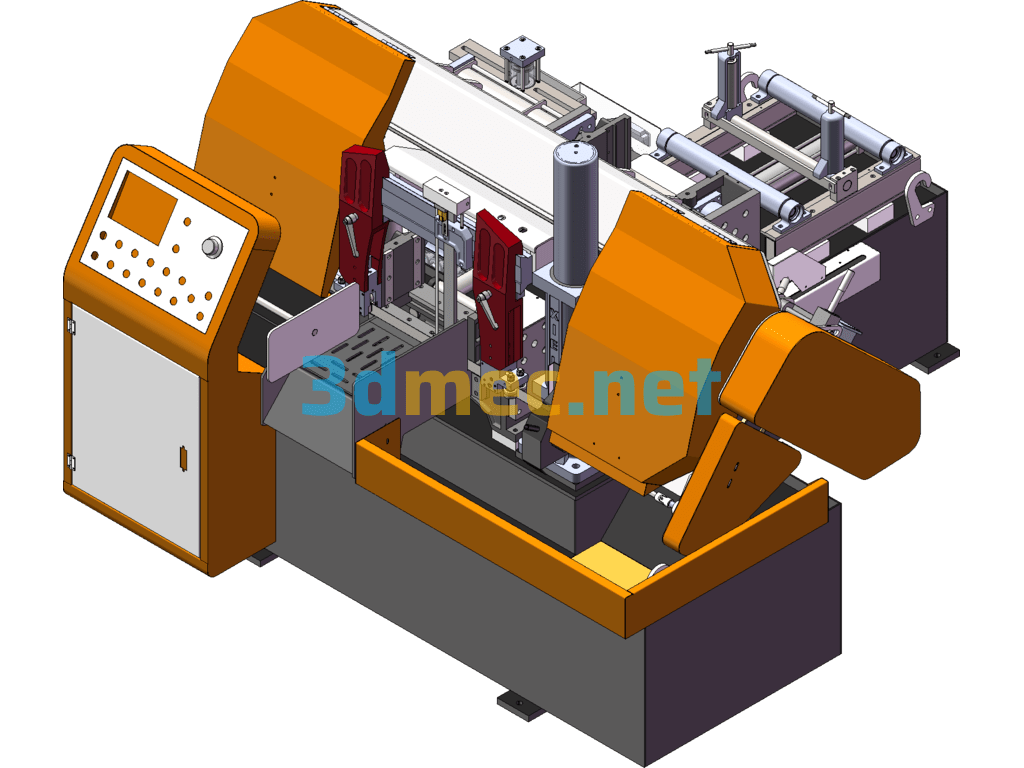

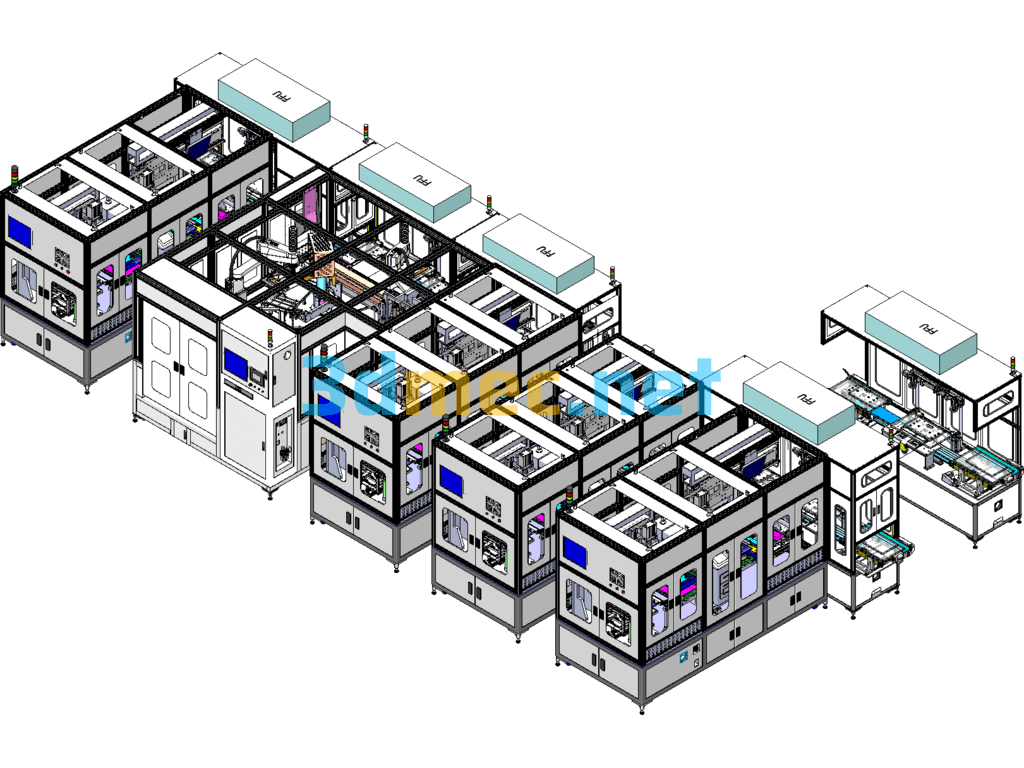

Belt Conveyor Loading Equipment With Hopper – 3D Model SolidWorks

3D model of belt conveyor feeding equipment with hopper SolidWorks 2014 design source file can be edited with parameters. Hopper belt conveyor, used for feeding. Working principle: It is mainly composed of two end rollers and a closed conveyor belt tightly sleeved on it. The roller that drives the conveyor belt to rotate is called the drive roller (transmission roller); the other roller that only changes the direction of movement of the conveyor belt is called the redirection roller. The drive roller is driven by an electric motor through a reducer, and the conveyor belt is dragged by the friction between the drive roller and the conveyor belt. The drive roller is generally installed at the discharge end to increase traction and facilitate dragging. The material is fed from the feeding end, falls on the rotating conveyor belt, and is driven by the friction of the conveyor belt to be transported to the discharge end for discharge.

Specification: Belt Conveyor Loading Equipment With Hopper – 3D Model SolidWorks

|

User Reviews

Be the first to review “Belt Conveyor Loading Equipment With Hopper – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.