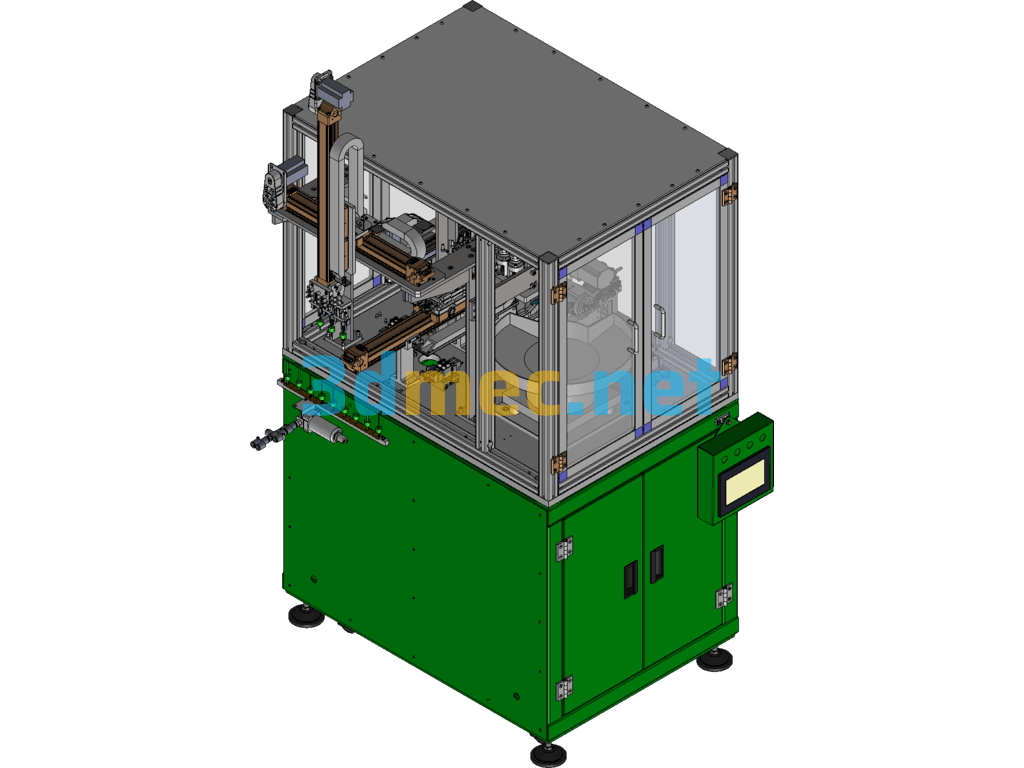

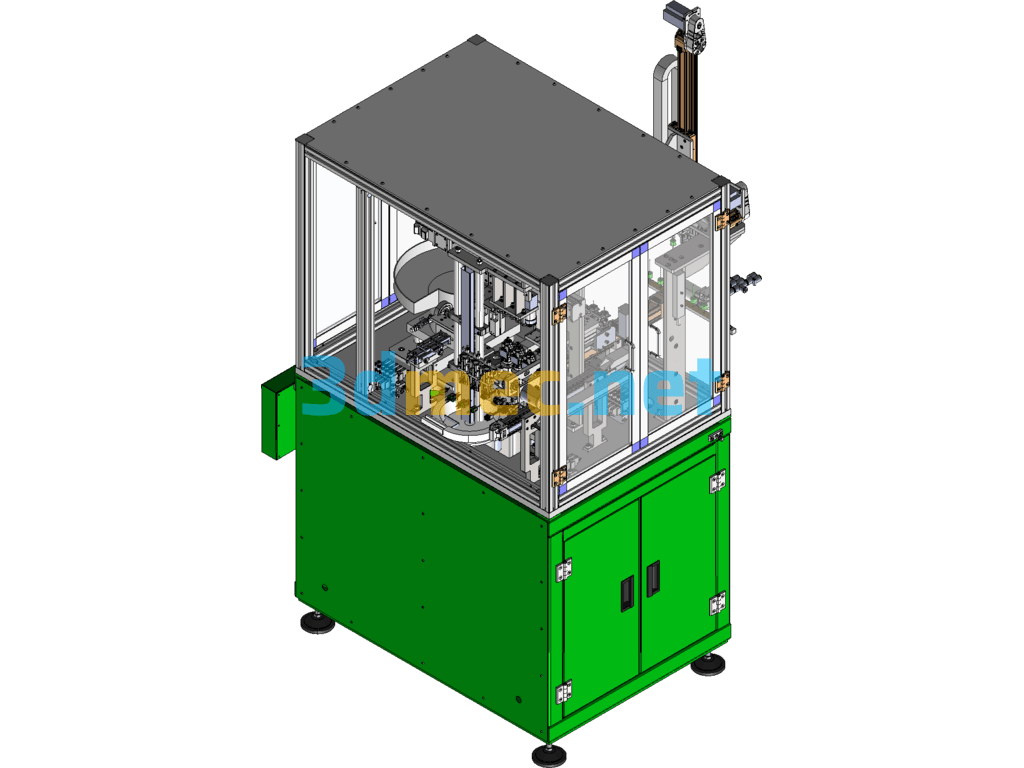

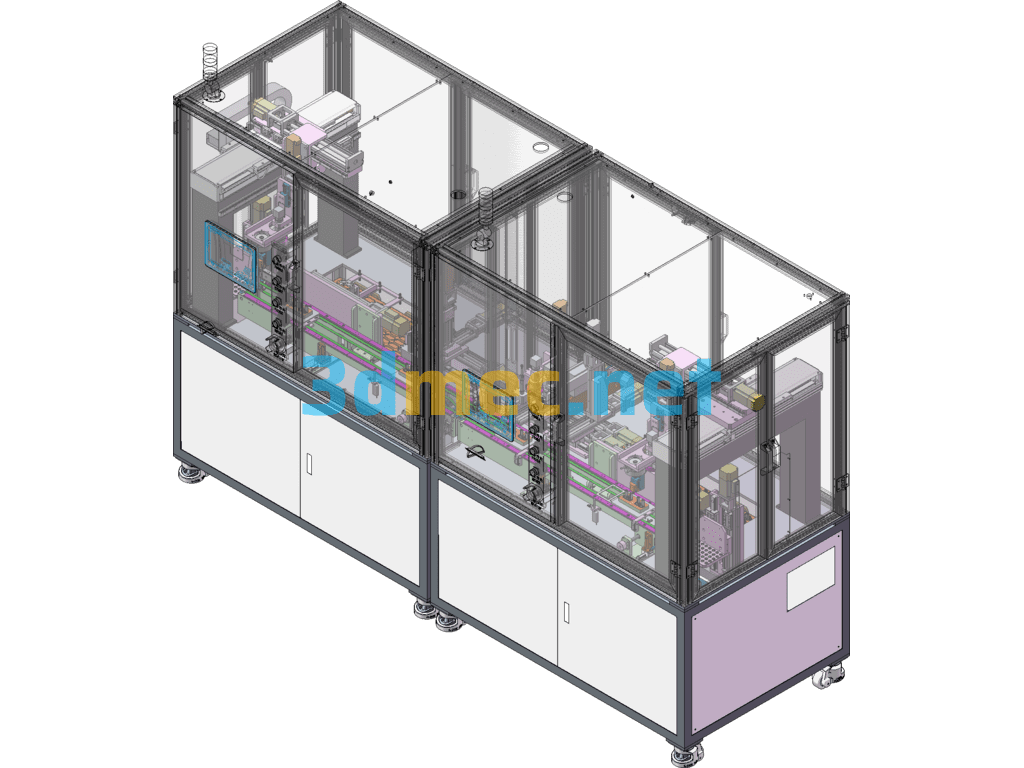

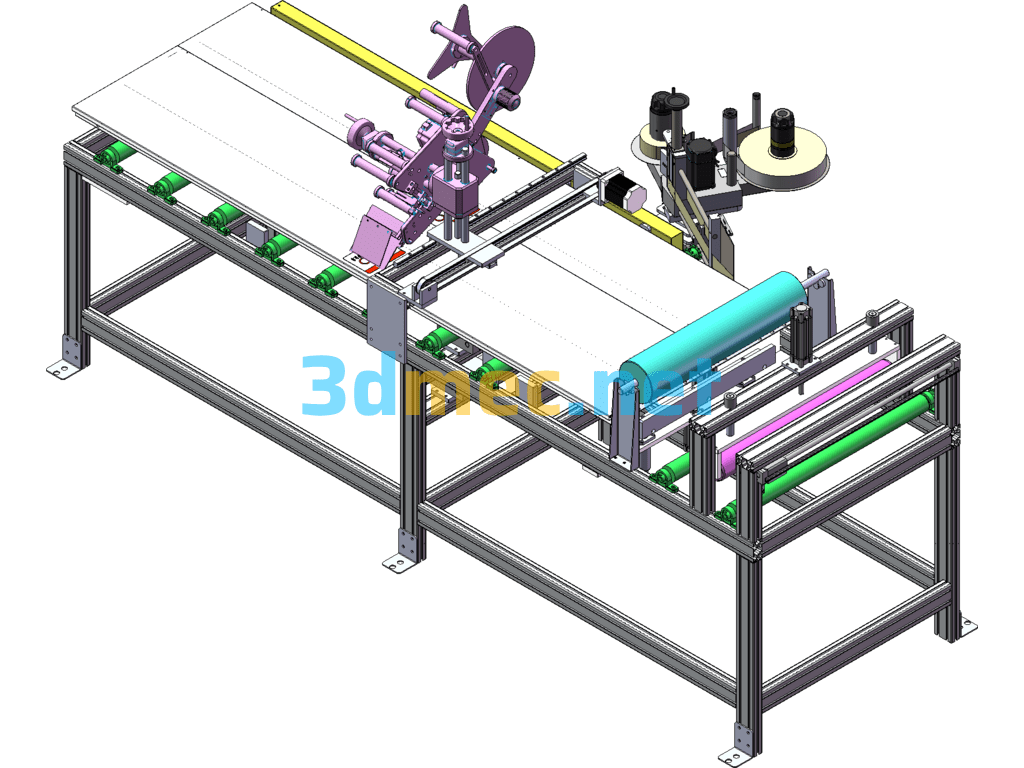

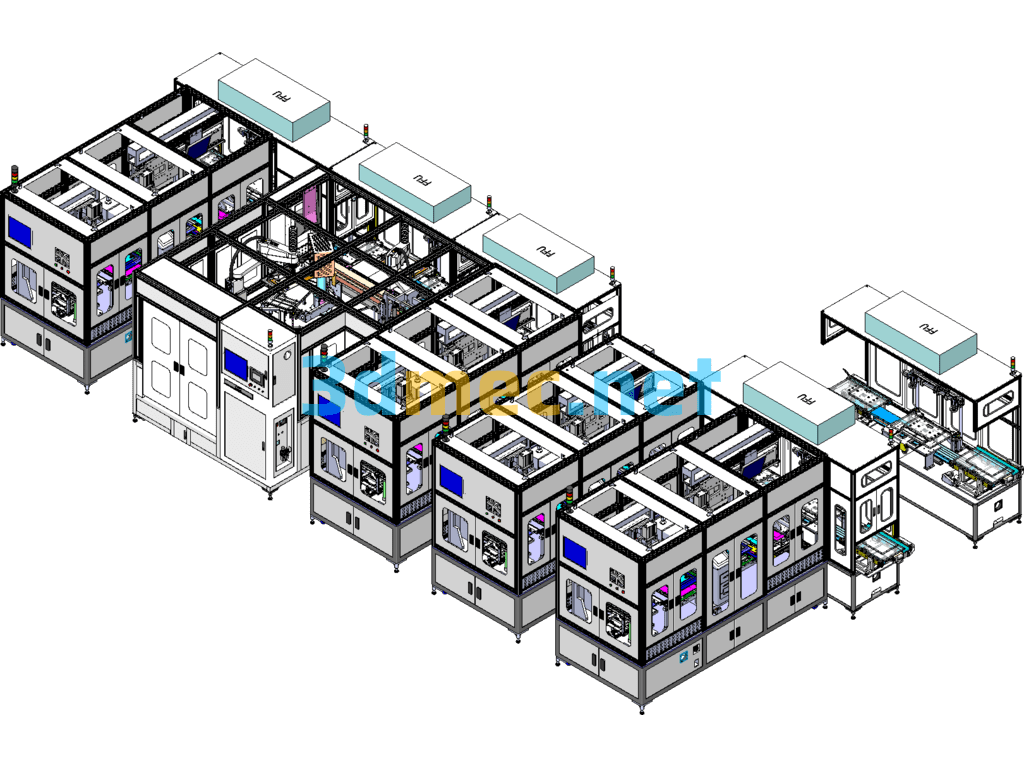

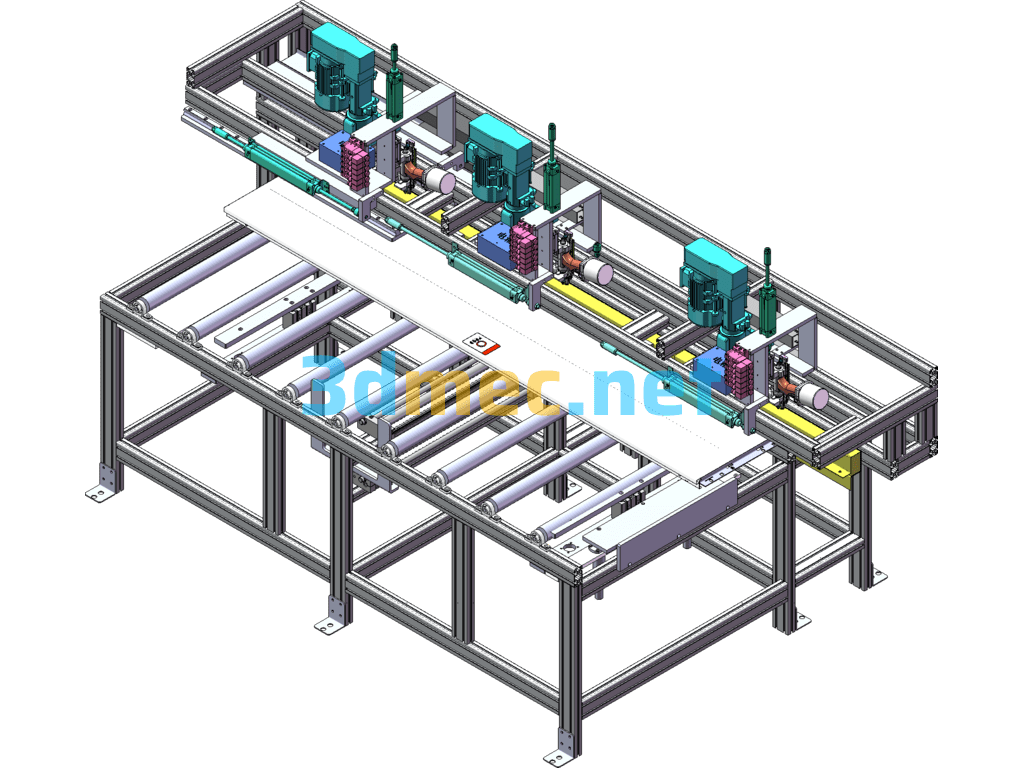

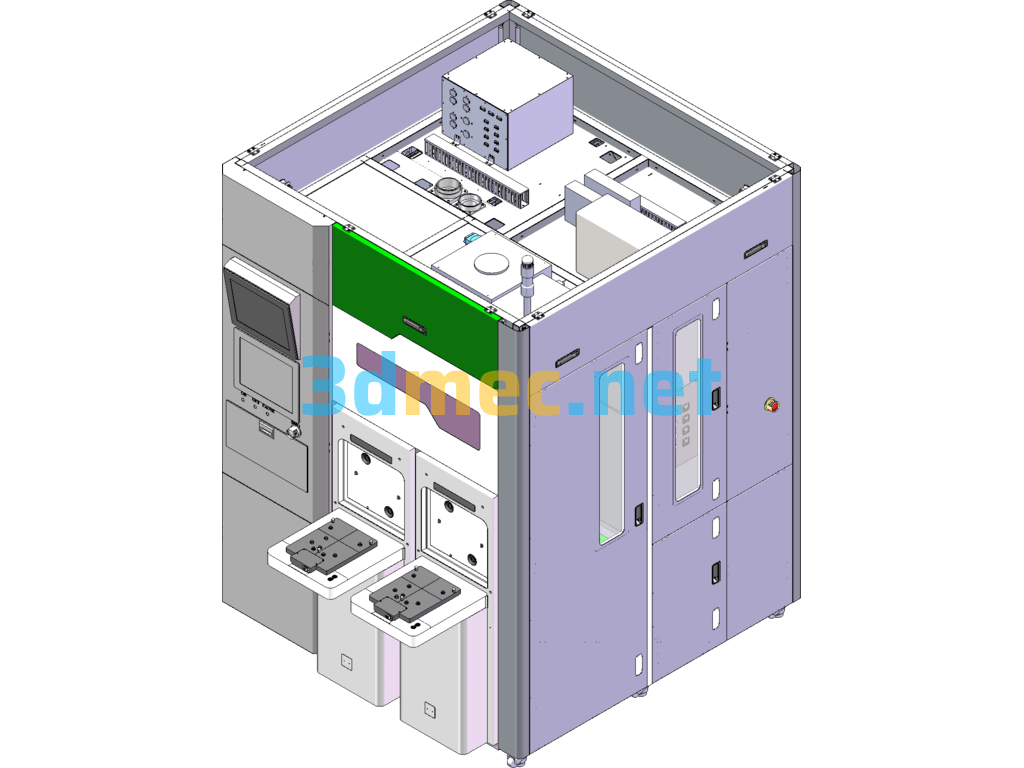

BD1901 motor rotor commutator assembly machine The rotor commutator consists of a cylindrical insulating base, commutator and mica sheet, the commutator is socketed and fixed to the rotor through the inner hole of the cylindrical insulating base, the commutator is mounted circumferentially in the annular mounting grooves on the outer peripheral surface of the insulating base, and the mica sheet is mounted in the insulating function between the neighboring commutator sheets. When working, the rotor commutator rotates with the rotor, with the commutator rotating each winding corresponding to the commutator and fixed brush connection relationship is changed, thus changing the direction of the current in each winding, to ensure that the rotor windings produce magnetic field magnetic force direction. Existing commutator insulating base ring mounting groove is usually used dovetail groove, the bottom of the commutator for the dovetail, through the dovetail and dovetail groove with the realization of the commutator axial bi-directional limit fixing and radial bi-directional limit fixing; mica sheet through the insulating base to achieve the axial bi-directional limit fixing and radial limit fixing inward, and the two adjacent commutator through the beveling with the realization of the radial limit fixing outward. In order to facilitate the installation of the commutator, insulating base dovetail groove side wall is usually set up an opening, assembly, commutator, mica sheet were inserted into the dovetail groove along the axial direction through the opening, and then in the dovetail groove along the circumferential sliding in place, and finally through a block closed opening, complete the assembly of the commutator. However, for the rotor commutator of high speed motors such as automobile starter motors, due to the high rotational speed, generally more than 20,000 rpm, the installation of commutator with dovetail groove structure is likely to cause the commutator to fly in high speed rotation. This equipment has been used in Dr., Dongcheng and other well-known enterprises to improve production efficiency, and has won the praise of customers. The drawings can be edited and are widely used in the industry.

Specification: BD1901 Motor Rotor Commutator Assembly Machine SolidWorks 3D Model

|

User Reviews

Be the first to review “BD1901 Motor Rotor Commutator Assembly Machine SolidWorks 3D Model”

You must be logged in to post a review.

There are no reviews yet.