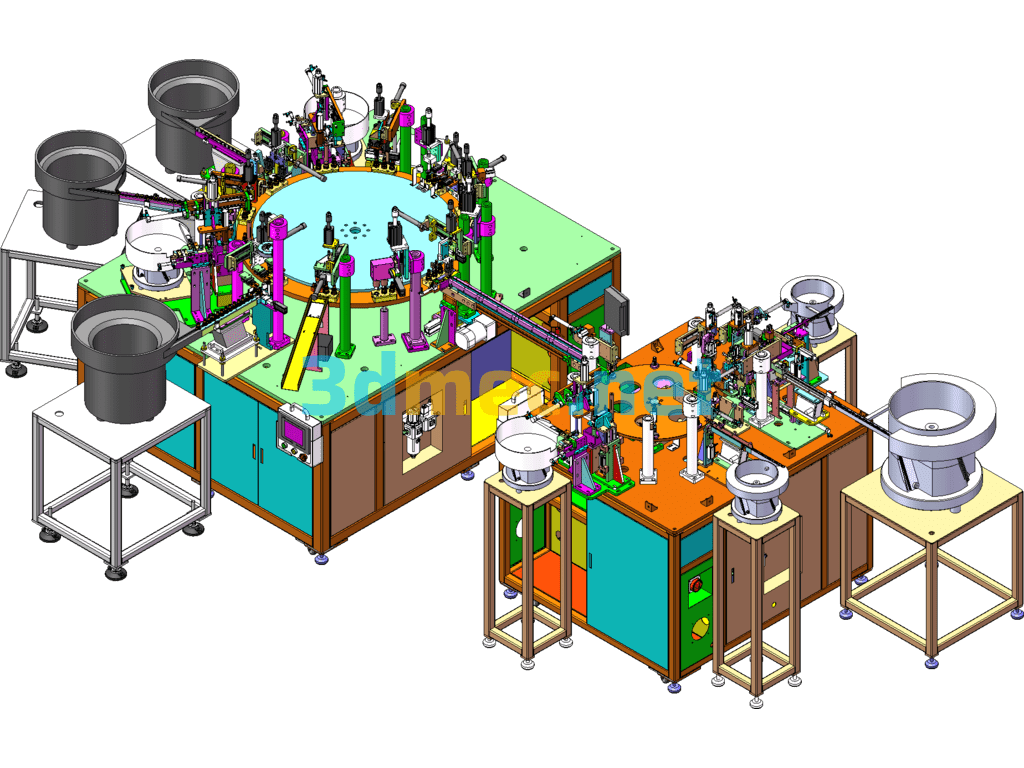

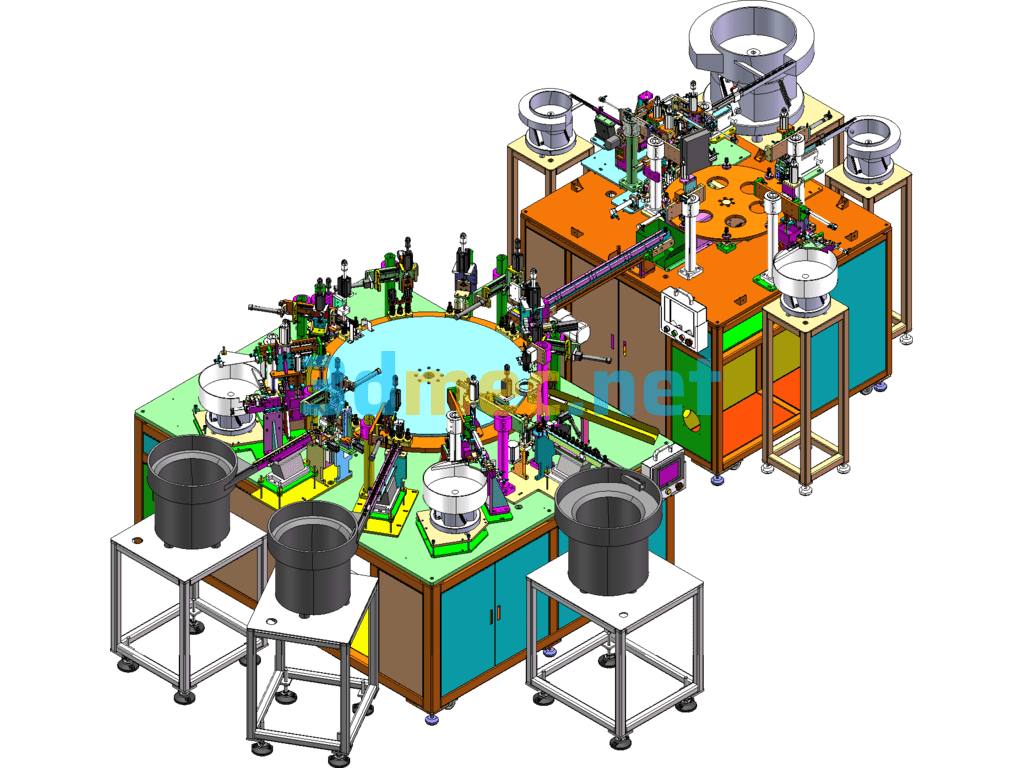

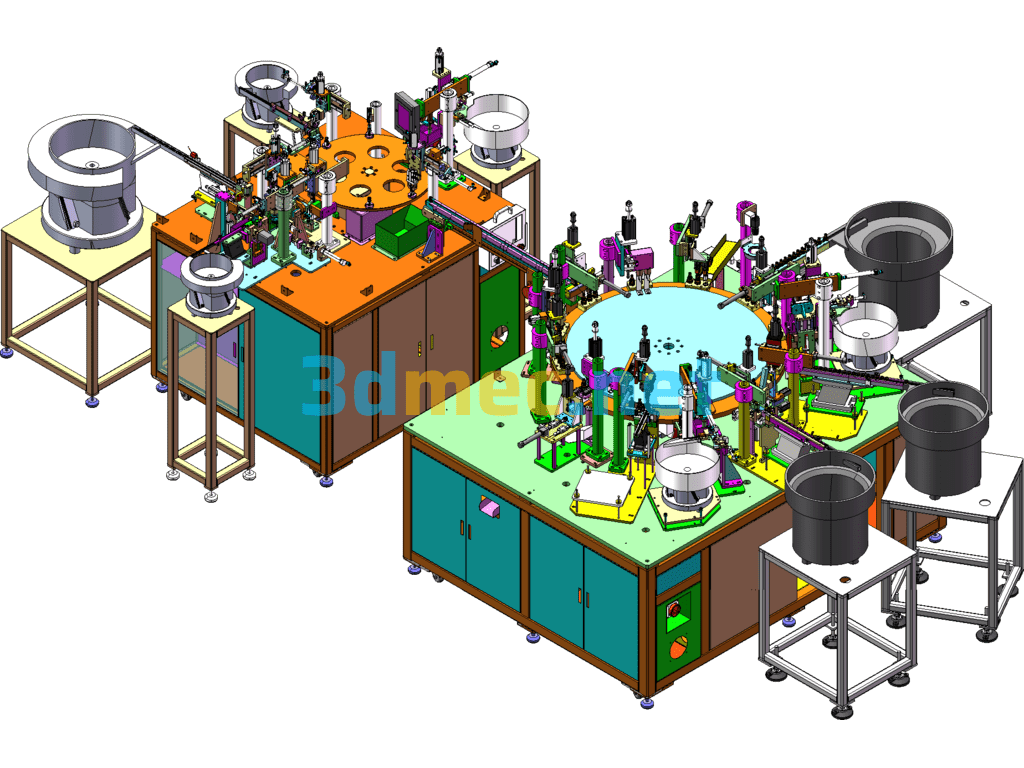

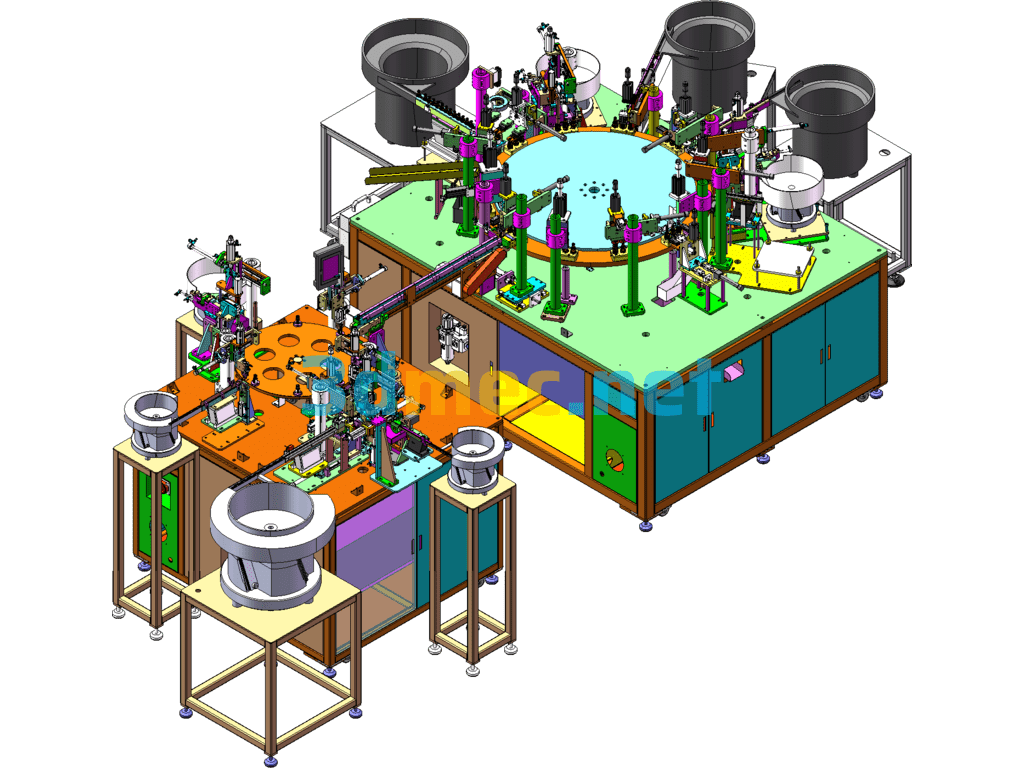

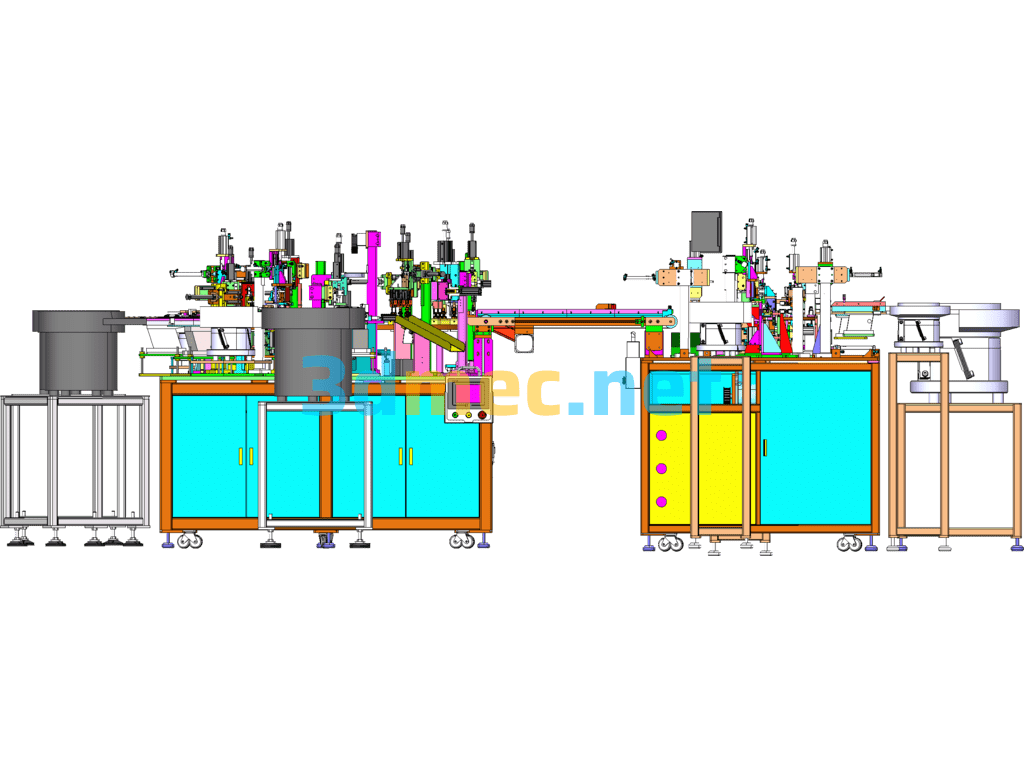

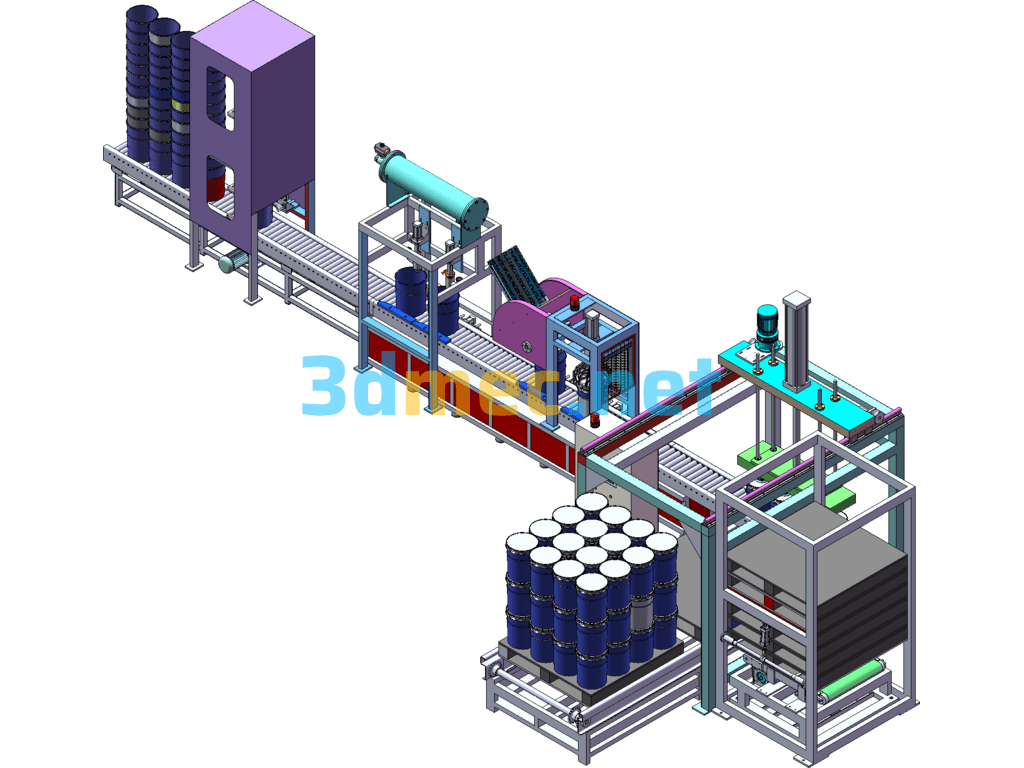

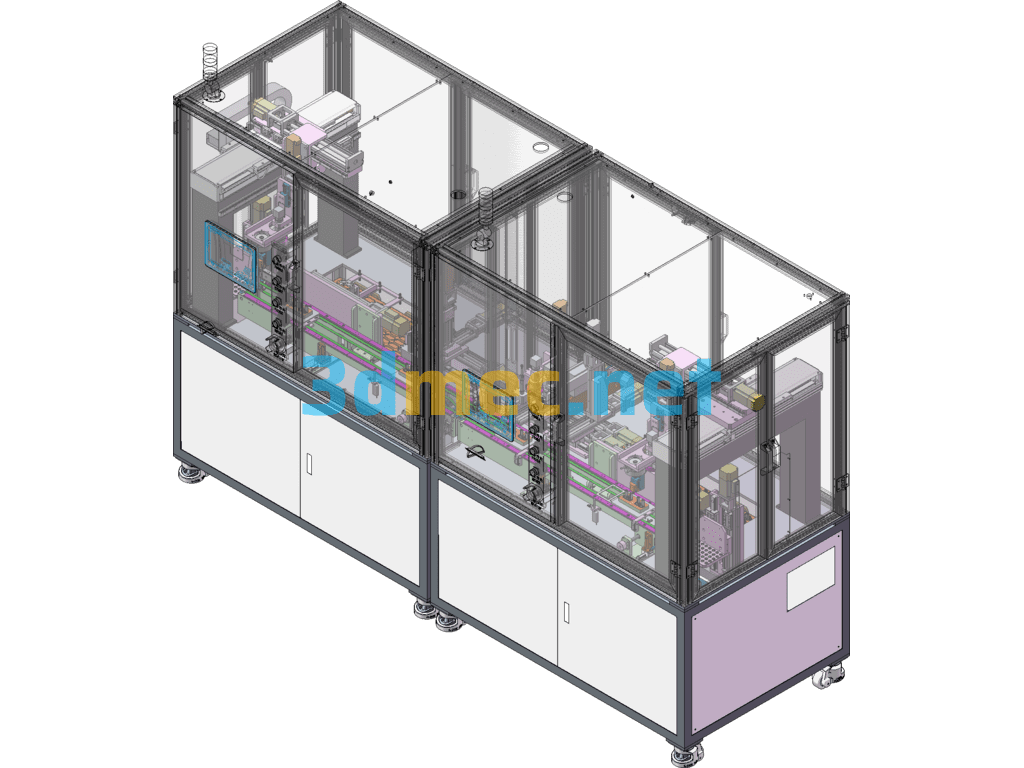

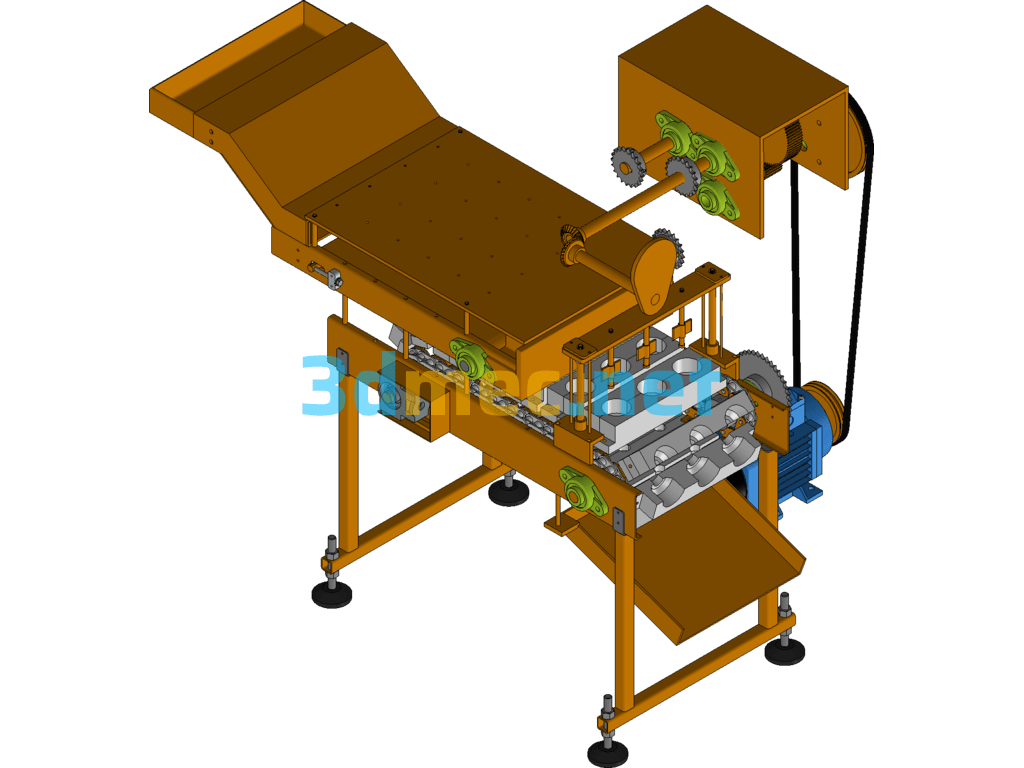

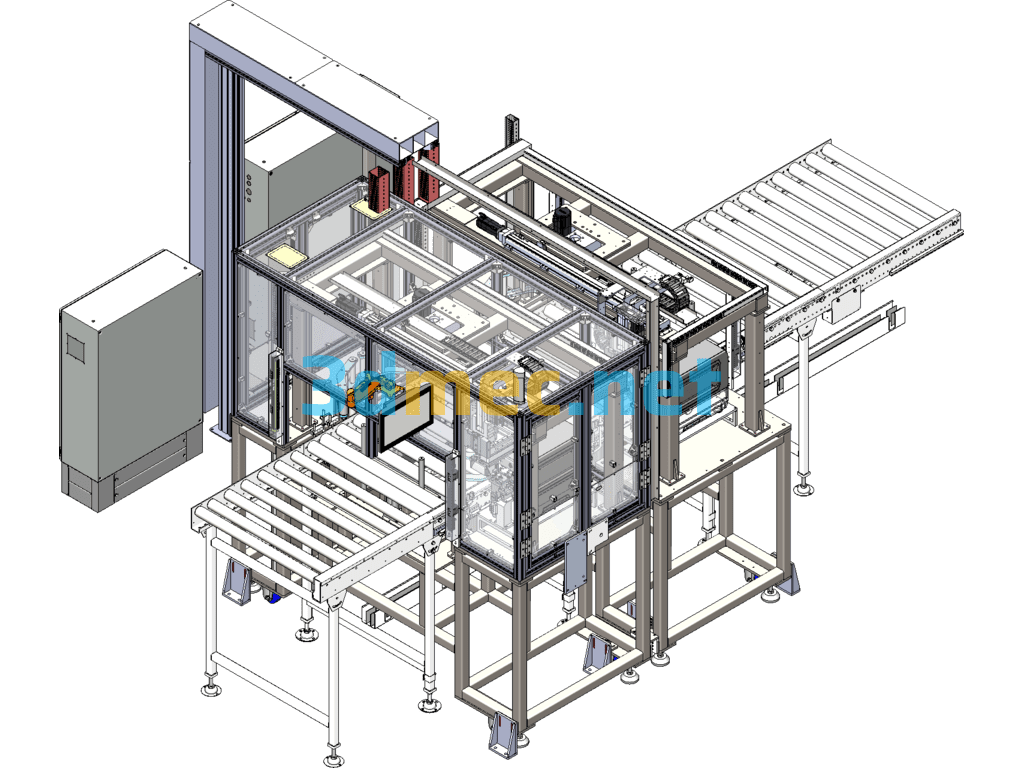

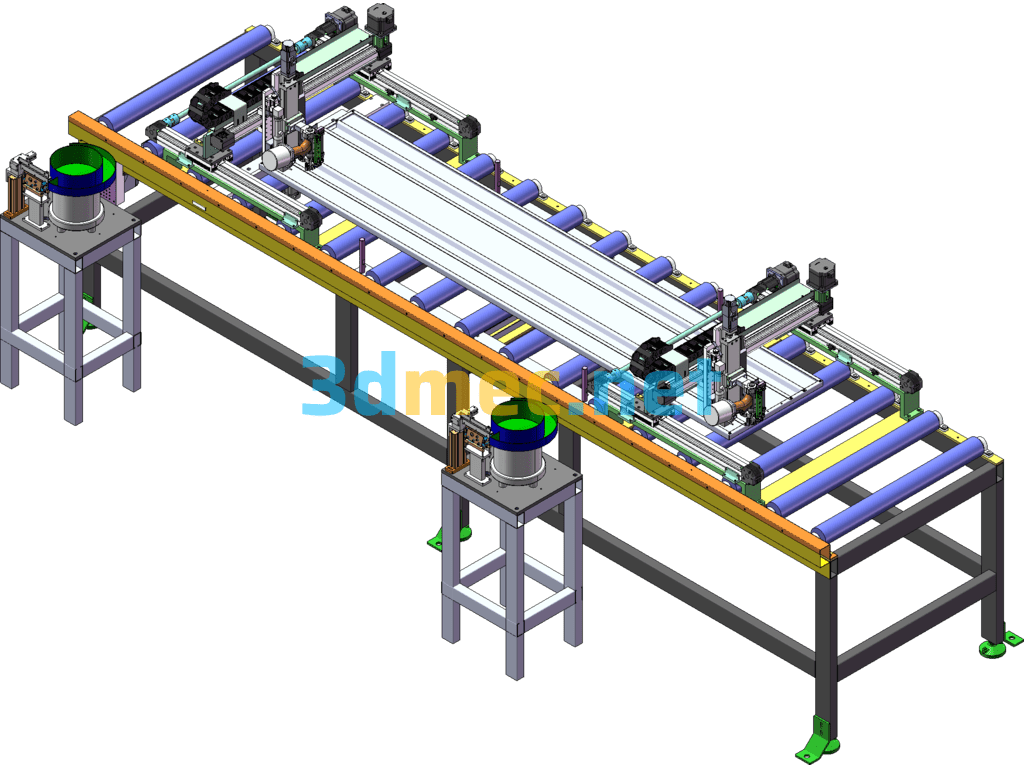

KV026-Automotive valve automation equipment A complex automated automotive valve assembly equipment, the equipment for the country’s first automated automated assembly of automotive valve throttle slide valve switch class spare parts machine, the bus runs at a fast speed per hour can be assembled 800-1,000 valves products, the equipment is divided into two machines operating first of all, the product is pre-installed another machine is the total product assembly machine, by the next two machines to complete the assembly of more than 10 parts, the equipment operates in a carousel type by 10 stations and 12 stations carousel division structure. More than ten parts of the assembly, the operation mode of the equipment for the carousel type respectively by 10 stations and 12 stations of the carousel dividing structure, pre-loading machine for the 12 stations of the carousel, first of all, the accessories by hand into the vibrating plate for feeding and distribution of materials, etc., the vibrating plate is through the different shape of the production of each customized, so from the picture you can see that there is a large vibrating plate and small, but also because of the product specifications are not the same size, then from the vibrating plate feeder, the vibrating plate can be used in the vibration of the product, and then the vibrating plate can be used in the vibrating plate. The same, then from the vibrating plate to send out the material is after feeding and distribution of material, here feeding is unified by the direct vibration feeding this direct vibration is also and vibration with the operation, the distribution mechanism is different, the product shape is not the same distribution of material is not the same as the practice, the distribution of material from the bottom of the top of the material from the bottom of the top of the left by pushing and stepping motor rotating to find the position of the material, as well as more difficult to distribute the material we have used the CCD vision of the positioning of the way, so the line in the body. way to carry out, so the structure of this line basically contains the structure and practices commonly used in automation equipment, so each station corresponds to a different product assembly, after the distribution of products by the robot directly clamped to the carousel for assembly, a station finished rotating to the next station in turn to complete the pre-assembly of all the accessories, when the completion of these actions by the downstream manipulator clamped semi-finished products to the conveyor belt from this machine to another machine, when the conveyor belt to the next machine, when the conveyor belt to the next machine, when the conveyor belt to the next machine, when the conveyor belt to the next machine, when the conveyor belt to the next machine. Another machine, when the sensor in the conveyor belt to detect the product into the beginning of the clamping semi-finished products to the assembly machine in the rotating disk for the overall assembly of the product, turntable by the distribution of 10 stations a station corresponding to a kind of accessories for assembly until all the accessories assembled after the completion of the discharging of the finished product by the discharging machinery clip finished products to the discharging box, the above is the principle of all the actions of the equipment and the operating process, due to the more equipment station More detailed structure and functional realization also need to download and open the drawings for research, because the drawings are relatively large download and decompression out of 700BM so download the network to choose a faster place to avoid interruptions, the drawings are very complete all the structure can be seen clearly for learning reference structure to learn from the graduation design is a very good work, of course, you can also be used to do similar products only need to make small changes to be able to Transformation of another different device, which is currently the automation industry’s most valuable analysis of the equipment.

Specification: Automotive Valve Assembly Machine Throttle Slide Valve Door Non-Standard Automation Equipment SolidWorks 3D Model

|

User Reviews

Be the first to review “Automotive Valve Assembly Machine Throttle Slide Valve Door Non-Standard Automation Equipment SolidWorks 3D Model”

You must be logged in to post a review.

There are no reviews yet.