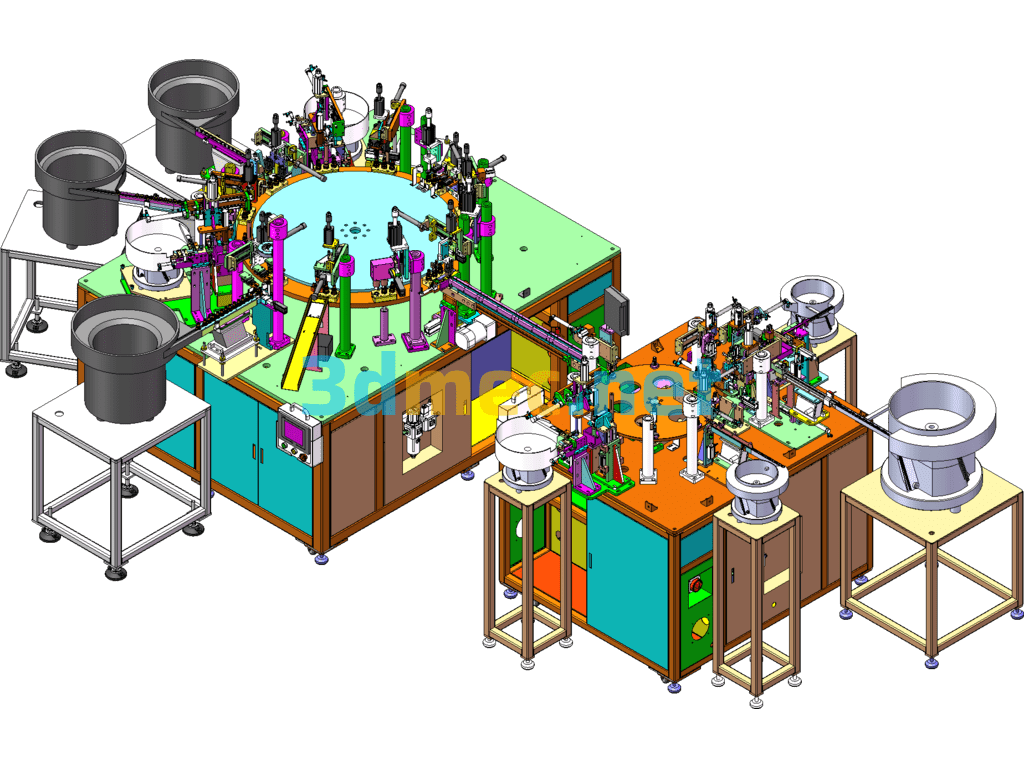

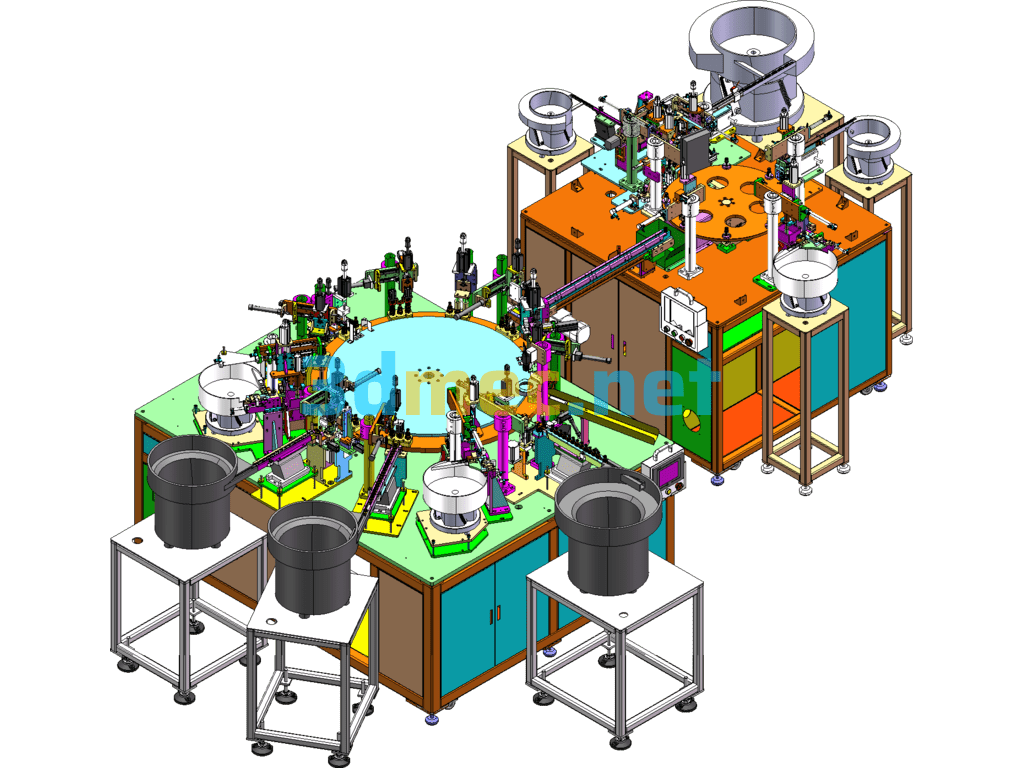

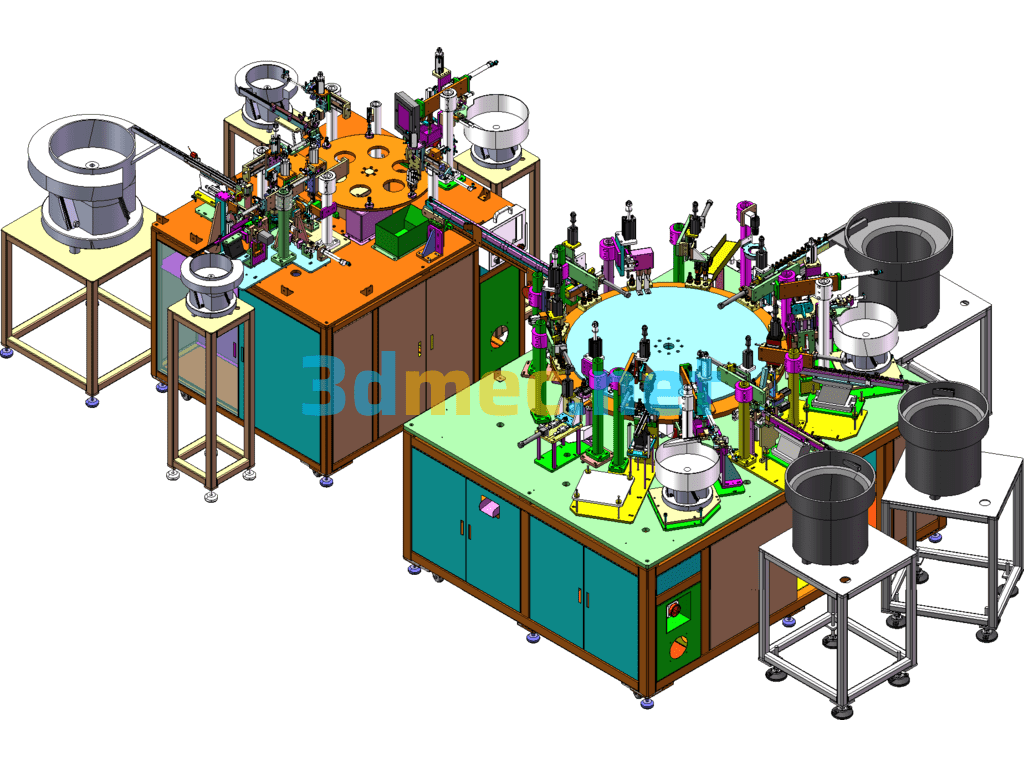

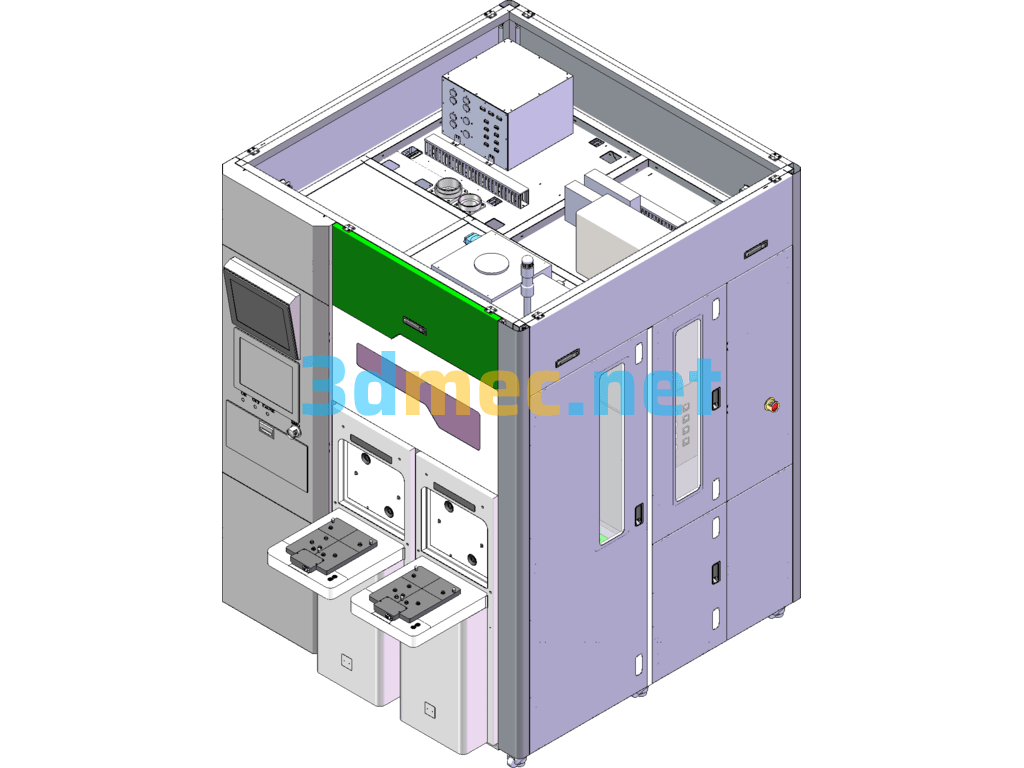

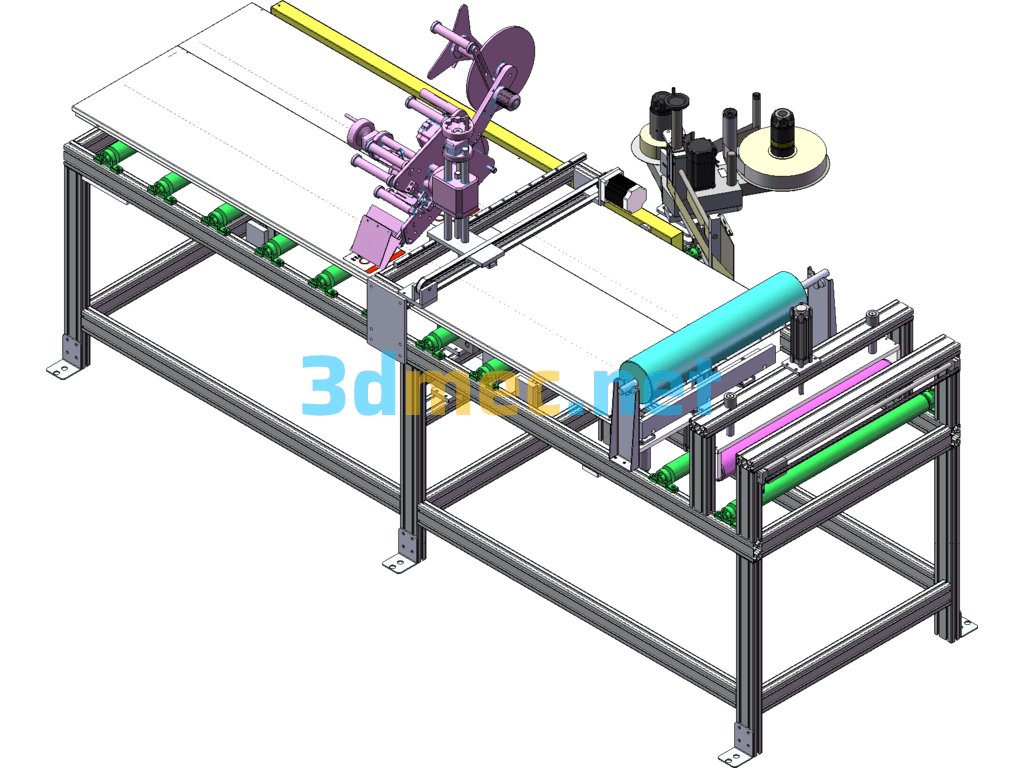

Automobile Valve Assembly Machine Throttle Valve Non-Standard Automation Equipment – 3D Model SolidWorks

KV026-Automobile valve automation equipment is a complex set of automobile valve assembly automation equipment. This equipment is the first automatic assembly machine for automobile valve throttle slide valve switch parts in the country. The bus runs fast and can assemble 800-1000 valve products per hour. The equipment is divided into two machines. The first is to pre-install the product and the other is the product assembly machine. The two machines complete the assembly of more than ten parts. The operation mode of the equipment is a turntable type, which consists of a 10-station and a 12-station turntable segmentation structure. The pre-installation machine is a 12-station turntable. First, each accessory must be manually placed in the vibration plate. For feeding, material distribution, etc., the vibration plate is customized according to different product shapes, so from the picture you can see that the vibration plate is large and small, and it is also because the specifications of the products are different. Then after the material is fed out from the vibration plate, it is feeding and material distribution. Here the feeding is uniformly done by direct vibration feeding, and this direct vibration also works in conjunction with vibration. The material distribution mechanism is different. The material distribution methods are also different for different product shapes. The material distribution here is done by pushing from the bottom to the top and from the left, and the stepper motor rotates to find the position for distribution. For the more difficult material distribution, we use CCD visual positioning. Therefore, the structure in this line basically includes This automation equipment contains the common structure and practices, so each station corresponds to different product assembly. The separated products are directly clamped by the robot to the turntable for assembly. After one station is completed, it rotates to the next station to complete the pre-installation of all accessories in sequence. After completing these actions, the unloading robot clamps the semi-finished product and puts it on the conveyor belt, which is then transported to another machine. When the sensor in the conveyor belt detects that the product has entered, it begins to clamp the semi-finished product to the rotating disk in the final assembly machine for overall product assembly. The turntable is distributed with 10 stations, and one station corresponds to one accessory for assembly until all accessories are assembled and unloaded. The machine clamps the finished product into the blanking box. The above are all the action principles and operation processes of this equipment. Since the equipment has many workstations, the detailed structure and function realization need to be downloaded and opened for research. The drawings are relatively large and there are 700BM after decompression, so choose a place with a faster network when downloading to avoid interruption. The drawings are very complete and all structures can be seen clearly. They are very good works for learning reference structures and drawing on graduation designs. Of course, they can also be used to make similar products. Only small changes can be made to transform into another different equipment. This is also the most valuable equipment for analysis and research in the current automation industry.

Specification: Automobile Valve Assembly Machine Throttle Valve Non-Standard Automation Equipment – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automobile Valve Assembly Machine Throttle Valve Non-Standard Automation Equipment – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.