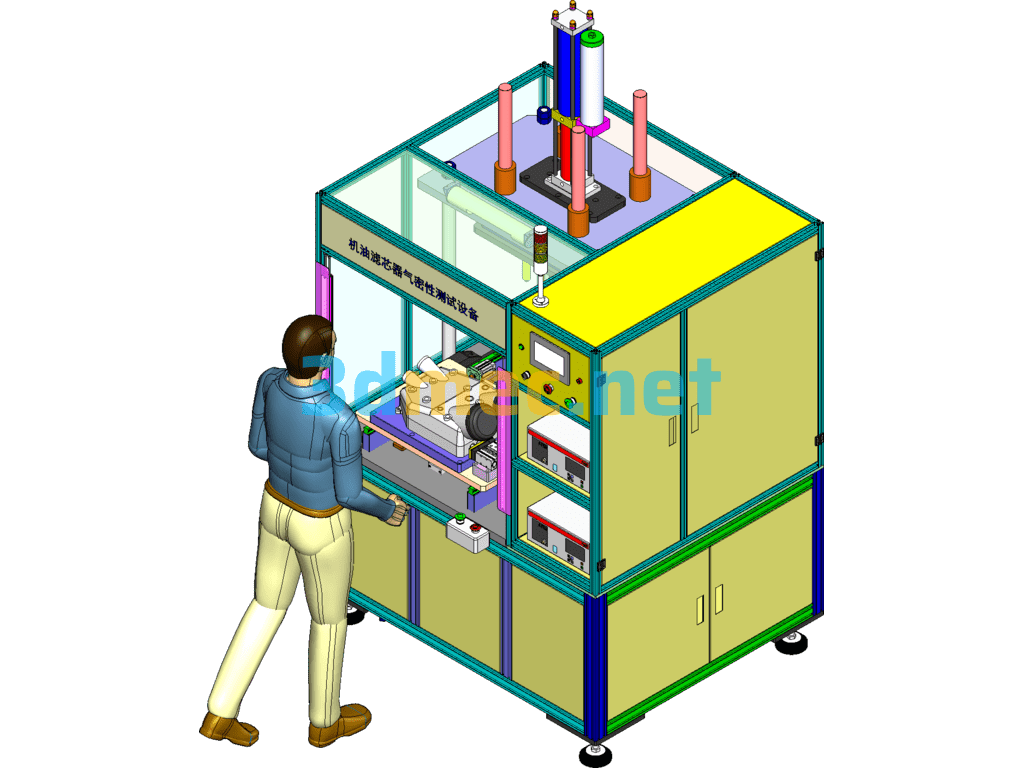

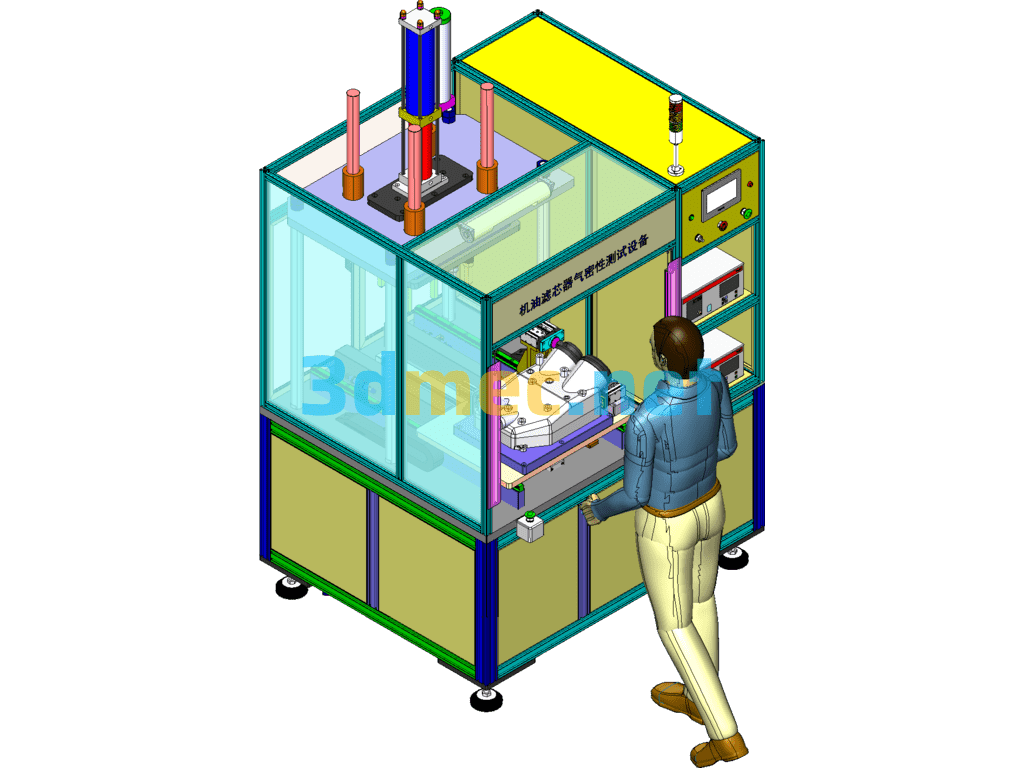

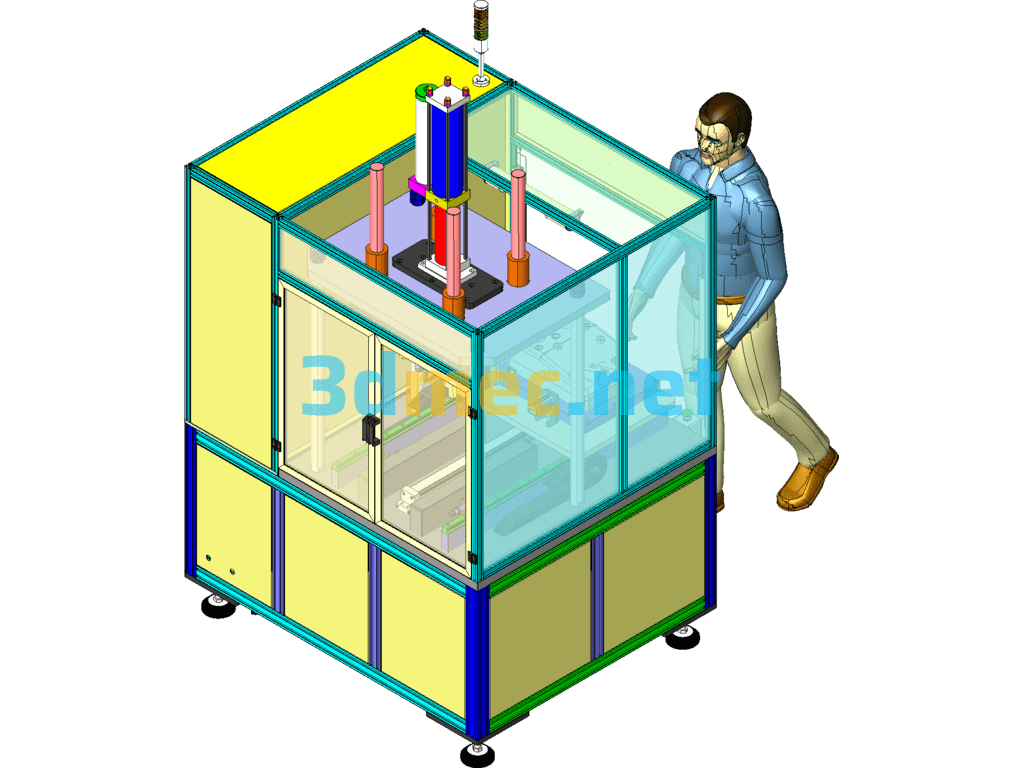

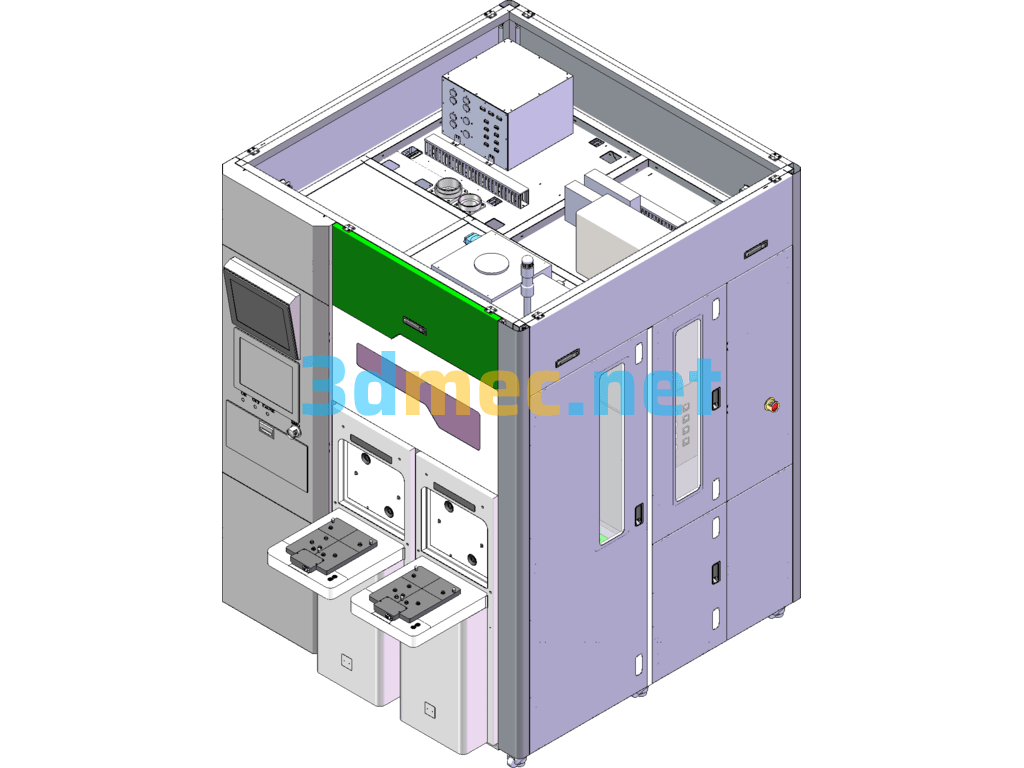

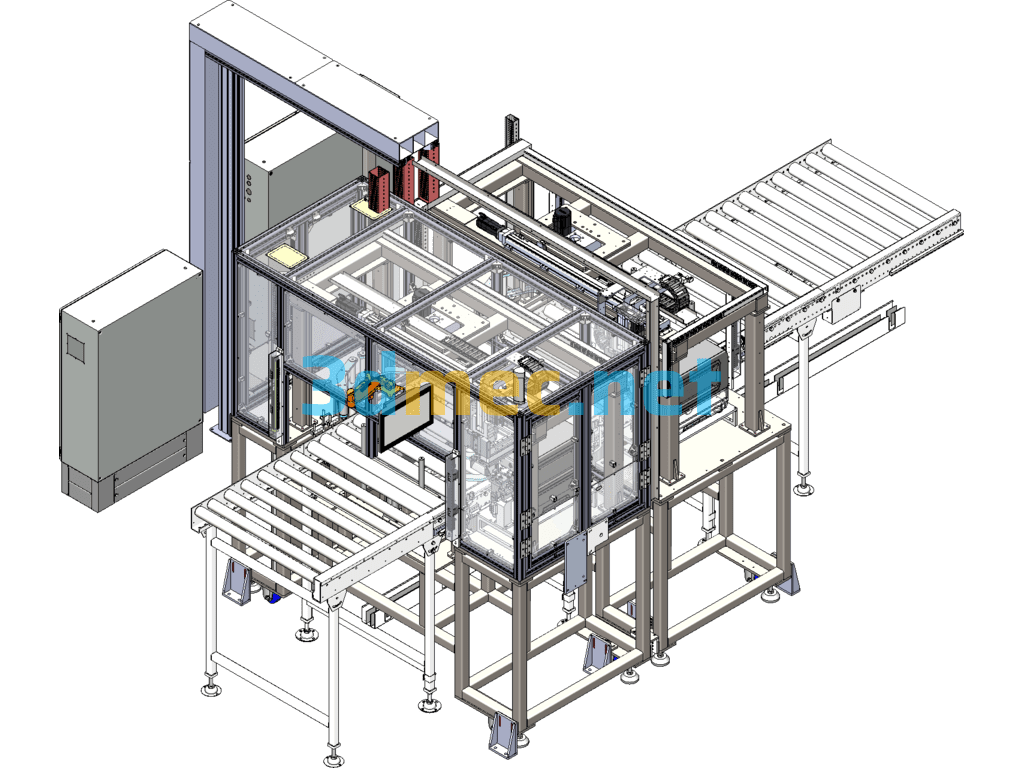

Automobile Oil Filter Air Tightness Test Equipment (Including 3D Model ++ Detailed Description) – 3D Model SolidWorks

! Automobile oil filter air tightness test equipment includes 3D model + engineering drawing + PDF working principle description + detailed description

Equipment working principle & step description:

1.Put the product to be tested into the equipment Holder (positioned by round pin and diamond pin);

2.After the photoelectric sensor on the Holder detects the product, OP starts the button with both hands (Holder & product automatically enters the pressing position through rodless cylinder transmission);

3.Holder & product After the product reaches the pressing position, the pressure head (spring pressure head & plugging head) automatically presses down;

4. After the pressure head is pressed down to the right position, the back plugging & side plugging cylinders are pushed out;

1#&2# airtightness leakage detectors start testing respectively; after the test is completed, the plugging cylinder retreats and the pressure head (spring pressure head & plugging head) automatically rises;

5. After the pressure head rises to the right position, the Holder & product are automatically pushed out of the original position through the rodless cylinder transmission;

6.OP takes out the tested products; (this cycle operation)

Specification: Automobile Oil Filter Air Tightness Test Equipment (Including 3D Model ++ Detailed Description) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automobile Oil Filter Air Tightness Test Equipment (Including 3D Model ++ Detailed Description) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.